Features of solid fuel boilers

Gas supply and centralized electricity supply are still not available everywhere in Russia. Gas is cheap only in capital cities, and even there it is becoming more expensive. Electricity is expensive everywhere.

Communication networks leave much to be desired: power outages and sudden voltage changes are commonplace outside the city. It is not always possible to connect to the main gas, and purchasing liquefied gas in cylinders is an energy-intensive business.

Heating with a solid fuel boiler has several advantages:

- you can choose the type of fuel that is cheapest in your area - firewood, peat, coal, wood waste, etc.;

- solid fuel boilers are the cheapest in the category. Long-burning models are more expensive, but their thermal efficiency is higher;

- a large assortment. Automation and auxiliary strapping elements can be purchased separately if necessary;

- Unlike gas units, the installation of a solid fuel boiler does not require permission from the local administration.

Now about the cons:

- fire hazard. But both gas and diesel models have this drawback. And in case of problems with wiring - even electrical ones;

- the need to monitor the amount of wood/coal in the firebox. A solid fuel boiler cannot be simply “turned on and forgotten”. It is less often necessary to add fuel to pellet and long-burning boilers, but in this regard they are not very autonomous;

- The combustion process of solid fuel is difficult to control (for other units it is enough to turn off the gas valve or turn off the electricity). The inertia of solid fuel boilers is high, and so is the entire system.

Solid fuel boiler design

Video description

Operation of a boiler using peat briquettes in the video:

Pellets

Occupying an intermediate place in terms of calorific value between coal and firewood, this type of fuel combines their advantages:

- ensures almost complete combustion with minimal solid residue in the form of ash;

- has a relatively low temperature of exhaust combustion products;

- allows you to fully automate the heating system, including the supply of fuel from the bunker to the combustion chamber, and does not require daily maintenance.

If we talk about prospects, this is one of the most attractive types of fuel - renewable and environmentally friendly, which does not harm the environment when burned.

Types of solid fuel boilers

Types of solid fuel heating boilers differ in the type of fuel:

- firewood;

- coal;

- pellets and briquettes;

- peat;

- wood processing waste;

- universal boilers with two or more fireboxes.

Calorific value of solid fuel

In addition, there are combined models for two or more energy carriers: wood + electricity, wood/diesel/gas, etc. Their purchase is justified if:

- In your area, the two energy sources are equally available and inexpensive. If you run out of firewood, switch to gas; if there are power outages, switch to firewood, and so on;

- in order to save money. For example, if you have a two-tariff payment for electricity, heat with wood during the day, and at night (when electricity is cheap) switch to fully automated electric heating.

Pellet boiler There are classic and long-burning t/t boilers. Types of the latter:

- with top ignition. When the flame spreads from top to bottom, the filling burns out more slowly;

- with an extended firebox and limited air supply. Horizontal flame propagation is also slower. By reducing the oxygen needed for combustion, you reduce the intensity of the flame;

- pyrolysis chambers are equipped with two chambers: in one the fuel burns, in the second the gases released during combustion are burned. The thermal efficiency of these units is the highest, but they are also more expensive than others.

Popular manufacturing companies

There are several reputable manufacturers that are preferred by clients:

- Stropuva - a Lithuanian brand that provides longer burning from one load of firewood. It has an interesting barrel-shaped design, which makes it possible to install the device in a small room. Lithuanian devices are quite expensive, but they are durable.

- Zota - for those who like to use firewood as fuel, the Russian brand is suitable. The devices are small in size and low in power. But they are also reliably constructed and affordable.

- Burzhuy-K is a Russian company that produces boilers independent of power supply, operating on pyrolysis. The cost of boilers varies from 40,000 to 76,000 rubles. The boilers have high power and retain heat for a long time.

Solid fuel boiler piping

A solid fuel boiler rarely includes a circulation pump, automation, or a safety group. The owner purchases all this himself, guided by the characteristics of his heating system.

Regardless of the type of wiring, the pipeline should be equipped with safety devices (see below). The second stage is to ensure the functionality of the system and comfort during its use. A couple of devices worth mentioning here:

- heat accumulator. Thanks to its operation, there will be no sudden temperature changes in the house during the boiler reboot process. This is a large volume tank that is installed between the boiler and the system on the supply pipe. To regulate the temperature at the outlet of the tank, install a mixer with a three-way valve;

- an indirect heating boiler for domestic hot water is connected in parallel to the heating system. They are equipped with a mixer and their own pump so that when moving from the boiler to consumers, the water does not have time to cool down.

Connecting a boiler with a heat accumulator

Whether or not to purchase a pump if DHW is not provided depends on the wiring.

Let's consider its main types.

How to make remote control of the heating of a country house with your own hands

The best option would be a GSM socket; I consider this modern device to be the easiest to install to control the heating system yourself. The unit has a built-in temperature sensor, and a maximum load of 4 kW is enough for small country houses.

All radiators must be connected in series, then the device is inserted into a regular socket, the smart heating temperature sensor is able to independently turn off the created system after heating the room to a given temperature, and the owner can do this from any gadget.

Open system with natural circulation

This installation scheme is considered the safest for a solid fuel boiler: even with a sharp increase in pressure and temperature, an accident is unlikely. Differences between an open system and others:

- the circuit uses an open expansion tank (it is installed at the highest point of the pipeline);

- There is no circulation pump. Water moves through pipes due to natural gravity. For this design, pipes of a larger cross-section are selected and installed at a slight angle so that the water moves by gravity.

Advantages of open systems:

- Since there is no pump, the heating does not depend on the mains. In suburban conditions, problems with electrical networks are common: interruptions due to broken wires, power surges;

- equipment for piping will cost less (there is no pump, an open tank is cheaper than a membrane one).

Minuses:

- installation is technically more difficult - you need to maintain the required slope of the pipes, install the piping elements at a certain height;

- oxygen inevitably enters the system, which leads to corrosion of pipes and metal fittings;

- for the same reason, airing of the circuit is inevitable;

- the coolant partially evaporates, it has to be replenished;

- even with large pipe diameters, natural circulation is slower than forced circulation. It is necessary to equip all heating devices with control valves, to minimize the number of shut-off valves, but even in this case, heating of the circuit will be uneven.

Natural circulation system piping

Experts recommend adding mineral oil to the expansion tank, a layer of 1-2 centimeters. This will reduce the flow of oxygen into the system and reduce the evaporation of coolant.

How to save coal

The issue of saving coal is relevant to everyone. Even if we consider an average of 3 tons per winter for heating a small house, this comes out to 10,500 rubles at the rate of 3,500 rubles per ton.

- This is high-quality home insulation that needs to be taken care of before winter begins. All cracks should be sealed, windows, and the attic floor should be covered with damask, coal slag or other insulating materials so that heat is not lost through the mezzanine.

- Water heating with labor laid throughout the house + “rough” (warm wall). A large yielding surface a priori saves energy consumption. If you run one pipe along the wall, you will get a double effect - heat transfer from both the pipes and the wall, which will constantly heat up.

- Burn residues can be reused. If you sift the ash after combustion, then a third of it will be unburnt coal, which can be put back into the furnace. Sift the ash and ash on a large sieve, leaving large fragments behind.

- Be sure to use the valves to adjust the draft. If there is no such valve, the fuel burns out very quickly (the draft is high) and the house also quickly becomes hot, and then everything also cools down instantly. In the absence of a valve, fuel consumption increases at least twice.

Of course, it is important what kind of winter it will be - warm or cold, but in general, you can optimize coal consumption and achieve excellent heat performance in the house.

Closed circuit with natural circulation

There is no pump, but the expansion tank is different - a closed (membrane) type. The system configuration will be the same as in the previous case (large cross-section pipes installed at an angle), but some of the disadvantages of an open circuit can be avoided:

- oxygen does not enter the pipeline through the tank, i.e. slower airing and development of corrosion of internal walls;

- you will not have to regularly restore the amount of coolant in the circuit.

When choosing this type of wiring, consider:

- the tank capacity must contain at least 10% of the coolant volume;

- A safety valve is required on the supply pipe. When the pressure in the system exceeds critical (i.e. more than three atmospheres), the valve discharges excess coolant;

- An air vent is installed at the top point of the circuit.

ZOTA Pellet 100A

The model is of the pellet type, works for several days without requiring additional fuel, is equipped with a fan, and carries out the process in an automated mode.

Advantages of the device:

- power;

- Efficiency is about 90%;

- convenient form (screw) of fuel supply;

- presence of an electronic control system.

Disadvantages are the significant weight of the device and the need to connect it to an energy source.

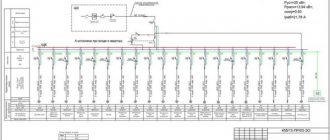

Installation diagram of a solid fuel boiler with a circulation pump

A system with a pump can only be closed. The advantages of forced circulation are obvious:

- high speed of coolant movement, uniform heating of all rooms;

- large diameter pipes are not required;

- There are no difficulties in installing the pipeline: there is no need to maintain a slope, the height of the membrane tank is not important.

Since the pressure in a system with forced circulation is higher, the requirements for the safety group are also increased.

Installation of such a circuit provides the possibility of switching to natural circulation in the event of a pump breakdown or power outages: the pump is connected in parallel, on a bypass with shut-off valves.

Main pipe and bypass pump

Most often, the pump is inserted into the pipeline in the return pipe section near the boiler; this is where the temperature is lowest. This allows you to save the resource of the device and is safer for the entire system: when installed on the supply pipe, if the water in the boiler boils, the vapors will block the circulation, which can lead to an accident.

On the return side, a filter is installed in front of the pump.

ZOTA Topol M 20

Reliability and elegant design are the distinctive features of this model. Heats a room of one and a half hundred square meters. m.

Advantages of the device:

- good thermal insulation;

- minimal heat loss;

- autonomous control;

- Efficiency is above 90%;

- use of different types of fuel.

The weight of the unit is considered its disadvantage.

Collector wiring

In a long, highly branched pipeline of a large cottage, one pump may not be enough. In this case, two or even more of them are installed, for each circuit. Separately heated floor, radiators, hot water supply. Since the temperature of heated floors is initially low (within 50 degrees), you can install a pump at the entrance to the circuit.

The optimal wiring option for a large house with several circuits is collector (radial). Each circuit receives coolant from the boiler through its own pipe. The heat is distributed evenly, the liquid does not cool down, consistently passing through the entire system.

The collector includes at least two combs, forward and reverse. The corresponding lines from the boiler are connected to the ends of the combs, and the forward/return pipes of the circuits are connected in parallel to the fittings on their bodies - radiators and heated floors, different floors, utility rooms, DHW - each with its own temperature regime.

Collector

A pressure gauge and a safety valve are installed at the entrance to the manifold, an air vent is installed on the opposite side on the “hot” comb, and a tap is installed on the “cold” side to drain the coolant from the system. The pipes are equipped with control valves - this is one way to set different temperatures in the circuits. A large house may have several pairs of combs.

Another way to set different modes is a hydraulic arrow. A vertically placed section of large cross-section pipe is connected to the direct pipe and the return pipe of the boiler, and circuits are connected to the body at different heights. The higher the connection, the hotter the coolant.

In small circuits, the temperature can be adjusted as follows: the free ends of the combs are connected by a bypass to a shut-off valve. When the valve opens, cool water from the return pipe is mixed into hot water from the supply pipe.

Which home heat is more economical?

I can say with confidence that heated floors will be the most economical in a country house, because hot air is generated from below and gradually rises upward, uniformly heating the entire area of the room.

Walking on such a surface is very comfortable, especially if the floors are filled with materials that are cold in structure or have tiles on them. To install this type of system, you can use water or antifreeze as a coolant and elements powered by electricity of your choice.

Security group

Functions of control and safety devices:

- protection of the pipeline from depressurization due to a sharp increase in pressure;

- protection against overheating of the boiler itself;

- temperature control;

- preventing condensation formation. This usually happens due to too large a temperature gap between the supply and return. The optimal temperature delta is 20 degrees.

This group of devices includes:

- safety valve for releasing excess pressure/excess coolant;

- control pressure gauge;

- air vent;

- emergency heat exchanger;

- control fittings, incl. thermostatic valves.

Security group

ACV TKAN 100

The unit provides heat to an area of three hundred square meters. m. The undoubted advantages include:

- Efficiency (above 90%);

- low fuel consumption;

- presence of a fire damper;

- complete safety.

The only drawback of the device is its high cost.

Installation features

Solid fuel boilers are not environmentally friendly equipment; their installation requires a boiler room. During installation, a number of rules are observed:

- At least 1 meter of free space should be left from the firebox to the wall;

- Ventilation ducts must be installed half a meter from the floor and a maximum of 40 centimeters from the ceiling;

- there should be no flammable substances in the boiler room;

- a metal or asbestos sheet of at least 50 by 70 cm in size should be laid in front of the firebox;

- a chimney is installed above the boiler. Recommended chimney parameters are in the boiler instructions.

Chimney of a solid fuel boiler

Inspection hatches should be provided in the chimney pipe for cleaning from soot. A condensate collector is installed at the junction with the boiler. Parts of a metal pipe located in cold rooms (unheated attic, etc.) must be wrapped with thermal insulation material to protect against condensation and icing.

Thermal insulation material for chimneys is basalt wool. All other insulation materials are flammable to one degree or another.

Prices: summary comparison table

| Model | power, kWt | Efficiency, % | Firebox dimensions, weight | Cost, rub. |

| Metal-Fach SMART EKO-20, Poland–Russia | 20 | 90 | 1250x1345x610 mm, 360 kg | 152 000-280 000 |

| Galmet Duo 17, Poland | 17 | 81-86 | 1130x1475x840 mm, 355 kg | 220 000-250 000 |

| ZOTA "Optima" 20, Russia | 20 | 82 | 1290x1590x890 mm, 376 kg | 151 000-211 000 |

| Pereko KSP Duo 18, Poland | 18 | 92 | 1160x1385x845 mm, 370 kg | 283 000-327 000 |

| Heiztechnik Q Eko Lux 15, Poland | 15 | 88 | 350x270x380 mm, 363 kg | 154 000-179 000 |

Ignition and combustion maintenance

The automatic boiler must be put into operation after installing the pipeline system, pressing it with a pressure of 1.25 of the nominal pressure and filling it with water. The further algorithm includes the following steps:

- Check the condition of the chimney.

- Fill the hopper with coal of the recommended quality.

- Using the control panel, manually feed a portion of coal to the burner.

- Place highly flammable fuel (paper, wood chips, etc.) on top of the coal portion.

- Carefully light the paper and add fuel as the flame intensifies.

- In manual mode, turn on the boost fan.

- When the temperature specified in the boiler's passport is reached, switch it to automatic mode.

Further operation of the solid fuel boiler occurs under the control of a processor that controls the frequency of fuel supply, the amount of air injection, and the coal consumption in the draft control bunker to remove combustion products. In addition to these measures, it is important to follow the recommendations of the manufacturer of complex units aimed at achieving complete combustion of fuel - each type of coal and operating principle of the boiler has its own burner design.

EVAN WARMOS TT-18

The unit heats more than a hundred square meters. It is used for heating both residential and industrial facilities. The only condition for effective operation is the presence of ventilation.

Advantages of the device:

- reliability;

- ease of installation;

- possibility of using a wide variety of fuels.

Disadvantages - quick burnout and the need to manually adjust the dampers.

Combustion structure and stages

A solid fuel boiler is a device assembled in a steel casing and consisting of the following components:

- heat exchanger (coil);

- cleaning hatch and combustion chamber equipped with a door;

- grates (grid);

- thermostat.

The principle of operation is to burn fuel: first it is dried, then it is oxidized and wood gas is released, everything is burned, turning into ash. Once in the chamber, the fuel is distributed on grates, which are located obliquely.

All moisture that is in the fuel evaporates during interaction with the chamber lining and from combustion energy. All combustion is carried out by forced air. Afterburning occurs in the firebox at a temperature of 95°C in the part where air enters from the layer between the lining and the lining.

After combustion, the heat exchanger transfers energy to the coolant. The heat exchanger is a simple device - it is a barrel, a vessel through which pipes go: hot air passes through the pipes and heats the water inside the barrel. Water moves in the coolant automatically using a pump. To regulate the volume of coolant, an inlet and outlet manifold with a temperature sensor are used.

Week "KO-90"

It is considered an ideal option for private homes. “Nedelka” is capable of heating up to four hundred square meters, and works for a whole week on one load.

Interestingly, the disadvantages are a continuation of the advantages of the vice-champion among solid fuel boilers.

Thus, the large weight and dimensions of the installation (minus) make it reliable and safe (plus).

The same can be said about condensate - its presence is a minus, but at the same time an indicator of a high efficiency.

ZOTA Yenisei 12

The deep firebox allows the use of wood material up to sixty centimeters long. Tightly fitting doors prevent combustion products from entering the room.

The possibility of an auxiliary heat source through the use of electricity is provided.

The biggest drawback of manufacturers is the difficulty of servicing the device.

Heating registers

Before installing stove heating, it is worth deciding on the type of heating water circuit, also called a register, heat exchanger, coil or water jacket. Most often it is a rectangular flat container or several tubes connected together.

But before connecting the heating to the stove, two pipes must be welded to the register. The first serves to draw hot coolant from the furnace, and the second supplies cooled water back to the heat exchanger.

The size of the heat exchanger can be determined by the level of heat loss in a particular house. So, if 10 kW of thermal energy is required, the heat exchanger area should be 1 m2. It is worth considering that the oven does not work all day, but for about 1.5-3 hours, depending on the outside temperature. This time should be enough to warm up the water in the heat accumulator. Consequently, to calculate the register area, the daily consumption of thermal energy in the house is determined.

So, with heat loss at home of 12 kW/hour, daily consumption will be 288 kW of energy. Let's assume that the oven operates 3 hours a day. It turns out that every hour 288÷3=96 kW of energy should be released. Then the area of the heating register will be 96÷10=9.6 m2. The shape of the heat exchanger in this case is not important, the main thing is that the surface area is no less than the obtained data.

When using antifreeze as a coolant, you can further increase the volume of the heat accumulator, since water and antifreeze have different heat capacities.

If the buffer tank is additionally insulated, the heat will be retained in it further, and the efficiency of stove heating will increase.

Teplodar Kupper OK 15

One of the best devices among long-burning fuel boilers. One load of wood fuel can work up to thirty hours. With briquettes the installation works for up to two days, and with coal – five.

Heats about 150 square meters.

Experts note the high build quality and cost-effectiveness.

The heaviness of the device practically does not allow it to be moved from one place to another.

Kentatsu ELEGANT-03

Durable and reliable installation. Does not require connection to a power source. Resistant to corrosion and withstands temperature loads well.

The advantages of the unit include:

- reasonable cost;

- relatively small dimensions;

- long service life.

Disadvantages - an inconveniently located tray makes it difficult to clean the device from combustion products (ash).