We have all gotten used to insulating our homes lately. The main activities in this direction are related to the installation of thermal insulation materials on wall panels. The presence of an insulation layer significantly reduces the intensity of heat exchange between the walls and the outside air. Preservation of heat inside residential premises is the key point for comfortable living, even with powerful heating equipment.

Insulation is a task that concerns not only the structural elements of a residential building. When using a water floor, you also cannot do without thermal insulation. Why thermal insulation is needed in this case and what its functions are, let’s look at it in more detail.

Is thermal insulation necessary for underfloor heating or not?

Thermal insulation in the “pie” of a warm water floor plays a huge role; the correct functioning of the entire heating system depends on it. The screed, poured over the thermal insulation, turns into a large surface that transfers heat.

The main functions that a thermal insulation flooring under a warm water floor should perform:

- distribute heat flows evenly throughout the heated room, this is especially important when laying a water structure, since the configuration of this system consists of straight and curved pipes, so the heat is not distributed evenly;

- prevent the outflow of warm air through the ceilings; it serves as a reflective screen, which also makes it possible to save thermal resources;

- act as sound insulation;

- prevent the entry of moisture and cold from below - when arranging a structure above an unheated room or on the ground;

- prevent the formation of moldy and fungal deposits.

In addition, by using polystyrene foam mats with bosses as insulation under a warm water floor, you significantly simplify the process of installing and fixing pipes.

For your information! If the thermal insulation layer is correctly selected and laid, the floor “pie” turns into a closed thermal device, where thermal radiation is distributed evenly and in the desired direction.

How does it work

A water-heated floor heats the room using small-diameter pipes through which the coolant circulates. The water temperature should not exceed 50 degrees - the key rule of the system. With a pipe diameter of 80 mm, the length of the heating circuit reaches 80 m, with a diameter of 20 mm - no more than 120 m. Pipes of maximum length are heated by a circulation pump with a pressure of 6 or 8 m. Otherwise, the system will not create sufficient heating.

The boiler heats the coolant up to 80 degrees if the same water is used by radiators. For a water floor, the temperature is needed twice as low: up to 50 degrees. For this reason, a mixing unit with a mixing valve and a circulation pump are installed in the system. The valve mixes water from the return and return collectors. In this way, a temperature suitable for a water floor is achieved. Water enters the distribution unit and is directed through the return manifold into pipes under the floor. The coolant makes a circle and returns through the return manifold to the boiler, and this cycle continues as long as the pump is running.

Types of insulation for water heated floors

When selecting a material for a thermal insulator for a warm hydrofloor, you should take into account the characteristics and technical indicators of the room, as well as the base on which the substrate will be installed.

For the most part, the thermal insulation material has the same degree of thermal conductivity. But the thickness of the layer is often required even in the same room.

The most common types of thermal insulation used under water-heated floors include: mineral wool, cork, expanded polystyrene, profile mats. This material has different thermal insulation characteristics and properties, and this should be taken into account when choosing and installing the floor.

For your information! When constructing a warm water structure on the ground, it is recommended to use natural raw materials for insulation: sawdust, expanded clay, washed granulated slag, expanded clay sand.

Let's take a closer look at each type of material for thermal insulation of a heating structure.

Cork backing

Cork is an expensive product because it is made from oak bark. Available in rolls or sheets, but there are no differences in technical characteristics. The only difference is the size and thickness.

Cork backing:

- has low thermal conductivity;

- waterproof;

- environmentally friendly;

- hypoallergenic;

- elastic;

- light-resistant;

- fireproof;

- resistant to sudden temperature changes;

- not susceptible to chemical influences.

A product made from cork is an ideal option for a water-heated floor system, and if funds allow, then it is better to choose it. The thickness of this substrate contributes to effective saving of heat resources, which is especially important when installed on the ground.

Cork is not subject to deformation and shrinkage when pouring concrete screeds. It cannot be harmed by insects and rodents, mold and mildew, and is also not terrible.

However, it should be noted that the use of cork as a substrate will affect the height of the ceilings, and additional reflective material will also need to be purchased.

Expanded polystyrene

Expanded polystyrene is the most common type of thermal insulation under water heating floors, and has a fairly affordable price. It provides high-quality protection from water and steam, a high degree of sound insulation, does not deform from exposure to temperature, does not react to chemicals and resists the formation of mold and mildew.

Thermal insulation consists of many bubbles placed in a shell. To add strength to the structure with this substrate, a reinforcing mesh is used. Ease of installation, which even an inexperienced person can handle, also plays an important role in its popularity. In addition, the service life is several decades.

The main disadvantage of polystyrene foam is a fire hazard, so it must be insulated with a foil backing.

Expanded polystyrene comes in several types, which differ in production technology and properties:

- Extruded polystyrene foam is durable and better performs its main function - thermal insulation. It has increased strength, since the particles are tightly bonded to each other. But the vapor permeability indicator is almost zero. Its thickness is at least 3 cm. The slabs are often colored.

- Foamed - also called polystyrene foam. It has a low specific gravity and a high degree of vapor permeability. It is not recommended for foundation insulation, as it is destroyed by moisture. The color is usually white. It is produced in a non-extruded way, that is, the structure has cells with air channels.

- Penoplex - its cost is not high. It has good performance in terms of reflecting heat flows, therefore it is considered one of the best insulation materials. During installation, a waterproofing substrate is not required, and the process itself is not complicated; it is easy to do the installation yourself. Available in slabs of various sizes, the thickness of which ranges from 20 to 100 mm. The package contains from 4 to 20 sheets - it depends on the thickness of the product.

Penoplex - types, scope, characteristics, advantages and stages of laying thermal insulation.

Main advantages:

- high heat and vapor insulation;

- absence of emissions containing harmful substances;

- resistance to the effects of microorganisms;

- does not allow moisture to pass through;

- has high strength.

- Profile mats - they are also based on polystyrene foam. They are stamped using a special technological method and covered with a film for waterproofing. The slabs are high-strength products that can withstand mechanical loads. They are equipped with protrusions; water heated floor pipes are laid in them, which facilitates the process of placing the circuit. They have side locks - this simplifies installation and minimizes the presence of seams. The model is considered the most profitable, in terms of financial investments, when constructing heating.

Mineral wool

Mineral wool is fireproof, unlike polystyrene foam insulation, but its price is more expensive. It is manufactured in slabs, making it easy to install.

When installed on an aluminum underfloor heating base, this insulation has high efficiency, even when placed on the ground. In addition, it has good noise and heat insulation, increased rigidity, and is resistant to chemicals.

The main disadvantage of the product is that it contains carcinogenic and toxic substances that are dangerous to human health. In addition, cotton wool is hygroscopic and vapor-permeable, and when laying it in a screed, care must be taken to protect it from moisture and steam emissions.

Rolled thermal insulation made of foamed polyethylene

Foamed polyethylene (penofol) is gaining popularity today. It is sold in rolls and has a thickness from 3 to 10 mm. The product is equipped with a foil surface, it reflects heat and allows you to significantly reduce the thickness of the “pie”, since there is no need to lay additional waterproofing made of lavsan or thermal insulation.

There are the following types:

- A - one side has a layer of foil;

- B - foil on both sides;

- C (self-adhesive) - there is foil on one side, glue is applied on the other;

- “ALP” - one side is foil, the other with a special film.

Each type is suitable for use under heated floors, and almost completely copes with the thermal insulation of the device.

The technical indicators of foamed polyethylene and polystyrene are largely similar, the thermal conductivity coefficient ranges from 0.037 - 0.049 W/m °C.

It is worth mentioning the ability of the material to absorb water, which results in a decrease in its thermal insulation properties.

In addition, under the influence of a wet screed containing chemicals, the aluminum foil layer becomes unusable. To combat this problem, manufacturers began to produce the product in sheets with a film-like coating on top of the foil.

Metallized lavsan film is capable of qualitatively protecting the screed and flooring from the effects of alkali. Insulation with an aluminum layer without a thermally resistant coating is not used. The positive side of the product is its high degree of heat reflection.

Important! When laying, the foil side of the product should face up.

What are polystyrene foam boards

How to install a mixing unit for a heated floor with your own hands

The term “expanded polystyrene” means a material made by foaming polystyrene. Plates made from it are the final product for thermal insulation.

The main advantages of expanded polystyrene are its small thickness, light weight, ease of installation and affordable cost.

Important! When installing heated floors using slabs, it is necessary to take into account the load and distribute it correctly!

The advantages of polystyrene foam for heated floors include:

- High heat retention performance. Its thermal conductivity coefficient is much lower than that of polystyrene foam, which makes it possible to lay slabs of smaller thickness.

- Good mechanical strength indicators make it possible to use it as a structural element for loaded structures, a reinforcing layer and an underlying layer.

- The heat resistance of expanded polystyrene makes it possible to use it regardless of temperature.

- Expanded polystyrene boards easily withstand the effects of chemical reagents and adverse environmental conditions.

- When making plates, molds can be used that form so-called bosses, which serve as protrusions for laying between them a heating element (tube), the diameter of which can be from 16 mm to 18 mm.

- The presence of side locks allows you to form boards from slabs without “clearings”, which in turn provides sufficient adhesion and avoids seams that cause thermal acoustics.

- Excellent sound insulation performance.

- Environmentally neutral and does not pose a threat to the human body.

- Absolutely resistant to microorganisms and fungi. Its synthetic base is a reliable barrier to putrefactive processes that can occur on other thermal insulation materials during operation.

- Moisture resistance is the main advantage of the material. Even with constant moisture on the slabs, they will not deform.

- A warm floor laid on expanded polystyrene slabs will not cause harmful fumes from heating the material, since its granules are carbon and hydrogen.

- Vapor barrier indicators are provided by air capsules in the composition of polystyrene foam. They are usually practically closed and impenetrable. Therefore, neither air nor steam can pass through the material. This is a wonderful vapor barrier that cannot accumulate moisture inside.

These advantages of the material became the starting point for installing floors, including warm ones.

Which insulation to choose?

As mentioned above, a warm water floor requires insulation, since without it it will not function effectively. In addition, if there is thermal insulation, the system is more economical. It is important not only to know how to properly insulate a heated floor, but also how to choose a suitable heat-reflecting material.

When purchasing thermal insulation, you need to look not only at the characteristics, heat-saving properties of the material and its parameters, but also at its service life. Since a number of products with good performance often have a short service life.

Therefore, there will be a need to replace it before maintenance of the system itself is required. This is especially important in rooms with tile flooring, because it is difficult to dismantle it. In this regard, experts advise purchasing a product with a warranty period of 10 - 15 years.

Among the properties that are recommended to pay attention to:

- level of thermal conductivity;

- resistance to mechanical loads and dynamic influences;

- density indicator;

- hydro and vapor tightness.

For rooms with high ceilings, it is better to choose durable, rigid types that have a polymer base. If you are insulating a room with wooden floors, mineral wool is an excellent option, because it is fireproof.

You should not skimp on thermal insulation material when laying a heated floor. Its cost will pay off within 3 years, and if you use natural gas for heating, the payback period will be significantly reduced.

Advantages and disadvantages

The main advantage of any insulation with a foil layer is its technical performance, which is significantly increased compared to similar materials, but without a foil layer. However, due to additional production costs and complicated technology, such a heat insulator is more expensive. In general, foil insulation has a lot of positive qualities.

Insulation with foil is significantly superior to conventional heat insulators

Advantages of the material:

- sound insulation;

- safety from an ecological point of view in most species;

- resistance to temperature changes;

- moisture resistance;

- easy installation;

- high thermal insulation properties;

- durability.

Pros and cons of foil insulation

The disadvantages of the material include softness, which prevents the use of foil insulation when laying some soft types of floor coverings, as well as high cost compared to ordinary thermal insulation materials.

Features of laying insulation

The principle of installing a thermal insulation layer is simple, no special tools or special experience are needed, the main thing is to follow the technological process.

Watch the video on how to choose insulation:

How to choose insulation for a heated floor. Lifehack from Design.rf

Installation of polystyrene foam boards

The work of installing polystyrene foam boards under a heated water floor is as follows:

- Regardless of the type of thermal insulation product, you need to start by preparing the subfloor. It should be smooth, without cracks. If irregularities and flaws are found in the surface, they need to be repaired.

- Waterproofing measures consist of arranging a layer that protects against moisture, this can be a polyethylene film.

- Sticking damper tape around the perimeter of the room is necessary to compensate for temperature fluctuations.

- Laying insulation boards over the entire area - the sheets are fixed to the base using plastic staples or dowels; the product can be installed with glue.

- Spreading foil film and installing reinforcing mesh over the insulation.

- Installation of heating elements (pipes) - they are attached to the grid according to the planned scheme. The seams between the plates should be taped with tape, this will help retain heat.

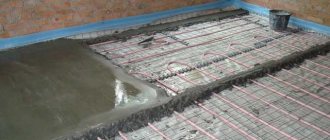

- Pouring concrete screed over the pipeline. To ensure surface strength, it is recommended to add plasticizers to the solution. It is necessary to let the mixture harden, this will take about a month.

- The last step is the installation of the finishing coating.

For your information! It is worth considering that underfloor heating pipes with the coolant inside have significant weight, plus the screed and finishing coating, all of this together will push through the insulation over time.

To avoid this, high-strength thermal insulation is required. In addition, to strengthen the structure and distribute the load evenly, it is recommended to reinforce or lay polystyrene foam slabs with bosses. In addition, such mats facilitate the process of placing pipes and fixing them.

Laying rolled polyethylene foam

Installation work on the construction of a water-heated floor using rolled polyethylene as insulation begins with leveling and cleaning the base.

At the second stage, the heat-insulating material is prepared. This consists of cutting the heat insulator into strips of the required length using a stationery knife.

Next, the foil product is placed on the prepared base with the metallized surface facing up to ensure the best reflection of heat. The canvas should extend onto the walls, this is necessary to compensate for the expansion of the screed when heated. The insulation is attached to the floor using glue or double-sided tape. And the seams should be taped using single-sided tape.

The process of installing a water circuit on polyethylene rolls is facilitated by the presence of installation markings printed on it, which show the distance between the pipes. Heating elements on penofol can be placed in a “snail” or “snake” pattern.

Further work on the construction of water heated floors consists of installing reinforcing mesh, pouring a concrete screed and laying the floor covering.

For your information! For use in a warm water device, ALP brand penofol is recommended.

Laying mineral wool

Mineral wool cannot be crushed, so the most optimal way to install it is on the floor, with the installation of logs.

Step by step, the installation of the “pie” of a warm system with a thermal insulation substrate made of mineral wool is as follows:

- Preparation of the base is a mandatory stage of work when installing any heated floors. If the floors in the house are old, then it is better to completely remove them down to the concrete floor or rough wooden floor. The surface must be inspected for irregularities and cracks; if any are found, they are repaired.

- Laying a hydro- and vapor barrier substrate is a necessary step when using mineral insulation, as it is resistant to moisture. For these purposes, roll-type waterproofing - roofing felt, or other modern materials - is suitable. The sheets are fixed to the base using polymer or bitumen mastic. The material is laid in an overlap, the seams should be coated with mastic.

- Arrangement of wooden logs - they are attached to the subfloor over the entire area. Blocks measuring 5 by 6 cm are taken and installed on a concrete surface, secured with dowels, and on a wooden floor with self-tapping screws. The pitch between the fasteners depends on the flooring that is planned to be laid; it ranges from 40 to 80 cm. It requires making cuts in the joists to rotate the contour.

Important! If mineral wool is used as insulation, then the distance between the logs should exceed the width of the material by 1.5 - 2 cm.

- Laying insulation - mineral wool is installed in the spaces between the bars. It is necessary that it sinks at least 5 cm, as a ventilation gap is required.

- Installing a second waterproofing layer is necessary, because cotton wool is not moisture resistant. An ordinary polyethylene film is used, which is placed in a stretch on the logs and fixed with a stapler.

- Preparing the substrate for pipes - slats are used that are nailed across the logs, with a distance of 30 cm from the walls. There should be grooves between the slats in which a metal profile for laying pipes will be placed. Their size depends on the step of laying the contour.

For your information! The metal profile can be replaced with foil in which the pipe is wrapped.

- Installation of the heating circuit - heating pipes are laid into the installed profile according to the planned layout.

- Installing interior flooring - this can be chipboard or plywood.

- Finally, the floor covering is laid.

At this point, the warm floor with a thermal insulation backing - mineral wool, is ready for use.

Using foam plastic to insulate screeds

The cost of installing a water heated floor and the installation process

Floor insulation with foam plastic under the screed is one of the types of floor insulation.

In order to form a thermal insulation layer, PSB-S-35 is used. To ensure that the joining of the slabs occurs more tightly, slabs with milled edges are used.

Before using polystyrene foam, it is necessary to create a polyethylene flooring. It will promote isolation.

Foam materials are not strong enough to withstand the load of a concrete screed. In order to reduce the load, a dense mounting mesh with a thickness of 40-60 mm is used.

Instructions for forming insulation:

- The dense bottom substrate is covered with plastic film.

- Foam boards are tightly laid around the entire perimeter. The joints are filled with polyurethane foam or firmly glued together.

- A mesh is installed on top of the insulation.

- A screed is placed on top. Its composition can be different; the basis is concrete.

If the floor is installed correctly and there is no unnecessary ventilation, the temperature in the entire room, including the floor, will be the same. After the screed is completely dry, coat. Complete drying time is at least 28 days.

There are several more commandments for forming a heated floor under a screed that cannot be violated:

- Floor insulation with foam plastic must correspond to the parameters of the room. Since the width of the foam and the screed take up part of the height of the room, there is no need to create too wide a layer where it is not necessary. For inter-apartment floors, a slab 2-3 cm thick is sufficient.

- For a more fragile type of insulation, a large layer of screed is used - 5 cm; for a more durable insulation, you can use a layer of 4 cm.

- Do not force dry the surface. The process should take place naturally in the absence of drafts and constant moisture.

- When mixing the solution, the proportions must be strictly observed.

Floor insulation

Optimal insulation thickness

It is important to make the right choice not only of the insulation model, but also of its thickness; thermal energy savings depend on this.

For your information! If the thickness of the insulation is small, then most of the heat goes under the floor, its amount is equal to the flow of warm air rising upward.

The thickness of the insulation should be selected depending on climatic conditions. It is clear that in areas with a cold climate, the layer of thermal insulation material should be larger.

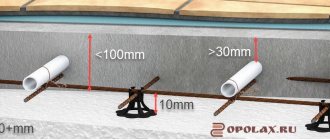

The type of room located under the warm water floor also plays an important role. If this is a cold basement, or the structure is laid on the ground, then the insulation layer should be made thicker, 100 - 120 mm. When constructing a heating floor over a heated room, a sufficient thickness of 30 - 50 mm.

Installing a thermal insulation layer under a heated water floor is not a luxury, but a necessity. Incorrectly done insulation will lead to deterioration in the quality of heating and unnecessary costs.

What is the basis for choosing an insulating material?

The basis for a heated floor is the so-called “layer cake” - a stacked structure in which each layer performs its own specific functions and tasks. Insulation takes one of the leading places in this pie, so a lot depends on the quality of the insulating material, its composition and structure. Thermal insulation must meet any changes in the operating conditions of the heating communication. The safety of the insulating material is one of the main factors determining its choice.

The second most important technological parameter of thermal insulation materials is thermal conductivity. Here there is a close relationship between the thickness of the material and the thermal conductivity coefficient. The proposed figure - diagram shows the parameters of various building materials used in everyday life.

*

The advantage of synthetic insulating materials and mineral wool is that, despite their small thickness, they have good thermal conductivity. When it comes to installing heated floors on interfloor ceilings or in wooden buildings, the small width of thermal insulation materials and their low weight play a decisive role.

Therefore, based on the data presented, it is easy to draw the following conclusion. Thermal insulation for warm water floors is created from materials with the following characteristics:

- low thermal conductivity coefficient;

- fire resistance;

- moisture resistance;

- soundproofing;

- technological compatibility with other materials.

The thickness of the insulation is determined by the texture and structure of the material. When purchasing insulating materials, base your choice on the given parameters. Price in this case does not play a special role. Today, all materials offered in the retail chain have approximately the same cost. In the general context of the cost of heating floor equipment, the price of thermal insulation is not critical.

How thick should the insulation be?

The retail chain offers materials of a certain standard thickness. The required thickness of thermal insulation in your case is determined by the conditions of the heating system design. The laid layer of thermal insulation in the case of using extruded polystyrene foam on the first floor must be at least 100-115 mm. If polystyrene foam of the required thickness is not available, thermal insulation is laid in two layers (50 + 50 mm).

To lay water floors on the concrete floor of the second floor, you will need a thermal insulation layer of much smaller thickness, 25-35 mm. We have already talked about the density of foam plastic earlier. The optimal density for thermal insulation foam should be 38-45 kg/m3.

A private house

Water-heated floors in a private home allow you to save on electricity. In addition, such a heating system in the house works smoothly. Engineers recommend taking into account the heating system before construction begins, at the planning stage. This will make calculations easier in the future.

This design is installed due to the cold inside the room. The cold climate forces people in Simferopol to buy water heated floors and use it with other heating sources.

It is also possible to install a heated water floor in a private house after construction is completed. However, it is important to comply with certain conditions. First you need to understand whether the house is suitable for installing such a heating system. If the room does not have thermal insulation, it is useless to install such a system - heat loss should not exceed 100 W/sq. m. A water-heated floor in a concrete house will subtract 15-20 cm from the total height of the room. Therefore, during installation, it is important to ensure that the dimensions of the doorways are maintained.

Pipe deformations and leaks occur due to an uneven and weak base surface. Therefore, before installing such a heating system, it is recommended to use special building mixtures.

Pie recipe"

Each element of the heating system performs a special function. In order to buy and install a heated water floor in a private home, you need the following “ingredients”:

:

- cement mixture;

- plastic film with a thickness of at least 0.1 mm;

- thermal insulation material;

- plasticizers;

- reinforcing mesh 50x50 or 100x100, rod thickness - 3-5 mm;

- heat-resistant floor covering.

A thin layer of polyethylene film is laid on the base, soil or concrete slab. Then the floor is covered with heat-insulating material: density from 40 kg/m3, thickness from 300 mm.

Plasticizers

added to cement fill for elasticity of the material. Inside this layer there will be water-heated floor pipes. The screed is reinforced with a reinforcing mesh, and then a heat-resistant floor covering is applied. Installing a water floor under tiles or laminate is a good idea, since these building materials have sufficient thermal conductivity.

Power

To install a water heated floor in an apartment, it is useful to know what the energy consumption of the system depends on. Power is determined by the temperature of the coolant: the higher the temperature, the greater the power output. When using such a heating system, it is important to remember: the water temperature should not exceed 50, and the power from 1 sq. m - no more than 140 W. When a water-heated floor in an apartment is the only source of heating, it is recommended to cover most of the room.