What could be simpler than a room thermostat? But no - it’s very easy to buy a thermostat that is not suitable for a specific task.

Therefore, before buying a thermostat, you need to understand how the seemingly identical models differ.

Household thermostats differ:

- execution;

- purpose;

- connection diagrams;

- food;

- integration;

- electronic or mechanical;

- sensors used;

- method of signal transmission.

Design and purpose of a temperature sensor

The temperature sensor is an important element for ensuring high-quality operation of heated floors. From it, data is sent to the thermostat, which regulates the temperature by increasing or decreasing the power.

Thanks to this, you can set comfortable temperature levels in the room, prevent overheating and damage to the floor covering, and significantly reduce energy costs.

The temperature sensor is simple: two wires connected to a thermocouple - two wires connected at one end. Actually, they are the unit for measuring temperature indicators.

Before pouring the screed, the functionality of the heated floor and the temperature sensor itself is checked. To do this, the resistance of each part is measured. The system works if the difference between the indicators and the values in the technical passport is no more than 10 percent.

How does a heating cable heating system work?

Heating of pipelines with a heating cable, which is connected to a 220 V AC electrical network, is carried out using two main methods:

1. The cable is placed outside the pipe. This method is used to insulate an already laid highway or sewer pipes, while the wire fits tightly to the outer surface of the pipe. On the construction market, pipes with a ready-made channel for placing a heating cable are sold - this allows to reduce heat losses; also, to save energy, additional insulation of underground pipelines is used with a shell made of foam plastic (penoplex) or polyurethane.

The electric cable is laid along the pipeline; to increase the heating temperature along the entire length or in critical nodes, spiral winding is used.

Rice. 6 Heating diagram for well water supply

2. Heating inside the pipes. The main disadvantage of external insulation with electric cables is low efficiency - most of the heat goes into the environment and additional insulation has to be installed, which leads to higher costs of work.

Therefore, in water supply lines it is better to lay the heating cable inside the pipes - this applies to water mains. In the sewer system, the presence of foreign objects inside can cause a blockage.

It is unprofitable to lay wires located inside pipes along the entire length - the cable is quite expensive and will increase hydraulic losses, reducing the useful cross-section of the pipeline. Therefore, it is more rational to install it in the area of the well head in front of the water supply system and pressure pipe that supplies water to the house. In this case, warm water will prevent freezing in the well, automatic devices and surface pumping station, and heated water will also flow into the water supply system leading to the house.

The main difficulty when installing an electrical cable internally in a pipeline is choosing an installation method and a sealed fitting for connecting it to the pipe when immersing the wire.

Features and Benefits

If you do not install thermostats, it is impossible to control the temperature of the heated floor. This is dangerous due to overheating of the device and the creation of an emergency situation. If we talk about the advantages of sensors, we need to consider: the device operates with or without electricity. The advantages of a mechanical regulator include low price and energy independence. The disadvantages include a relatively short period of operation and increased inertia.

The electric device allows you to set the exact temperature and can be controlled remotely. But such a device costs more.

Even more expensive is a programmable device that also runs on electricity. Cunning electronics guard the safety of the home: when the set temperature is reached, the thermostat turns off the heating. Moreover, he can program connection and shutdown for the required time, which saves electricity while people are away from the apartment.

There are options for temperature controllers that are equipped with an external IR sensor. It is able to detect the temperature of the floor covering. The device is powered by a battery and is attached to the wall using Velcro.

Heating/cooling.

The easiest way to turn a heating thermostat into a cooling thermostat is a changeover contact.

Some thermostats have an option in the settings that clearly indicates that cooling work is required.

There are thermostats with separate control channels for the heater and air conditioner.

Multi-output cooling thermostats are designed for central air conditioning systems where it is necessary to control the air conditioner fan and the coolant valve of a split system.

Functions and selection of thermostat

When choosing a regulator for a heated floor, you need to take into account the following characteristics:

- Technical specifications. Think about which device is suitable - mechanical, electrical or programmable.

- Installation method: surface-mounted, built-in or for mounting on a DIN rail.

- Stylistics. The thermostat can be of different shades and shapes (square, circle).

- Number of channels. Devices can be single-channel or dual-zone.

The control also differs - it can be carried out mechanically, electronically or sensory.

Rules for connecting a cable floor

Before starting the main work, the surface must be well leveled, and a damper tape must be secured along the walls. When installing a heated floor on the ground floor of a house, thermal insulation material must be laid. If there is a heated room under the ceiling, then the heating cable can be laid on the subfloor.

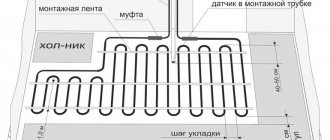

First of all, pull the power wires of the heating element to the thermostat. In this case, the coupling must be located in the concrete screed.

Subsequent work involves performing the following actions:

- The mounting tape is laid over the subfloor or thermal insulation material.

- The cable is laid in a convenient way. You can choose any installation method, but most often craftsmen choose a snake. It is very important to control the installation process and ensure that the cable lines do not intersect.

- The mounting tape has special fixing elements that allow you to evenly distribute and securely fasten the heating element.

- Next, take the sensor and place it in a plastic pipe.

- The system is tested and the cable resistance is checked for compliance with the certified values.

- The concrete screed is poured.

The question of how to connect the thermostat to the heated floor can be resolved only after the concrete solution has completely dried. During operation, it is necessary to connect the electrical wiring, wires from the sensor and heating cable to the thermostat. For this, special screw clamps are used. For safety and quality of work of this type, it is recommended to entrust it to professionals.

Types of temperature sensors

The classification of thermostats according to their operating principle was considered when reviewing their advantages and disadvantages. But it’s worth learning more about how they work.

Electromechanical

The simplest and most inexpensive type of regulator. Its main working part is a special metal plate that reacts to an increase or decrease in temperature. The system is turned on and off by changing the curvature of the plate during heating and cooling. It will not be possible to set the exact temperature value on such a regulator.

Electronic

The device contains a special element that produces a special signal. Power depends directly on the ambient temperature values. On such devices, you can set precise heating temperature indicators down to a fraction of a degree. The system is controlled via buttons and a small screen.

Programmable

The most expensive of thermoelements. You can set certain values on it, upon reaching which the entire system is turned on or off by the regulator. Thanks to the device, a microclimate is created in the room that suits a specific person. It is possible to configure the thermostat so that the system turns on at a certain time. That is, the floors are heated before the owner comes home, and electricity is not consumed when the owner is away.

Many models have a bright and stylish design, and are also equipped with LCD screens that display information and facilitate precise settings.

Advantages and disadvantages of which cable is better to choose

When choosing a heating cable for pipes, it is important to know the pros and cons of each type on sale. Let's briefly list them

Single-core cable is in demand for the following reasons:

- Inexpensive;

- Durable (10-15 years of operation);

- Relatively easy to install.

The disadvantages include the need to accurately calculate the length, since it has to be laid so that the other end returns to the power source. In addition, as we have already said, working with resistive cables (except for zonal cables) is complicated by the manufacturers’ ban on cutting. For this reason, when purchasing, you need to know exactly the required length and power.

Another limitation for all resistive systems is the inadmissibility of crossing sections of the cable line. In this case, the temperature at the contact points rises sharply, which can lead to melting of the insulation and burnout of the wire.

A two-core resistive system is easier to install than a single-core system, but it is also more expensive. When laying such a cable line, you do not need to pull it back to the outlet. Simply attach it to the pipe and cover the top with a heat insulator. In terms of durability and protection from external influences, single-core and two-core tube heating options are the same.

A self-regulating heating cable (SGK) does not have the disadvantages of a resistive one, but its cost is significantly higher. The high price is partially offset by simple installation, the ability to cut and shorten, as well as cost-effectiveness. If the water supply runs underground below the freezing mark, then you just need to purchase a small piece of SGC cable and place it in the most critical area - the transition of the pipe from the ground to the house.

The overlap of current-carrying turns of a “smart” line is not dangerous. There will be no overheating at the contact points. The semiconductor matrix will automatically reduce the temperature there. In addition, when a self-regulating cable operates, the coldest areas heat up more strongly, while in others the temperature is maintained at a lower level. Due to this, energy savings are achieved, in contrast to resistive routes operating at full power along the entire length.

SGK between two water pipes laid at a depth of half a meter at the entrance to the basement of the house.

Sensor selection rules

A temperature sensor for a heated floor is selected taking into account such characteristics as power, type of top covering, installation method and additional functionality.

Power

The value must necessarily meet the requirements and load of the heated floor. Otherwise, the sensor will not operate correctly. When the power of the heating element is greater than that of the regulator itself, it becomes necessary to additionally install a magnetic starter between them - to prevent damage to the device due to increased load.

Feature Set

The heated floor is controlled by an electrical unit, which allows you to configure the operation of the heating elements. Modern regulators have such functionality as starting and de-energizing the system, adjusting temperature conditions, and also setting the frequency of connecting and switching off the heating element.

Ease of use

If you don't think you can handle programming, you shouldn't buy a complex device. Even taking into account all its functionality. For example, it is quite problematic for older people to understand programmable devices. They are better off choosing the mechanical option.

Easy to connect

The accompanying documentation for the thermostat always indicates how to connect the heated floor sensor. The terminals are located at the edge on one side of the control unit. Having connected the electrical wires according to the diagram, you will need to check the functionality of the heating system. To do this, measure the resistance at the terminals of the temperature sensor and the heating electric cable, or connect a heated floor and increase the temperature values from zero to the value recommended by SNIP, that is, up to 30°C.

Appearance

The temperature sensor should not only be functionally understandable, but also attractive in design. Modern regulators are available in various color and shape variations. You can choose an option that harmonizes with the interior of the room.

Connection diagrams for thermostats.

A clear idea of the purpose of the thermostat is given by its connection diagram.

Connection diagrams were discussed a bit in the articles “Which Wi-Fi thermostat to buy on AliExpress?” and “Review of thermostat models with WiFi and cloud service.”

Let's look at several thermostats of the same model with different designs.

Connection diagrams for thermostat MOES BHT-002.

AliExpress.com Product – Smart WiFi Thermostat Temperature Controller Water and Gas Boiler Works with Alexa Echo Google Home Tuya

Data sheet for thermostat MOES BHT-002.

In the thermostat data sheet we will find connection diagrams.

From the connection diagrams it is clear that there are several versions of this thermostat model: GA, GB, GC.

GA - for water heated floors.

GB - for water heated floors.

GC - for the boiler.

Connection diagrams using the example of POER PTC10 thermostats.

Operating instructions in Russian POER PTC10.

AliExpress.com Product – Wireless Boiler Room Controller 868MHz Heating Thermostat Weekly Programmable With Large LCD, App Remotely Control

Connection diagrams using the example of POER PTC20 thermostats.

AliExpress.com Product – WiFi Smart Thermostat Temperature Controller for gas boiler electric underfloor heating humidity display works with Alexa

Several additions to one model:

Cheap thermostats.

These are thermostats without a normal housing, costing up to 200 rubles.

W3001 Digital Control Temperature Microcomputer Thermostat Switch Thermometer New

It is worth keeping in mind that they come in two types: with output dry relay contacts and with a 220V output.

Here are diagrams of some seemingly similar thermostats.

The difference is visible only when studying the diagram from the documentation.

Holding the thermostat itself in your hands, it is difficult to understand what type of design it is.

Before use, you must make sure that the thermostat has exactly the design that is intended.

Thermostats with two control outputs.

Thermostats are available with two outputs to control two different devices, which can control both the boiler using a dry contact and the actuator using a low-current high-voltage output.

The second control channel appears to the detriment of the remote sensor terminals.

And a remote sensor is not needed when controlling a water heated floor.

| AliExpress.com Product – BEOK Programmable Gas Boiler Heating Temperature Regulator APP Controls WIFI Thermostat & Hand Control Thermostat with Kid Lock | HESSWAY 3A TUYA refrigerator temperature controller wifi thermostat for 2 in 1 Linkage Gas Boiler&Dry contact NC/NO |

Thermostats with unusual connection diagrams.

Models with 4-7 channel control.

Designed to control centralized air conditioning. To do this, you need to control the split system fan and the coolant supply valve.

| AliExpress.com Product – 95~240VAC Two Pipe LCD Weekly Programmable Central Air Conditioning Room Fan Coil Thermostat | AliExpress.com Product – HESSWAY 2P4P cool heat wifi touch screen room thermostat Google Home,Amazon Echo,Tmall Genie, IFTTT for fan valve control |

The connection diagrams for these thermostats are also worthy of adding to the collection of connection diagrams. You can choose a model with the ability to control two or three devices.

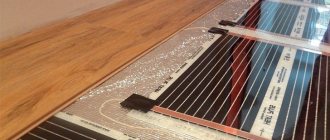

Features of choice depending on the floor covering

Sensors for the “warm floor” system are divided according to the type of coating they are installed under. However, the installation differs.

Under soft cover

A temperature sensor mounted under carpet, linoleum, or cork flooring is a small cylinder attached to the end of a piece of cable. Place it when the screed is completely set. To do this, a narrow groove is made in it.

Under hard surface

Mounted, for example, under wood, tiles. The temperature sensor here is larger and covered with gel that protects it from damage. Its installation is somewhat more complicated and can be direct or using a mounting box.

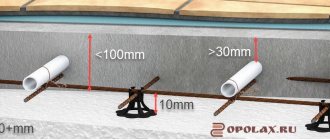

Installing a heated floor temperature sensor

Installation of a heated floor temperature sensor is carried out in several stages:

- Installation. Produced at a height of 1 meter from the floor level. This is an approximate indicator - it can be a little higher or lower;

- Grooving. Special channels are made in the floor and wall through which cables will be laid connecting the regulator and temperature sensors;

- Wiring installation. Wires are installed in the grooves, secured with special clamps. They are pre-placed in a protective corrugation, which prevents damage to the insulation.

Warm floor in the bathroom Source skladpolov.com.ua

Installation sequence

Before installing the regulator, be sure to read the attached technical documentation. It is best to install the thermostat next to sockets at a height of 60–100 cm from the floor. Before installation work, turn off the electricity in your home network.

Directly

To install a temperature sensor using this method, the regulator and heating cable are connected directly. With this type of connection, the heating element itself is in conjunction with the thermostat.

Using a junction box

This part is used as an intermediate part between the thermal device and the heating element. The connection diagram is as follows: one cable is pulled from the regulator to the wiring block, and another to the heating wire.

In order to mount the regulator you will need: corrugated tube, screwdriver, mounting screws, mounting box, level, indicator.

Step-by-step installation instructions:

- A hole is cut in the wall for a box for mounting a thermal device. Below is a groove for pulling electrical wires. The box is placed in the right place.

- Electrical wiring is being pulled. The power cable and temperature sensor element are connected to the junction box.

- The electrical wires are connected to the thermostat, after which it is mounted in the box and secured.

- The main system components are connected to the product in accordance with the technical documentation.

- Once finished, the front panel is leveled and secured with screws.

Continuous operation of the heating system should begin no earlier than 3–4 weeks after pouring the screed. And if you chose tiles, after laying them. Under the influence of heat, the screed may simply burst.

Types of thermostats by design.

- In the building.

- For installation box.

- Without a normal body.

- In the form of a socket.

1. In a wall-mounted housing.

2. For installation in a regular installation box.

3. Without a normal body.

The first and second versions can be used normally in the room.

The third type of design cannot be normally installed in a residential area without additional costs, only in a garage or chicken coop.

Such thermostats are discussed in detail in this review of thermostats.

4. In the form of a socket.

The thermostat looks like a tee, but with one socket.

There are three possible operation options for the thermostat:

In one housing there is a switching device and controls.

The socket does not contain controls and is controlled via a radio channel by an external thermostat.

In one case there is a switching device and controls with the ability to configure via Wi-Fi.

| Wireless WiFi Thermostat RF Plug Remote Control Smart Home | Nashone LCD Digital Programmable RC Wireles Thermostat for underfloor heating |

| Pymeter Digital Thermostat PID Temperature Controller | Nashone Thermostat Temperature Controller |

What to do if the sensor is not installed

The simplest solution is to connect a thermal device that has a built-in control temperature sensor that turns off the heating wire when the air warms up to the required temperature.

If a warm floor is needed only to make the surface pleasant to walk on, a thermostat with a smooth power control mode in the range from 0 to 100 percent is suitable.

The thermostat operates on the principle of a timer. For example, when set to 80 percent for 10 minutes, electricity flows to the heating element for 8 minutes, but not for 2 minutes.

There are regulators that can automatically switch to timer mode.

Heating cable power for water supply

It is quite difficult for a user even with an engineering education to determine exactly how much power is required for the effective operation of a resistive or self-regulating heating cable - the calculation formulas are too cumbersome and the calculation takes a long time. The task is only possible for qualified specialists, and its solution in everyday life is carried out by manufacturers and distributors of heating electrical cable products.

For household water pipes made of HDPE with a standard diameter of one or one and a half inches, the optimal thickness of the insulation shell is 30 mm; when using sewerage, you will need a higher power cable of about 20 W per meter or spiral winding, with an insulation thickness of 50 mm.

For external heating, the power of the heating cable is linearly related to the ambient temperature and the state of the heated elements; for pipelines, its average value is about 20 W per linear meter; on roofs and in drainpipes, powerful resistive electric cables of up to 60 W per linear meter are used.

Rice. 12 Connection diagram for single-core and two-core cables

How to check a temperature sensor

To find out why the temperature sensor is not working, you can use a multimeter:

- The input line is being tested. You need to turn on the power and check if there is voltage in the wires.

- If no problems are found, the output line is tested. The heating cable is disconnected from the regulator and the power is turned on.

If there is no voltage at the output terminals, we can say that the thermal device has become unusable. It is removed and replaced with a new one.

What to look for when choosing a heating cable

When choosing a heating cable for pipes, the following factors are taken into account:

- Operating principle. The disadvantage of resistive cables is their uniform heating temperature along the entire length. In order to save energy, it is better to use a self-regulating cable on underground pipes. In addition, its design, in the absence of a remote sensor, is convenient for placement inside pipelines, and the minimum power of the device is 10 W. per linear meter is sufficient for its linear placement underground in a heat-insulating shell.

- Power. For external heating, devices with high power are used; the best performance is achieved by linear cable modifications with a spiral winding of the heating wire inside.

- Insulation. When installed internally in water pipes, devices with insulation made of food-grade plastic should be used; it is better to choose modifications with a copper screen - the presence of the element reduces interference and protects the user from electric shock if damaged. Also, a braid of tinned copper wires promotes more intense heat removal from heating cores or matrices.

- Manufacturer. The market offers a wide range of models of heating cables from various manufacturers; among foreign suppliers, the products of Raychem, Nelson, Lavita, Ensto, Devi are well known; a wide range of cable heating products from a domestic manufacturer - a company from the Moscow region - is sold on the construction market. Special systems and technologies SST .

Rice. 21 Table of dependence of heater power on pipe diameter and insulation thickness

The use of a heating cable for sewerage and water supply is the most effective method of combating icing, because any thermal insulation does not heat the pipeline, but only increases the time it freezes. Self-regulating cables, which have recently appeared on the construction market, are slightly more expensive and more efficient compared to resistive devices; they are the best option when lowering into water supply.

Review of manufacturers

There are many companies involved in the production of heated floors. The most popular brands are Devi, AEG, Thermo Industri AB. Each manufacturer's sensors have their own characteristics.

Devi devices

Temperature regulators of this brand work with any type of heating elements. They are divided into mechanical and electronic, with conventional or touch controls. In addition, the Devi line of regulators includes models controlled remotely via smartphones.

Advantages of devices of this brand:

- availability of models for outdoor installation;

- savings on the operation of heating appliances up to 30 percent;

- availability of control via the Internet.

The advantage is the variety of options to solve any problem.

AEG regulators

Thermal sensors of the German brand belong to the premium class. Excellent quality guarantees durability and trouble-free operation. But such devices also cost a lot.

The product range is wide: from simple basic devices to “smart” temperature sensors that fully control the operation of the heated floor and the microclimate in the room.

But even basic models have many advantages:

- maintain temperature indicators at the required level;

- controlled very simply - by manually turning the key on and off;

- Thanks to convenient controls, they are suitable for older people who are not familiar with programming.

An external timer can be connected to the device to control the temperature reduction mode.

Devices Thermo Industry AB

Such thermostats are installed exclusively indoors. Capable of controlling elements of a heating cable or thermomat. Models have been developed that are ideal for parquet or laminate flooring. Most devices are equipped with smart air temperature meters.

Electronic devices are capable of adjusting heating with an accuracy of 1°C.

They are used for anti-icing systems if it is possible to combine them with a thermostat in the house. Built-in intelligent heating sensors make it possible to reduce electricity consumption, and Swedish quality guarantees many years of operation.

Thermostats with integration with external systems.

The thermostat can be a regular device, or it can be integrated into smart home systems or available for control remotely and from other systems.

The following methods of external communication with the thermostat can be distinguished:

- Wi-Fi;

- WEB;

- Cloud service;

- MOD Bus;

- Radio channel;

Wi-Fi.

The article “What is a thermostat with Wi-Fi” discussed ways to control thermostats via Wi-Fi. The easiest way is to directly connect to the thermostat as an access point.

WEB.

More convenient connection to the Wi-Fi thermostat via a Wi-Fi router.

But such a thermostat is a WEB device and can be connected to it via the Internet.

Cloud service.

In order to access the thermostat without an IP address, a third-party server is used - a cloud service with a mobile application or WEB interface.

Such thermostats were discussed in detail in the article “Review of thermostat models with WiFi and cloud service.”

MOD Bus.

I've seen discussions about such thermostats. Most likely it makes sense to control cooling with a central air conditioner and with a central air conditioning controller.

Probably it can somehow be used in zone heating systems with a central controller.

Model SML-1000 version GB,GD,GC.

16A Touchscreen Black Color Programmable Modbus Thermostat for Electric Heating (with Modbus function)

Remote.

Thermostat with the ability to be remotely controlled using a remote control, like a TV.

Perhaps it makes sense when controlling an air conditioner or an infrared heating panel.

| Wireless Remote Room Digital Thermostat | Eco Art Outdoor Infrared Heater, 2400W Outdoor Patio Heater wall mounted heater with Smart thermostat |

The best thermostats for an aquarium

To maintain a comfortable climate in a fish aquarium, special heating systems with a thermostat are also widely used. After a given range of acceptable indicators, the controller will turn off the heating in a timely manner, then turn it on. It can be a mechanical, electronic or infrared thermostat; they differ in adjustment accuracy, service life, and control method. After testing and expert assessments, the best offers on the market were identified.

Tetra “HT 50”

This thermostat operates with a power of 50 W, suitable for containers from 25 to 60 l. The case is made of heat-resistant heavy-duty Borosilikat glass; it is protected from moisture penetration and overheating. The operating temperature range is 19-30 °C, and the error does not exceed 0.5 °C. For ease of control, a light indication is provided. The heating element is made of ceramic, the double system guarantees even heat distribution.

Advantages

- Build quality;

- Compliance with TUV/GS, CE quality certificates;

- Warranty service;

- Reliability of fastening;

- High security;

- Clear indications of the heating system.

Flaws

- Price.

The heater quickly brings the water in the aquarium to the desired temperature, and then turns off. The error is minimal, this is confirmed by testing by specialists. The manufacturer is trusted; users do not note any shortcomings. Perhaps the price is slightly higher than that of similar devices, but it is justified by its reliability and long service life.

Xilong AT – 700

This heating device with a thermostat in its design is designed for all types of aquariums with a volume of up to 300 liters. The owner can set the operating range from 17 to 35 °C, protecting pets from temperature changes. For reliable fastening, the manufacturer includes 2 suction cups in the kit. The case is 100% waterproof and sealed. The maximum power is 300 W. More often, such a device is installed vertically.

Advantages

- Compactness;

- Water protection;

- Easy installation;

- Easy to read indicator;

- Versatility;

- Minimum energy consumption.

Flaws

- Chinese production.

Users actively use this device for freshwater and marine types of aquariums. It is recommended to install Xilong AT – 700 in a place with constant maximum water circulation in order to heat it evenly.

Malfunctions

The reliability of thermostats depends on the quality of the components from which the devices are made.

Typical faults:

- Mechanical damage is a common failure for low-price devices. Rough handling can lead to failure of buttons, wheels and faceplates.

- An important component of the thermostat is a contact relay, the resource of which is limited by the number of on-off cycles. Over time, the part wears out and power stops being supplied to the heating cable;

- Voltage surges in the electrical network are guaranteed to damage the electronic “stuffing” of the controller;

- Incorrect connection of the device can lead to a short circuit and damage to the device.

The best thermostats for the refrigerator

If you need to buy a thermostat for a refrigerator, then consider a relay that gives a signal when the compressor motor is turned off, the freezer is cooled, or there is any malfunction in the operation of the household appliance. Outwardly, it resembles a small box, which is attached to the refrigerator on one side and to the electrical outlet on the other. On sale today you can see mechanical and electronic types that are matched to refrigerator models. After analyzing the popular products, taking into account reviews and expert ratings, the rating nominees were named.

Ranco K-50 (0.8) L3392

The device in question is an analogue of the well-known thermostat TAM-112. The manufacturer emphasizes that it can only be combined with single-chamber refrigerators, which have only one door, one freezer with a temperature range of at least -12 °C. The length of the siphon tube is 0.8 m. The body is made of durable white-gray plastic.

Advantages

- Italian production;

- Reliability of operation;

- Accuracy of temperature determination;

- Long service life;

- Stable body.

Flaws

- Suitable for single chamber refrigerators only.

There are not many reviews about the manufacturer due to the rare presence on the market of the former CIS countries. Users note good workmanship, service life is several times longer than Chinese analogues.

TAM 133

The main task, namely maintaining the desired temperature by automatically turning on or off the refrigerator compressor, is performed perfectly by the TAM 133 thermostat. We are talking about a mechanism with a contact system and a power lever. The manufacturer emphasizes that it can be used for refrigerators Ariston, Indesit, Stinol, Atlant and other 2- or 3-chamber appliances. Operating temperature from –25 to +5 °C.

Advantages

- Italian production;

- Easy installation;

- Thermosensitive system;

- Long service life;

- Compatible with many refrigerators.

Flaws

- Many types of models;

- Rarely in stock.

When choosing such a device, it is important to consider that there are many varieties of it on sale, for example, TAM 133-1M-1, TAM 133-1M-2, etc.

Each option has slightly different characteristics and is also suitable for a specific group of refrigerators.

Which thermostat is better to buy?

Any of the presented nominees for a temperature controller is an element of safety and protection of household appliances. This means that the question of choice is more than relevant. The criteria by which you can buy a good thermostat have already been named, and after comparing the best models, experts made the following conclusions:

- The brand with the best reputation and high-quality technical support is DEVIreg Smart;

- The best automation with remote control – Teplolux MCS 350;

- The longest service life declared by the manufacturer is Valtec angular ½;

- Premium quality, popular manufacturer – Ranco K-50 (0.8) L3392;

- Self-learning, the best set of functions, security - Terneo EG.

Which of the presented options to purchase is a purely individual decision. Much depends on the budget, purpose, and personal principles for assessing each potential user. The review will help you narrow down your search for the best thermostat for household and climate control equipment.