Strip foundations are often used in low-rise construction - they are easy to make, and they are universal, suitable for all types of buildings and almost all soils. Let's look at the strip foundation for a house from all sides: what it should be like according to construction science and standards, and how this theory is embodied by the hands of FORUMHOUSE users.

Design features Shallow strip foundation MZLF Fully buried strip foundation Tape: calculation algorithm How to build a strip foundation with your own hands Example: MZLF 11*14 m Example: foundation made of FBS 10x10 To help the strip builder

Design Features

A strip foundation is a closed loop of reinforced concrete beams laid around the perimeter of the building and under the load-bearing walls, and transfers the load of the building to the underlying soil. Both light garden houses and frame houses, as well as heavy monolithic “castles” and stone cottages are built on it: the load-bearing capacity depends on the width and height of the tape. Even twelve-story apartment buildings are built on solid soils on strip foundations. Also, this type of foundation is used for houses with basements and basements - the tape is considered as a basement wall.

Almost all types of soil are suitable for such a design, except for unstable peaty soils - therefore, on weak-bearing and waterlogged lands of the Leningrad region, houses are built on complex and expensive foundations, but in Moscow such structures would be a waste of money.

A strip foundation is usually installed on a bed of medium-fraction sand with vibration compaction every 100 mm. The depth of the structure is calculated taking into account the characteristics of the site:

- presence or absence of basements;

- soil depth;

- weight and other characteristics of the building.

al185MODERATOR FORUMHOUSE

The foundation should be built not according to wishes and fanatically beautiful ideas, but according to calculation. The foundation in individual housing construction is calculated based on the design resistance of the base soil and the load of the object, with mandatory consideration of possible unfavorable factors: hydrogeological, frost heaving forces, heterogeneity of the base, subsidence and swelling soils.

All deformed houses with skewed openings are built on an incorrect foundation, calculated and built without taking into account the characteristics of the soil, groundwater level, weight of the house, etc.

Depending on the design features and depth of installation, there are several types of strip foundations.

By design:

| Type | Design Features |

| Monolithic | One-piece reinforced concrete casting with high strength and maximum load-bearing capacity. It is poured in one go. The reinforcement must be of high quality, of appropriate cross-section - this provides resistance to bending loads. |

| Made | Consists of factory foundation blocks (FBS). It is somewhat inferior to monolithic tape in terms of performance properties; it is often used in low-rise construction. To increase the stability and durability of such strip foundations, a sand cushion is made, specialized FL reinforced concrete soles are placed on it, and FBS is placed on top of them on a cement-sand mortar. This structure can be topped off with an armored belt for strength and even distribution of loads. |

By depth

| Type | On what soils is it used? |

| Non-buried | Only on rocks and completely motionless soils, so it is done extremely rarely and not for houses, but for outbuildings. Such a strip foundation is made only monolithic. |

| Shallow | On strong soils that are not susceptible to frost heaving. They are laid to a depth less than the freezing level of the soil. |

| Fully recessed. | Suitable for almost all soils and hydrogeological conditions, deepened below the calculated freezing depth (but not on hard clays and sandy soils with low groundwater level). Performed in trenches and pits with backfill. |

Such a number of varieties of strip foundations, both monolithic and made of blocks, allows you to make the right choice for the conditions of a particular site and get a good result. The strip foundation has one big drawback (not counting the abundance of excavation work and the time it takes for the concrete to mature after pouring) - it can be expensive, so if we are talking about light buildings, it is better not to choose another option. But still, the strip foundation has obvious advantages, these are:

- long service life;

- high load-bearing capacity;

- the loads of the house are evenly distributed on the soil foundation;

- The construction technology is quite simple.

Pouring directly into the ground, or the so-called “Kuban version” of a strip foundation, is a violation of technology; FORUMHOUSE warns against this.

RNikonovForumHouse Member

I consider the construction of a strip foundation with pouring “into the ground” unacceptable. It is almost impossible to make a tape “in the ground” with high quality.

Preparatory stage

It’s worth starting with pits or drilling. The main goal of this activity is to find out what soils are located on the site, as well as to find out the level of groundwater. The foundation must be laid in compliance with the rule: the mark of the sole must be at least 50 cm above the level of the water horizon.

How to do soil testing correctly? Two methods are used for this:

- excerpts of pits (deep holes, dimensions in plan are usually 1x2 m);

- manual drilling.

In the first case, the soil on the walls of the pit is examined. They also check to see if water has left the bottom. In the second option, the soil on the tool blades is examined.

Once you have determined what kind of soil is on the site, you will need to find its strength indicators. This can be done using special tables.

Table of bearing capacity of different types of soils

The cost of laying the foundation for a house can be up to 30% of the estimate for the entire building. To avoid cost overruns, you need to perform a calculation that will allow you to find the optimal design parameters that will simultaneously guarantee minimum costs, strength and reliability. For your convenience, you can use online payment.

Shallow strip foundation MZLF

According to SP 22.13330.2011 “SNiP 2.02.01-83*. Foundations of buildings and structures,” the type of MZLF depends on the degree of heaving of the soil.

RolandspbFORUMHOUSE Member

There are restrictions on the type of foundation for different types of soil heaving. Loam with different fluidity indicators can be classified into any group according to the degree of heaving; therefore, with more fluid loam, according to the joint venture, it is necessary to make a monolith.

Thus, it is recommended to make MZLF made of monolithic reinforced concrete on heaving soils with a groundwater level no higher than 1 meter from the ground surface.

It is laid above the freezing level, at a depth of 200-500 mm from the surface. With a low manufacturing cost, these foundations are characterized by high reliability; they last 15-20 years without repair.

The only thing: MZLF needs high-quality insulation - both the tape and the blind area - to reduce the impact of frost heaving. According to their design, MZLFs are divided into two types: classic rectangular section and T-shaped.

The MZLF sole with a T-shaped section makes the support area larger and works on bending, and the upper rib receives vertical loads from the structures above.

Heavy stone buildings are built on shallow strip foundations with a sole, while rectangular ones are suitable for frames and wooden buildings.

On slightly heaving and non-heaving soils, you can make a shallow tape of FBS.

Installation of formwork

Formwork is a form for pouring concrete that determines the width and height of the tape. It is built from edged boards; in some cases, reusable special shields are used.

The formwork panels are assembled next to the trench. They should be tight, without cracks or gaps. The finished panels are lowered into the trench, installed in the desired position, aligned along the axes and horizontally and fixed from the inside with crossbars, and from the outside by vertical support bars, reinforced with inclined struts.

The formwork must be strong, capable of reliably withstanding the load from concrete during pouring and hardening.

Fully recessed strip foundation

This type of tape is suitable for any buildings, except frames and houses made of SIP panels - for them its load-bearing capacity is excessive. It is made from FBS, monolithic reinforced concrete, and solid brick.

This type of foundation requires careful calculation - it is necessary to take into account the ground level, geological features (this type of foundation must rest on dense layers of soil with high bearing capacity); if basements are planned, their height is taken into account.

Such foundations are made 150-200 mm below the soil freezing depth. The groundwater level should be no higher than 500 mm from the bottom of the sand cushion, but it can be higher if you make very good waterproofing and drainage. Just like MZLF, a recessed tape can be rectangular and with a sole, but the second option is used in the construction of high-rise buildings; for low-rise construction this may be redundant.

The recessed strip base is made either monolithic or prefabricated from FBS blocks. A monolithic strip foundation is inferior to a block foundation on soft and crumbly soils - masonry joints make the structure flexible enough so that cracks do not form on it.

Melnich23 Member of FORUMHOUSE

A foundation made of FBS significantly speeds up the construction process, all reinforcement and other parameters have long been calculated by the designers, assemble it yourself calmly. With a monolith, only when tying the reinforcement you will curse everything, and there’s also the formwork and pouring!

Waterproofing and backfilling

Once the concrete has completely hardened, you can remove the formwork. To prevent the foundation from starting to collapse due to freezing in winter, it must be waterproofed.

Scheme of waterproofing and backfilling of the foundation

It is imperative to carry out this procedure, although some developers neglect it. One should not exclude groundwater, from which a layer of roofing material can protect. Roofing material needs to be cut into sheets, which not only cover the top of the foundation, but also cover the sides. After the entire foundation is covered with rolled material, it must be coated with liquid bitumen waterproofing.

Next, the foundation must be filled both outside and inside the future building. Cover with any non-heaving soil; you can take previously dug soil from the trench. Heaving soils can tear apart a deep-seated strip foundation, even if it is made in compliance with all technological aspects.

Tape: calculation algorithm

This issue is given great importance at FORUMHOUSE.

al185MODERATOR FORUMHOUSE

I beg you not to prescribe a foundation design based on “people’s experience” and the advice of various advisors who “have always built this way.”

A member of our portal with the nickname MaximGvozdev created the LentaOnline v calculator. 1.0, which will help with the construction of this type of foundation. The tool can calculate the resistance of the foundation soil, the width and length of the designed tape, reinforcement and concrete, concrete composition, and the number of concrete batches in a concrete mixer.

For beginners, the FORUMHOUSE moderator with the nickname al185 recommends first deciding on the soil conditions (soil composition, groundwater level, topography) to design a strip foundation and resort to the following methods:

- Ideally, order a project from an adequate designer who can get good recommendations on FORUMHOUSE.

- You can borrow an already calculated analogue foundation design for similar soil conditions and a similar building.

- Master design for amateurs: an algorithm for designing a strip foundation for dummies.

Next, you need to compare the cost of the options received and choose the appropriate one.

Additional documents

In addition to the design documentation, which is attached to the foundation plan of the structure, a set of the following documents is attached:

- a summary specification indicating the requirements for each element located below the “zero” level;

- development and planning for the installation of prefabricated support elements;

- a diagram showing the reinforcement of the site, taking into account the load effects of the object on the foundation;

- tables indicating the performance indicators of the foundation support pillars;

- information about the placement of slopes.

To ensure a reliable and durable foundation, accurate calculations and qualified specialists are used. Attempts to save money on drawing up a project will definitely lead to the appearance of defects that will entail financial expenses.

How to build a strip foundation with your own hands

To build the ribbon you will need the following materials:

- For formwork: edged board 15-20 mm thick;

- For waterproofing formwork - waterproofing material;

- For the reinforcing frame - corrugated reinforcement with a diameter of 14-20 mm; to twist the reinforcement you will need knitting wire;

- For the pillow - sand and crushed stone;

- For pouring formwork in low-rise construction, concrete grade M200-M300 is used - this is more than enough.

bobik123FORUMHOUSE Member

Read the forum... they want to use the M500 for the fund. Your houses must be registered with the military registration and enlistment office in order to be transferred to bunkers in wartime. And the forum will be renamed “How to build a fortification structure to survive a nuclear strike.”

RemstroygarantFORUMHOUSE Member

I’ve been building country houses for ten years, and I use concrete M200 - M300, and not M150, in the foundations, just so that the customer’s soul is at peace.

You should also take into account that the strip base is poured in one go, so it is recommended to buy ready-made concrete.

These instructions for building a strip foundation with your own hands provide that all soil research work has been completed, all calculations have been made, the optimal type of strip has been selected and its parameters have been calculated, and all this has been done professionally and competently. The construction site is cleared of anything that could interfere with the work . The construction of the tape consists of the following stages:

- Marking;

- Excavation;

- Drainage device;

- Pillow device;

- Placing formwork;

- Reinforcement;

- Pouring concrete mixture.

The construction of the tape begins with markings - the straightness of the foundation and its technical and operational properties depend on how correctly it is done.

How to markup:

- Remove the top layer of soil by 20-20 cm over the entire area of the future house;

- Mark the contours of the tape using wooden pegs and cords.

- Drive in stakes with a slight indentation from the axes of the walls;

- Pull the cords, check the difference in diagonals - the permissible maximum deviation is 20 mm.

The trench can be dug manually: equipment is used to prepare wide trenches. The bottom of the trench is leveled and a drainage system is made with a general slope of 3-4° away from the house. Its structure is clear from the diagram below.

EvanFORUMHOUSE Member

The deviation from the protrusion of the foundation to the axis of the drain is equal to half the width of the fractional filter (usually a two-layer) drainage pipe + the excess of the base of the foundation above the bottom of the drainage trench, divided by the tangent of the angle of internal friction of the soil. Typically from 1.6 to 2.8 m.

Drainage pipes are laid in recesses filled with crushed stone (with compaction), the bottom of which is covered with geotextiles, and are filled with crushed stone to the level of the beginning of the tape.

Drainage is not a necessary step, especially if the house does not have a basement, and many instructions for making a strip foundation with your own hands skip it.

gmu9765 FORUMHOUSE Member

In a humid environment, concrete only gains strength over time, sometimes even higher than that specified by the project.

The next stage is creating a pillow. For a pillow, you can only use coarse or medium sand; fine sand inevitably shrinks. At least 150-200 mm of sand is poured onto the bottom of the trench, wetted with water and compacted, and the same amount of gravel or crushed stone of a fraction of 20-40 mm, the stones are compacted layer by layer.

Experienced FORUMHOUSE Member

Crushed stone compacted into sand reduces the flow of capillary moisture into the foundation body.

In practice, many people make a pillow only from sand, saving on crushed stone.

al185MODERATOR FORUMHOUSE

P/e film placed in the formwork and left on the concrete makes the difference forever.

Next, the formwork is placed:

- non-removable, for MZLF, made from sheets of polystyrene foam;

- removable, for all types of tape, assembled from edged boards.

So that the concrete does not dry out, but gains hardness, and the cement laitance does not leak out of the structure, the wooden formwork is covered from the inside with either waterproofing, or, if the waterproofing will be done after concreting, with ordinary polyethylene film.

Reinforcing frames are installed in the prepared formwork, which are made from corrugated reinforcement.

- The cross-section of the longitudinal rods should be 14-20 mm;

- The cross-section of the transverse rods is 8-12 mm.

- The wider the tape, the more rows of longitudinal reinforcement there should be. Between the formwork and the reinforcing frame on all four sides, gaps must be left for a concrete layer that will protect the reinforcement from corrosion.

- Welding of reinforcement is not allowed, it negatively affects the strength of the rods, so only knitting wire.

The last stage is filling the tape.

The strip foundation is poured in one step; in extreme cases, breaks of 1-2 hours are allowed. What subtleties should you pay attention to:

- For high-quality pouring, it is important not to distribute the entire volume of concrete from one place, but to supply it to several different places so that the properties of the concrete do not deteriorate during distillation.

- The horizontal plane of the foundation must be below the sides of the formwork.

- The maximum height of concrete discharge should not exceed 2 m.

- After pouring, the concrete must be compacted with an internal vibrator. This is a mandatory stage and cannot be neglected.

After pouring, the concrete should be covered with a film to prevent unnecessary evaporation of moisture, and the foundation itself will have to be moistened regularly throughout the week. They begin to water the tape 8-12 hours after pouring, in hot weather - every 2-3 hours, in cool and cloudy weather every 4-5 hours. The foundation is not watered if the outside temperature is below +5 degrees.

The concrete must harden correctly, then the structure will not crack and will be strong. It will take a long time to gain hardness, but it will be possible to continue working with the tape within a week: there is a rule of seven days and twenty degrees that concrete needs for this.

Either coating waterproofing is applied to the finished tape, or it is covered with a special GI pasting. It is important to treat all surfaces, both vertical and horizontal, to avoid capillary suction of moisture from wall materials.

The last stage of work is backfilling. Here, too, careful compaction is required. Then a blind area is made around the entire perimeter of the house.

How to make and pour concrete mixture

To prepare concrete you will need several components in the following proportions:

- Cement – 1 part;

- Sand – 3 parts;

- Crushed stone or gravel - 2 parts;

- Water – 1 part.

Interesting: if you do not want to prepare concrete yourself, then you can order it ready-made. To do this, you need to understand that M500 cement produces a B150 concrete mixture. This concrete is ideal for the construction of a strip foundation, which is located below the freezing level of the ground. If there is a large volume of pouring work, it is necessary to do the pouring in parts, in which the formwork is divided into sections located vertically and poured separately. It is this filling option that will help the base not to collapse over time. If you fill the base with horizontal stripes, then very soon it will begin to delaminate.

The process of pouring a deep foundation

They start pouring from the corners, and then continue along the walls. Then the concrete is compacted; this must be done very carefully, since air cavities may form in the concrete, which must be eliminated. They weaken the concrete base. As soon as the concrete is poured, it must be carefully leveled with a spatula until cement laitance appears on the surface.

To prevent moisture from leaving the surface of the base too quickly, you need to cover it with cellophane or roofing felt. Some experts advise putting down burlap, which is wetted once a day.

The concrete base is left to dry for about a month, sometimes more time is needed. Until complete drying, no further construction work can be carried out.

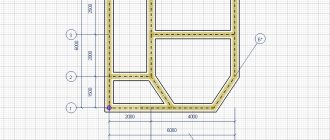

Example: MZLF 11*14 m

When building a foundation, future homeowners use different materials and offer their own solutions. Let's look at a few examples of tapes made by members of our portal. The work of our user with the nickname Alexey_$ received good reviews.

Alexey_$ FORUMHOUSE user

The height was 90 cm, they were buried 60 cm, of which in the end there was 30 cm of sand cushion and 30 cm of tape underground. The width varies and is indicated in the foundation design.

The trench was dug with a tractor according to markings made with white spray paint directly on the grass. While digging, Alexey “shot the level so as not to over-dig or under-dig.”

Small errors were eliminated with a shovel. High-density waterproofing material was laid in the trench.

The foundation design provided for a 30 cm sand cushion; pouring and compaction with a vibrating plate was done every 10 cm.

Alexey_$FORUMHOUSE Member

After all the manipulations, the error in level was within a centimeter over the entire area.

Ruberoid was laid out on the pillow in two layers

and set up the formwork: longitudinal boards 150x40 mm, every 60 cm - 100*50 mm. The inside of the formwork was lined with polyethylene and reinforced with 8-diameter studs.

12 mm reinforcement was knitted in 2-4 rows depending on the thickness of the tape (400 - 650 mm). The protective layer on the bottom was 5 cm, on the other sides 3-4 cm. Every 40 cm there were vertical jumpers with 8 mm reinforcement.

Alexey_$FORUMHOUSE Member

Spliced at least 50 cm, mating, where necessary, was carried out in a run.

Pouring concrete:

The foundation was covered with polyethylene. A little more than a week passed, the inside of the formwork was dismantled and waterproofing was done.

Backfilling: 10 cm of sand along the tape, the rest is sulinka - 5 cm below the level of the upper edge of the tape.

To reduce heat loss into the ground, the voids were insulated with EPS. This is part of the complex insulation of the sub-foundation space: voids + tape outside + blind area.

Alexey_$FORUMHOUSE Member

The house will have to spend the winter without heating for a couple of years and the influence of frost heaving forces will be reduced.

Fill

Filling is carried out simultaneously, without interruptions. If the time gap is more than a day, you have to interrupt the process and wait for the material to completely harden, which will stop work for a month.

Concrete must be poured from several points to obtain an even distribution of the material along the entire length of the tape. This will help equalize the loads occurring on the tape mass during crystallization.

Additionally, water is irrigated during the first 10 days to equalize the stresses that arise between the wet internal areas and the drier external ones. The formwork is removed after 10 days, and continuation of work is allowed 28 days after pouring the concrete.

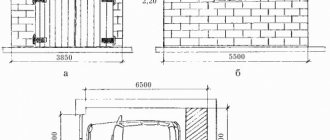

Example: foundation made of FBS 10x10

For his house, a user of our portal with the nickname Zheka888 built a foundation from gas silicate blocks - a strip of FBS. The soil in his area is heaving, the freezing depth is 1-1.2 meters.

Scheme of work:

- We dug a pit 1 meter deep;

- We made a tape without a sand cushion using six bars of reinforcement No. 14. The structure is built on dense continental soil. Width 500mm, height 400mm. The sole is not rated - Zheka was criticized for this on the forum;

- We installed three rows of FBS 400mm wide (height 1800mm);

- Two layers of waterproofing were applied on the outside;

- Covered with 20 mm EPPS;

- The sinuses were filled with clay. Additionally, they compacted it with a bulldozer;

- We made an armored belt with a height of 200-250mm using four bars of reinforcement No. 16;

- We poured a lintel over the basement gate, length 2800mm;

- Covered with floor slabs.

FBS is inferior to a monolithic strip foundation due to the large number of seams, they are also cold bridges. According to the well-known saying, “water will find a hole” - you need to take a particularly responsible approach to the issue of waterproofing.

And here is a foundation similar in design, made by FORUMHOUSE user with the nickname MartynovD: reinforced sole 500x500 - three rows of FBS - armored belt 400x300-PB-74. The slab above the door lies on an armored belt, reinforced in two layers of three D12 rods, B20 concrete.

MartynovD FORUMHOUSE user

When I was building it, a lot of different people walked by. And everyone said: “Where is such a margin of safety on the sole, on the armored belt, etc.” But I did it in accordance with the project.

Correct height above ground

The section of the tape that rises above the ground level is called the plinth.

It is necessary to solve several problems:

- Raising the floor level of the first floor. The height of the plinth determines the installation plane of the ceiling, which most owners want to raise above the ground.

- Protection of wall material from contact with snow masses in winter. If the snowdrifts come into contact with the walls, the materials may become wet and saturated with water, which contributes to the destruction of the house’s structures.

- Giving the house solidity and respectability. A high base makes the house more attractive and increases its size.

Usually the height of the base is made at least (minimum value) 40 cm and above.

To help the tape builder

Anyone can build a strip foundation for a house, provided all calculations are completed and all work is carried out responsibly. Our users, without much construction experience, made their monolithic strip foundations and structures from FBS, literally following the technology and strictly observing SNiPs. The materials on our portal will help you achieve a successful result.

On FORUMHOUSE you can get all the necessary theory, documents, constructs, reports, find step-by-step instructions for making a strip foundation with your own hands, study the strip design algorithm, read articles with arguments against carrying out geotechnical surveys and finally decide for yourself the main question: is it true? you need a sand cushion under the tape.

Our video talks about how to independently build a reliable foundation on problematic soils.

Subscribe to our Telegram channelExclusive posts every week

Pile

It consists of one or more piles united at the top by a special slab. Concrete is used for its production. Additionally, it can be strengthened with iron reinforcement.

This type of foundation is used for building houses on any soft soils, with the exception of rocky soils. Suitable for all regions, for the construction of country houses and multi-storey buildings. This design allows the base to withstand heavy loads.

A pile foundation is made of wooden piles, reinforced concrete, metal or a combination of concrete and metal piles.

According to the type of production, piles are divided into:

- pressable;

- printed;

- driving;

- screw.

Advantages of a pile foundation:

- simple and quick construction, even on a small plot and at any time of the year;

- versatility;

- possibility of use on difficult terrain;

- high strength;

- small amount of excavation work.

Disadvantages: high cost of construction, use of expensive special equipment.

Video description

To see all the work involved in preparing the site and pouring the foundation, watch the video:

Formwork

Before pouring the foundation for the house, it is necessary to form a strong, reliable formwork. To form removable formwork you can use:

- wood;

- metal;

- plywood;

- plastic.

Permanent formwork becomes part of the structure and avoids the dismantling stage. To form it use:

- expanded polystyrene;

- wood boards;

- fiberboard

Permanent formwork block for strip foundation Source ofacade.ru

What to do next

After concreting the foundation, you need to dry it by covering it with insulating material. The strip base gains strength in 26–28 days (at low temperatures, the period can increase to 4 weeks).

Removing formwork

It is recommended to dismantle the structure after the concrete has reached grade strength. Dismantling the formwork should begin from top to bottom, from the protruding parts of the foundation and corners.

Removal of formwork is done from protruding parts of the foundation.

The process goes like this:

- First, unscrew the bolts and remove the top ties.

- The lower ones are released.

- Separate the shields from the racks.

- The supports are removed.

- Remove the formwork boards.

It is undesirable to abruptly tear off all structural elements, because in this case, chips and cracks may appear in the concrete.

Insulation and waterproofing

Protection of the foundation from the effects of groundwater is carried out before pouring concrete or simultaneously with it.

For waterproofing the base, the following materials are used:

- Bitumen-polymer emulsion.

- Liquid rubber.

- Rolled pasting materials – fiberglass, fiberglass, polyester.

Roll materials are used for waterproofing.

Experienced builders do not recommend using parchment, roofing felt, roofing felt, etc. for waterproofing the base.

It is best to insulate the foundation at the stage of its construction.

The work can be divided into 4 stages:

- Preparation and cleaning of the base.

- Laying waterproofing materials.

- Insulation with polyurethane foam, foam boards or backfill method.

- Finishing.

Other popular insulation materials include expanded clay, mineral wool, penoplex and slag.

To insulate the base with bulk materials, it is necessary to dry the soil and remove dirt and sand from the surface. Slag, gravel or sand are used as backfill.