Due to the constant increase in energy prices, owners of country houses and city apartments in high-rise buildings are switching to alternative, more profitable types of heating, mainly choosing autonomous options. Some people prefer to install gas boilers so as not to overpay for central heating, which in some regions is paid not only in winter, but also in summer. Other homeowners have become interested in heating their homes using electrical appliances.

DIY induction heating boiler

Electricity is more convenient in the sense that the installation of such a water heater does not require coordination with permitting organizations, drawing up and approval of a project. But many are put off by high tariffs. This means that you need to opt for electric boilers, which are characterized by increased efficiency and economical operation. These, of course, include units of the induction operating principle. They rightfully created quite high competition for gas heating appliances.

But the induction boiler itself is a very expensive “pleasure”. Therefore, many home craftsmen are interested in the question of whether it is possible to make an induction heating boiler with their own hands. It turns out, yes, this is a feasible task, but it requires a certain skill and knowledge, especially in the field of electrical engineering.

Let's immediately make a reservation about the following. The author of these terms is not a supporter of “home-made products” in the field of electrical equipment operating with life-threatening voltages. Therefore, this publication should be considered as an overview of possible options, but not as a step-by-step guide to action. You should very soberly weigh your strengths, knowledge and capabilities before embarking on such a task.

How to make your own induction boiler

Now about how to make an induction boiler with your own hands. If you do everything yourself, you need a lot of knowledge. For example, two electronics engineers tinkered for more than six months, transferred a lot of spare parts, and spent a lot of money on them. In the end, the working installation was assembled, we were very pleased with the result, but they only posted photos.

This is what two electronic engineers created

Manufacturers' websites contain only general information demonstrating operating principles and no diagrams. It is, in general, understandable.

Those models that propose to make: fill a plastic pipe with pieces of wire and wind the wire on top, may work, but are clearly unfinished. Serious protection is needed: the coil turns are on top, and current runs through them. And from the 220V network. In addition, there is no temperature control, which is fraught: the plastic melts. It is also necessary to calculate the speed of movement of the coolant and much more. In general, it is unsafe.

This is the whole diagram of a basic induction boiler, which they suggest making with your own hands

Below is a video that presents one of the options for such a homemade induction heating boiler. It is simple to perform:

- Metal elements are stuffed into a thick-walled plastic pipe (in the video - polypropylene with aluminum reinforcement). In some cases these are small pieces of metal wire 5-7mm in diameter, in this video they are magnetic fechral wire, which will not rust, but will be magnetic.

- A stack is placed on both sides of the pipe. It will not allow metal elements to fall through.

- Fittings are installed at both closed ends, with the help of which the boiler (now a boiler) will be installed into the system. An approximate installation diagram is shown in the figure.

Connection diagram of an induction boiler to a heating system

Please note that a security group is required. According to the author of this boiler, the water heats up poorly

Requires more power (he has about 1.8 kW and needs 3 kW)

Copper wire is wound onto the pipe itself. It is advisable to find enameled wire. You need to make 90-100 turns, it is advisable to maintain the step. Well, try to cover the coils with something. For example, as in the previous version from the video (it was clogged with pieces of wire). After which you need to integrate the boiler into the heating system, start circulation and only then connect the coil to the power supply. Without coolant, the pipe will melt very quickly.

According to the author of this boiler, the water heats up weakly. It requires more power (it has about 1.8 kW and needs 3 kW).

Is the induction heating method really effective and reliable?

Before you buy or start making an induction boiler, it is worth understanding how effective this heating method is. In specialized shopping centers you can hear only positive characteristics of systems operating on this principle from sales consultants. However, not everything they say is 100% true. And these heating units have their own so-called “pitfalls”.

Sellers operate with a whole list of theses, trying to increase sales of boilers operating on the induction principle:

- For example, it is a common statement that the operating principle of these devices is an innovative development.

In reality, this is not true, since electromagnetic induction was discovered back in 1831 by the English experimental physicist Michael Faraday. In the second half of the twentieth century, induction systems were successfully used in the metallurgical industry.

From this we can conclude that these devices can hardly be classified as innovative technologies. However, this also has its own “plus”, since such a system has already been time-tested and proven to be effective.

- The next important quality that sellers focus on is the cost-effectiveness of using an induction boiler. It is usually stated that this type of unit consumes 25-30% less energy than other electric heaters. Can we agree with this?

Prices for induction heating boilers

induction heating boiler

Probably not, though. Any electric heater consumes electricity according to its power specified by the manufacturer in the technical data sheet. That is, to generate one kilowatt of heat, in the most ideal case (at 100 percent efficiency), the device needs to consume a kilowatt of electricity. Moreover, even with the above parameters, the efficiency of the unit may be lower, since much also depends on the specific operating conditions of the boiler.

Induction boilers, largely due to the “reactive” energy generation based on the principle of self-induction, have high efficiency rates tending to 100%. But you still shouldn’t expect some kind of “fabulous” savings from them.

The time it takes to heat the coolant to the desired temperature depends on the power and efficiency of the heating element. It must be said that part of the expended energy, one way or another, is wasted, since the materials from which the device parts are made have non-zero resistance. However, heat loss from the operation of an induction boiler does not go “down the chimney”, but remains in the room where the device is installed, which is often their obvious advantage.

So, the conclusion suggests itself is that it is unlikely that you will be able to save any serious money on electricity when using an induction boiler. But their efficiency and heating speed are really high.

- Despite the approximate service life specified in the data sheet, established by the manufacturer (not to be confused with the warranty!), sellers assure that the induction heating boiler will last at least 25 years. It is necessary to agree that this information is reliable if the electronic control unit is made of high quality. The unit includes semiconductor elements, which can still fail. As a rule, manufacturers provide a ten-year warranty on the components of the electronic unit. However, quite often they work perfectly for 25–30, or even more years.

But in the boiler itself, by and large, there is simply nothing to break. Thus, the primary winding, usually made of copper, has a large margin of safety and will last a long time if it is properly cooled (and this is ensured by coolant circulation).

The core rod or the material of the internal channels, of course, will begin to deteriorate over time, since it will be constantly adversely affected by the aggressive environment of the coolant, as well as by alternating cooling and heating. However, for it to become completely unsuitable for use, more than a dozen years must pass.

Considering the design of a boiler operating using an induction circuit, we can conclude that it is much more reliable and durable than heating devices that use heating elements as heating elements.

Prices for heating boilers

boiler

- Another quality that is a plus for an induction heating device is its silent operation - supposedly this distinguishes it favorably from other heating units. The question arises, is this so?

But here, exactly the opposite is true. Yes, electric heating units operate silently, since during their operation no acoustic vibrations are created and no mechanical components are used. However, it is during the operation of the induction device that low-frequency vibrations can be clearly felt, which can irritate people with acute hearing. This negative phenomenon is minimized in vortex-type boilers, in which the supply voltage to the primary coil is first converted to high frequency.

In addition, if a low-quality circulation pump is installed in the system, it can also become a source of mild annoying noise. But this already applies to all heating systems, regardless of the type of boiler. But the modern range of pumps makes it possible to purchase a completely silent model.

- The buyer can evaluate the compactness of the boiler visually. We can say that this unit consists of a piece of pipe of a certain length, which does not take up much space, unlike other heating devices. True, the mass of an induction boiler is usually quite impressive, which means that reliable brackets will be required.

Induction boilers are usually very compact.

And they are often even placed in “batteries”, putting into operation, as needed, only the number of devices required under given operating conditions. However, do not forget that space will be required for the accompanying elements of the system, as well as the wiring of circuits and the installation of collectors, if required by the circuit. If it is necessary to heat a fairly large area of the house, then several induction devices are often installed, and the entire system will require a lot of space.

- The statement that boilers of this type are completely safe, and that this quality of boilers is more pronounced than that of their heating element counterparts, is incorrect. The operating safety of these two types of heating devices is approximately the same, and depends on the correct connection and the performance of the systems designed to protect them from extreme situations.

For example, if a coolant leak occurs in an induction device, and the electromagnetic field does not turn off in time, and heating of the internal core continues, then the housing and fastenings can melt literally in a matter of minutes. Therefore, when purchasing a device or designing it yourself, you need to pay attention to the automatic shutdown of the unit in the event of an emergency.

Induction boilers are reliable and efficient devices that do not take up much space, but their advantages are often significantly exaggerated

As you can see from the information presented above, induction boilers, just like other heating units, have their own shortcomings, and they are not unique devices that allow you to pay mere pennies for heating. However, their effectiveness is beyond doubt. And yet, thanks to the compact size of the boiler, it can be placed in an apartment, for example, in a niche, so that it will be almost invisible.

Operating principle

The operation of induction boilers and other heating devices of this type is based on the ability of conductive materials to heat up under the influence of eddy currents created as a result of electromagnetic induction.

The source of induction is a high-frequency alternating current passing through the primary winding of the heating device, made in the form of a coil. The heating element placed inside the coil plays the role of a secondary short-circuited winding. It converts electromagnetic energy into thermal energy.

Eddy currents also occur at an industrial frequency of 50 Hz, but the efficiency of the heater will be low, and the operation of the device will be accompanied by strong hum and vibration. When the frequency increases to 10 kHz and above, the noise disappears, the vibration becomes imperceptible, and the heating increases.

This article talks about how to build stoves for a wood-burning cottage with your own hands. You can learn about the features of operating a wood-burning boiler with a water circuit here. You can see the features and advantages of the design of a brick stove with a water circuit: https://gidpopechkam.ru/pechki/kirpichnaya-vodyanym-konturom.html

Results

So, the efficiency of induction boilers is approximately 99%, they operate silently, using any liquid heat carrier, they do not require maintenance, and it is also safe and practical. Although such a boiler is quite expensive, such costs are recouped. And if you create it yourself, it will be even more profitable.

Of course, the choice is yours, but it’s better to contact specialists who will tell you whether such heating is suitable for you. But, in general, induction boilers are an excellent alternative to traditional heating systems.

Another option

To make it you will need a plastic pipe with a diameter of 63 mm and a length of 50 cm, steel wire with a diameter of 3 mm, a copper conductor with a cross section of 2.5 mm2 and a length of 11 meters.

- The steel wire is cut into 7 cm pieces. It is placed in a piece of plastic pipe.

- Two adapters for a 1″ threaded connection are soldered into the pipe. Coarse filters are screwed on both sides through 1″ nipples.

- Parallel strips of PCB are glued to the surface of the tube.

- Turns of copper conductor are laid on them. The distance between them should be the same. After this, they are filled with epoxy resin.

- The product is mounted in a heating system pipe and connected to a high-frequency voltage source.

The number of turns, as well as the length of the conductor, will have to be selected experimentally, since the length and capacity of the system is different for everyone. The steel wire, heating up from inductive currents, will give off temperature to the water that will pass through the pipe. This option cannot be used as a stand-alone device, but it will be an excellent addition to the main source, which will allow you to save on coolant consumption.

Advantages and disadvantages of plastic pipe boilers

Advantages of induction boilers:

- The water in the heating system heats up twice as fast and has double heating.

- Inertia is much less than when using gas or other fuel boilers.

- Magnetic induction prevents scale formation.

- Quiet operation.

- There is no need for cleaning and maintenance of the boiler.

Like any phenomenon or design, induction boilers also have their disadvantages:

- Before use, you must make sure that the core is completely filled with water and that the water level should not drop during operation, otherwise the plastic will simply melt.

- The boiler can only be used in a closed forced heating system.

- High cost of industrial designs.

The boiler power must provide the proper level of heating in the room. The most acceptable formula: 1 kW per 10 m 2.

An induction boiler is an excellent alternative to other heating devices. If you have the opportunity to make it at home, the skills to work with tools and assemble equipment, and the ability to install heating equipment, then you can make such a device yourself. If you are not confident in yourself, then it is better to buy a ready-made boiler and invite specialists to install it.

Watch the video that shows how you can make an induction electric boiler yourself:

https://youtube.com/watch?v=F6yIXht5gks

This video shows the process of making a boiler for an induction cooker:

Conclusions and recommendations

We deliberately presented options for induction water heaters of simple design, so that anyone could make such a unit on their own. But the question remains whether it is necessary to engage in this matter and waste your own time. There are a number of objective considerations in this regard:

- Users who do not understand electrical and radio engineering are unlikely to be able to increase the heating power above 2.5 kW. To do this, you will have to assemble a frequency converter circuit.

- The efficiency of the inductor is no higher than that of other electric boilers. But assembling a heater with heating elements is much easier.

- If you don’t have an induction panel lying around at home, you will need to buy it for about 80 USD. e. This is how much cheap Chinese products cost in online stores. Ready-made electrode boilers with a power of up to 10 kW are sold for the same money.

- Electric stoves are equipped with automatic safety systems that turn off the household appliance after 1 or 2 hours of operation. This causes inconvenience during operation.

- If, for various reasons, the coolant leaks out of a homemade heat generator, then the heating will not stop. This is fraught with fire.

Of course, you can do without expensive purchases, thoroughly understand the design and make an induction heater from scratch. But you won’t be able to do everything for free, because you will need to purchase components for the circuit. Please note that the bonuses from such a heating unit are small, so it is not advisable to seriously undertake its manufacture for the purpose of heating a private home.

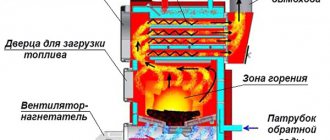

Mechanism of operation of an induction boiler

By design, such boilers are a kind of electric inductors, which include two short-circuited windings.

Thus, the internal winding is responsible for converting incoming electrical energy into special eddy currents. An electric field is formed in the unit, which subsequently enters the secondary coil. The latter simultaneously performs the functions of the heating element of the heating unit and the boiler body.

Diagram of an induction vortex unit for a heating network

The secondary winding is responsible for transferring the generated energy directly to the coolant of the heating system. Special oils, antifreeze liquids or clean water are used as coolant in such installations.

The internal winding of the heater is exposed to electricity. As a result, some voltage appears and eddy currents are formed. The created energy is transferred to the secondary winding, after which the core begins to heat up. Once the entire surface has been heated, the coolant will begin to provide heat to the radiators, and they will begin to provide heat to the heated rooms.

Important notes on installation and use of the boiler

Homemade induction boilers are extremely easy to assemble, install and operate. However, before you start using this kind of heater, you need to know a few important rules, namely:

a homemade induction heating installation is intended for use only in closed-type heating systems, in which air circulation is ensured by a pump;

Closed heating system

the wiring of heating systems that will work in conjunction with the boiler in question must be made of plastic or propylene pipes;

Plastic pipes for heating

To prevent the occurrence of various kinds of troubles, install the heater not close to the nearest surface, but at some distance - at least 30 cm from the walls and 80-90 cm from the ceiling and floor.

It is strongly recommended to equip the boiler pipe with a blast valve. Through this simple device, you can, if necessary, rid the system of excess air, normalizing pressure and ensuring optimal operating conditions.

Explosion check valve

Thus, using inexpensive materials and simple tools, you can assemble a complete installation for efficient space heating and water heating. Follow the instructions, remember the special recommendations, and very soon you will be able to enjoy warmth in your own home.

Main structural elements

In general, an electric boiler consists of the following components:

- Heat exchanger: This is a reservoir connected to the heating system in which the working medium flowing through it receives thermal energy.

- Heater: An element in a heat exchanger in which electrical energy is converted into thermal energy through resistance.

- Electrical circuit: a set of parts due to which electric current appears in the heater.

- Automation unit: monitors the temperature of the coolant using sensors and, if necessary, turns on or off the electric boiler.

All of the above is placed in a steel box with thermal insulation - the housing.

Heating boiler made of induction stove

But those who want to make an induction boiler do not necessarily have to assemble the heater themselves. All you need is to buy an induction household hob. It costs $50 and up. Next are the options:

If you have a metal or cast iron radiator (aluminum ones are not suitable), you can simply lean the tile against the radiator and turn it on. The radiator begins to heat up, spreading heat throughout the room. In a room of 20 m2, the tiles were set to 0.8 kW. At -20 o C in the room it was +25 o C. This is not the most effective method, but quite good. And checking its operation is as easy as shelling pears. Especially for those who have tiles.

We can’t say that this is a boiler, but it heats the room well, and draws little electricity

The second simple option. Weld a “cauldron” of metal. Just a container for water. Supply cold water on one side, take heated water from the other, install a circulation pump. Place the same tile against one of the walls, which will heat the water in the container. It works. As proof, see the video below.

This version of a boiler from an induction cooker can really be made by anyone.

Just pay attention once again. For a liquid or surface to heat up, the metal must be magnetic.

Good stainless steel (non-magnetic) or aluminum are not suitable: Foucault currents do not propagate in them. In addition to the fact that you almost don’t need to do anything, this option is good because the tile has a control and safety system that will turn off the device in case of overheating.

And another model of a boiler on a tile. It's a different approach, but the idea is the same.

Of the three presented options for homemade induction heating boilers, two are not really boilers (or not boilers at all - depending on how you look at them). But at the same time, you can heat rooms with their help. Methods with an induction cooker are easy to test, especially easy for those who have such a cooker. To increase heat transfer in the tile + radiator option, you can arrange a fan (if necessary). But how well it works needs to be tested from your own experience.

When is it better to make your own?

Making a boiler with your own hands is advisable for houses with seasonal residence. As a rule, low-power equipment is installed in such buildings, and there is no need to spend huge amounts of money on purchasing a ready-made model. The costs of making the device yourself are minimal.

Even for a home-made unit, it is easy to select additional automation units that allow you to set the required temperature parameters. Such a device will not only allow you to set the desired parameters for a long period of time, but will also provide remote control of the entire heating system.

Strengths and weaknesses

The large dimensions and difficulty of making a drawing of a long-burning solid fuel boiler with your own hands makes it favorable to use such devices only in large cottages. As for small dachas, it is recommended to choose more economical options for them.

The main advantages of long-burning TT boilers are:

- High efficiency (about 95%)

- Autonomous heating.

- Economical.

- Reliability and durability.

- High efficiency.

- Availability of fuel.

- Environmentally friendly.

- Wide choice of fuel (coal, firewood, sawdust, pallets).

There are also disadvantages:

- Large dimensions.

- The need to equip a separate boiler room.

- Complex design of a long-burning wood-burning boiler.

- Need for constant maintenance.

Advantages of homemade units:

- Cheapness.

- Versatility in terms of fuel used.

- Possibility of subsequent modifications to increase efficiency and add power.

The most difficult thing is to make the structure cylindrical: for this you need to use a rolling machine. If you don't have one, there is an option with old propane tanks. Any pipe of a suitable cross-section will also work: the thickness of the metal walls must be at least 5 mm. In villages they are accustomed to being content with small brick stoves, which demonstrate good efficiency in heating one-story houses and cottages. If you need to heat a large cottage, then in this case you will need a large supply of fuel. In addition, large temperature changes cannot be avoided as you move away from the stove, and caring for it is much more difficult than a solid fuel boiler.

Vortex induction boiler is the best way to reduce heating costs

Vortex heater

Another advantage of using electric heating is the ease of maintenance of heating systems mounted on electric boilers. However, the convenience of using electricity for home heating is becoming an increasingly expensive way to obtain heat in the home - paying the bill for electricity consumption with each heating season becomes unaffordable for many.

Home owners are beginning to look for an alternative to electric boilers, the design of which is based on a standard heating element.

Induction electric boilers are gradually gaining popularity, also converting electricity into heat necessary for heating rooms. However, their design makes it possible to use energy much more economically, which significantly reduces the ongoing costs of maintaining a house during the heating season.

Energy savings occur due to the rapid heating of the heating system coolant. This happens thanks to an induction device that replaced the traditional heating element in the boiler.

In addition to reducing heating costs, these boilers have a significant number of advantages over other electric boilers - high efficiency, long service life (at least 25 years) and lack of scale.

Internal device

Structurally, an induction electric heating boiler is a transformer enclosed in a welded metal shell. Under the casing there is a heat-insulating layer. The coil is located in a separate compartment, hermetically sealed from the working space. This placement is safe because it completely eliminates contact with the coolant. The core consists of thin steel tubes with a toroidal winding.

Please note that a heating boiler made from an induction stove does not have heating elements, which is fundamentally different from traditional heat generators equipped with heating elements. Its design features ensure uninterrupted, highly efficient operation of the heating system for a very long period of time.

DIY induction boiler

Do you want to furnish your home with efficient and at the same time cost-effective heating? Then be sure to pay attention to modern induction boilers. Such units are characterized by high productivity and at the same time have an extremely simple design, so you can easily handle the assembly of an induction heating boiler with your own hands

The operation of the equipment in question is based on the use of inductive electrical energy.

Such boilers are absolutely safe and environmentally friendly. During their operation, no by-products are released that can harm humans and the environment.

Contents of step-by-step instructions:

Homemade induction heating boilers

With the topic of the efficiency and economy of induction boilers, the further we go, the more incomprehensible everything becomes. The discussion is active, including on many forums. But only those that prove that these savings are inventions of unscrupulous sellers remain open and accessible. Others become inaccessible.

The main argument of opponents of the use of induction boilers is the law of conservation of energy. Moreover, it is interpreted as follows: no matter what heater is supplied with 1 kW of electricity, it can only generate slightly less than 1 kW of thermal energy. A little less - due to losses and not one hundred percent efficiency. Because the heating element, an induction heater will spend the same (or almost) amount of electricity to produce one amount of heat. And since induction boilers are much more expensive, buying them is a waste of money.

Does an induction boiler save electricity or not? That is the question…

There were also opponents. There are few of them, but they exist. This theory is not simple, and requires deep knowledge. But the essence of the objection is this: when a heater consumes 1 kW of electricity, it produces 1 kW of energy, but not all of this energy is thermal. And in terms of the production of thermal energy, induction heaters turn out to be much more productive than traditional heating elements. And direct confirmation of this is household induction cookers. They require less electricity to heat the same amount of water. This is easy to check: take two tiles of the same power - induction and with a spiral. Then put two identical pots of water, turn them on and note how much time each unit takes at the same power. The shorter the time before boiling, the less electricity is spent.

A little theory

Anyone can make this device

Many people know that induction cookers exist, but not many know about the principle of their operation. And this is very simple - a special coil of the plate generates magnetic fields of a certain frequency, which, when exposed to metal, excite electric vortices in it.

The latter, in turn, heat it up due to the resistance of the metal. This is how kitchen utensils: pots and pans are heated. The main condition in this process is a metal with magnetic properties, for example, stainless steel, cast iron and iron, but aluminum and other non-ferrous metals will not heat up.

Simple option

The simplest boiler can be assembled at home if you have the skills to work with a welding machine, as well as an angle grinder. Before making a boiler, you need to prepare a square metal pipe measuring 50x50 mm with a wall thickness of 2 mm. You can see the manufacturing process in the Video section.

The dimensions of the pipe and the shape of the pipe may differ, but the wall thickness should not be small.

- Using a grinder, you need to cut the profile pipe into pieces 50 cm long. You will need 5-6 pieces (everything will depend on the width of the induction cooker used).

- Additionally, you need to prepare two elements 25 or 30 cm long (it all depends on how many sections were selected).

- Parts of 50 cm are welded together. All of them must be positioned vertically. First, you can fix them with tacks, and then thoroughly weld all the joints.

- Two additional blanks need to be cut off on one side to form a U-shaped profile.

- To the finished module of 5 elements, two sections with one wall removed are welded onto the lower and upper parts. Their goal is to combine all the individual sections into a circuit.

- Next, you need to hermetically seal the resulting holes on the sides.

- The inlet and outlet pipes are inserted. They should be located diagonally, one at the bottom, the other at the top. You can use a ¾" pipe. Two threaded outlets are welded to them to make it easier to install into a finished heating system.

- All seams after welding are cleaned using a grinder. The finished structure is degreased and coated with paint.

- The device is mounted in the installed circuit. The return flow of the coolant is supplied from below, and the outgoing pipe is supplied from above.

- The heating element is a conventional induction cooker. It is necessary to purchase a stove with the ability to adjust the current and temperature.

- It is located behind the boiler close to its back wall.

- Water passing through this structure has time to warm up. The system must have an expansion tank, as well as a forced circulation pump.

The same option can be made horizontally. To do this, we need a 20x25 cm profile pipe. Its two ends are welded using metal plugs to form a closed vessel. Two holes are cut in the upper wall, an air release valve is installed in one, and a pipe through which water will flow into the system is installed in the other. The return pipe cuts into the side.

The internal structure of an induction heater and its operating principle

The design of such a device, created to generate heat energy, is in its simplest form similar to a transformer.

Like a transformer, an induction generator consists of short-circuited windings - primary and secondary. The primary winding serves to convert electrical energy into eddy currents, which create an electromagnetic field directed towards the secondary winding. The secondary winding is both the inductor body and the heating element, which transfers the received energy to the heating system. The coolant can be any electrically conductive liquid, from ordinary process water to oil and antifreeze.

Since a vortex induction heater (or simply a heater) does not emit fuel decomposition products during operation, it is the safest among various types of heating equipment used to provide heat to buildings for various purposes. Such a heating system guarantees a favorable composition of the atmosphere, which means maintaining its environmental purity.

The heating system starts working immediately after voltage is applied to the internal winding. The resulting electromagnetic field directs eddy currents to the surface of the core located outside.

Their density increases almost instantly, heating the surface of the core, and then the entire element. This heat serves to heat the coolant circulating in the boiler.

It should be borne in mind that the device fits into the heating system using two pipes. The lower one serves to supply cooled coolant. It is mounted at the entrance to the boiler, and through the second pipe the heated coolant is directed into the heating system.

The supply of heated coolant is carried out due to hydrostatic pressure. Since the coolant constantly circulates in the system, discharging hot liquid into the heating system, the possibility of overheating of the equipment is completely excluded.