The rafters are the foundation on which the entire roof is based. The strength and durability of the building depends on how correctly the section of inclined beams is chosen, how they are located and connected to each other and other structures of the building.

Reminder table: at what distance the rafters are placed*

| Roof slope length, m | Roofing material | Section of timber (pine), cm | Rafter pitch, m |

| Less than 3 | Easy | 8x10, 10x10 | 1,2…1,8 |

| Less than 3 | Average | 8x10, 10x10, 10x13 | 0,9…1,2 |

| Less than 3 | Heavy | 10x10, 10x13, 12x15 | 0,3…0,9 |

| 3…4 | Easy | 12x15, 9x18, 8x20 | 1,2…1,8 |

| 3…4 | Average | 9x18, 8x20, 10x20 | 0,9…1,2 |

| 3…4 | Heavy | 8x20, 10x20 | 0,3…0,9 |

| 5…6 | Easy | 8x20, 10x20, 12x22 | 0,9…1,2 |

| 5…6 | Average | 8x20, 10x20, 12x22 | 0,6…0,9 |

| 5…6 | Heavy | 8x20, 10x20, 12x22 | 0,3…0,6 |

*The table data is indicative and requires calculation verification!

What determines the distance between the rafters?

This parameter, like any other in construction, is selected on the basis of “necessary and sufficient” considerations. There is no point in installing rafters more often than necessary - a large number of them will increase the load on the load-bearing walls of the building. Reducing the amount in relation to the calculated one is also bad, since the load capacity of the roof will decrease, it may simply collapse under its own weight and the weight of the snow piled up during the winter. That is why it is very important to accurately determine the required number of beams with an error of no more than 3...5%.

To calculate you need to know:

- length of the supporting wall(s);

- roof type - single, double or multi-slope;

- the nature of the roofing material (necessarily its specific gravity per square meter);

- thickness of the “roofing cake” (insulation, hydro- and vapor barrier, noise protection), weight of the materials used;

- features of the sheathing (solid, sparse, sheet or slats);

- the material of the rafters themselves and their cross-section;

- a method of connecting rafters and supporting (connecting) elements.

In frame buildings, the pitch of the rafters is often linked to the pitch of the frame posts - a much more reliable and durable scheme is one in which the rafter is directly connected to the post, rather than resting on the mauerlat between the posts.

Moreover, a significant part of the listed characteristics depends on the area in which the building is located and, accordingly, what the snow and wind load on the roof is.

If the design of the future roof is not yet known, the calculation begins with determining the snow and wind load and selecting an approximate roof design. Then there are two options: either, starting from the selected rafter section, calculate the pitch, or select the section after choosing the distance between the rafters.

Content:

- What you should pay attention to before making a calculation

- Calculation method

- Dependence of rafter pitch on roofing material

- Determining the rafter pitch for a pitched roof

- Distance between rafters for a gable roof

Before proceeding with the installation of the roofing, it is necessary to calculate the rafter system, which will depend on the material used, design, and climatic conditions.

Influence of snow and wind load

The weight of snow and the effect of wind are significant factors in the collection of loads on the rafters.

In addition to the distribution of snow masses over the roof surface (see diagram above), it is necessary to take into account the average snow cover by region. By selecting a known value, it is added to the total distributed load.

At the same time, the average annual rainfall affects not just the details of the roof structure, but also its very shape. Read more about the rules for choosing a roof slope depending on snow and wind load in our article.

For most regions of the Russian Federation, a slope angle of 5 to 50 degrees is considered normal, while low-slope (5...15 degrees) roofs are preferable for multi-story residential buildings with very high-quality waterproofing, and for private buildings an angle of 20...40 degrees is usually chosen.

Preparatory work

The walls and floors of the building are prepared, although differences may not be visible visually. The difference in height becomes obvious when the support beam is laid in succession. They try to level the corners of the house. The masonry is leveled with mortar, screeding in the right places, and the wooden frame is prepared with the help of linings, and the bulges are trimmed off.

To correct the frame, a cord is used; it is attached to the two outer beams at the required height. The slabs are cut together so that horizontal areas are formed at the edge of the beams. The control template is applied to three beams simultaneously and the horizon level is checked. If the rail with the device is short in length, tie a long block. Mark the sampling points for the rafter teeth, and place pieces of control slats that indicate the central axis.

Selection of roofing material

This is the second basic component of the prefabricated load, since the weight per square meter of the roof must be taken into account when calculating. In addition to financial and aesthetic considerations, the possibility of installing a roof on slopes with an already selected slope angle is taken into account.

The favorites of private construction are:

- fiber cement sheets (ondulin, slate and analogues);

- corrugated sheeting and seam roofing;

- metal tiles;

- bitumen shingles;

- slate;

- ceramic tiles.

Accordingly, the weight comparison is carried out specifically for these materials.

| Type of roofing material | Weight 1 sq.m. surface, kg |

| Ondulin | Approximately 3 |

| Metal tiles | 3,5…4,5 |

| Bituminous shingles | 6…8 |

| Corrugated sheet | 6…15 |

| Slate | 10…14 |

| Cement-sand tiles | 20…30 |

| Slate | 45…60 |

| Ceramic tiles | 40…60 |

If we take into account both the snow load (the wind load is much less) and the weight of the roofing material, then for one square meter there is from 130 to 240 kg/sq.m for the Moscow region, but for Petropavlovsk-Kamchatsky it is already 450…520 kg/m .sq.

Can modern online calculators be trusted?

Construction is, in fact, a whole science that does not tolerate and does not forgive even the slightest inaccuracies in any calculations. Specialists, of course, know how to correctly perform certain actions, how to quickly determine any of the indicators described above.

For a non-professional who is going to arrange and cover the roof of his, for example, a small country house, the task will be much more difficult to cope with. Gable structures are the simplest option, but it also requires increased scrupulousness in calculations.

Today on the Internet there are many sites that have an online calculator for calculating a gable roof; you can use it to calculate a gable roof in a few seconds if you enter the requested data in the appropriate fields. This is a convenient and quick way to solve the problem, but you must also understand that each calculation is an individual matter, everything must be done taking into account the nuances of a particular object.

Weight of insulating and insulating materials

The calculation of the insulating layer depends on how the space under the roof will be used - for a residential attic you need the most effective insulation, for an unheated attic this is not important, you can do without insulation at all. However, waterproofing is mandatory in this case as well.

Accordingly, the weight of the insulating materials under the roof can either not be counted (the weight of the membrane or film is 1...2.5 kg), or clearly calculated based on the materials used.

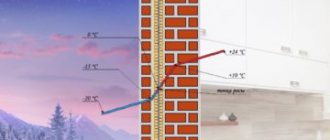

Example: when insulating an attic with mineral wool 200 mm thick (density 190...220 kg/m3), a square meter of such an insulating layer will weigh approximately 40 kg. Adding the mandatory vapor and waterproofing, we get approximately 45 kg/sq.m. In total, for the Moscow region, the load on the rafters for an insulated attic will be 175...285 kg/sq.m., and for Petropavlovsk-Kamchatsky - 495...565 kg/sq.m.

Calculation of the area of the pediment, and why it is needed

Find out how to calculate the gable roof gable, or rather its area, because its height is equal to the distance to which the ridge girder is raised from the base, it will be necessary in order to determine how much material will need to be purchased for its cladding, as well as insulation and lining. For calculations, we use a formula from trigonometry, according to which, to find the area of a triangle, you need to multiply the height by the width and divide the result by “two”.

In our case:

- width is 9 m;

- height – 3.15 m;

- area = (9 * 3.15) / 2 = 14.18 m2.

Sheathing, sheathing, counter-lattice

It is difficult to make accurate calculations here without knowing in advance about the planned work options.

But it’s better to count on the maximum load, so you can take for calculations:

- continuous sheathing made of plywood sheets (thickness of at least 12 mm, weight about 6.5 kg/sq.m.), OSB (same thickness, weight approximately 7.7 kg/sq.m.), gypsum fiber (thickness 12...12.5 mm, weight 12…14 kg/sq.m.);

- obligatory counter-lattice (an option for installing a metal tile roof) made of 50x50 mm timber. Considering that the bars are not packed solidly, but in increments of 300...400 mm, the weight of the counter-lattice per square meter of roof can be taken to be approximately 3...4 kg;

- The interior cladding is often done with clapboard; an option is possible with cladding with sheets of plywood or OSB followed by plaster. In the first case, the weight of the finish will be approximately 6...11 kg/sq.m., in the second - 8...11 kg/sq.m. (taking into account the layer of plaster, the weight of which can be calculated here).

The weight of the fasteners should also be added here - at least half a kilogram per square meter. Result – 16…22 kg/sq.m.

Thus, for the examples already given (Moscow region and Petropavlovsk-Kamchatsky), the load per square meter will already be 195...312 kg/sq.m. and 516…592 kg/sq.m. respectively.

How to determine how much to raise your skate

Having decided on the slope of the pitched planes, you can find out what the height of the roof should be. Anyone who even slightly remembers the school geometry course can cope with this task. We recall that in a right triangle, the length of one leg will always be equal to the length of the other, multiplied by the tangent of the angle formed with the base. From here, if we take the height as one of the legs, then we can calculate it like this:

- select the optimal angle of inclination (for example, 35 degrees);

- calculate the tangent (we get approximately 0.7);

- take half the width of the building (for example, 9 m /2 = 4.5 m);

- As a result, the required leg is 4.5 m * 0.7 = 3.15 m.

Selecting the cross-section of rafters and their material

For the Moscow region, taking into account the already collected load, wooden rafters are applicable. They can be made in the form of a beam or a rounded log; the cross-section clearly correlates with the pitch of the rafters and the length of the rafter leg.

As can be seen from the table, even with a short slope length (up to 3 m) and a small distance between the rafters, a cross-section of at least 80x100 mm is required. The dead weight of such a beam (or a log with a diameter of 100 mm) will be about 8 kg. It is necessary to check how much the dead weight of the rafters will increase the total weight of the roofing pie (and, accordingly, the load on the rafters).

Calculation example 1 (Moscow region)

To do this, we will take the length of the wall to be 6 m, the length of the slope to be 3 m and pre-select a step of 1 m. 7 pieces of rafters weighing 56 kg are required, the total roof area is 18 sq.m. Total for the Moscow region (we take the load to the maximum)

18x312+7x8=5,672 kg (for the entire roof). Remembering the strength of strength formulas, we use the standard method of calculating the load-bearing capacity of a beam (in this case, rafters).

Permissible moment of resistance of a beam with a section bxh=8x10 (height by width)

W = bh2/6=133 cm3

A beam with such a moment can withstand deflection (R in the formula is the modulus of elasticity of wood, for second-grade pine, which is usually used in structures, R = 150 kgf/cm2)

M = WR=133x150=20,615 kg*cm = 206 kg*m

Taking into account a span length of 3 m, the distributed load per linear meter of beam

Q=8M/l2=8x206/32=183 kg/m.

If the pitch of the beams is taken to be 1 m, then the maximum distributed load per square meter is, as already calculated above, a maximum of 312 kg, which is almost twice as high as permissible. Therefore, this pitch and/or rafter section is not suitable.

We carry out a repeated check, choosing a rafter pitch of 600 mm. In this case, the maximum permissible load per linear meter of rafters will be

Q=183/0.6=305 kg/m.

This is much closer to the required load.

But it is more rational not to reduce the pitch of the rafters of a gable roof, but to increase the cross-section of the beam.

If we take the next section in order from the table proposed above (8x13 cm), we get

W = bh2/6=225 cm3

M = WR=225x150=33,800 kg*cm = 338 kg*m

Q=8M/l2=8x338/32=300 kg/m.

By reducing the rafter pitch to 0.9 m, we obtain a permissible distributed load of 300/0.9 = 33 kg/m, which is quite sufficient for the given conditions.

Calculation example 2 (Petropavlovsk-Kamchatsky)

Under the same initial conditions - wall length 6 m, slope three meters, pitch 1 m - the load on the roof is a maximum of 592 kg without taking into account the weight of the rafters. From the calculation example given above, it is clear that for such a load it is necessary to either seriously increase the cross-section of the beam or reduce the pitch. Both options are not rational, since due to the weight of the beams they will increase the load on the load-bearing structures of the building by 12...25%, which is undesirable.

But you can replace the material by adopting metal rafters.

In this case, the sheathing will not be solid (as suggested in the load collection example), but sparse, and also metal. Accordingly, the weight of the structure will decrease by at least 15...30 kg/sq.m., and the load-bearing capacity will increase.

It is more difficult to calculate the load-bearing capacity of an I-beam or channel than a beam with a rectangular cross-section; for this it is necessary to use special formulas.

As an example, the form for calculating an I-beam in the calculation program is given.

We use the calculation formulas from example 1, replacing the calculated moment of resistance with the already known moment for the steel beam. We mean that the modulus of elasticity of steel (both in compression and tension) is 21,000 kgf/cm3.

For I-beam No. 10

W = 39.7 cm3

M = WR=39.7x21,000 =833,700 kg*cm = 8337 kg*m

Q=8M/l2=8x8337/32=7410 kg/m.

The resulting value far exceeds the maximum roof load. Accordingly, the span here can be safely increased to 2m - this will not lead to destruction of the structure.

DIY installation features

Method of laying rafters on the mauerlat

Nests for supporting rafters should always have horizontal platforms and vertical walls. Violation of the rule leads to loss of stability and displacement of load-bearing elements.

Making a truss template:

- Two boards 25 mm thick, 10 cm longer than the rafters, are fastened at the top with a bolt to allow rotation.

- The estimated height of the system is measured on the rail in the center of the tenon.

- The fastened boards are placed on the end gaps so that their edges rest against the notch.

- Combine the attachment point and the marks on the rail to determine the length of the rafter.

- The size of the tooth is marked on the lower edge, the template is lowered to the ground and the tenon is cut out.

- They try on the workpiece on site, inserting the tenons into the designated notches.

If after installation the vertex does not coincide with the mark on the rail, it is corrected by releasing the bolt, and the new position is marked on the rail. Measure the dimensions of crossbars, racks, fillies, tie rods and other elements of the truss truss. After the required products are manufactured, they are placed in the installation position.

conclusions

When calculating the pitch of the rafters of a pitched roof or a more complex structure, you must keep in mind:

- It is better to make calculations “with a margin”, since an increase in the load on the supporting structures is still better than the collapse of the roof as a result of insufficient strength of the rafter system;

- When using heavy roofing materials (ceramic tiles, cement-sand tiles), it is better to immediately take the next rafter section in the memo or reduce the step size to the previous value. In any case, it is necessary to check the correctness of the choice using an estimate;

- When taking insulation under a corrugated sheet or under a metal tile, it is worth remembering the need not only for thermal insulation, but also for protection from noise - otherwise the sound of rain or hail on the roof can nullify all the comfort of living. A slight increase in the load on the rafter system in this case is justified.

Mansard roof rafter system

Most private houses have a usable under-roof space called an attic. This design is characterized by an increased height of the slope, which is caused by the need to create a living space of a comfortable height. As a rule, the slopes of an attic roof are broken, having a varying slope angle. For their installation, a double rafter system is used.

The steepness of the lower slopes of the attic roof significantly exceeds the slope of their upper extensions. The plane load perceived by them is not large. Thanks to this, the rafters in the lower part can be installed with maximum spacing. It is recommended to install the upper ridge slopes with a reduced gap from each other.

Common types of roofing

The most famous types of roofs are:

- single-pitched - rests on two walls located at different height levels, and is constructed specifically for utility facilities and small buildings;

Shed roofing is laid on walls of different heights - gable - consists of two slopes connected at an angle, the area of which may not be the same;

A gable roof usually has two equal slopes - hipped - assembled from four slopes in the shape of an isosceles triangle, as a result of which it resembles a pyramid and is ideal for square houses;

Hip roofing is constructed on square-shaped buildings - hip - created from two trapezoidal and two triangular slopes;

The hip roof consists of four unequal slopes - attic - used to create a room in the attic and is formed by changing the shape of the roof, for example, using broken lines;

The attic roof looks like a complex structure, because an additional floor of the house is created under it - multi-gable - constructed on buildings built in the form of a polygon.

Multi-gable roofing is an interesting combination of roofs of different shapes