For a long time, “warm floors” and laminate floors followed parallel paths. This greatly hindered their further advancement in the construction market. Therefore, just a dozen years ago, an innocent question - is it possible to lay laminate on heated floors - caused bewilderment among professional builders, because... these two concepts were incompatible. Everything changed immediately and suddenly - laminate manufacturers could no longer tolerate the current situation and presented consumers with products with completely different characteristics that allowed symbiosis with heating systems mounted under the floor.

Why can you lay laminate flooring on a heated floor?

In life, situations often arise when it is easier to explain why it is possible by analyzing the reasons why it was impossible before. Same with laminate. For a long time there was a categorical ban on its combination with floor heating from below. And then immediately yes. Consequently, the manufacturers eliminated the reasons why it was forbidden to lay slats on a “warm floor”.

- The main reason is the release of toxic formaldehyde (chemical formula HCHO) at +27oC. In the combination of laminate and “warm floor”, the heating of the lamellas reaches +30oC. The emitted fumes of formaldehyde resins did not meet the requirements of sanitary standards for residential premises.

- The insufficiently high thermal conductivity of the laminate reduced the efficiency of the floor heating systems used - the room was not entirely comfortable. Attempts to increase the temperature in the apartment led to a sharp increase in costs for heat sources.

- Laminate flooring was in no way compatible with water floor heating due to frequent temperature fluctuations (with a large number of expansion-compression cycles, any wooden flooring, and laminate flooring is related to it, is deformed).

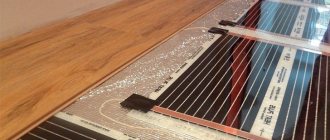

Electric heating coating

An electric floor heating system is characterized by the fact that the cable element generates heat when current passes through it. The cable can have one or two cores. In this case, it is imperative to determine exactly which laminate is suitable for heated floors, and what specific technical characteristics it should have.

When choosing panels, you need to take into account that the coating must have the appropriate type of heating. In addition, the material must meet the following characteristics:

- abrasion resistance;

- good thermal conductivity;

- high resistance to damage;

- safety.

In order for a floor covered with laminated panels to work as efficiently as possible, you need to make the screed correctly. Only in this case can you count on maximum thermal conductivity.

Rules for choosing laminate floor heating

Industry today produces laminate for all occasions. Therefore, not all commercially available laminate panels will fit on top of a “warm floor”. There are many reasons:

- low level of heat conductivity;

- high emission (release) of formaldehyde;

- poor water protection, etc.

To help consumers navigate the world of laminate, pictograms and signs of letters and numbers are placed on special inserts. Let's try to understand some of them. So, in the photo below there are pictograms showing that the flooring can be used in combination with a “warm floor”.

Marking of lamellas.

The inscriptions state:

- H2O - for water heated floors (everyone knows the formula of water);

- Warm Wasser (translated from German - “hot water”) - for heating the floor with water (not shown in the photo);

- Underfloor heating (translated from English - “underfloor heating”) - for cable and infrared floor heating.

Black pictograms with stylized pipes indicate good heat conductivity (which is required for underfloor heating), brown ones directly indicate that the slats are intended for heated floors.

But that's not all. These icons are not enough to make the right choice. The consumer needs additional characteristics in order to buy laminate for heated floors - the marking should help with this.

The problem of harmful fumes. When the temperature rises to 27oC, ordinary laminate begins to actively release harmful formaldehyde. Manufacturers have slowed down the heat-induced chemical reactions in the formaldehyde resin. As a result, harmful substances begin to be released at a temperature of +28-30oC.

The pictograms in the photo above indicate this. Class E0 means that there will be no formaldehyde emissions up to a temperature of 30 degrees. E1 claims that the minimum emissions start 2 degrees lower, but up to the critical point of 30oC they comply with sanitary standards.

Classification (classes) of formaldehyde emissions.

The influence of high temperatures. The laminate above the “warm floor” is exposed to high temperatures, this indicator is especially important for heating systems with water as a coolant, where temporary jumps up to +40oC are possible. The ability of a laminate to withstand overheating is indicated by the letter B and the number 1 (see pictogram below).

Thermal conductivity. According to the European standard EN4725, the total thermal resistance of lamellas with a substrate for “warm floors” cannot be higher than 0.15 m2 x °K/W, including lamellas 0.05-0.10 m2 x °K/W, substrates - 0.04-0.06 m2 x °K/W. The lower the coefficient, the better the heat transfers from the heater to the room. This information can be found on the package insert.

Wear resistance. The last controlled indicator for slats mounted on heated floors is wear resistance. Its level shows the abrasion class. Experts consider AC3 to be the minimum class for lamellas on heated floors, and AC4 to be the optimal class.

Abrasion classes.

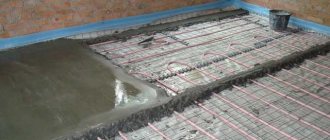

Water heating coating

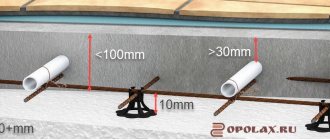

Water heating systems are multi-layered. Their base is waterproofed, and then a layer of thermal insulation is laid, which will not allow heat to escape downwards. Then pipes of small diameter are installed, which are covered with concrete screed or gypsum fiber. Only after this is the flooring laid.

In this case, it is very important to know which laminate is suitable for heated floors so that you can make the most correct choice. Laminated panels for such purposes must be:

- made of high quality material;

- have a high density;

- protective covering.

If the laminate meets all these requirements, then it will be ideal for installing a water floor system. Heating on such a basis is characterized by high humidity. Conventional laminate panels are unable to withstand such conditions for a long time, but high-quality laminated materials can maintain their excellent appearance and performance for a long time. This is why it is best to choose:

- laminate class 33 (12 mm);

- moisture resistant;

- marked H2O.

When operating a heated floor, it is imperative to observe a certain temperature regime. The indicator should not be higher than +27 degrees, as otherwise the panels may become deformed and lose their appearance.

Which underlay is better to choose for a heated floor?

Laying laminate flooring without a backing on a heated floor will not work. After all, it performs a number of very important functions, which are described in detail in the work: “Which substrate to choose for laminate?” In the version with “warm floor”, two more functions are added:

- reflect heat upward when laid under a heating system;

- allow warm currents to pass freely when laid on top.

Selecting a substrate for laying under a heating system is very simple: it must be foil (you can learn about this type of damper in the article: “Foil substrate”). The reason is easy to explain - foil reflects infrared rays.

The substrate in the “above the heating system” option must have additional characteristics:

- Good thermal conductivity, which is achieved in several ways: the property of the material to conduct heat well (the heat transfer resistance coefficient should not exceed 0.04-0.06 m2 x °K/W); small thickness; the presence of perforations - through the holes heat easily reaches the floor covering;

- Be resistant to high temperatures - do not melt or deform (sag);

- Remain environmentally friendly at high temperatures - do not release toxic substances when exposed to heat;

- Be vapor permeable to provide protection against condensation.

These conditions are best met by substrates made of balsa wood, foamed polyethylene and extruded polystyrene.

Cork material can be purchased in the form of rolls or sheets. It is heat resistant and environmentally friendly. Due to its high thermal resistance (good insulation), its use in an electric heated floor system is excluded. The high retail price also gets in the way.

Foamed polyethylene is easy to lay, comes in different thicknesses, is easy to cut, which is convenient for complex room configurations, connecting seams can be glued with tape. However, the main advantage of such a substrate is its low price, and therefore foamed polyethylene constantly tops the sales rankings.

Extruded polystyrene with small holes (perforations) appeared on the construction market relatively recently (represented by the Polish brand “Arbiton Floor Ther”). This is so far the best option for a laminate underlay with a decentralized heating system: it performs basic functions more efficiently compared to foamed polyethylene and transmits heat perfectly. At the same time, it has a reasonable price.

Arbiton Floor Ther underlay.

Selecting a substrate

The underlay plays an important role in the efficiency of a heated floor system covered with laminate. Therefore, her choice should be taken responsibly. If the substrate is very thick, then as a result the thermal insulation will increase significantly, however, the heating productivity will automatically decrease significantly. Accordingly, it is necessary to increase the temperature range on the thermostat for high-quality heating. And this entails additional energy costs.

The optimal thickness for laying it between the panels and underfloor heating should be 1.5–3 mm. Some planks designed for heated floors are equipped with a special backing. For example, from extruded polystyrene, which has small technological holes. In addition to this, such a substrate plays the role of compensating for minor curvatures of the floor and the so-called support of the laminate.

Is there a preferred type of heated floor for laminate?

The requirements for lamellas and substrate when installing decentralized heating are discussed above. But it is also important for owners of apartments and houses to know which “warm floor” is better for laminate. To answer the question posed, you need to know what types of “warm floors” can be installed, their fundamental difference from each other, the advantages and disadvantages of each of them.

The following will be offered for sale at any major hardware store:

- water;

- electric;

- infrared (also called film) “warm floor” from various manufacturers. In addition, you can buy infrared rods, which represent a symbiosis of electric and infrared floor heating systems.

- Prohibited by law;

- Damage to a pipe or coupling leads to flooding not only of the apartment with such a floor, but also of the neighbors below (central heating mainly heats apartment buildings), which is not quickly eliminated. The water accumulated in the screed and pipes will flow to the lower floor until the entire system is dismantled;

- It is impossible to meet the requirement that the laminate be heated to no more than 30 degrees Celsius - in central heating the coolant temperature is much higher. Installing a thermostat will not help - you need a bulky cooling system for the incoming coolant. But then the neighbors will have complaints - cooled water will flow into their heating pipes.

- difficult and expensive to install, maintain and repair;

- a complete replacement of the system and floor is required (water in most cases destroys the slats, despite their additional protection from moisture) when a leak appears;

- It is difficult to regulate the temperature of the coolant entering the system.

A system of small-diameter pipes hidden under the floor (can be made of copper, metal-plastic, polypropylene or cross-linked polyethylene), through which coolant is supplied in the form of hot water (sometimes antifreeze is used), is called a water “warm floor” . Let us immediately note that in the classical definition, including in various encyclopedias, the main feature of such space heating is the connection of the system to central heating, which is impossible in principle:

The first conclusion: water “warm floors” can only be installed in private houses and cottages or multi-apartment one-story buildings with an individual boiler or gas (electric) heating boiler.

This heating system also has many disadvantages:

Conclusion two: for laminate flooring, if there is an alternative choice, it is better to refuse a water-heated floor.

Water type.

It is also not advisable to install heated electric floors There is only one reason - it is difficult to warm the room to a comfortable temperature when there is severe frost outside. Several factors are intertwined here:

- The heating temperature of the cable is not very high and fixed - otherwise it will simply melt;

- The cable is laid in a screed, which requires its heating, and it gives off heat not only upward, into the room, but in different directions. Thermal protection device from below and from the sides solves the problem, but not 100% - materials for household needs with absolute thermal protection have not yet been invented;

- Laying underlay and laminate on the screed aggravates the problem - it is difficult for heat to penetrate through such a sandwich to the top.

Conclusion: the combination of electric “warm floor” and laminate is unacceptable for the Far North, undesirable for central Russia, and a convenient heating option for the southern regions of the country.

Cable type.

The ideal option for residents of Russia is infrared film “warm floor” . The name of the system is formed from two concepts:

- infrared - heat obtained as a result of infrared radiation;

- film - conductors are mounted in strips in a thin film.

The undoubted advantages of such floor heating:

- Cost-effective - the heating film is laid on a substrate, and the laminate is placed directly on it. As a result, there is no need to heat the screed - the heat goes directly to the floor covering;

- Safety. There are two points here: there is no risk of flooding the neighbors below; the temperature of the heating elements is easily regulated, which prevents overheating of the floor panels;

- It is possible to restore the system: for minor repairs, the failed strip is simply disconnected from the general power supply system; for major repairs, the floor covering is dismantled.

Infrared type.

Infrared rods must be laid in a screed. Therefore, the disadvantages of an electric heated floor immediately appear. However, there is still a plus here - the temperature of the heating elements is higher than that of the cable, which allows you to heat the room more efficiently.

General conclusion on infrared heat sources : the rods are much more effective than cable floor heating, but not so much as to recommend them for latitudes with low temperatures; the film is so effective that it completely removes from the agenda the question of whether it is possible to lay laminate flooring on a heated floor.

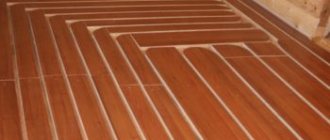

How to install a dry floor on a wooden base?

A floor without screed can be made using two systems:

- Polystyrene plates;

- Wooden slats and modules

Polystyrene mats, smooth or with bosses, are laid on the wooden surface. If they are smooth, then you need to cut holes in them for laying pipes. This dry floor installation system is not very expensive and is very convenient. Most often, ordinary polystyrene foam up to 4 cm thick or expanded polystyrene is used. If the slab has bosses, that is, protrusions no higher than 25 mm, then polyethylene pipes (diameter 16 mm) are placed in the grooves and secured with mounting locks.

Modules can be bought in a store and assembled at home. The pipes are laid in recesses on the surface. The rack system is made from planks 2 cm thick and 130 cm wide with a pipe pitch of 150 mm (MDF or chipboard material). Often metal plates are also installed, which create a continuous warm field. At the end, the underlay and laminate are laid on the surface of the heated floor pipes.

Which laminate is best for each type of “warm floor”

Each floor heating system has its own operating characteristics, which must be taken into account when choosing a laminate. Therefore, it is important to know which laminate is best to choose for underfloor heating with different coolants.

Water floor heating. Affordable purchase price and low operating cost have made water-heated floors very popular. The laminate for such a floor must be resistant to high temperatures, up to +30 degrees Celsius, and its frequent changes and not collapse if leaks occur. In this situation, it is difficult to choose the right type and type of slats for the floor covering. The following criteria will help you choose:

- The panel locks must be treated with wax, which will allow the number of expansion cycles to be increased many times without destroying the lock. In addition, wax serves as protection against moisture penetration into the body of the lamella. Instead of wax, a number of manufacturers have developed special sealants with the same functions. Treating the ends with sealant is a decisive factor when choosing a laminate;

- Wear resistance cannot be less than class 3;

- The thickness of the lamellas should be within 8-9 mm, which will protect them from deformation when overheating above 30 degrees, and also effectively transmit heat into the surrounding space;

- The level of formaldehyde emission during overheating should not exceed class E1;

- Additional protection against moisture is provided, allowing direct contact with water.

Infrared film heating. Using infrared rays as heat sources has a number of advantages:

- good heat transfer does not require high electrical power, which compensates for the high cost of the system itself;

- is mounted on top of the screed, which allows access to it during operation.

Based on the given characteristics of the system, the minimum requirements for the laminate are:

- wear resistance class 3-4;

- thickness not less than 8.5 mm.

Electric floor heating using a cable. You can lay a laminate with the following characteristics on an electric “warm floor”:

- increased thermal conductivity (the thermal resistance coefficient together with the substrate should be within 0.10 m2 x °K/W);

- low level of formaldehyde emissions - class E0 or E1;

- have high strength for static and dynamic loads.

Rod infrared “warm floor”. The combination of electric and infrared flooring is actively gaining popularity among consumers.

The requirements for the laminate in this case are the same as for electric heating.

Film (infrared)

The film flooring system is optimal for laminate flooring. The system is a thin film on which conductive material in the form of strips is fixed. The film is placed under the substrate and heating of the screed is not required, which ensures economical operation. The required panel surface temperature is achieved quickly and can be accurately set within the permitted values.

Currently, leading manufacturers have begun producing laminate flooring with an integrated infrared heated floor system, but the cost of such models is still inaccessible.

The nuances of laying laminate flooring on a warm floor

Making a floor covering for a “warm floor” system is not very difficult. You can handle this kind of work yourself. For those who are starting such an operation for the first time, we advise you to study the instructions for installing laminate flooring - they are given in the work “How to lay laminate flooring on a concrete floor?”

However, there are several important nuances here.

1. Before laying the laminate, the screed must be heated to a temperature of +27–30°C. This will solve two problems at once:

- dry the base of the floor to 5% humidity;

- find a place for the screed when expanding - if there are mistakes in pouring, it is better to get burst concrete before installing the floor than after.

The warm-up process involves a 2-week cycle. In the first days after turning on the heating, you need to add 3 degrees until the power reaches 50%, and in the next 2 days reach full power. Two days before the start of work, the heating is turned off.

Important: the heating system with a finished floor is turned on in the same mode. Switching off occurs in the reverse order. Violation of the rule threatens damage to pipes and cables due to rapid expansion or contraction of the screed (expansion coefficients do not match).

2. Carrying out waterproofing measures along the top of the screed is mandatory. For these purposes, a polyethylene film with a thickness of 200 microns is well suited (laminate manufacturers prohibit waterproofing with a substrate under the laminate, which is possible with central heating).

3. Before laying the laminate panels, they should remain in the room where the installation will take place for several days. In this way they adapt to the temperature and humidity in the room.

Useful tips

Regardless of which system you choose, it is important to follow a few simple tips:

- PCB must be dried, with a maximum moisture content of 1.5 percent. Before installing the lamellas, warm up the floor, check the correct connections and the functioning of the entire system. You need to start heating 14 days before laying the lamellas.

- When the laminate flooring is completed, you need to turn on the heating according to the same scheme as for drying - a maximum of 5 degrees per day. It is allowed to heat the floor up to +27 degrees.

Wooden floor with water heating

Water floors are installed on a wooden base quite rarely. The fact is that wood is a material with low thermal conductivity. This prevents heat loss. However, due to the long heating of the base, the floor itself will heat up more slowly, and the heating temperature will have to be increased.

Another serious problem with wooden floors is that when temperature changes, there is a significant change in linear dimensions in the wooden flooring, which can lead to the formation of cracks in the flooring and deformations. In addition, this is caused by almost inevitable moisture and condensation released during the operation of the system.

Finally, another difficulty arises - how and where to hide the pipes. There are several options for this:

- Chipboard slabs milled to fit the size of the pipes;

- slats laid so that there is space between them for heating elements;

- relief polymer mats.

The last option is the most effective in terms of heat savings, but also the most expensive.

Materials and tools

To create a “warm floor” cake, from the ceiling to the floor covering, you need to buy the following materials:

- a set of water heated floors for laminate (boiler, collectors, electric pumps);

- pipes along with special fasteners;

- fittings for polypropylene or coupling-press for metal-plastic;

- roll waterproofing or mastic (only for concrete floors);

- insulation;

- damper tape;

- reinforcing metal mesh;

- metal profile for beacons;

- cement M300;

- sifted river sand;

- fiberglass fiber;

- plasticizers for cement-sand mortar;

- underlay for laminate;

- slats or wedges;

- laminate.

Tools you will need:

For preparatory work:

- perforator;

- level;

- hydraulic level;

- roulette;

- construction cord;

- trowel.

For laying pipes:

- grinder or hacksaw;

- wrench or adjustable wrench;

- soldering machine (needed for joining cross-linked polyethylene).

For the screed:

- concrete mixer (rented);

- bucket;

- rule;

- grinder (rent).

To lay laminate:

- jigsaw or hand saw for cutting laminated boards;

- mount;

- a block or a special metal bracket for padding the lamellas;

- wooden or cast rubber mallet;

- square;

- marker or construction pencil.

Pipe length calculation

The total length of the pipes is calculated by adding the length of each circuit. In turn, the number of circuits depends on the diameter of the pipe. Thus, through a 16-millimeter pipe, a pump of any power can pump water over a distance of 80-100 m (depending on the material of the pipes).

When this indicator is exceeded, a “locked loop” effect occurs - the movement of liquid stops due to the resistance of the pipe walls. Therefore, in large rooms, several circuits are installed. To simplify calculations, the pipe length for each room is determined, and then the number of circuits is determined. The calculation is carried out according to the formula:

L = S/P*1.05+(K*2) , where:

- L—pipe length in m;

- S—room area in m2;

- P - laying step in m (optimal - 0.2 m);

- K is the distance to the collector in m.

For information: a factor of 1.05 is used for the margin for radii and connections.

The value obtained after calculation is divided by the maximum possible length of the circuit for each type of pipe and rounded up. The calculation can be carried out in a simplified manner: multiply the area of the room by 5 - according to SNiP, there should be 5 m of pipes per 1 m2 of floor.

Malfunctions and their elimination

The design of a water heated floor is simple in structure, so there are not many reasons for malfunctions. Let's look at the most typical ones and how to eliminate them:

- If the circulation pump does not make a characteristic noise when power is applied, then it is recommended to check the distribution panel on each circuit - the shut-off valves are typically in an open position.

- “Airing” of the system can occur due to a sharp drop in pressure inside the heating circuit, its overheating, leakage and depressurization of connections, or improper installation of the system. You can solve the problem by closing all the kennels, leaving one, and then running each branch separately with the circulation pump turned on at low speed.

- To set up the system, it is important to understand the principle of operation of the collector, which directs waste and warm liquid. To adjust the operation of the circuits, use the balancing table. The valve is closed after removing the cap from it. According to the table, the revolutions are determined for each circuit by turning the valve the required number of times.

- The reason for the low system temperature may be insufficient boiler power, which needs cleaning, maintenance or replacement of the temperature sensor.

- A decrease in heat transfer occurs if the floor is filled with furniture and covered with carpet, as well as due to poor-quality, unsuitable insulating material.

- The cause of uneven heating can be not only air, but also poorly organized vapor barrier

Finally, we invite you to watch a video on how to lay laminate flooring on warm water floors.