Purpose of the grid

Is reinforcing mesh needed when pouring heated floors? Laying is not mandatory, but experts advise using it. After all, with its help, you can get a number of positive effects, such as:

- Increased strength and durability - it will protect the structure from deformation when the system heats up, and therefore from the formation of cracks.

- Uniform distribution of load across the base from furniture and finishing coating.

- Reducing cement consumption when preparing the mixture.

- Reducing the thickness of the screed, but this does not affect the strength properties of the device.

- Possibility of fixing heating elements to it.

- Increased system performance. Does not allow the heating cable or pipes through which the coolant circulates to lie close to the base. After all, cement mortar must penetrate into the space between them, this increases the heat transfer of the floor.

In addition, the use of a reinforced structure allows you to obtain the most even surface.

Total screed thickness

So, two tasks of the TP screed, distribution of operating load and uniform distribution of heat, are a priority. It is to accomplish these tasks that all further discussions about the thickness of the screed will be directed.

Two parameters are important in screed thickness. The first is the overall thickness of the screed, which is usually left out of brackets. The second parameter is the thickness of the screed layer above the pipes. First things first.

The total thickness of the heated floor screed, namely the screed, and not the entire heated floor structure, should be as follows:

- If the heated floor is installed above an unheated room, basement, or ground, the minimum thickness of the screed is 85 mm. This standard value is very controversial (more on this below);

- If the TP is done on a concrete slab, the total minimum thickness is the sum of 10 mm of screed under the pipe (cable), the diameter of the pipe (cable) and the permissible technological thickness of the screed above the pipe.

- It is recommended NOT to make the maximum thickness of the screed more than 100 mm, due to the large inertia of the system. Thick screeds will take a long time to heat up and spend heat not on warming up the room, but on heating the screed itself.

Note: if you need to raise the overall floor level, you do not need to do this with a heated floor screed. You need to first make a leveling screed, and then install a warm floor, and not try to solve all the problems in one screed.

Types of reinforcing mesh

Reinforcing mesh is available in different types, each with its own characteristics and features, which significantly increase the efficiency of the heating system. They have different cell widths, from 5 x 5 to 30 x 30.

Video

Installation. Warm water floor on mats instead of reinforcing mesh. Everything is in your mind

Metal

The metal mesh used for floor screeding is made from wire with a diameter of 2.5 to 6 mm. The roll size can be up to 25 meters, this makes it possible to minimize the number of joints. Reinforced products are also produced from wire, which has a smaller thickness, but it is usually small in size.

The cells are square-shaped, which increases strength and thanks to which the structure does not stretch during reinforcement. The surface is equipped with notches that improve the adhesion process to the concrete composition.

In addition, the mesh coating has a protective galvanized layer that protects against the negative effects of moisture and components in the solution.

For your information! In a reinforced lattice, the pitch and size of the cells are calculated in such a way that excessive consumption of metal is not allowed and the necessary strength of the concrete base is created.

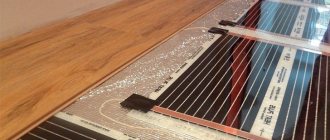

The use of a metal structure makes it possible to make high-quality reinforcement for a heated floor. Suitable for pouring a thick cement layer, and promotes long-term retention of shape. In addition, heating elements - water system pipes or electrical cables - are attached to the grille.

The main advantage of metal reinforcement is its strength; in the event of damage to several cells, the overall integrity does not suffer.

The main disadvantage is corrosion, which provokes the formation of voids, as a result of which the structure collapses.

Composite

Composite mesh is made from fibers containing basalt or carbon.

Its main advantage is:

- resistance to chemicals and water;

- a light weight;

- not high thermal conductivity;

- long service life, since corrosion does not form on it;

- plasticity, which facilitates installation;

- affordability.

The disadvantage of this type of reinforcement, when used for heated floor structures, is its low heat resistance. When heated to 200 degrees or more, the product may become deformed.

But in our case, achieving such temperatures is impossible, so the use of mesh material is acceptable.

The thickness of the mesh structure ranges from 4 to 14 mm. It is produced in the form of sheets or rods, which are connected with knitting wire.

Fiber reinforcement

This is one of the types of composite reinforcement - the basis is fiber (fiber). The length ranges from 6 to 20 mm. If you need a strong concrete base, then you should take fibers of 5 - 6 cm.

The use of this model significantly improves the quality of the resulting surface, but you cannot attach a heating cable or a water system circuit to it.

Types of fiber:

- glass - its use reduces the consumption of cement mixture by up to 15%;

- basalt - intended for floors that are exposed to the environment;

- polypropylene - the fibers have a thickness of 15 - 25 microns, a length of 0.6 cm, the use of this fiber allows you to avoid the formation of the smallest cracks in concrete;

- steel - the most durable and common model.

Plastic

Using a plastic mesh to screed a heated floor with a water or electric circuit is an excellent solution. The design is lightweight, has a long service life, and is not afraid of moisture and corrosion.

Sold in rolls, 2 meters wide and 50 meters long. But the cells come in different sizes. Its main purpose is to strengthen the screed and reduce the level of stress.

Positive aspects of a plastic grill:

- shrinkage of concrete does not damage the mesh, it only stretches;

- simple transportation and easy installation;

- increased strength - it is achieved by a feature of the technological process in the manufacture of plastic types of reinforcement (bi-basic orientation of threads, nodal connection is used);

- low cost compared to metal structures;

- the reinforcing material is easy to cut with scissors during installation;

- plastic does not shield the wiring.

Fiber fiber

The principle of using fiber as reinforcement for screeds is significantly different from mesh reinforcement.

Fiber - fibers of basalt, glass, polypropylene, metal, in dry form are added to the ingredients of mortar or concrete. When the floor hardens, the fiber gives the effect of a durable monolith, protects the floor surface well from microcracks, but will not save you from significant mechanical impact.

The fiber-reinforced screed is laid and leveled along the beacons, just like concrete or mortar for other types of reinforcement.

If fiber is used simultaneously with metal or polypropylene mesh, a super durable coating is obtained.

When working with fiber, you need to add it in small portions to the mortar mixture, waiting until the fibers are completely distributed in a concrete mixer or other container. If you add all of it at the same time, the fiber can bunch up into a shapeless lump.

Popular manufacturers

Reinforced mesh structures, which are used to screed electric or water heated floors, are produced by many companies. The most popular manufacturers include:

- Armplast specializes in the production of fiberglass products, which are used for pouring electric-type heated floors. In addition, a fiberglass product is used to strengthen the plaster layer or masonry mortar.

The advantages of fiberglass reinforcement from Armplast: it is not subject to corrosion, has a long service life, is light in weight, 2 times stronger than steel, has a similar coefficient of expansion to concrete and does not conduct electric current.

- Fibrasnab produces reinforced products from metal welded rods. The company's mesh is characterized by increased rigidity due to the almost perfectly square shape of the cells. And the optimally selected wire laying step allows you to avoid waste of material.

Fibrasnab products are made of steel 0.65 mm thick, in rolls of 25 meters, which reduces the number of joints. Coated with a galvanized layer - this protects against damage and extends service life. The adhesion of the solution to the surface is increased due to the location of the mesh ribs at an angle.

- Tepah - products are made by extrusion from polypropylene. This method makes it possible to obtain products with increased strength and flexibility. Tepah mesh is an excellent option for laying screeds up to 8 cm thick under a water or electric floor heating system.

Distinctive characteristics of the company's products: it does not deform when concrete shrinks, it is lightweight, it is not susceptible to chemical attack from the outside, it is easy to cut, which simplifies the installation process.

- Gridex - specializes in the production of basalt types. Basalt fiber has low thermal conductivity, which is ideal for constructing structures for underfloor heating. In addition, it is not exposed to aggressive environments, therefore it is used for reinforcement using cement-concrete mortar.

Gridex impregnates basalt mesh products with acrylate, which improves the adhesion of the material. The standard cell size in manufactured meshes is 25 by 25 mm.

- LenStroyDetal - produces high-quality products from steel rods coated with a galvanized protective layer. The use of metal products significantly increases the service life and strength of the concrete surface.

The company produces mesh for underfloor heating from wire with a diameter of 4 mm, with a cell size of 100 by 100 mm.

Video

Water heated floor. About reinforcement, furniture, crimping and discomfort

Which grid to choose and why

Today there are a large number of models of reinforcing mesh on the market from various manufacturers. When choosing a mesh covering when constructing a water or electric heated floor screed, you should give preference to:

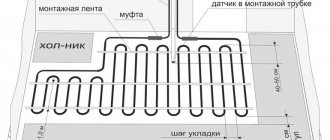

- For square models with cells of 150 mm, in extreme cases, 100 mm. Indeed, more often, the pitch of the heating elements of a water heated floor is 150 mm, so cells of this size will be optimally convenient for fixing them.

- A reinforcing product made on a CNC machine, since it is smoother than a homemade one. In homemade ones, in addition, the cell size is often not respected.

- The mesh, with a rod thickness of 4 mm, fits well on polystyrene sheets and is convenient for fixing a water system pipe or cable to it.

In addition, choosing a model for installation should take into account:

- the consistency of the cement-sand mortar, because it must penetrate freely through the cells;

- level of mechanical loads - the higher the indicator, the smaller the cell size.

Video

Mats or mesh. What is better to use for installing heated floors?

Tasks of screeding heated floors

To figure out how to make a screed for a heated floor, let’s define its tasks more precisely. First of all, remember that ties are fundamentally divided into tied and floating. The floating screed is not connected either to the base of the floor or to the walls of the room. If, relatively speaking, you look at a floating screed, then it is a separate, often concrete slab in the room that performs its tasks.

It is worth noting that a floating screed is the priority type of screed in the construction of a concrete heated floor.

The tasks of a floating heated floor screed include:

- Holding pipes or underfloor heating cables;

- Be a heat exchanger between the floor heating system and the room, ensuring uniform heating of the floor surface;

- Take on the power load of operating the premises.

It is to solve these problems that specific requirements for installing heated floor screed are aimed.

Installation technology

When constructing a heated floor with laying reinforcing mesh, it is important to install it correctly.

For your information! Regardless of the type of reinforcement chosen, reinforcement is carried out throughout the floor, with a small indentation from the walls.

When pouring a large area, overlapping laying is permissible, and the products are connected with wire. For a non-standard surface with steps or transitions, it is necessary to repeat the base topography.

The mesh is mounted suspended on fasteners, at a distance of 2 cm from the rough base.

Video

Foundation reinforcement USHP / Mesh for water heated floors. Part 18

Preparatory work

If there is a ready-made base, it needs to be leveled and unevenness repaired. Then lay a polyethylene film for waterproofing and a thermal insulation layer. Along the perimeter, the room must be taped with damper tape to compensate for temperature deformations.

Before starting the process of pouring the screed on the ground, it is necessary to prepare a “pie” - gravel and sand, a layer of thermal insulation and waterproofing. And only then, install the masonry network and pour the mortar.

If reinforcement is carried out on a fill base, then two layers of reinforcement should be made.

Laying the mesh

An important point when reinforcing is the correct placement of the mesh. It is placed at a small height from the base. This height is determined taking into account the thickness of the screed of a warm electric or water floor, and the diameter of the mesh rods.

To create a gap between the base and the reinforcement, you can place wooden blocks, pieces of brick or a metal profile under it. It is necessary that these supports allow the solution to penetrate under the heating elements.

Reinforcement should be placed in the lower third part of the concrete layer. The supports should be placed in places where the rods intersect.

To facilitate the installation process, you can buy ready-made accessories for the stand, which are shaped like crowns, stands or chairs. The strips of the product are laid with an overlap of 10 cm, with a distance from the walls of about 2 - 3 cm.

Important! The distance between the supports depends on the thickness of the planned screed.

The process of laying a composite or plastic structure, other:

- after arranging the “pie”, 1/3 of the solution is poured and leveled;

- then a mesh is placed on top and pressed into the screed layer;

- The cable or pipes of the water heated floor are laid on top, and filled with the remaining solution, the surface is leveled according to the beacons installed in advance.

Plastic and composite types of mesh can be placed directly on the pipes of the water system, but there is a risk of voids during pouring.

Attaching heating elements

The easiest way to secure a water-heated floor circuit or cable to the mesh is to use clamps.

For your information! When the clamps interact with hot water, they become softer and more convenient to fix. To do this, place the clamps in hot water for 10 minutes.

You can fix it using fastening tape or wire, but the option with clamps is more convenient and practical.

Features of reinforcement

There are uniform rules that must be followed when reinforcing warm water or cable floors:

- regardless of the type of reinforcing material, in order to increase the strength and elasticity of a solution of cement and sand, it is recommended to add plasticizers to it;

- It is prohibited to touch the product with a rough coating; it must be inside the mortar layer;

- It is unacceptable for the mesh to be dirty;

- It is impossible for reinforcement elements to protrude on the surface of the screed.

In addition, before starting work, you should read the accompanying documentation attached to the reinforcing products.

What can replace the mesh?

When constructing a warm water or electric floor, the mesh is often replaced with special bosses, which can be separate or mounted on polystyrene insulation, and heating elements are attached to them.

If time permits, you can make a reinforcing product with your own hands from reinforcing bars or a metal profile. To do this, the rods are placed on top of each other to form a lattice and connected by spot welding or wire.

To strengthen the screed of heated floors of a small area, it is allowed to use panser mesh from beds.

To obtain a flat surface when constructing a heated floor structure, it is recommended to reinforce the concrete screed. Indeed, during the heating process, the surface may crack, and the presence of a mesh in the “pie” prevents this. In addition, this product makes the floor smoother and significantly increases its service life.

Advantages of composite materials

Composite materials are rapidly replacing structural steel due to their engineering and technical qualities:

- Gain in weight and savings on delivery - for 100 m2 of screed (thickness 40 mm, mesh 50x50x3) is 160 kg less than for steel mesh (180 kg steel, 20 kg composite).

- Does not rot or rust, service life is from 80 years (for basalt).

- Increased moisture resistance – use even in sea water.

- Chemical resistance. Compatible with any additives to concrete, and basalt mesh for flooring is applicable in anhydrite compositions without additional treatments.

One or more cracks rarely compromise the integrity of the floor screed. In fact, a professional can successfully apply a number of corrective measures to repair cracks and ensure a high-quality foundation that meets specifications. But the use of floor reinforcement with mesh eliminates costly and costly repairs.