Photo: installation of protective hatches

Convenient is that for the operation of such cesspools there is no need to equip a ventilation outlet. Gas formation is minimized due to the absence of large accumulations of feces. At the same time, a certain part of the wastewater and gases always goes into the ground. This feature solves two problems at once: reducing the volume of runoff due to gas and the presence of an unpleasant odor in the area.

Video: finished cesspool with overflow https://www.youtube.com/watch?v=tddX0DlE844

Caring for a cesspool with overflows is also not difficult. Cleaning with sewer machines is carried out as necessary. On average, no more than once every six months. Every month you need to check the filters for contamination and siltation. If you use bacterial cleaning, it is recommended to update biological filters every 2 weeks.

Cesspool with overflow: design features, operating principles and diagrams

The problem of waste disposal in a private suburban area has long been solved with the help of an ordinary cesspool, which is a storage tank. The structure has to be constantly pumped out and there is no escape from the unpleasant smell. To solve the problem, it is better to use a more modern independent treatment facility - a cesspool with an overflow. The design is capable of processing large amounts of liquid waste. These are wastewater from shower stalls, dishwashers, washing machines, bathtubs, and appliances used to improve comfort. Therefore, it is necessary to consider the device, operating principle and possible options for an improved sump. This will allow you to avoid the issue of constructing a treatment plant on private territory that is not connected to a centralized sewerage system.

Owner reviews

Mikhail: With the growth of suburban construction, the municipality does not have time to fulfill all cleaning contracts, so when I became the owner of a sewage disposal machine, I quickly found my first clients, and then I hired people and do only accounting and scheduling.

Oleg: For such a business, you need to find areas remote from the city. The main thing is to collect enough orders in one region to save fuel and time. With the right approach, you can get much more than 2.5 million per year.

Semyon: The work is not very pleasant, although in modern conditions it is greatly simplified with the help of new machines. But the benefit from the daily earnings outweighs any shame and disgust. And it’s only to our advantage that people simply don’t want to engage in this type of activity, since they don’t have to compete with anyone.

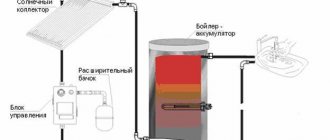

Design and principle of operation of a cesspool with an overflow well

Installation of a treatment plant with an overflow is carried out for the effective disposal of sewage generated as a result of human activity. The degree of processing allows part of the wastewater to be discharged into the soil, onto filtration fields, and used for watering plants.

Sump design with overflow well

A drainage pit with an overflow of simple design is a two-chamber treatment facility. A sewer pipe is used to connect the compartments. The first tank is made in the form of a large container with a sealed bottom and walls. This is a receiver where sewage from a private house enters through a polyvinyl chloride sewer pipe with a diameter of 110 mm. It is laid in the ground.

The second container has the same design as a sewer well with a filter bottom. The lower part of the tank is not a monolithic structure. Liquid can leak through it. It is a filter with a minimum thickness of 1 m. Slag, crushed stone, sand, and gravel are used as the filter element.

An overflow well is an absorption structure. The walls of the container can be solid or have holes. The second option allows you to increase the speed of removal of treated sewage.

The two tanks are connected by a PVC sewer pipe located at an angle. It allows sewage to flow naturally from the receiver into the absorption well. The depth of pipe installation is influenced by the climatic conditions of the area. It should be located below the freezing point of the soil. The diameter of the connecting pipeline is usually 50-110 mm, and its length is determined by territorial features.

A ceiling equipped with a hatch is installed above the drainage pit. Both tanks of the treatment plant are covered with lids. Hatches allow you to monitor the operation of the device and carry out repairs. This design also facilitates pumping out sewage.

The treatment plant is equipped with ventilation. The air duct in the form of a pipe is installed above the level of the drains. It must always be above the sewage horizon, regardless of the degree of filling of the tank. Often the ventilation pipe is installed only in the filter well. However, it is recommended to install ventilation in each compartment of a simple wastewater treatment facility.

Operating principle of a sump tank with overflow well

The installation of a cesspool with overflow in a private countryside area, including summer cottages, allows you to process sewage more efficiently and in less time compared to a conventional waste tank. The operating principle of a septic tank in the form of a sump with an overflow well is quite simple. Sewage from the house first enters the first sealed compartment. In it, wastewater accumulates and settles. This is where heavy particles settle. They have the appearance of silty deposits. Solids are periodically removed from the tank. The sediment can be used by the homeowner during composting.

As waste accumulates, the liquid level in the receiving container rises. After reaching the overflow pipe, sewage flows into another tank without a sealed bottom. The settled wastewater enters the second container already partially purified, for example, by bacteriological microorganisms. The post-treatment process of liquid sewage mass is carried out in the absorption well. It passes through a filter layer at the bottom of the tank. It is the placed bulk materials that additionally purify sewage.

Note! On private property, a drainage pit with an overflow well with a sealed bottom can be constructed. In this case, the second tank is also a settling tank. The sewage is re-settled in the container. They can also be cleaned by bacteria, which feed on biowaste and organic matter. If aerobic microorganisms are used, then the treatment plant must be equipped with a ventilation duct or aerator. After this, the wastewater flows into the infiltrator or onto the filtration field.

When organizing a septic tank in the form of a cesspool, grease traps and filter meshes are often installed. The elements are installed on the overflow pipe. They retain some of the dirt when the sewage mass moves between containers.

Advantages and disadvantages of a cesspool with an overflow well

Almost all designs have pros and cons. An overflow septic tank is no exception. The positive and negative aspects of the treatment plant will help you make the right decision regarding the need to construct the structure.

Advantages of a waste overflow pit

The main advantage of a septic tank with an overflow is the less frequent calls for a sewage truck to pump out sewage. Wastewater that has undergone a purification process in a cesspool is often used for technical purposes. They are suitable for watering crops in dachas, washing paths and other structural elements in private areas.

Additional advantages of a waste pit with an overflow well are the following:

- Good performance, since the minimum volume of treatment facilities of this type is 2 m3. The cesspool has a throughput capacity of 0.2 to 0.5 m 3 per hour. If necessary, you can always increase the number of containers, which will increase the performance of the septic tank.

- Cost savings during the operation of the structure, since special equipment has to be ordered less frequently due to the same multi-stage sewage treatment. Solid elements of wastewater are filtered out already in the first tank, and the liquid medium moves further. Therefore, the formation of solidified masses and overflow of the treatment plant is eliminated. Moreover, part of the wastewater is absorbed by the soil, and a certain amount is simply dumped into the ground.

- Almost complete absence of unpleasant odor. It will completely disappear if special microorganisms are used to process sewage.

Not bad cleaning efficiency, because the waste treatment process consists of several stages depending on the number of containers. Increasing the number of tanks makes it possible to improve the quality of processing and the safety of wastewater for nature.

Conventional cesspools make unpleasant popping sounds when overfilled. Designs with overflow do not have this drawback. This allows you not to monitor the amount of waste. You can use water and not worry that the treatment plant will overflow.

Disadvantages of a sewage overflow pit

The disadvantages of a treatment plant with an overflow well include the complexity of installation. The homeowner needs to accurately calculate the angle at which the pipe needs to be laid to and between the tanks. You will also need to calculate the location of the tanks relative to each other. Another disadvantage is the high cost of installation compared to a conventional cesspool, since it is necessary to construct at least 2 independent wells.

How often should a septic tank be pumped out?

The use of a septic tank is considered the optimal solution when arranging an autonomous sewage system for a country house. Such a treatment facility can easily cope with the collection and processing of liquid waste. At the same time, insoluble compounds gradually accumulate in the sedimentation tank, which have to be removed from time to time.

Independent removal of liquid waste is used quite rarely, given the complexity and danger of this activity, as well as the need to dispose of pumped out wastewater. Therefore, in this situation, it is more advisable to use the services of professional vacuum cleaners. On average, a car is called 1-2 times a year. In this case, the frequency of pumping depends on factors such as:

- volume and model of septic tank;

- number of permanent residents;

- intensity of sewerage operation;

- composition of household waste.

The septic tank must be pumped out in a timely manner, preventing the tank from overflowing.

Economical options for septic tanks with overflow

The price of building a treatment plant with an overflow well is affected by the volume of the pit and the type of materials used to equip the structure. However, you can save money if you choose one of the budget options:

- Using tires to build a drainage pit. It will take approximately 8 pieces of products to equip one tank. Typically old tires are used. They can be taken or purchased at a car service station. The work also uses sealant. It is used to seal joints. Concrete is used to fill the bottom. You will also need to buy plastic pipelines and crushed stone to create a drainage layer. Using such materials, it will be possible to build a structure that will last about 10 years.

- The use of bricks for arranging a cesspool. During the construction of a house, building material is often left behind in a suburban area. It can be used to create a drainage hole. A brick structure will last from 30 to 50 years. The service life is affected by the type of material. It is recommended to use red ceramic bricks. However, it is more expensive compared to white blocks, which are also suitable for constructing a drainage pit. The price of installing a wastewater treatment plant is directly affected by the type of brick. The laying of material in the second section of the cesspool can be done with gaps. This will create permeable walls. In this case, it will also be possible to reduce the consumption of bricks during the construction of a wastewater treatment plant.

- Using boards and barrels to create tanks that process sewage from the home. However, such material is short-lived. Therefore, the structure will last no more than 2-3 years. Typically, reservoirs from boards and barrels are installed if temporary sewerage is created. This treatment facility option is the most budget-friendly, because the homeowner will only have to spend a couple of thousand rubles. It must be remembered that it will not be possible to build large-volume containers from boards.

The most common materials for constructing a cesspool are concrete rings. With their help, it will be possible to create a structure with a longer service life. A cesspool made of concrete rings can be built without the involvement of specialists. In this case, it will be possible to reduce the costs of constructing a treatment plant.

Note! There is a more expensive way to build a sealed compartment of a treatment plant with an overflow - using concrete mortar. The composition is poured into a pre-prepared sheathing, reinforced with reinforcement.

Installation of a pipe for pumping water from a septic tank ↑

In order not to depend on the length of the sewage hose, a pipeline is laid from the treatment plant to allow the removal of wastewater. In this case, the pipe for pumping out of the septic tank must correspond to a certain type and technical parameters.

Why you can’t use pipes for internal sewage ↑

During the process of pumping out liquid, a negative pressure or, in other words, a vacuum is created inside the pipe. At high vacuum, the pipeline tends to compress, and in this situation, the reliability of the system will depend on the strength of the material used and its suitability for working in such conditions.

Conventional gray sewer pipes, which are used for indoor installation, have a wall thickness of 2.2 mm, which is insufficient to work under pressure or vacuum conditions. Therefore, such a pipeline is used exclusively for non-pressure systems.

So, what kind of pipe is needed for pumping out a septic tank? For such purposes, you should use special pressure pipes with increased wall thickness or an orange PVC pipeline, which is intended for outdoor placement.

Orange pipes have a multilayer structure, which increases their strength and reduces thermal conductivity

Correct pipe diameter for pumping concrete waste ↑

The diameter of the pipeline must correspond to the size of the suction pump hose. Theoretically, the size of the pipe for pumping water from the septic tank can be smaller. However, it should be borne in mind that in this case the pump will need more effort to create the required pressure, and it will work with increased load.

Since the diameter of the suction machine hose is usually 100-104 mm, it is advisable to use a 110 mm PVC pipe. The interpipe space can be covered with a wet rag or an adapter can be used to seal the pipeline and hose.

Installation technology ↑

Pipe laying must be carried out taking into account the following rules:

- The pipeline is laid at a shallow depth from the septic tank to the roadway. The slope is towards the septic tank.

- The pipe cuts into the septic tank at a depth of about 1 m and, using an angle, turns down, resting with an oblique cut (45°) on the bottom.

- Exit to the street is realized using a 90° corner, which is located in a small pit near the intended entrance of the sewer truck.

A pit with a pipe for pumping out a septic tank is usually located near the road

Regulatory rules for the construction of a wastewater treatment plant with overflow

The construction of a sump with an overflow well begins with choosing a location for the structure. It is necessary to ensure that special equipment, including a sewer truck, can approach it. The selection of the location is carried out taking into account the distance of the future structure from other objects, since it is necessary to take all measures to prevent contamination of groundwater. The type of soil in the area is also taken into account. If it has high permeability, then the distance to objects increases.

The sewerage structure from the house is installed at a distance of at least 15 m if the site has sandy, gravel, or pebble soil. The distance to a residential building should be at least 10 m when the soil on the territory is sandy loam.

The construction of a treatment plant with an overflow effect is possible only in an area where the soil has good filtration qualities. The construction of an absorption structure is not carried out if the area has rocky or clayey soil.

The construction of a cesspool with an overflow well is carried out from a source of drinking water at a distance of at least 50 m if the soil on a private territory is sandy, and no closer than 30 m when the soil on the site is sandy loam.

The distance between tanks must also be taken into account. The optimal value is 1 m. However, it is possible to create a structure whose compartments are separated by a thick wall. This is where the overflow holes are located. This design of a cesspool with an overflow tank is less efficient.

In order for wastewater to move naturally between tanks, the overflow pipe must be laid with a slope of 150 mm per 1 m. If installed correctly, the treatment facility will operate properly throughout its entire operational life. However, it is still recommended to periodically check the level of sewage in the containers. When installing filters, their performance must be monitored at least once every 30 days.

Operating principle of a sewage disposal machine ↑

The main elements of any sewage disposal machine are: a reservoir (tank) for transporting liquid, a vacuum pump, a pipe for pumping water from septic tanks, sewer wells, drainage systems of car washes, natural reservoirs, etc. The operating principle of such equipment is as follows:

- One end of the pipe is connected to the machine, and the other is lowered directly into a container of liquid.

- Using a vacuum pump, water mixed with sludge is pumped into the tank. The process continues until the septic tank is completely empty or until the tank is full.

- Disposal of reinforced waste products is carried out in strictly designated areas, taking into account environmental standards.

Theoretically, the transport tank and pumping equipment can be installed on any vehicle chassis that meets the technical requirements. In Russia, as a rule, GAZ, KamAZ or ZIL are used for such purposes.

Machine for collecting and recycling wastewater based on GAZ 3309

The maximum distance within which water can be drawn depends on the length of the pipe (hose). The standard length, regulated by the manufacturer, usually varies between 6-15 m. By individual order, this parameter can be increased to 25 m. Some sewer trucks use additional hoses, which allow increasing the length by another 5-10 m. However, even this is sometimes not possible enough to clean a septic tank located at a great distance from the roadway. In this case, additional measures will be required from the owners of the site.

Overflow treatment facility with three chambers

When the site has a large area, it is better to build a cesspool, the design of which involves the construction of 3 tanks. All containers of this design are connected by overflow pipes. The compartments of a three-chamber cesspool can be located at a distance of 700 mm from each other. For the construction of such a structure, it is recommended to use concrete rings with a diameter of at least 1 m.

The first two chambers are completely sealed, and the last tank is created with a filter bottom and water-permeable walls. Often, together with a cesspool of three compartments, a filtration field is constructed. It is connected to the treatment plant using drains. They are pipes with holes through which the purified liquid is released.

Drains are allowed to be installed in sedimentary, loose soil with heterogeneous densities. It is best if there are no layers of loam in the soil. Drains are laid below the freezing point of the soil. Pipes with holes must be wrapped in geotextile material and covered with sand mixed with gravel.

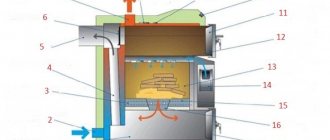

Ventilation

The installation of a ventilation system for the treatment plant is one of the key works. This is due to the performance of the following tasks by such a system:

- preventing the spread of unpleasant odors from wells and mains;

- protection against rarefaction of air in sewer pipes.

The technology for constructing this system comes down to connecting the waste pipe of the treatment plant to the ventilation riser, which is discharged onto the roof of the building. In this case, it is necessary to ensure that the riser pipe has at least the same diameter as the pipe with which the septic tank is connected to the facility’s sewer system. The most suitable value for the diameter of the waste pipe is 110 mm.

If the selected cross-section is small, then as a result of water drainage, the pipe lumen will be blocked. A piston effect will occur, due to which liquid will be sucked from the siphons of plumbing fixtures, against which the principle of the water seal will stop working. The most unpleasant thing here will be that odors from the sewer will begin to spread into the room.

Features of the design of a two-chamber sewage pit

The cesspool design with two compartments is used in small and medium-sized areas. Construction of the structure begins with marking the territory. At this stage, the configuration of the pits is determined. However, in some cases it is advisable to create one large pit. After installing tanks in it, the space between the tanks is filled with soil.

In the receiving chamber, the bottom is filled with concrete mortar. To make the screed as strong as possible, crushed stone is added to it. The walls of the compartment are constructed directly on the created foundation. If concrete rings are used during the construction of a structure, then the solution is poured inside the structures. It is recommended to coat the sealed container with waterproofing material on the inside.

Concrete rings can be dug into the ground without the use of construction equipment. To do this, a reinforced concrete structure is first installed on the ground surface. Then the soil is removed in an area whose boundaries are the inner space of the ring. Then it is necessary to gradually undermine the soil under the walls of the structure. As a result, the reinforced concrete ring will be lowered into the shaft being created. This method is especially relevant if there is light soil on the site, as it does not allow the walls of the pit to crumble. When using other materials to create a treatment plant, you need to dig a hole with inclined walls. A slight slope will prevent them from collapsing.

When using a plastic tank as a reservoir, it is necessary to fill it gradually while simultaneously filling it with water. This will prevent deformation of the container, which may occur due to soil pressure.

The second chamber is equipped with a waterproof bottom. Then the pipes are laid below the freezing point of the soil. For additional protection of pipelines from freezing, you can use any of the popular heat insulators. It is recommended to install vertical sections at the ends of the overflow pipe. This will allow the treatment plant to function better because it will be impossible for wastewater to flow in the opposite direction if the tanks overflow. When an overflow well is equipped with additional drainage, a pipe is used that is laid in the ground on a bed of crushed stone.

Methane gases are removed from sewage depending on the type of bacteria involved in the operation of the treatment plant. Some microorganisms are always found in wastewater. However, the process of processing sewage can be accelerated if more anaerobic or aerobic bacteria are added to a sealed tank. The first type of microorganisms can live without oxygen, unlike the second type of bacteria. Therefore, it is better to use anaerobic microscopic organisms in a sealed tank.

When a ventilation device is finally installed, then a hole is created in the cover of the treatment plant for a pipe whose diameter is approximately 100 mm. This ventilation duct is closed from above with a conical cap. This will prevent sediment and debris from entering the cesspool.

Use of biological products

Pumping out chambo can be done much less frequently if special biological products are used. They are also responsible for:

- Disinfection of wastewater. During storage, they begin to ferment and release dangerous toxins.

- They reduce the volume of waste.

- Eliminate odors that are present in any case.

Dietary supplements or, in other words, specific bacterial cultures can be used in dry or liquid form. Prices for products vary - it all depends on the manufacturer and type of microorganisms.

Advice! In order for bacteria to live longer and multiply more actively, it is worth limiting the discharge of aggressive chemicals into the chambo, in particular chlorine.

Metal container for shambo

Cesspool with overflow in a private house

A cesspool with an overflow is one of the most optimal options for pumping out contaminated wastewater in dachas, country houses and cottages. The installation is used where there is no central sewerage system. A cesspool will make life at your dacha easier and more comfortable; it is a necessary component of everyday life. In order to make the most of this tank, you need to know about the main advantages, features of the device and installation specifics.

Advantages and disadvantages of a cesspool with overflow

A cesspool with an overflow in a private house accumulates both human waste and sewage wastewater. The installation receives contaminated water from dishwashers, washbasins, bathtubs, showers, toilets, washing machines, etc., which cannot be used a second time without first being cleaned.

The main advantages of such a pit are:

- Infrequent calls for sewage disposal trucks to clean the pit (if the installation is used by four or more people, then the tank is filled much more often, this is where the overflow cesspool helps).

- After purification, water can be used a second time, for example, to water the garden.

- No noise during operation.

- you will never hear gurgling sounds in case of overflow from the toilet or washbasin.

- No unpleasant odors.

- You can use water in your home in any unlimited volume.

As for the shortcomings. You will not be able to install a cesspool with an overflow in any place convenient for you, since there are generally accepted standards for installing a tank. For example, the pit should be 12 m from the house and 1 m from the fence. If you install the device in an inappropriate place, its operation will be disrupted, which will lead to breakdown and contamination, in which case a vacuum cleaner will help you. It is also very important to know how to clean a cesspool.

Construction of a cesspool with overflow

Most often, these installations consist of two chambers, which are connected at a certain slope by a special pipe. In the first chamber, settling and processing of sewage and household waste is carried out using special microorganisms and bacteria for cesspools, which form activated sludge and water. The sludge sinks to the bottom of the first chamber of the tank, and the water rises to the top. When the water reaches the overflow level, which is set at 30% of the surface of the device, the settled wastewater is sent to the second chamber, in which it is filtered and then discharged into the ground. The second chamber does not have a bottom, but it contains several layers, such as geotextiles, sand, crushed stone and broken brick.

In order for the organic elements in wastewater to decompose better, special biological products with microorganisms and bacteria should be added to the pit. Also, in order for the device to function better, it is worth leaving a special hole that will let air in. The reservoir of the second chamber can be completely filled with crushed stone, and geotextiles and black soil can be laid on top, on which flowers and plants with a shallow root system can be planted. But this method of construction is implemented exclusively on loose and sandy soil. If the soil on your site has a different composition.

The device, principle of operation, installation of the Topol septic tank can be found on this page

Read how to make a country toilet without a cesspool here

Scheme of construction of a cesspool with overflow

In order to build a cesspool with overflow, you will need the following tools and materials:

- Concrete rings for the bottom of the first tank.

- Red brick for the base of the second tank.

- Sand.

- Crushed stone.

- Geotextiles.

- Special sewage pipes made of plastic.

- In order to avoid sewage entering the second sump, a T-shaped pipe is used.

- Shovels (bayonet and shovel).

- Bucket.

- Rope.

- Hammer.

- Chisel.

In order to dig the first tank, it is necessary to install concrete rings in advance in place of the cesspool. Climb inside the ring and start digging, the rings will drop to the required level. After the first ring is level with the ground, place the second one on it and continue digging. Dig up and remove excess soil using a bucket and rope.

Next, install pipes through which sewage wastewater will be directed from the house to the pit. Make a special hole in the ring using a chisel and hammer.

After 0.5 meters from the first cesspool, dig a second one, the depth of which will be 4 meters and the walls of which are laid out from special red bricks, without using mortar. Make gaps between bricks. Place a layer of geotextile, sand, geotextile and crushed stone at the bottom of the tank.

Connect the two pits with a plastic sewer pipe that has a T-shaped end at the end, which provides additional safety and prevents contaminants from flowing into the second tank from the first. Install the pipe below the level of the inlet drain pipe at an angle of 2 degrees.

If you use full filling of the second tank with crushed stone or gravel, then install the overflow pipe in the middle of the layer. Place a layer of geotextile and black soil on the crushed stone.

The device, principle of operation, installation of the Bars septic tank can be found on this page

You can read about the disposal of liquid household waste here

Before installing a cesspool with overflow, be sure to consider the following features:

- The distance from the tank to the house for clay and rocky soil is at least 5 m;

- The distance from the tank to the house with loamy soil is 10 m;

- Distance for sandy and loose soil – 15 m;

- The distance to a source of drinking water or a well is 20 m for clay soil, 30 m for loamy soil, and 50 m for sandy soil.

Be sure to choose the right location for your cesspool with overflow, take into account the sanitary standards for the cesspool, calculate the amount of material you need to install the tank, and be sure to monitor the level of filling of the cesspool with sewage drains. These points will help you maintain the installation for a long time and ensure its high-quality operation. You will avoid breakdowns and frequent calls to sewerage equipment.

Did you like the article? Subscribe to site updates via RSS, or follow updates on VKontakte, Odnoklassniki, Facebook, Google Plus, Twitter.

Subscribe to updates by E-Mail:

Tell your friends! Share this article with your friends on your favorite social network using the buttons in the panel on the left. Thank you!

To connect plumbing fixtures to the water supply network, a flexible water supply is used. It is in demand when connecting faucets, showers, toilets and other water intake points, and significantly simplifies the installation process. Flexible connections are also used when installing gas equipment. It differs from similar water devices in its manufacturing technology and special safety requirements.

Remote removal of reinforced waste: type and installation of pipes for pumping out a septic tank

One of the conditions for the proper operation of an autonomous sewer system is pumping out the septic tank. For this purpose, owners of private plots periodically use the services of vacuum cleaners who, using a special machine, remove liquid household waste. If it is not possible to provide convenient access for the vehicle to the treatment plant, an additional pipe is installed for pumping out from the septic tank, which allows dirty water to be collected from a considerable distance.

Characteristics and types

The flexible hose for connecting plumbing is a hose of different lengths made of non-toxic synthetic rubber. Thanks to the elasticity and softness of the material, it easily takes the desired position and allows installation in hard-to-reach places. To protect the flexible hose, there is an upper reinforcing layer in the form of a braid, which is made from the following materials:

- Aluminum. Such models can withstand no more than +80 °C and retain functionality for 3 years. At high humidity, aluminum braiding is prone to rust.

- Of stainless steel. Thanks to this reinforcing layer, the service life of the flexible water line is at least 10 years, and the maximum temperature of the transported medium is +95 °C.

- Nylon. This braid is used for the manufacture of reinforced models that can withstand temperatures up to +110 °C and are designed for intensive use for 15 years.

The fasteners used are nut-nut and nut-fitting pairs, which are made of brass or stainless steel. Devices with different permissible temperatures differ in the color of the braid. Blue ones are used to connect to a pipeline with cold water, and red ones for hot water.

When choosing a water line, you need to pay attention to its elasticity, reliability of fasteners and purpose. It is also mandatory to have a certificate that prevents the rubber from releasing toxic components during operation.

Which material is better

When selecting a hose for a sewer system, it is very important to pay attention to the type of material from which the drainage hose is made. The following types of materials are most often used here.

- HDPE – low-density polyethylene. The double-walled structure of the hose ensures the highest level of reliability and extends the service life of the product. Single walls are used in products intended for use inside home wastewater systems.

- PVC – polyvinyl chloride. The universal version made of synthetic material allows you to create sleeves with an average level of resistance to precipitation and frost. Used for drainage systems or drains inside buildings.

- PP – polypropylene. Withstands contact with hot water, it is used mainly in operating conditions of an intra-house sewer network.

- Synthetic rubber. Rubber hoses are the most inexpensive, but quite convenient for discharging fecal waste. They are accessible and easy to use.

All flexible sewer pipes must withstand operation in atmospheric temperatures ranging from -20 to +60 degrees Celsius, can be positioned at an angle, and can be reinforced with a PVC spiral.

Features of gas connections

When connecting gas stoves, water heaters and other types of equipment, flexible hoses are also used. Unlike water models, they are yellow and are not tested for environmental safety. For fixation, end steel or aluminum reinforcement is used. There are the following types of devices for connecting gas appliances:

- PVC hoses reinforced with polyester thread;

- made of synthetic rubber with stainless steel braid;

- bellows, made in the form of a corrugated stainless steel tube.

The Santekhkomplekt holding offers engineering equipment, fittings, plumbing fixtures and devices for connecting them to communications. The assortment is represented by products and materials from well-known foreign and domestic manufacturers. Discounts apply for bulk purchases, and product quality is confirmed by standard certificates. For information support and assistance, each client is assigned a personal manager. The ability to arrange delivery within Moscow and to other regions of the Russian Federation allows you to quickly receive the purchased goods without unnecessary hassle.

Drainage is a drainage and drainage measure to remove excess groundwater.

If water does not leave the site for a long time, the soil becomes gleyed, if shrubs and trees quickly disappear (get wet), you need to urgently take action and drain the site.

Hoses for storm drainage

Taking into account the purpose of the sewer system will help you choose the right hose.

- for storm drainage , capable of quickly discharging and passing significant volumes of water. For outdoor use, the material must be frost-resistant.

- For an external or external autonomous network, the most mechanically and climatically resistant flexible pipe options are selected. The optimal solution would be corrugated HDPE hoses that can withstand operation in the most difficult conditions.

- PVC hoses with an internal diameter of up to 50 mm are suitable for the internal sewerage system They are suitable for collecting water from sinks, shower trays and bathtubs. For home sewerage, the diameter of the flexible waste pipe should be from 110 mm.

- For fecal wastewater with forced removal of contents by a pump, the cheapest budget rubber hoses are used.

Causes of soil waterlogging

There are several reasons for soil waterlogging:

- clay heavy soil structure with poor water permeability;

- aquifer in the form of gray-green and red-brown clays is located close to the surface;

- high groundwater table;

- technogenic factors (construction of roads, pipelines, various objects) that interfere with natural drainage;

- disruption of the water balance by the construction of irrigation systems;

- The landscape area is located in a lowland, ravine, or hollow. In this case, precipitation and the influx of water from higher places play a big role.

Tips for choosing a sewer hose

Sewage hoses are a modern solution for pumping fecal wastewater or water discharged from a building’s plumbing or storm water systems. A flexible pipe of this type is used in the operation of special sewage disposal equipment and pumping equipment. Products for forming sewer hoses must withstand work under pressure and be resistant to atmospheric influences. When choosing products, it is worth taking into account the diameter of the pump inlet, operating conditions, and type of waste - in this case, the operation of the equipment will be quite efficient.

What are the consequences of excess moisture in the soil?

You can see the results of this phenomenon yourself - trees and shrubs die. Why is this happening?

- the oxygen content in the soil decreases and the carbon dioxide content increases, which leads to disruption of air exchange processes, water regime and nutritional regime in the soil;

- oxygen starvation of the root-forming layer occurs, which leads to the death of plant roots;

- the supply of macro and microelements by plants (nitrogen, phosphorus, potassium, etc.) is disrupted, because excess water washes out mobile forms of elements from the soil, and they become unavailable for absorption;

- intensive breakdown of proteins occurs and, accordingly, the processes of decay are activated.

Plants can tell you at what level groundwater lies

Take a close look at the flora of your area. The species inhabiting it will tell you at what depth the groundwater layers are located:

- perched water - it is best to dig a reservoir in this place;

- at a depth of up to 0.5 m - marigolds, horsetails, varieties of sedges grow - bladderwrack, holly, foxtail, Langsdorff's reed;

- at a depth of 0.5 m to 1 m - meadowsweet, canary grass, ;

- from 1 m to 1.5 m – favorable conditions for meadow fescue, bluegrass, mouse peas, rank;

- from 1.5 m - wheatgrass, clover, wormwood, plantain.

What is important to know when planning site drainage

Each group of plants has its own moisture needs:

- with a groundwater depth of 0.5 to 1 m, vegetables and annual flowers can grow in high beds;

- depth of water layer up to 1.5 m is well tolerated by vegetables, grains, annuals and perennials (flowers), ornamental and fruit shrubs, trees on a dwarf rootstock;

- if the groundwater is more than 2 m deep, fruit trees can be grown;

- The optimal depth of groundwater for agriculture is from 3.5 m.