A double-walled coaxial chimney is used to remove combustion products from gas boilers and water heaters equipped with a closed combustion chamber. It significantly simplifies the installation of water heating devices in terms of smoke removal; you do not have to build a classic pipe from a modular sandwich or ceramic blocks. The procedure is as follows: get acquainted with the design, study the requirements of the standards for installing a coaxial chimney and do the installation work yourself, using this manual.

Regulatory requirements

According to the table of definitions NPB 252-98, the exhaust pipe for a gas water heater is the connecting pipe for the smoke exhaust pipe of the device and the smoke duct.

Accordingly, it transports gas combustion products and must meet the requirements for chimneys. Failure to comply with them can lead to gas pollution in the room and carbon monoxide poisoning. All requirements for chimneys are set out in the following regulatory documents:

- NPB 252–98;

- Rules for the production of pipe and furnace works VDPO;

- SP 42-101-2003, Appendix G

- SP 60.13330.2012, which is an updated version of SNiP 41-01-2003 (replacing SNiP 2.04.05–91).

The main provisions that directly relate to smoke removal from household gas water heaters boil down to the following points:

- The cross-sectional area of the exhaust pipe is taken to be no less than the cross-section of the outlet pipe of the unit;

- It is necessary to ensure complete tightness of the chimney, its resistance to corrosion and high temperatures up to 200 °C;

- Laying connecting pipes through living rooms is prohibited;

- The vertical section of the exhaust pipe at the outlet of the column must be 500 mm high, in some cases it can be reduced to 250 mm;

- Connecting pipes should be up to 3 m long in new buildings and up to 6 m in existing ones;

- It is allowed to use no more than 3 turns with a bend radius no less than the diameter;

- The exhaust pipe is installed at a distance from the ceiling or wall made of non-combustible materials of at least 5 cm, if they are combustible or difficult to burn, then at least 25 cm. The distance can be reduced to 10 cm by taking protective measures in accordance with SP 42-101-2003;

- If the connecting pipe for a gas water heater passes through an unheated room, then thermal insulation must be used;

- The exhaust pipe must be laid with a slope of 0.01 or more towards the appliance.

Smoke ducts are installed in walls made of non-combustible materials and are insulated, if necessary, to prevent condensation. If there are no suitable walls or the building in use does not have channels for removing combustion products, then install a top-type or root-type chimney.

Each fuel-burning device must have a separate smoke duct or pipe. In some cases, it is allowed to remove exhaust gases from the column and boiler into one chimney with an increase in the cross-section of the pipe. In this case, the combustion products must be introduced into the channel at different levels at a distance of at least 0.75 m or at the same level using a cut with a height of 0.75 m and a thickness of 0.12 m.

The chimney must be strictly vertical and have at the base a removable pipe or pocket 250 mm deep with a door for cleaning soot. If it is necessary to bypass existing obstacles, a deviation of up to 30° from the vertical is allowed, while the cross-sectional area is maintained, and the offset should not exceed 1 m.

The height of the chimney is a key factor in creating good draft. It is this that is decisive in the issue of high-quality removal of combustion products. The height of the chimney must be determined in accordance with the diagram given in SP 42-101-2003 (Appendix D).

If there are taller buildings or trees nearby, then it is necessary to additionally check the height of the wind pressure zone and, if necessary, increase the height of the chimney. In any case, the elevation above the adjacent part of the roof must be at least 50 cm, and with a combined (flat) roof - at least 200 cm.

After installation is completed, the tightness of the smoke exhaust pipe and the presence of draft must be checked. To avoid the risk of loss of draft as a result of freezing of the tip or its blocking by foreign objects, it is prohibited to use nozzles on chimneys in the form of umbrellas, deflectors, etc.

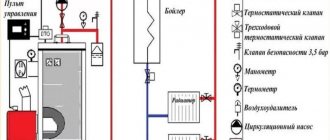

Operating principle of a parapet boiler

When purchasing a non-volatile boiler, you need to turn on the device using the piezo ignition button. If the device is volatile, then the automation automatically turns it on. Boilers of the first type are common in Russia.

So, the parapet boiler works as follows. First, the pilot light ignites the main burner, which heats the water circulating in the heat exchanger. As soon as the water temperature reaches the required level, the burner automatically stops working. After some time, the temperature of the coolant drops again, and the igniter once again ignites the burner.

Selection of pipeline material

When going to purchase an exhaust pipe, you need to carefully study the installation conditions, know the model of the gas water heater, the diameter of the smoke exhaust pipe and the required lengths of the pipeline sections. It is advisable to stock up on a diagram of the location of the water heater indicating all the distances; this will help you better navigate when choosing the necessary elements and, if necessary, obtain specialist advice.

According to SP 60.13330.2012, connecting and chimney pipes must be made of non-combustible materials with an equivalent internal surface roughness of no more than 1.0 mm. In addition, they must be tight with tightness class B and prevent air leaks at the connections and in places adjacent to the smoke duct. The use of materials such as ceramics and stainless steel is recommended.

SP 42-101-2003 allows the use of roofing or galvanized steel with a thickness of 1 mm or more, flexible metal corrugated pipes and standardized elements supplied with the unit.

It is very important that the material of the exhaust pipe is resistant to corrosion, since condensation can destroy it quite quickly. The smoother the inner surface, the less soot will accumulate on it.

The roughness of the outer surface is not standardized, but from the point of view of ease of cleaning, a smoother material for the connecting pipe will be more practical.

However, corrugated pipes are quite popular for connecting a gas water heater to a smoke duct. They are easy to work with and very convenient in tight spaces. Their use allows you to successfully avoid obstacles and carry out hidden installation, hiding equipment in cabinets and covering the pipeline with removable panels.

The main disadvantage of corrugated pipes is the possibility of burning out under the influence of high temperatures. Therefore, for fire safety purposes, it is recommended to use stainless steel corrugation rather than cheaper aluminum.

Galvanized steel 1 mm thick is an acceptable material, but there is an opinion that when heated strongly, galvanizing can release harmful substances. Accordingly, its use is undesirable for models with high flue gas temperatures.

Exhaust pipes made of steel coated with heat-resistant enamel have proven themselves quite well. White shiny pipes look quite nice in the kitchen and can fit into almost any interior.

The ideal material in terms of durability, aesthetics and compliance with all requirements is stainless steel. It is not at risk of corrosion, burnout, dust accumulation, or accidental damage. Quite naturally it turns out to be the most expensive.

FLEXIBLE STAINLESS STEEL CHIMNEYS

Stainless steel corrugation for a chimney is the most acceptable option when connecting to equipment with high flue gas temperatures: wood stoves, fireplaces, pellet boilers. Without loss of sealing, stainless steel corrugation can withstand heating up to 900°C.

A corrugated stainless steel chimney has the following advantages:

- Steel thickness is from 0.12 to 1 mm.

- Ability to compress and stretch.

- Flexibility.

- Resistant to high temperatures and acidic environments.

The corrugation for a stainless steel chimney has one undeniable advantage, which is the ability to install the chimney without the use of adapters, corners, adapters and other fittings. The pipe bends in the desired direction without loss of integrity.

Kinds

Chimneys for gas heaters are classified depending on the material from which they are made. Highlight:

Corrugated flexible air ducts. Inside these pipes there is a wire spiral, and the pipe itself is made of aluminum foil. The advantage of such a chimney is the ability to bend at any angle and change the length using metal tape.

Aluminum exhaust pipes. Their advantages are light weight, accessibility, and the absence of condensation inside the chimney. However, in winter, without insulation, such pipes can freeze up.

Chimneys made of galvanized steel. They are light in weight and have fairly high corrosion resistance.

It is also important to insulate a steel chimney during the cold season.

Sandwich chimneys. Their design consists of one pipe located inside the second, and between their walls there is non-flammable insulation (often mineral wool) to prevent the formation of condensation

Such a chimney is called durable and reliable. It is often recommended for installation in a private house, when the chimney pipe needs to be routed through the roof and ceilings (especially if they are made of flammable materials).

Corrugated flexible air duct

Aluminum exhaust pipe

Chimney made of galvanized steel

Sandwich chimney

Is it possible to install a corrugated chimney pipe?

A chimney made from corrugated pipes can be used for heaters, stoves and boilers. Pipe bends are used to complete heating equipment that runs on different types of fuel: diesel fuel, wood, gas and pellets.

Corrugated pipes are designed for the following operating conditions:

- Internal chimneys.

External smoke removal systems.

As adapters for connecting boilers and furnaces to the main smoke exhaust system.

For carrying out repair work - lining the chimney.

At the moment, there are two main types of products that have the same design, but differ in the material from which they are made. The consumer is offered products made of stainless steel and aluminum.

Rules and regulations for installing a gas hood

According to technical requirements and standards, the hood for a gas water heater is equivalent to chimneys, since it is a transportation route for removing combustion products.

Based on this, it is subject to the same requirements as chimneys:

- the calculated temperature for choosing a material is 200 degrees;

- the diameter of the exhaust pipeline must be larger than the outlet pipe of the gas water heater;

- the vertical tube at the outlet of the equipment must be at least 50 cm long (halved in some cases is allowed);

- during installation, do not make more than 3 turns of the pipeline;

- Exhaust hoods to living rooms are prohibited;

- sections of continuous pipe in new buildings are at least 6 m, in old buildings - at least 3 m;

- the clearance between the pipe and the walls of the room depends on the material of the walls: fireproof - at least 5 cm; difficult to ignite, flammable - 25 cm or 10 cm (subject to additional insulation).

The installation of the pipeline for extracting the gas water heater is carried out with a slope towards the gas equipment of at least 0.01. The walls of the room are pre-insulated. All sections of the chimney passing through cold rooms must also be additionally insulated.

If there is no chimney exhaust in the room where the gas water heater is installed, then install a main or removable pipe. Temporary connection of gas equipment to the stove flue is allowed if it has the necessary performance qualities.

At the same time, it is prohibited to install equipment with forced evacuation of combustion products in rooms with stove heating if there is no forced air flow from the outside. Here the output is a coaxial pipeline.

What to consider when choosing a chimney system ↑

- Select the appropriate model of the chimney system. Select the necessary components for this design.

- Chimney height. The smoke duct must be at least 4.5 meters in height. In this case, any narrowing of the channel is strictly prohibited, otherwise the thrust of the entire system will decrease.

- Chimney diameter. It depends on the boiler model, but most often the standard value is 11 or 13 cm.

- Climatic conditions. Gas equipment and the smoke exhaust system are quite susceptible to temperature changes that occur between combustion products and the environment.

- The location of the chimney relative to the roof of the house. The chimney system must rise above the cover by at least 1 meter.

Purpose

To eliminate it, you need a smoke exhaust pipe that will remove carbon monoxide to the street and will not cause harm to household inhabitants. For a gas water heater, you can install a chimney yourself.

Varieties of corrugation

In the production of corrugated pipes, two main materials are used:

- Aluminum;

- Steel.

Aluminum, or rather its alloys, are used for equipment with temperatures up to 500 degrees. As the temperature rises, the walls begin to burn out. Therefore, such materials cannot be used with solid fuel boilers and fireplaces. But in the case of geysers, they are perfect.

It is not subject to corrosion, so it can be installed even in conditions of high humidity. The only weakness of aluminum is acidic and alkaline environments.

Stainless steel is not temperature sensitive and can be used in high temperature environments. Alloy steel is not afraid of high humidity.

Advantages and disadvantages of corrugation

The advantages of corrugation include:

- The spiral shape of the corrugated pipe is the most convenient for gas venting. Since carbon monoxide is much lighter than oxygen, it rises. Unlike smooth-walled tubes, it goes in a spiral and leads out. Square pipes are prone to condensation forming in the corners, which over time corrodes the profile.

- The round cross-section is convenient to install. There is no need to use adapters or additional adapters.

- In case of damage, it is possible to quickly change the pipe. Minimum tools and time saving.

- No corners or other fittings are needed. The corrugation bends easily and allows you to turn it in any direction.

- Flexibility allows you to lay the pipeline the way you want it.

Flaws:

- Insulation required. Mobility requires thin walls, so they cool quickly when the temperature drops. Mandatory insulation with mineral wool or asbestos is required.

- High susceptibility to shock. Direct mechanical impact will lead to guaranteed damage to the tube.

Features of the parapet boiler "Lemax Patriot 16"

This model of equipment costs consumers 21,000 rubles. The boiler can work in conjunction with forced or natural heating systems. No connection to the electrical network is required. The rectangular heat exchanger is based on high-quality 2 mm steel, which meets the European standard.

The heat exchanger is coated with anti-corrosion enamel and treated with an inhibitory compound, thanks to which the material is reliably protected from the effects of aggressive factors, namely mineral oils and salt solutions. The boiler can only be used in conjunction with a heating system that is equipped with original gas burner components. Heating can be connected from both sides.

The boiler power is 16 kW. The heated area reaches 160 m2. The front panel has holes that create a convection effect. You don’t have to worry that the boiler will overheat, because the manufacturer has equipped it with a special protection system. Servicing the boiler is quite simple, since the design has removable cladding elements and profile equipment. You can observe the combustion of the pilot and main burners through the viewing window.

Installation details

Installing a geyser hood is a process that requires utmost attention

But, before you start creating such a design, it is important to make sure that the column itself is placed in accordance with the basic requirements

In order for such a system to function effectively, it is necessary to correctly calculate the installation of the gas outlet channel: it is this that will ensure the removal of all harmful substances from the room.

We recommend that you follow the basic principles for installing such a hood:

- determine its diameter correctly. It must match the parameters of the outlet. The length of the pipes should not be too long, since its dimensions will also affect the draft;

- think over the optimal shape of such a pipe: it is better if it is round;

- take into account the power of the installed geyser: the more powerful it is, the greater the draft required;

- Observe safety precautions both during installation of the hood and when using it. Make sure that the structure is complete and does not allow gas to pass through, and also use special sealants if necessary.

To avoid unforeseen incidents, try to install the gas water heater at the maximum height, having previously made marks for attaching the equipment. Using a drill or hammer drill, make several holes for the self-tapping screws and begin installing the column. The pipe is installed to an already fixed column in such a way that combustion products enter the ventilation shaft without obstacles.

Important! Both the material itself and the walls in the area where the column with hood will be installed must be fire resistant.

If there is no exhaust duct in the wall, use a root or cap pipe for the column. If the column and stove operate uniformly, you can connect the pipe to a common chimney.

If, after starting to use the column with a connected hood, you notice some malfunctions, immediately seek the help of specialists. Microholes and cracks in materials can also be removed on your own, for example, using a soldering iron.

When choosing a gas water heater for the kitchen, it is advisable to immediately decide on the need to purchase a special hood. Firstly, it will be easier to check the compliance of the basic parameters before fixing the equipment, and secondly, the specialists will share with you all the operating features of such equipment.

The highest quality options for geysers will work properly regardless of extraneous factors: in this case, there will be no need to purchase a chimney at all.

If you realize the importance of using exhaust mechanisms in your kitchen, be responsible for the selection and installation of materials. Any malfunctions will manifest themselves over time, and it is quite possible that thoughtless operation of gas equipment could cause harm to both you and your neighbors

Advantages and disadvantages

The advantages of parapet boilers include:

- no electricity consumption;

- no internal air is used, there is no additional load on the ventilation system;

- there is no need to connect to a common chimney;

- low fuel consumption;

- efficiency, practicality, resistance to external loads.

The disadvantages of the models are:

- installation requires making a hole in the wall from 25 to 31 cm in diameter;

- installation is only possible near an external wall;

- it is not possible to provide full-function control and protection of units and parts of the unit (for non-volatile models).

Despite the existing disadvantages, parapet boilers are highly rated by users. The demand for them is constantly growing.

Features of internal installation of chimney pipes

Installation of chimney structures inside houses and premises has the following distinctive features and specifics:

- It is necessary to prepare areas for pipes in the roof and walls.

- The assembly of chimney structures is characterized by increased complexity, as well as repair work if necessary.

- The likelihood of toxic combustion products entering a living space is relatively high.

- It is necessary to carefully observe fire safety regulations and provide reliable protection for wooden elements and products.

First of all, markings are applied, and then, in accordance with it, holes of the required sizes are cut in the wall structures and roof. After this, the chimney structure is assembled, starting from the gas device.

The pipes are fixed to the walls using brackets and clamps. The section of pipe passing through the roof is protected using sheet metal. The connecting zones are insulated using heat-resistant sealant and insulation. The outer section of the pipe should end with a cone-shaped tip.

Rating of the best manufacturers

Gas double-circuit parapet boiler, which manufacturer is better, what to focus on. It is necessary to analyze the rating of parapet gas boilers and read reviews.

Imported parapet gas boilers. Among them, it is worth highlighting equipment with cast iron heat exchangers, their advantage is reliability, with a power of 12 to 60 W. They will be able to heat larger houses and apartments. A distinctive feature of this kind of heat exchangers is their resistance to temperature changes and mechanical deformation. Thus, the Electrolux company produces equipment that can withstand critical temperatures above 90 degrees.

It should be noted the high-quality products of such companies: Italian - Fondital, Beretta; Slovak – Alphatherm Beta, Attack; Hungarian - Alphatherm Delta.

Russian parapet gas boilers. Domestic manufacturers often use components from the CIS and EU countries to manufacture equipment. These are cast iron heat exchangers, sensors, controllers. Thus, while maintaining quality characteristics, the final cost is reduced to approximately 15%.

This type of product includes: “Titan N” boilers (Ryazan); Lemax Leader GGU-ch (Taganrog); Siberia KCHGO (ZAO Rostovgazoapparat). These models are distinguished by a wide range of equipment power. Manufacturers offer single-circuit and double-circuit boilers of various types.

It is worth noting the high-quality products of Russian companies Helios, Danko, Conord.

We can conclude that parapet gas boilers are universal equipment for heating a home, which combines high quality indicators (efficiency 93-95%) and optimal prices. They compare favorably with chimney models with an open gas chamber in that they do not require a separate room for a boiler room. At the same time, compared to turbocharged models, it is easier to operate. The advantageous aspect of this type of equipment is its independence from the power supply system. This makes it possible to install the boiler in areas where there is a risk of power outages.

Features of installing a chimney in an apartment and a private house

The installation begins with all the necessary measurements, preparation of tools and components, while the installation of a chimney in an apartment and a private house differs.

Chimney in a private house

As a rule, pressurized gas boilers are installed in houses, which work not only as water heaters, but also as heating devices.

The distance from the wall to the chimney should not be less than 5 cm if the material is resistant to combustion, and not less than 25 cm (if the walls are made of flammable materials, for example, wood). When installing an asbestos or steel shield, the distance between the boiler and the fire-hazardous wall material can be reduced to 10 cm.

The total length of all horizontal sections of the chimney should not exceed 3 m. A vertical chimney can be installed with a protrusion of 1 m and a slope of 30° when it is necessary to go around building structures.

No more than three turns of the pipe are allowed. When laying a chimney through a fireproof wall, an opening of a certain size approved by the design is made in it, and after the pipe is laid, the gap is filled with non-combustible material.

A through hole is cut out in a wooden wall, the dimensions of which exceed the diameter of the chimney by 38 cm. On one side it is sewn up with galvanized iron, then insulation based on basalt rock is laid and also sewn up with a sheet.

Chimney installation technology:

- Weld a pipe of the required length and configuration.

- Cut a hole in the wall with a diameter greater than the diameter of the pipe. Install a sleeve in this gap that will protect the wall from heating.

- Fill the space between the pipe and the sleeve with asbestos or expanded clay.

- Secure the pipe with a support ring at the intersection of the floors.

In the apartment

When installing a chimney for apartments in apartment buildings, they are often faced with the fact that they do not have chimney shafts. Connecting gas outlets to ventilation ducts is prohibited. The only way to solve the problem is to install a more modern turbine column with a coaxial chimney.

If there is a chimney duct, the task is made easier: a corrugated pipe of the required length is secured to the outlet of the gas heater using a clamp. The second end of the pipe is fixed in the smoke channel.

To install a chimney made of other materials, it is important to prepare all the parts in advance and connect them together, fasten them with clamps, and treat them with sealant. https://www.youtube.com/embed/G2rPgtWNkt4

Advantages and disadvantages

Advantages of parapet boilers:

- No need to connect to the mains. The autonomous system is powered by a battery, and the fuel is supplied from the gas pipeline, or cylinders are connected to the system.

- Such boilers are easier to install, connect, and do not require maintenance. To regulate the operation of the system, the necessary sensors and controllers are installed on them.

- The design of the device is simple, which simplifies the task of maintenance.

- Universal equipment can become a heat source for a heating system made of pipes and radiators, or an individual means of heating due to convection windows.

- The equipment is installed in small rooms (small apartment, small private house or cottage). You can place it where it is more convenient. There are floor-mounted and wall-mounted varieties. Such devices are compact.

Convection holes

Disadvantages:

- Weak internal pressure, which needs to be artificially increased by a circulation pump.

- Possibility of icing of the chimney during severe frosts.

A detailed overview of the parapet installation model can be seen in the following video:

Location of exhaust pipes for a gas water heater

Exhaust pipes can be located both inside the building and outside. Installing a hood using one of these methods has its own characteristics. When the pipes are located inside the building, these are:

- places for installing pipes in concrete floors and roofs;

- complexity of the structure and measures for its repair;

- risk of combustion products entering the room;

- Fire safety.

Chimney pipes are made of resistant materials

Additionally, clamps are used to connect its components. Where pipes pass through ceilings, it is necessary to use special sealants and insulation. Their use should be aimed at maximum resistance to high temperatures.

External installation of pipes is more convenient, but is not always used due to the design features of the building. With this arrangement of the chimney, the kitchen pipe from the gas water heater to the wall should be more than 25 cm. The rest should be taken outside and well insulated. The pipe from the equipment is connected to the chimney pipe and the required number of elbows. So it is brought out into the street by extension.

The external ventilation device is easy to install and completely safe for residents of the house. Coaxial pipes are often used as a material. Installation and repair of such are most convenient if all norms and rules of SNIP, as well as safety precautions are observed

It is important to coat the outer part of the pipe with special anti-corrosion mixtures, and install protection against water ingress on its top

The use of special anti-corrosion agents makes it possible to protect the outer part of the exhaust pipe from the effects of not only precipitation, but also from the formation of condensation. It is formed when there is a difference in temperature inside and outside the structure. Sometimes such an exhaust system is supplemented with a special drain of liquid accumulated in the pipe. The made mechanism allows you to quickly utilize moisture from the chimney.

Combined models

In addition to traditional heating equipment, it produces 3 combined series of boilers:

- Electric gas heat generators KS-G-SN / KE with a heat output of 10-12 kW.

- Units "Zhytomyr-9" burning coal and natural gas. Designation - KS-G-SN / AOTV, power - 10, 12 and 15 kW.

- Heating and hot water installation “two in one” KS-G-SN, otherwise – “Zhitomir-10”. The range of models covers the range of 7…30 kW.

The line of gas-electric boilers is built on the basis of Zhytomyr-3 units and does not differ in appearance from conventional floor-standing units. The design is complemented by a control unit and an electric heater placed inside the water jacket. 2 types of heating elements are installed - with a power of 4.5 and 9 kW. Important feature: both heating methods can be turned on one by one or simultaneously.

The coal-gas heat generator “Zhytomyr-9” has the following parameters:

- on the left side of the body there is a firebox with a volume of 47 or 70 liters for storing anthracite or firewood;

- to the right of the solid fuel chamber there is a gas firebox with a Polidoro burner and an SIT 630 automation unit, a common heat exchanger, and separate smoke exhausts;

- efficiency on gas – 92%, solid fuel – 78%, operating water pressure – 1 Bar (Max 1.5 Bar);

- work in a closed system is allowed, condition - installation of a safety group with a 1.5 bar safety valve;

- duration of 1 coal combustion cycle – 6…8 hours;

- There are modifications with a DHW water circuit.

The operating algorithm is simple: while the coolant is heated by coal, the gas burner does not ignite. When the sensor detects a drop in temperature, the gas supply will open and the right side of the heat generator will start working. The main thing is that the pilot light is lit.

The gas installation “Zhytomyr-10” consists of two separate sections - a boiler furnace and an instantaneous water heater. Burners, safety devices and heat exchangers are completely separated. In fact, the gas water heater and the boiler are combined in one housing. The goal is to increase water consumption for hot water supply to a comfortable level without compromising heating efficiency.

Selection of exhaust pipes depending on the column

The development of water heating gas technology involves the introduction of a closed combustion chamber into the device. To ensure the removal of combustion products from it, coaxial chimneys are used. When using such equipment it is necessary:

Disassembled coaxial chimney is used to remove combustion products

- install pipes only in a vertical position;

- use non-flammable materials;

- do without changing the air vent sections;

- seal the seams with special heat-resistant agents;

- use no more than 3 ventilation pipe elbows;

- ensure the integrity of all ventilation elements.

The geyser hood with a forced function is equipped with a special fan. It begins its work when the ignition is turned on and forcibly pushes combustion products out of the ventilation. A hood in a private house with low draft is perfectly compatible with such a device. The advantage of a column with a forced exhaust system is the complete absence of combustion products in the room, in the kitchen or in the boiler room.

Choosing a gas boiler

Reliability primarily depends on the thickness of the steel used in the design of the heat exchanger. Unfortunately, not all manufacturers indicate this parameter, so when choosing a boiler you need to clarify this point with the seller separately, as this can play a key role in the operation of the parapet boiler.

Steel with a thickness of around three millimeters is considered optimal. If the steel is thicker, the heat transfer process will slow down, which will negatively affect the overall efficiency of heating the room. In addition to the thickness of the steel, its quality also matters. The quality of the metal and the entire boiler as a whole can be determined by the maximum pressure level allowed by the manufacturer. The higher it is, the more reliable and better quality the selected parapet boiler is made.

The quality of metal during manufacturing can be determined by the maximum level of pressure

The efficiency of a parapet boiler is influenced by the design of the heat exchanger and its efficiency. In order to determine how economical the selected boiler will be in operation, you need to find out its efficiency (efficiency factor), this parameter will most accurately show the efficiency of the heat exchanger and the boiler device as a whole.

To date, almost all manufacturers have achieved an acceptable level of efficiency, which is 90-92%. But just in case, it’s worth checking the efficiency level when purchasing, since in some cases two or three percent can make a difference. This indicator is the only one that will objectively reflect the efficiency of the boiler, because different rooms differ from each other in the level of their own thermal insulation, so reviews from people who have already bought a boiler will always be subjective.

Significant technical parameters include the size, dimensions of the boiler, location of connection connectors and power. The size and dimensions are selected individually in each case and depend on the location and installation conditions. Also important for the boiler is the location of the connectors. The modern model range includes options with both right-hand and left-hand connections of the boiler to gas and water supply. There are also universal models that can be connected from any side.

Boilers come in different sizes, it all depends on the power

The power of a parapet boiler is no less important than its efficiency. The quality of room heating, as well as the efficiency of using the boiler, will depend on the choice of a model with optimal power, because if it is too powerful, gas and electricity will be wasted. The formula 1 kW per 10 m2 is often used, but in fact this is not correct, since this indicator is averaged so much that it almost never corresponds to reality

When calculating a power of 1 kW per 10 m2, the difference between an apartment and a house, the number of windows in the room, wall material, ceiling height and other parameters that make up the overall level of thermal insulation are not taken into account

The formula 1 kW per 10 m2 is often used, but in fact this is not correct, since this indicator is averaged so much that it almost never corresponds to reality. When calculating a power of 1 kW per 10 m2, the difference between an apartment and a house, the number of windows in the room, wall material, ceiling height and other parameters that make up the overall level of thermal insulation are not taken into account.

It is best to double this formula, that is, for 10 m2 take 2 kW of power, and not one. In this case, a margin is obtained that takes into account windows, possible drafts, thin walls or high ceilings of the room. But, of course, it is best to consult with specialists when purchasing and determine the optimal boiler power individually in order to achieve the most optimal price-quality ratio for heating.

A parapet boiler is economical, easy to use, has a low cost, can perform the functions of a water heater and does not require the creation of an additional heating network, since it is both a stove and a convector. The ease of installation allows you to connect the parapet boiler yourself, without the help of specialists.

To summarize, we can say that a parapet boiler is a convenient modern heating device that can be installed in any type of premises, in a private house, apartment, garage or any outbuilding.

Material for making the hood

Exhaust device

The main qualities that materials for making a hood must have are strength and fire resistance. This is necessary to prevent air and carbon monoxide from penetrating through the pipe into the room. Most often, such devices are made from corrugated pipe with a diameter of 110 or 130 mm and a length of about 3 m. This material is very convenient because it has the necessary flexibility and lightness. A special metal tape is used to connect the two pipes together.

In addition to corrugated pipes, aluminum or steel pipes can be used. In the latter case, the hood must be coated with enamel, which protects the steel from high temperatures. If the design provides for turns, they should be performed using adapters and additional pipes.

It must be remembered that the presence of turns in ventilation pipes helps to reduce draft. With each such turn, efficiency will decrease by 10%. In total, the number of turns should not be more than three. If the angle of rotation is too large, the traction may be lost completely.

COST OF A SET OF CORRUPTIONS FOR CHIMNEY

To calculate the cost of corrugation, you will need to take into account several important points:

- The total length of the chimney. The standard package includes an aluminum pipe capable of stretching from 0.65-3 lm. Stainless steel corrugation stretches slightly, so when making calculations it is necessary to take the length indicated on the package. You can buy one aluminum sleeve for 350-380 rubles. A stainless steel pipe will cost 650-700 rubles. for 1 p.m.

- Pipe diameter – stainless steel hoses are manufactured with a cross-section from 80 to 500 mm. Aluminum ones have a diameter of 110 and 130 mm. When choosing, you must take into account the parameters of the heating equipment and strictly follow the manufacturer’s recommendations. If a material is selected for the rehabilitation of a chimney made of corrugated aluminum, which will be used in wood-burning stoves, then the diameter of the pipe should be smaller than the internal channel of the brickwork.

- Fittings - you will need to buy adapters, adapters and flanges.

Installation Aspects

Geysers and boilers always produce toxins that can enter the room. To avoid this, listen to the advice of installers on selection and installation.

Types of gas outlet pipes

Gas outlets are often made of metals. A noticeable disadvantage of this is the guaranteed formation of condensation. The reason is the temperature difference between the gases inside and the cold air outside. To avoid this, you can buy and install fire-resistant thermal insulation. Some requirements already come with insulation inside.

The problem is also solved using a coaxial gas outlet. Two separate compartments for carbon monoxide removal and oxygen intake will prevent water droplets from forming.

Corrugated pipes can be used. Since waste moves quickly inside, it does not have time to cool before exiting.

Dimensions of chimney pipes

Dimensions (diameter, wall thickness, length) are calculated based on the power of the equipment and the environment. In most regions of the CIS, the use of pipes 11 centimeters in diameter is acceptable.

The instructions for the heating device indicate the recommended dimensions.

Installation standards

The gas outlet in contact with the wall must be insulated with fire-resistant material. It is advisable to use mineral wool.

Sometimes two devices can be connected to one pipe:

- If two boilers are installed on one floor;

- Two speakers installed.

When installing, observe the following rules:

- Mounting elements must not burn;

- Butt sealing is carried out using non-flammable mixtures;

- You cannot use more than three knees;

- The pipes must not be damaged.

To prevent condensation indoors, it is better to insulate the walls in the room.

Features of boilers and columns

Systems with a closed combustion chamber must be equipped with a coaxial flue exhaust. It will be able to create active oxygen saturation and removal of combustion products. Boilers and dispensers with forced air supply require the installation of a blower fan. The ventilation system turns on simultaneously with the heating. Proper installation will reduce the likelihood of toxins entering the apartment.

Compatibility of the chimney with the hood

The simultaneous use of a gas outlet and an exhaust hood is not allowed. A running exhaust system can knock out the fire, which can lead to gas poisoning.

Even if attenuation does not occur, there is a possibility of carbon monoxide entering the room. When using gas equipment, this is unacceptable.

Chimney draft

An indicator expressing the efficiency of combustion products exiting through a pipe. Determined by the rate of removal of toxins from the chimney system.

The higher the indicator, the better the removal of carbon monoxide and the penetration of oxygen to the burner.

Dangerous consequences of malfunctions

The exhaust pipe for the geyser may become clogged. Because of this, carbon monoxide can penetrate into the room, creating a danger to human life. Carbon monoxide is odorless and tasteless, so its penetration may not be noticed. This is especially dangerous at night. The sooner a leak is detected, the better. In case of mild poisoning, unpleasant symptoms appear: migraine, nausea, dizziness, vomiting. If it's strong, it means death.

Blockage is also dangerous because oxygen stops getting into the system. This causes the wick to fade. Combustible substances enter the atmosphere, poisoning the air. However, it can be detected by smell.

User manual

In order not to lose the warranty for the maintenance of your unit in any case, you do not need to carry out work on installing the boiler and repairing it yourself. Connecting the product, its proper configuration, and the first start-up must be carried out by service specialists. They will make a separate entry about the work performed in the passport of the unit you purchased. It is necessary to carry out preventative maintenance of the entire boiler once a year - this is also noted in the technical data sheet of the device. Failure to maintain such records may void your warranty.

The Conord burner may sometimes not ignite. This may happen because:

- There is a lot of dirt on the burner. Before turning on the structure, you need to clean the nozzles with a soft brush or just a vacuum cleaner.

- There may not be enough oxygen to start the burner quickly. Again, it is necessary to clean the nozzles that supply air, thoroughly ventilate the room, and try to light the burner again.

- Perhaps the contacts in the thermostat have simply oxidized. This is where the cleanup takes place.

- Automation sensors are broken.

- It is necessary to blow out the igniter or clean it of any existing dust or dirt.

If your coolant cools down very quickly, you just need to switch the thermostat to maximum settings or increase the supply of fuel to the burner, if only the device instructions allow this kind of action.

In the summer, you will need to turn off the heating circuit altogether. You just need to turn off the tap at the coolant inlet. If the burner works alone, the water will heat up to 60 degrees in 1 hour. If the heated liquid is not all removed at once, it will retain heat for about another 2 hours.

Domestic has already earned an excellent reputation in the domestic heating equipment market thanks to the production of high-quality equipment. Among users, Conord units, reviews of which have mostly positive features, are always in fairly high demand.

To learn how Conord gas boilers are produced, see the following video.

Chimney installation

To ensure long-term and safe operation of the hot water column, it is necessary to meet all the requirements for the chimney set by regulatory documents. The result of compliance with these requirements will be the presence of stable good draft, which is so important for the normal functioning of atmospheric heaters. In addition, the standards take into account measures to protect against fire and carbon monoxide poisoning, and minimize the impact of emissions on the environment or people living nearby.

When laying a coaxial chimney outside, the following rules must be observed:

- the total length of the horizontal section of the pipe should not exceed 3 m;

- the number of channel turns by 90º is no more than three, with a radius of curvature equal to the pipe diameter or greater;

- It is not recommended to install the double-walled gas duct of an instantaneous heater vertically and pass it through the ceilings and roof. The length of the channel will increase, and then the aerodynamic resistance will increase; the unit’s fan may not be able to cope with it;

- The passage of the coaxial pipe through the wall is carried out in a steel sleeve and with a slope of about 2º towards the street to drain condensate.

The hole in the wall where the chimney of the gas water heater will pass must be at a certain distance from various elements of the building and ventilation devices. The table below shows the minimum distances that should be maintained:

The requirements for installing smoke ducts for units with an open combustion chamber are somewhat more complicated. The number of turns of the pipe here is the same as in the previous case, only the deviation of the vertical part is still allowed by no more than 30º with a displacement of no more than 1 m. If it is planned to jointly connect the boiler and the column to one shaft, then its cross-section should be designed for simultaneous operation two units. In this case, the connection of the gas water heater to the chimney must be made above or below the insertion from the boiler at a distance of at least 75 cm.

The diameter of the connecting pipe cannot be less than the outlet pipe of the heater, and immediately behind it there should be a vertical section of the channel 25 cm long for rooms up to 2.7 m high and 50 cm in rooms with ceilings higher than 2.7 m. A steel or corrugated chimney inside the room must be fixed with clearance 5 cm from walls and ceilings made of non-combustible materials, and sagging of the horizontal section of the corrugation is not allowed. If the wall is made of combustible material, then the gap between it and the pipe increases to 25 cm.

To avoid the zone of wind pressure and deterioration of draft, the height of the chimney must be observed in accordance with the diagram:

Connection

The process of installing a geyser with a chimney can be divided into several stages. Let's consider the simplest option for installing a chimney, using a corrugated pipe:

- Installation of a geyser begins with choosing the location of the equipment, so that it is convenient to install the hood;

- Then a hole is made in the ceiling and roof;

- A piece of asbestos pipe one and a half or two meters long is inserted into the prepared hole;

- A pipe sticking out of the ceiling can be disguised with a special decorative rosette;

- Next, using dowels and self-tapping screws, a gas water heater is installed;

- When the column is fixed to the wall, take a piece of corrugated pipe, one end is put on the outlet pipe of the column, and the other end is inserted into the chimney socket (if an enameled steel pipe is used to install the chimney, then a tee is used to connect the chimney to the gas column);

- To supply gas to the equipment, a tee is cut into the gas pipe, a gas tap is installed, and a flexible line is connected to the column with a fitting with a union nut;

- In the same way, a tee is cut into the water supply system, a water tap is installed and the water supply pipe is connected to the column (salt and magnetic filters must be installed);

- All that remains is to connect the column to the hot water supply system. Read the instructions on how to make an insulated chimney on this page.

Options for installing a gas chimney in the figure.

When installing a chimney for a gas water heater, you should adhere to some rules:

- do not use more than three taps;

- the constituent elements of the chimney must be rigidly fixed and not bend;

- cross sections should not have narrowings;

- an inspection grille and a condensate collector are installed at the bottom of the chimney;

- the chimney should not have joints in the ceiling;

- the internal surface of the chimney should have as little roughness as possible.

Types of pipes for organizing an air duct

An air duct that discharges air directly to the street is installed in a private house. In the apartment, the outlet is carried out to the ventilation duct. Also in houses there is the opportunity to design an air duct to suit your needs and bring it out to any suitable place on the wall, but in an apartment everything is limited by the existing duct.

Most often, pipes for the exhaust device are made of the following materials:

- corrugations;

- become.

Corrugation is made from laminated multilayer aluminum foil. The shape of the channel is given by a wire inserted inside the pipe. Corrugated channels are highly resistant to the negative effects of condensation and are lightweight. They are quite reliable and very inexpensive. The big advantage of corrugation is its ease of installation and the ability to bend it in the desired direction.

Steel air ducts for geysers are made of high-quality steel and coated with white heat-resistant enamel. The advantage of such a pipe is the smooth internal surfaces, on which much less soot and debris accumulate than on rough ones.

WHAT CORRUPTION IS USED FOR CHIMNEYS

Installation of a corrugated chimney is recommended when connecting to heating equipment operating on any type of fuel, subject to the emission of low and high temperature flue gases.

The strength of the material is ensured by the following design:

- The body is made in the form of a cylindrical pipe twisted into a spiral. The strips are connected to each other with a special locking seam.

- Wire is used as a reinforcing layer, which gives the body resistance to mechanical damage, but at the same time the pipe retains its elasticity and flexibility.

The consumer is offered two types of pipes made of stainless steel and aluminum.

- Gas supply to a private house

- Flushing the heat exchanger of a gas boiler with citric acid

- Connecting a thermostat to a gas boiler

Additional hood installation

Usually, to operate a column with an open combustion chamber in a city apartment, natural ventilation in the room is sufficient, which is ensured by the presence of a window in the room and an unclogged ventilation shaft. At the same time, many speaker owners are thinking about additionally installing a hood in order to improve safety and increase traction. In fact, if the traction is sufficient, there is no need for such actions. On the contrary, installing a hood above a column can lead to the following problems:

- If there is insufficient air flow into the room (for example, if the window is closed), the hood will draw air from the bathroom ventilation shaft, which will lead to an unpleasant odor in the kitchen.

- If there is only one ventilation duct and the room already has a hood above the stove, an additional installation of a hood will create reverse draft, which is dangerous for the health of the occupants.

Most common problems

A parapet floor-standing gas boiler, like a wall-mounted one, can sometimes go out.

The most common reasons:

- Icing of the external chimney unit. In this case, the access and removal of air is disrupted. It is recommended to try starting the boiler at minimum power and try to warm it up in this way. Or carefully knock off the ice.

- When using boilers of all types, it is advisable to install water purification filters. If it is hard enough, the heat exchanger system may clog. In this case, you need to disconnect it and clean it.

- When there is a strong gusty wind, sometimes its gusts enter the exhaust chimney (backdraft), which leads to the flame being blown out.

- The fire may go out if there is insufficient gas pressure. The cause must be eliminated; there may be a leak.

- Failure of various sensors and controllers. Replacement or repair of boiler parts is required.

Tips for installing a chimney

Before installing a gas water heater in a private house, you need to decide where and how to remove flue gases. Exhaust pipes - chimneys - are used for this purpose; they are made from the following materials:

- Galvanized or stainless steel.

- Asbestos pipes.

- Brickwork.

When the house has an exhaust duct made of the listed materials and with sufficient draft, the problem is solved; you can select and install a gas water heater of any type. You just need to correctly connect the outlet pipe of the device to the entrance to the smoke duct. It would seem that the task is not difficult, but many people make mistakes when performing it. So, when cutting into a finished vertical shaft or installing a chimney for a gas water heater, you must adhere to simple rules:

- The number of turns of the smoke channel from the outlet of the heater to the insertion into the vertical channel should not exceed 3.

- Connections between fittings and straight sections should be made hermetically.

- The vertical pipe for the gas water heater must have a condensate sump at the bottom and an inspection hatch or drainage.

- The section of the chimney pipe located outdoors should be insulated.

- It is prohibited to use various weather vanes or umbrellas. It is recommended to install a special nozzle on the exhaust.

- Do not combine the exhaust duct from the boiler with the chimney from the boiler.

Installation of connecting sections made of aluminum foil is not allowed. You can use a corrugated chimney made of stainless steel.

The rules for using gas installations prohibit the connection of ventilation ducts to them as a chimney; the shaft for the emission of combustion products must be made separately from the ventilation shaft. An exhaust hood can be used in a country house or apartment if the cross-section of the shaft meets the requirements in the product data sheet and when there is an additional exhaust duct in the same room.

In order to comply with the rules, it is best to place the column in the furnace room, where natural air exchange is organized. When this is not possible, you will have to mount an additional chimney pipe on the street, securing it to the outer wall and raising it to the height shown in the diagram:

Exactly the same rules must be followed when installing a geyser in an apartment. Only here you don’t have to install external chimneys, but only hang the unit from the wall and make all the connections correctly.

It is somewhat easier to install a gas water heater without a chimney. That is, there is a chimney in it, but it is short and in some models of heaters is almost invisible, since it comes out directly from the back wall of the device and immediately horizontally penetrates the outer wall.

Installation of a gas water heater without a chimney

Such a pipe is called coaxial and consists of two channels; combustion products move through the inner one to the street, and air, driven by a fan, passes through the outer one. All heaters without a chimney are equipped with a closed combustion chamber and an electronic control unit; they can take combustion air both from the street and from inside the house. When installing a coaxial kit, a simple rule is followed: to prevent condensate from flowing through the pipe into the column, it must be laid with a slight slope towards the street.

Operating principle of a supercharged heater

If we talk about the principle of operation in general, then all gas instantaneous water heaters work the same way: when the corresponding tap on the mixer is opened, the burner in the unit is ignited by the pressure of the flow and begins to heat the water passing through the heat exchanger.

Another thing is how this is implemented in a gas instantaneous water heater with forced air injection. Functional diagram of a water heater equipped with a turbine

Unlike other types of water heating devices, a gas water heater with a closed combustion chamber operates according to the following algorithm:

- In standby mode, the household appliance is connected to the electrical network. Nothing burns in the chamber because there is no igniter there.

- When the user opens a hot water tap, the flow sensor and the membrane of the water unit are activated. The latter mechanically opens the gas valve and fuel flows to the gas burner device.

- At the command of the controller, a spark discharge occurs on the electrodes located near the burner, igniting the gas. The flame sensor detects the appearance of fire, informs the control unit about this, after which sparking stops. At the same time, the fan is turned on, pumping air.

- The flame, controlled by the controller, heats the water to the temperature set by the user, which is monitored by a separate sensor. When it is reached, the burner power is reduced by reducing the flame (modulation) or turning off 1-2 burner stages.

- After closing the DHW tap, the gas supply is shut off, the burner goes out and the water heating process is completed.

Modulating (left) and stepped burner (photo on the right) Thanks to a more advanced design, the efficiency of turbocharged columns is higher than that of conventional atmospheric ones (88-90% versus 84%). Efficiency is achieved in the following ways:

- precise dosing of the amount of natural gas and air required for combustion;

- Maintaining the set temperature helps save fuel, since gas is not consumed for excessive heating;

- preheating the air flow in a coaxial chimney.

Details about the design of coaxial chimneys are shown in the video:

Closed chimneyless dispensers are equipped with several safety levels that are triggered for the following reasons:

- disappearance of draft in the chimney due to the fan turning off after a power outage;

- spontaneous extinguishing of the burner (flame control);

- too low or high gas inlet pressure (automatic gas valve);

- the pressure in the water supply exceeds 10 Bar (water safety valve);

- overheating of the heat exchanger, which can cause a pressure surge and depressurization of connections;

- very low water consumption;

- controller failure.

Any of the above reasons entails the operation of the gas valve and the cutting off of the fuel supply. Moreover, after a power outage, burner extinguishment and pressure surge in the gas pipe, the valve operates independently, without controller intervention.

To appreciate all the delights of using turbocharged gas water heaters and find out their weaknesses, we suggest that you familiarize yourself with their advantages and disadvantages.

Boiler structures and chimney outlet

Structurally, a gas boiler is a device consisting of a gas burner, to which gas is supplied through nozzles, and a heat exchanger, which is heated by the energy obtained during gas combustion. The gas burner is located in the combustion chamber. Heat movement occurs using a circular pump.

In addition, modern types of gas boilers are equipped with various self-diagnosis and automation modules, allowing the equipment to be used in autonomous mode. When choosing a chimney, pay attention to the type of boiler combustion chamber. The method of intake of air necessary for gas combustion, and as a result, the optimal type of chimney, will depend on its design.

Different types of chimneys are suitable for different types of combustion chambers

The combustion chamber of gas boilers is of two types:

- open - provides natural traction. The air is taken from the room in which the heating equipment is installed. The removal of combustion products is carried out through natural draft using a chimney with an exit through the roof;

- closed - provides forced traction. Air intake for fuel combustion comes from the street. In rare cases, air can be taken from a special room equipped with forced ventilation. To simultaneously remove flue gases and intake fresh air, a coaxial type chimney is used, which is vented outside through the nearest load-bearing wall.

Knowing the type of combustion chamber, you can easily select or manufacture a chimney suitable for the design. In the first case, when the boiler is equipped with an open combustion chamber, a conventional thin-walled or insulated chimney is used.

For boilers with a closed combustion chamber, a coaxial chimney is used, which is a structure consisting of pipes of different diameters. A pipe with a smaller cross-section is fixed inside a pipe of a larger diameter using special racks. Carbon dioxide and other combustion products are removed through the internal channel, and through the gap between the outer and inner pipes, fresh air enters the closed combustion chamber.

Methods for installing chimneys

According to the method of installation, chimneys are divided into:

- internal - chimneys made of metal, brick or ceramics. They are available in both single-wall and insulated double-wall constructions. Positioned vertically upward. There may be several elbows with a 30° offset;

- external - coaxial or sandwich chimneys. They are also located vertically upward, but the chimney is led out horizontally through the load-bearing wall. After the pipe is removed, a 90° rotary elbow and support brackets are installed, allowing installation in the desired direction.

The chimney can be vented to the street through a wall in the immediate vicinity of the boiler or in the traditional way through the roof.

When choosing a chimney installation method, you should take into account the size of the building in which the equipment is located. For small buildings, it is more advisable to use external chimneys, as they allow the chimney to be taken outside the room.

In other cases, you should build on your personal capabilities. If space allows and it is possible to provide high-quality insulation where the pipe passes through the ceilings, then an internal chimney will be the best solution. Especially if the structure is lined with brick or protected by a ceramic box.

How to reduce the temperature of flue gases in a chimney

The combustion of natural gas produces carbon dioxide, steam, sulfurous salt-forming oxides, etc. The optimal temperature of the flue gases at the chimney outlet should be 100–110 °C.

If the temperature of the flue gases is below the dew point, that is, the condensation temperature of the air, then the water vapor contained in the combustion products will settle on the walls of the chimney. If this happens constantly, the chimney can quickly collapse.

If the temperature of the flue gases is too low, condensation will form at the outlet of the chimney, and the outer part of the pipe will begin to freeze.

In addition, the presence of constant condensation in the smoke channel leads to a weakening of natural draft. Therefore, it is so important to monitor the temperature of the flue gases, which directly depends on the cross-section of the chimney.

From the above we can conclude that with correct calculation, the temperature of the flue gases will be in the region of optimal values. If the temperature is too high and needs to be reduced, this directly indicates that the cross-section of the chimney does not correspond to the power of the gas boiler. To reduce the temperature of the exhaust gases, it is recommended to reassemble the smoke exhaust system taking into account the standard values.

Video: condensation in the chimney

Why does the boiler blow out in the wind and what to do in this case?

Blowing out may indicate a failure in the connection of the chimney and automation; more often it indicates a lack of wind protection on the head. However, in general, blowing out the burner flame by the wind is a significant and most well-known problem with parapets, which is why they never gained super popularity.

As a rule, the casing of a coaxial chimney, manufactured in a factory, already has a special insert that protects against gusts of wind. If it is not included in the kit, then you will have to look for a suitable deflector or make it yourself: give a sheet of galvanized steel the desired shape, and then attach it to the head with press washers or rivets.

Factory wind protection and an example of a homemade solution by the owners.

When the boiler still goes out after installing the protection, there is no point in doing anything further: you can, of course, continue to install new heads and deflectors, add bends to the coaxial pipe, or install a vertical chimney, but then the whole point of installing a parapet model will be lost.

Types of parapet units

Parapet gas boilers have some features that distinguish them from conventional units:

- A closed combustion chamber, in which the installation of a coaxial pipe is sufficient to remove flue gases. It simultaneously ensures the supply of combustion air to the burner from the street and the removal of flue gases.

- The devices do not depend on electricity and can work autonomously.

- They can be used to heat rooms as an independent device without radiators.

Parapet-type units may differ in other characteristics. They are:

- single-circuit and double-circuit;

- power from 4 to 40 kW;

- on the outlet side of the pipe: left-handed, right-handed;

- floor and wall.

Such units can be equipped with burner devices of different types: single-stage, two-stage and modulating. Also, different models differ in the automation equipment.