The ventilation duct is usually removed to shorten it to a minimum

Every building has ventilation ducts. They are necessary for distributing air flows and removing unpleasant odors from rooms. When performing any actions with the ventilation duct in the kitchen (remodeling, dismantling), you need to take into account that the intensity of air flows in the building should not be disturbed and such actions may not always be legal. As an alternative, you can use the ventilation duct to your advantage and use it as decoration or hide it under furniture and decoration.

Easy way to calculate

In theory, the dimensions of the supply ventilation window in a kitchen in a private house for calculations are taken to be 70% smaller than the cross-section of the exhaust pipe.

In practical work, adjustable gate valves are installed for air flow, with the ability to change the flow area from 70% of the calculated value to 150%. In this way, you can effectively and accurately regulate ventilation performance and the level of gas exchange in the kitchen, without using noisy electric exhaust systems. In a situation where the room is divided into several sectors or levels, the ventilation system in a private house in the kitchen is calculated based on building regulations No. 60.13330.2012, 62.13330.2012, 7.13130.2011. But there is one problem. The longer the air duct pipes, the more difficult it is to take into account the influence of turns, elbows, splitters, valves, filters on the resistance of the air ducts and the loss of flow energy.

Therefore, the design of a kitchen ventilation system for two- to three-story private houses is traditionally calculated in several stages. Initially, calculations are performed using air flows under ideal conditions, without taking into account friction. In the second pass, the air speed values are checked, taking into account losses in elbows and turns, joints and branching of pipes. Speed reduction coefficients have long been calculated and tested experimentally; their values can be taken from reference tables in SNiPs.

The work is not difficult, but requires accuracy. If you don’t want to bother with calculations, you can use pipes that are obviously larger than 10-15% of the cross-section accepted for a standard kitchen. A small reserve of throughput will allow you to reduce the flow speed to 0.8-1.0 m/s, which will make the operation of the ventilation system less noisy, but more cumbersome.

You cannot arbitrarily choose the cross-section of pipes used in the kitchen ventilation layout; there are limitations here. In pipes of small diameter, usually 90-110 mm, at a speed of more than 2 m/s, the air flow begins to hum at joints and turns, especially in windy or frosty weather. For the kitchen, this limitation is especially relevant, since hot air is removed from the room. As it moves through metal air ducts, the flow quickly cools and loses its energy of movement before it rises to the roof and is thrown out through the vent pipe.

Making air ducts with a large cross-section, especially if one central exhaust pipe is used, is also dangerous. The slow and at the same time massive air flow after turning off the hood can easily tip over and return to the ventilation system of a private house. Even if there is a check valve in the kitchen, kitchen fumes and odors easily flow through the air ducts into the bedroom and living room.

Ventilation system design

A project for private housing construction or an apartment building without organizing a natural ventilation system will not be accepted by the relevant organizations.

To remove accumulated moisture, heat flow, and unpleasant odors, ventilation exhaust ducts are planned.

The flow of fresh air is carried out naturally, or through organized channels near the window.

Carrying out measurements and calculations

As you can see, it is quite difficult to take into account all the factors and make an accurate calculation. But you need to try not to regret purchasing a device that cannot cope with the tasks assigned to it.

There are criteria developed by manufacturers:

- A device with a capacity of 200 to 300 cubic meters. m/hour is suitable for those who cook little or have a small kitchen. That is, 1-2 burners are constantly used.

- Hood with a capacity of 300 to 400 cubic meters. m/hour is recommended for families of 3-4 people, or for a medium-sized kitchen, as well as where 2-3 burners are used daily.

- A device with a capacity of 500-600 cubic meters. m/hour will clean the air in a large kitchen and cover the needs of a large family. Such a hood will be indispensable if the stove is actively used every day and all burners are turned on (there may be 5-6 of them).

For approximate indicators, you can use special tables or data from manufacturers.

To quickly calculate productivity, two values are used: kitchen area and ceiling height. These approximate data can be multiplied by the slab coefficient

If the kitchen has non-standard dimensions or its area does not exceed 40 cubic meters. m, then calculate this value for a specific room by simply multiplying the length of the kitchen by its width and the height of the ceilings. The result must be multiplied by 10 or 12

The numbers 10 or 12 are constant coefficients based on sanitary standards. They mean that the air must be cleaned every 5 minutes, that is, 10-12 times per hour. Therefore, productivity exceeds the volume of the kitchen by at least 10-12 times.

Sometimes this coefficient increases due to the frequency of switching on and the characteristics of the stove used. For example, for a gas stove with large burners that are turned on every day, this number can reach 20. For an electric stove, you can take a factor of 15.

If the stove is non-standard and is cooked daily, then to calculate productivity it is worth using additional coefficients for the number of floors, for the stove, for smokers. But you should not purchase a device with a large power reserve

For example, the length and width of the kitchen are 2 and 3 m, respectively, and the ceiling height is 2.5 m.

Therefore, the estimated productivity will be: 2 * 3 * 2.5 * 10 = 150 cubic meters. m/hour.

This figure can be multiplied by the number of storeys factor of 1.3. It meets sanitary standards.

If someone smokes in the kitchen, then another 15% is added to productivity for each smoker of the total number.

The data obtained is correct for enclosed spaces. If the kitchen is not closed by a door, but is separated from other rooms by a passage, then another 30% of the received power should be added.

On our website we have detailed instructions for calculating a kitchen hood.

The next indicator is the height of the cook

It is very important that the hood does not touch your head and does not interfere with reaching distant burners or placing large pots

Therefore, before purchasing and installing, take measurements and simulate the process of working behind the stove. To avoid mistakes when taking measurements, remember that an inclined hood should be measured from the lowest point to the burners.

All straight hoods (dome or built-in) should be measured from the filters to the slab surface.

Experts recommend choosing inclined hoods for electronic, halogen and induction cookers. They do not require much space and do an excellent job of purifying the air.

You should also take into account the length of the hood. Determine how far it will protrude above the hob, how convenient it will be to cook and replace charcoal and grease filters, as well as wash the stove and reach distant burners.

All described factors affecting the distance must be consistent. Otherwise, there is a risk that the hood will not cope with its tasks. Even the most powerful device installed too high will not cope with all the impurities in the air. Or soot that has settled on the bottom of a hood that is installed too low may ignite.

A competent choice of installation height will extend the life of the hood and allow the device to work at full capacity with minimal costs. In the worst case, the device may not cope with its functions or simply burn out.

Advantages and disadvantages of box demolition

Advantages

There are a huge number of benefits available when removing a vent box. The working area in the kitchen is significantly increased. After demolishing the box, a niche is formed in its place, where you can install a variety of large-sized equipment, or fill this space with various shelves for all kinds of kitchen utensils. After demolition takes place, the resulting space may be used as part of the kitchen interior.

But with all the above advantages, there are also a number of different disadvantages.

Disadvantages when demolishing a ventilation duct

The neighbors who live below you will constantly complain that they have poor air flow. If the redevelopment was not approved by the Housing Inspectorate, and it was discovered during the inspection, everything will have to be returned to its original form. Also, if the demolition work on the ventilation duct was carried out in violation of certain rules, it will also certainly have to be restored.

Why does the check valve sometimes not work and close?

On the kitchen side, a check valve is mounted on the tee. In the factory version it will be quite long. In this case, it is better to shorten it so that this “gun” does not stick out too much.

The valve is inserted inside a section of a standard air duct d-125mm, and this air duct is put on and siliconized onto the tee.

If this whole structure seems too cumbersome to you, and the protruding pipe with the valve is not very aesthetically pleasing, you can do it a little differently. You make the air duct not with a round pipe, but with rectangular channels.

In this case, you install the above check valve on a straight section, as close as possible to the turn.

You can't achieve a factory connection here, so you'll have to farm collectively. Buy a rectangular tee with a round outlet on one side. Next, this round timber is cut off and a check valve is glued in its place.

The valve is placed strictly at an angle (2 degrees). Otherwise, it will open every once in a while or not open at all.

Many people have encountered this problem and easily solved it this way.

The damper itself is also mounted with a vertical deviation. The upper turning point, based on the hour dial, is at 13.00 (1 o'clock), and the lower one is at 17.00 (5 o'clock). This is if your flow direction is from right to left.

Otherwise, the circle is placed at the 11 o'clock - 7 o'clock position.

For more reliable operation and stable opening of the damper, you can stick some kind of weighting material (no more than 2 grams) on one side. Glue it close to the edge.

By the way, do not throw away the previously cut round pipe. It is tightly inserted onto the valve from above, after which a decorative grille diffuser is mounted on it.

What nuances might there be with this method? If your hood stands exactly above the entrance to the ventilation shaft, and the duct pipe goes straight, without any turns in the horizontal plane, then the valve installed on such a straight section does not work normally, at least at 1st speed.

You will simply have nowhere to get the increased pressure to close it. The air will fly through this “turn” in a straight line. You definitely need an angle.

The valve cover and its rotating mechanisms are easy to clean and do not be afraid of them becoming overgrown with grease. For this to happen, you will have to fry huge wild boars on the stove and stew them in your oven for several hours a day, no less.

If you don’t want to see a protruding “hollow” under the ceiling at all, then, as an option, you can install a tee so that the middle elbow rests against the wall, otherwise, where the valve is located, it would look to the side. In this case, also close the hole with a decorative cover.

Everything will look much nicer. However, due to the additional rotation, the performance of natural ventilation will deteriorate slightly. And the grill will reduce it by another twenty percent.

In addition, it will no longer be possible to clean the channel by hand or with a vacuum cleaner. But many do this deliberately and even hide the entire structure in a wooden or plastic box.

As they say, beauty requires sacrifice.

How to obtain a demolition permit

Illegal redevelopment and unauthorized dismantling of the ventilation duct create problems when selling real estate. Not a single realtor will undertake to sell an apartment if he discovers that its layout does not comply with the technical passport. All changes in the linear dimensions of the premises must be agreed upon by the housing inspectorate and included in the documents confirming ownership rights. An approval procedure exists and usually concerns the following problems of refurbishment of apartments:

- Changes in installation locations of plumbing equipment, transfer of heating system lines and radiators to another location;

- Dismantling of partitions and walls that do not support a payload;

- Displacement of doorways, heating devices and engineering structures;

- Installation of a separate entrance for apartments on the first floors.

Usually the housing inspection requires a simple sketch, but in order to remove the ventilation duct, you will have to submit a redevelopment project developed by a licensed organization. You will also need:

- An expert opinion with calculations confirming that the living conditions of other residents of the house will not be disturbed by the redevelopment;

- A house plan drawn up after a survey, indicating the composition of the owners' common property. The technical passport is compiled by BTI engineers. They come with measuring tools and draw up a floor plan of the apartment. It should realistically reflect the size of each protrusion;

- A copy of the decision of the meeting of co-owners of the house on the transfer of property (in this case, the box), which will be used for redevelopment;

- A copy of the agreement on such transfer, if the decision to conclude such a transfer was made by the general meeting.

Your application, along with a package of specified documents, is submitted to the MFC and after 1.5 months you will receive a response. In Moscow, the answer will be negative, since changing the configuration of the mine is prohibited by Appendix 1 of Moscow Government Decree No. 508-PP. Kitchen ductwork remodeling can end in disaster. You will have to make the ventilation duct again, and even incur significant material costs.

Which one is best to choose?

There are many brands of kitchen hoods on the market - Hansa, Krona, Hephaestus, Elikor and many others. Existing models differ in design, size, operating principle, and installation method. When deciding which hood is best suited for a particular kitchen, we are usually guided by the following criteria:

- type of exhaust system - recirculation, flow (direct-flow) or combined (can operate in both recirculation and direct-flow system modes);

- its appearance, how much it fits into the overall design of the kitchen set;

- the material from which the equipment is made - it affects both the appearance of the device and its durability;

- such technical characteristics as the power of the equipment and the noise level it produces during operation;

- dimensions - it is strongly recommended that the dimensions of the system neck do not exceed the dimensions of the surface of the slab, and in addition, the air ducts must fit into the existing ventilation openings;

- installation method, on which the installation of the hood significantly depends - there are wall-hung, built-in, corner, telescopic, island models, which are attached in different ways.

How to decorate a ventilation duct

instead of a duct there is a stone column.

What to do with a ventilation duct in the kitchen? Decorate.

We offer two ways to hide the ventilation pipe in the kitchen.

Option #1

Cover the ventilation duct in the kitchen with hanging shelves or decorative elements. Inventive owners use the ventilation shaft in the kitchen as a stand for a flat-screen TV or paintings.

The presence of a ventilation shaft makes it difficult for many owners to play around with the kitchen design. How to arrange the furniture?

Some experts recommend installing a bar counter or folding tabletop near the box. The picture is complemented by a bar stool.

An inconvenient vent pipe in the kitchen can be hidden as a base for worktops or wall cabinets.

Option No. 2

The same box is hidden behind an elegant shelf.

To properly close the ventilation box in the kitchen, hide it behind a floor cabinet with shallow open shelves. It will fit perfectly into an L-shaped kitchen set or installed along one of the walls.

Build a ventilation duct into the furniture. Designers often resort to this trick.

There are many ways to use a ventilation duct in the kitchen or make it invisible.

For example:

- Install a decorative fireplace at the bottom;

- Reinvent the ventilation shaft in the kitchen as a Roman column;

- Cover with mirrors;

- Cover with mosaic;

- Cover with tiles that imitate concrete or brickwork.

Hiding the ventilation pipe is as simple as tiling it with the same tiles as the kitchen backsplash. Decorate the lower part of the column in the style of kitchen furniture.

Standards and requirements for kitchen exhaust systems and installation

Exhaust systems, like any other equipment, are subject to installation requirements and technical characteristics:

- Match the size of the exhaust system and the gas stove underneath for maximum efficiency in removing odors.

- The hood must be installed no less than 50-60 cm from the stove. This is done for ease of use. In addition, if the hood is lowered too low, there is a high probability that the fat accumulated on it will ignite.

- The capacity of the hood should replace air at least 10 times per hour. To calculate how much volume the exhaust system should process, you need to take into account the area and height of the ceilings in the kitchen. Calculate using the formula: V = S * h * 10 * 1.3, where S and h are the area and height of the room, respectively, 12 is the minimum air treatment rate in 60 minutes, 1.3 is the correction factor.

- If there is no veterinary duct in the kitchen, then it is better to install the hood with the ability to adjust the performance and recirculation. If you connect a flow hood to natural ventilation, this will lead to disruption of the latter. Also, you should not turn on such devices for a long time.

- Craftsmen must strictly follow the instructions in the equipment passport.

- The hood is leveled.

- Turns at an obtuse angle are not allowed; any turns should be as few as possible.

- If the length of the route exceeds 300 cm, then a second exhaust fan is required.

- There is no need to choose equipment with high power, it makes a lot of noise, and it is not intended for residential premises.

Different ceiling levels and a sleeve as an element of style

Arranging a ceiling in the form of several levels is another way to aesthetically design a hood hose.

The second-level design will help not only hide the sleeve, but also securely secure it in the area between the ventilation and the hood.

The main thing is to place the sleeve so that it does not deform. This method of masking is ideal in cases where:

- the owners have started renovations and plan to radically redo the ceiling;

- an apartment in a new building is being prepared;

- A very old building is being reconstructed;

- the ceiling height is very high, and there is a desire to reduce it by making a two-level structure;

- The usable area of the room is large enough or when decorating the interior of a studio apartment.

Expert advice

Tips from experts on equipment selection and installation:

If you choose a strong and durable hood, take a closer look at models made of stainless steel and aluminum. If you choose a fan with high power and too much air flow, this may lead to blockage of the air duct. This will cause all the smell and smoke to spread to other rooms. Ventilation ducts and air ducts should be cleaned periodically. Please consider this before choosing. If the kitchen is more than 15 square meters, install two ventilation ducts

One will serve to fill with fresh air, and the second will serve for exhaust. It is important to consider that the decorative grille and valve sometimes reduce the speed of air movement by 10 times. In this regard, do not opt for a device with minimal power. When choosing a hood, take into account the volume of air that needs to be purified within an hour

We take the volume of the kitchen, multiplying the area by the height, multiplying by the air exchange rate (12) and multiplying by 1.3 (minimum reserve coefficient). This way you will get the performance of the hood. When determining the dimensions of the hood, take into account that the area of the air intake should correspond to the area of the working surface of the stove, or better yet, exceed it. How to take into account a comfortable noise level? 20 decibels is like the rustling of pages, 25-35 is about like a loud whisper, 50 dB is the noise level like during a normal conversation, 89-90 is like the noise of a passing motorcycle or a hair dryer when drying, 110 is like how it works drill or hammer drill, 130 dB is already exceeding the pain limit. When choosing a hood, the question may arise: do you need lighting? They are automatic, touch-activated or with a button. Experts believe that the presence or absence of lighting does not in any way affect the main tasks of the hood, so when choosing, be guided solely by your budget and your own taste. Focus on how the hood design will fit with the interior design.

The principle of filtration at the hood without venting into ventilation ducts

The stove in the kitchen can be mounted at such a distance from the ventilation opening that it is inconvenient to connect outlets to it. You can solve the problem by using a kitchen hood without venting to the ventilation.

The operation of such an installation is based on the filtration of dirty exhaust air. After this, it can be reused without harm to health.

The main design detail is the filters. They are used to clean the air from fat, moisture accumulation, and reduce the concentration of unpleasant odors.

There are two types of filters:

- Grilles made of plastic or metal clean the incoming air flow from grease, oil, dust, and moisture. These coarse filters are used repeatedly.

- Carbon filters with adsorbing properties purify the air more thoroughly. They work more efficiently if they are changed frequently (at least once a month). If this is not done, the air flow will be reduced.

The clean air flow is drawn from the recirculation hood by a powerful fan, which is equipped with the kitchen unit.

Manufacturers produce flat, built-in, suspended and inclined hoods for kitchens without ventilation according to their design. The built-in model is chosen for a kitchen with an original design. I like the hanging ones for their small dimensions. The inclined model is considered more effective.

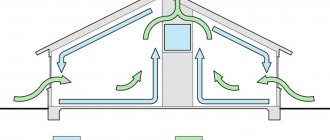

Features of forced ventilation

Scheme of supply and exhaust ventilation.

With the increasing complexity of the modern layout of interior spaces in a private house and the emergence of insufficiently ventilated areas for this reason, it turned out that natural ventilation does not always cope with its main functional task. There was a need for forced supply and exhaust ventilation.

The simplest and most common method of such ventilation is the well-known household electric hood, with the help of which contaminated and humid air is removed from the kitchen to the outside. In addition to exhaust-type appliances, there are also filter hoods that do not exhaust the air flow outside, but pass it through built-in filters and return the purified air back into the kitchen.

The hood is usually located directly above a gas or electric stove. When installing it, you should follow the manufacturer's instructions, however, there are installation rules that are common to all such devices. In particular, there should be a distance of 60-80 cm between the hood and the gas burner, and 50-70 cm between the hood and the electric stove. An exhaust device located above these levels will be ineffective.

Another, more complex, option for forced flow-exhaust ventilation is an exhaust system that includes a special box with a fan. When using it, the ventilation of the kitchen space will become part of the ventilation system of the entire house. It involves not only the removal of air flow outside, but also the flow of air from the street. To purify the atmospheric air, filters are included in the system, and special air heaters are used for heating.

It should be noted that such a system also has its pros and cons. The disadvantages include both its relative high cost and certain installation difficulties, which can mainly be handled by specialist installers.

https://youtube.com/watch?v=w9KQZIVzlvs

But, on the other hand, this system is more reliable in operation; it can be used to create a balanced air flow to certain zones and with certain temperature parameters, which is especially valuable for the kitchen.

Circulation hood

The circulation system does not require an air duct. Polluted air undergoes thorough filtration using carbon and grease removal complexes and is returned back with a purified composition. The demand for circulation hoods in kitchen design is determined by a number of competitive advantages:

- When installing a circulation air exchange system, there is no need to think about how best to hide the pipe from the hood in the kitchen. The device operates autonomously, the functionality is not connected to the ventilation shaft of the building and does not provide an air duct;

- The hob can be installed anywhere in the kitchen due to the independent operation of the circulation hood.

The disadvantages of using a circulation device include:

- the equipment is sold in the expensive segment;

- periodic replacement of filters is necessary, which implies additional costs;

- relative difficulty of care and maintenance.

Hidden circulation hood

At the same time, due to its ergonomics, the design fits harmoniously into the interior, eliminating problems with the violation of the aesthetics of the kitchen space.

Preparatory work for installing a kitchen hood through the wall

Connecting the hood to an outlet through the wall is an option for private houses or apartments where ventilation is not provided for by the design or is in poor condition. In such cases, for the normal functioning of the exhaust unit, the outlet is made directly to the street, punching a through hole in the wall, providing a channel of minimum length. For the air duct, it is recommended to choose a round pipe.

To prevent the external channel from freezing and leaking, a check valve is installed in the hole inside the wall.

At the preparation stage, the exact installation location of the unit is determined and materials are purchased: a galvanized pipe with a canopy for arranging external ventilation, a corrugated aluminum pipe for the air duct, clamps and a check valve. You will also need hardware.

When preparing the room:

- remove kitchen utensils, textiles and decorative items;

- cover furniture and equipment;

- cover the floor in the installation area with thick fabric;

- clear the wall where the unit will be installed.

Equipment location and dimensions

The location for installing the air purifier is selected taking into account the location of the exhaust unit and the area of the kitchen.

According to the location of installation, exhaust units are divided into:

- Island - above the stove located in the center of the room.

- Wall-mounted. The dome is attached to the wall on one side, and the opposite side is located above the slab.

- Corner ones are installed above the hob in the corner of the room.

The shape of the hoods is flat, inclined and dome. The size of the suction surface should not be smaller than the area of the hob, otherwise the hood will be ineffective.

According to the rules of SNiP, the socket for powering the hood is installed above the wall cabinet, inside it or in the casing of the device at a height of 1900-2200 mm from the floor.

Selection of materials for the exhaust duct

When choosing a check valve and an outer pipe for the air duct, they are guided by the thickness of the wall and the material from which it is built. The best option is a galvanized round pipe with a canopy. Any moisture-resistant material is suitable as insulation for such a pipe. Most often, penofol with a thickness of 100 mm is used.

The check valve for the hood is made of:

- PVC;

- polypropylene;

- polyurethane;

- vinylurethane;

- plastic;

- polyethylene.

The most durable valves are made of polyethylene and reinforced vinyl urethane. The latter is almost impossible to damage.

Creating and preparing a ventilation hole in the wall

The hole for the air duct in the wall should be located at a distance of 200-300 mm from the ceiling on the outer wall as close as possible to the slab. Ideally, directly above the hob.

Before starting work, empty the kitchen of decorative items, utensils, small accessories, and cover furniture and appliances with film or cloth. The location of the hole is measured on the wall and markings are made for the air duct.

A through hole in the wall and installation of a ventilation duct are done in several stages:

- Drill a hole in the wall to install the frame.

- Hammer a dowel into the hole and screw in a pin to secure the frame.

- Attach the frame to the wall and install the hammer drill.

- Install a coolant drain for the crown made of foil or tin cans.

- The drill bit of the hammer drill goes through the finishing layer inside the room.

- The crown is freed from the building material and the inside of the wall is passed.

- The front part of the wall is drilled out, after which the frame with the tool is dismantled.

- Prepare the hole for installation of the ventilation duct, freeing it from debris and dust.

Next, a system of check valves is assembled, which will prevent dust and debris from entering the channel and will not let cold air from the street into the room. After installing the valves, the hood body is attached.

Ventilation device for a room with a gas boiler

ideal boiler room ventilation

There are the following types of ventilation for a gas boiler in a private house:

- Natural and mechanical based on the principle of traction;

- Exhaust, supply and combined according to purpose;

- Duct and ductless according to the design solution.

When installing ventilation in a room with a gas boiler with an open combustion chamber, the following is taken into account:

- In the room with a gas boiler, a ventilation chimney is installed to remove carbon monoxide to the street;

- A general exhaust ventilation system is installed from the room with a gas boiler;

- Supply ventilation is provided in the boiler room for a gas boiler, supplying fresh air and oxygen from the street.

Gaps in windows and doors, gaps through which air can enter the room, are quite suitable as supply ventilation for a room with a gas boiler. This is especially true for private houses, where a separate room is allocated for the boiler.

When choosing equipment, you should take into account the power of the boiler, otherwise the cost of installing gas ventilation will not be justified. The oxygen supply must be sufficient to maintain a normal flame. Otherwise, soot accumulates on the heat exchanger and heating performance decreases. If there is no air flow in the room with a gas boiler, the atmosphere in it is discharged. The oxygen level drops, and reverse draft may appear, that is, combustion products will be drawn into the room. The situation is dangerous when the boiler is installed in the kitchen. By absorbing oxygen, it will cause oxygen starvation in people: pain in the eyes, headache, malaise.

When calculating the air flow, the volume of the room in which the boiler is installed is also taken into account.

Air movement principle

With mechanical draft, the air is driven by a fan. It is located in the ventilation grille at the entrance of the air duct to the room. With natural draft, air moves due to the difference in pressure outside and indoors. And even if there is good natural draft, it would be useful to install a small exhaust fan that will support air movement.

If you equip a mechanical air supply, then increased pressure is created in the room and the exhaust air is pushed out through the air duct.

There is another type of ventilation for a gas boiler room - supply and exhaust or combined. In this case, it is a combination of the previously described systems.

Duct or ductless ventilation

Ductless ventilation for a gas boiler in a private house consists of holes in the ceiling or walls. Openings connect adjacent rooms. For example, a hole is made between the bathroom and the toilet, and a ventilation duct is led out from the toilet.

Duct ventilation of a room with a gas boiler is a complex system of ventilation pipes running throughout the house. This type is most relevant for damp and dusty rooms.

Drywall

Installing a plasterboard box around the hood ventilation pipe is the simplest and most functional way to preserve the aesthetics of the room. It is recommended to use a metal box that matches the diameter of the air duct as a sheathing. Next, the sheathing is lined with sheets of plasterboard along the entire length of the pipe along the wall and ceiling.

When installing a plasterboard box, you can simultaneously provide additional lighting for the work area, since the structure is located in the upper part of the room. The final finishing usually involves painting the sheets in a color that is in harmony with the overall design of the kitchen interior.

Sometimes this method of hiding the ventilation pipe is combined with the installation of a two-level suspended ceiling.

Pros and cons of natural ventilation

Among the advantages of natural ventilation systems it should be noted:

- Constant operation, with rare exceptions.

- Independence from additional equipment, which can sometimes fail.

- Completely autonomous and “free” operation, independent of the availability of electricity.

- The ability to remove all major types of kitchen contaminants released into the air during the cooking process - including carbon monoxide and explosive propane.

- Completely silent operation of the entire system.

The disadvantages of natural ventilation include:

- Ineffectiveness of the ventilation system when the weather is hot outside. Cool and dense internal air cannot rise up through the heated and light external air. In some cases, a reverse movement may even begin, completely paralyzing the kitchen ventilation process. The way out in such a situation is to ventilate the premises using open windows and vents.

- Relatively low air exchange rate. If a large family lives in the house, and you have to cook food often and in large quantities, then it is better to abandon the natural option in favor of forced ventilation.

- The need to ensure air flow from outside for normal natural circulation. In this regard, supply ventilation can be organized or unorganized. In the first case, the inflow occurs through specially made technical holes. With an unorganized method, outside air enters the house through natural leaks in doors and windows, pores in wooden structures.

Attention! Modern plastic windows and metal doors reduce the possibility of unorganized circulation. Therefore, in order to improve air exchange, it will be necessary to insert additional inlet valves into the walls or window frames

Proper organization of natural kitchen ventilation

Ventilation ducts in apartment buildings are installed already at the construction stage. In a private house, you will have to install the ventilation system yourself. Already at the design stage, a number of rules should be observed:

- The natural ventilation system should cover all rooms of the house, including the kitchen.

- Ventilation design should be carried out in accordance with the provisions of building regulations. SNiP set the minimum air exchange rate for the kitchen at 100 m³ hourly when using a gas stove, and at 60 m³ when food is cooked on an electric oven. A similar circulation rate is ensured by paired holes in opposite walls, each of which has a diameter of 16 cm.

- The optimal height difference between the inlet and exhaust openings of the ventilation system should be about 5 m. This way you can provide stable draft for natural ventilation. Therefore, it is recommended to place the outlet of the ventilation duct in a private house under the ridge.

Subject to these conditions, a natural ventilation system can provide effective air exchange in the kitchen and other areas of the house.

Plastic box

You can effectively hide the pipe using a plastic box. Such options exist in various designs and have a wide selection of shapes, colors and decor. Some models may even be equipped with built-in lighting. But the option with a plastic box is suitable only if the air duct opening is located in close proximity to the hood.