They say that all new products are well forgotten old ones. The creation of heating systems based on pyrolysis combustion is no exception. The first plants using pyrolysis technology were built back in the 70s of the 19th century.

Homemade pyrolysis boiler

This technology is still widely used both here and abroad for oil refining. Actually, “pyrolysis” is the process of chemical decomposition of organic matter under the influence of high temperature. In devices using solid organic fuel (usually firewood), the solid part and the gases released from it during thermal decomposition burn separately, which significantly increases the efficiency of such boilers.

Despite the complex name and sophisticated description of the process, you can easily build a pyrolysis boiler with your own hands; for this you will need sheet steel, a welding machine and drawings, which you can take from our website.

What is pyrolysis combustion

Heating with wood is not very convenient, since under normal conditions the wood burns very quickly, and a significant part of the heat is not used. You have to constantly load fuel into the boiler or furnace. Pyrolysis involves creating conditions under which the fuel burns much more slowly, while releasing a noticeably larger amount of heat. This effect is achieved when wood burns with a low oxygen content, i.e. very slowly. As a result, ash, coke and flammable gas are formed.

This gas is mixed with air in the pyrolysis unit and also burns at very high temperatures, releasing a significant amount of thermal energy. Thus, the operating principle of a pyrolysis boiler includes two stages of combustion:

- first, with a limited supply of oxygen, the wood burns, releasing flammable gas;

- then combustion of the air-gas mixture occurs.

A similar principle of two-stage combustion is used in various home-made installations, for example, in a slow combustion wood stove and even in solid fuel generators that allow the use of wood as fuel for cars. However, the operation of the pyrolysis boiler should be properly adjusted so as not to damage the heating system of the house.

The high price of industrial boilers is completely justified. Firstly, because they are created using high-quality materials that can withstand high combustion temperatures (heat-resistant iron, 8 mm alloy steel, fireclay clay, etc.). Secondly, due to the complex automatic control system, which ensures high efficiency of the equipment.

To ensure maximum combustion effect, the heating temperature of the wood and its initial humidity are taken into account, since the process of water evaporation significantly affects the amount of energy released. To control the combustion process, it is necessary to carefully control the amount of air supplied to the installation. The air supply is carried out using a fan, the operation of which will require constant access to electricity. The presence of a fan turns the pyrolysis boiler into an electrically dependent installation. During a power outage, it is recommended to use a UPS or other similar device.

How does a boiler function in practice?

It is convenient to consider the practical application of the equipment in a step-by-step process:

- Loading firewood - placing the upper area of the chamber on the grate.

- Ignition the fuel and start the smoke pump.

- Formation of wood gas at a temperature of 250-850 °C.

- Transition of wood gas to the lower area of the firebox.

- Combustion of wood gas with additional air supply.

Next, the heat obtained in the lower region of the fuel chamber is used to heat the coolant. The coolant can be either water or air.

1 – active camera; 2 – water inlet; 3 – secondary air; 4 – chimney; 5 – outlet pipe; 6 – throttle valve; 7 – water outlet; 8, 9 – sensors; 10 – thermostat; 11 – passive chamber door; 12 – primary air; 13 – passive chamber; 14 – air pump; 15 – heat exchanger circuit; 16 – nozzle; 17 – active chamber door

If you pay attention to all the existing designs of domestic boilers operating on solid fuel, the main alternative to a pyrolysis boiler is the design of a traditional design.

This is a similar version of a wood-burning boiler, where there is one undivided firebox and the principle of lower air supply into the combustion chamber operates. But such a system is considered less efficient and uneconomical due to the rapid combustion of fuel.

A pyrolysis boiler is capable of delivering an efficiency of 85-95% at 100% load. However, efficiency drops sharply if the load is less than 50%. That is why manufacturers of pyrolysis equipment recommend that users operate the equipment at maximum load.

A similar approach is also valid for home-made structures, provided they fully comply with the classical pyrolysis scheme and operating requirements.

For “pyrolysis”, the operating requirements, it should be noted, are quite stringent:

- mandatory equipment with an air pump;

- permissible fuel moisture content is not higher than 25-35%;

- the load on the equipment is not lower than 50%;

- return coolant temperature is not lower than 60 °C;

- loading only with large fuel arrays.

It should also be noted that industrially manufactured pyrolysis systems are expensive. This is probably why the “do it yourself” option is so popular.

Advantages and disadvantages of using a pyrolysis boiler

Pyrolysis boilers have the following advantages:

- absence of soot and acrid smoke, minimal release of combustion waste; This is one of the most environmentally friendly types of stoves;

- For work, you can use any solid dry fuel, for example, sewing waste;

- high-quality fuel ensures 12 hours of continuous operation of the boiler on one portion of fuel, that is, you will only have to load firewood twice a day;

- economical technology, utility bills are reduced by an average of 60% per year;

- the use of pyrolysis technology makes it possible to automate the control of the combustion process, which increases the safety of the furnace.

Disadvantages should also be considered:

- Before the equipment pays for itself, you will have to invest a lot of money in the purchase of a boiler and its installation, but from the first days of operation its efficiency will become noticeable;

- The fuel used must have a moisture content of about 20%, otherwise combustion will stop. Therefore, wet fuel must be dried;

- The boiler may go out if the coolant temperature is not high enough. This problem is solved by installing a bypass pipe. This change complicates the design and reduces operating efficiency.

- If an electric pump is used to pump air, then the operation of the boiler becomes dependent on the electrical network.

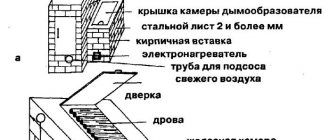

Budget option for a summer residence

The gas cylinder, with its round shape and metal thickness, is excellent for making a pyrolysis boiler. It is almost a meter high and has a diameter of 35 cm. These dimensions are enough to create a heating device capable of heating a medium-sized room. The device burns well the most wasteful types of fuel: wood chips and sawdust, raw firewood.

The installation works as follows:

- load through the top or side door and set on fire;

- after a stable fire has arisen, cover with a piston (popularly called a pancake) and a tight lid in which there is a hole for the pipe;

- a limited amount of oxygen enters the firebox through the air duct, causing the pyrolysis process to begin;

- gases rise along the walls of the boiler and burn in the upper part;

- the remaining products are removed through the chimney.

The balloon is cut at the point where the rounding begins. On the side there is a hole for the door, which should close very tightly. Therefore, it is usually used for cleaning, and fuel is loaded from above. The cut part is used for the lid:

- grind the cut to achieve a tight seal;

- make a hole 2–3 mm larger than the air duct pipe connected to the pancake;

- scalded at the bottom with a steel strip.

The piston has a unique design. Its blades are designed to swirl air currents over smoldering fuel, and a round piece of metal welded onto them prevents an open fire from occurring.

The chimney is made of pipes of different diameters: horizontal section - 120 mm, vertical section - 180 mm. This design helps create less active traction and inhibits the removal of gases. The right angle also plays a role in slowing down the combustion process. This ensures pyrolysis and continuous operation of the boiler for 8–10 hours.

A hole is made at the bottom for an ash pan with a door. Its design should ensure a tight fit. You can use a cut piece of the cylinder wall, onto which strip iron is welded around the perimeter. A grate welded from reinforcement is installed a little higher. Residues of fuel fall through it, which are then removed.

A lot of moisture condenses in the vertical chimney pipe, which collects in its lower part. A ball valve is installed to remove water. It is convenient because if it becomes clogged, it can be easily cleaned with a piece of wire.

Analysis of diagrams, drawings and calculations

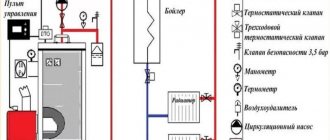

To better understand the operating principle of the device, it is recommended to study the diagram of a pyrolysis boiler.

Before starting work, it is recommended to carefully study the design diagram of the pyrolysis boiler in order to understand the principles of its operation and avoid mistakes

It reflects the position of such necessary elements as:

- air hole;

- the combustion chamber;

- smoke ducts;

- pipes for supplying and draining water;

- regulators;

- fan installation location, etc.

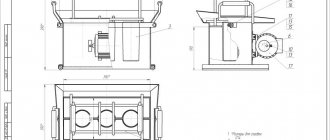

Since the pyrolysis boiler is a rather complex device, it is recommended to adhere to the drawing when manufacturing it. One of the most common device models, which is suitable for self-production, is presented below:

This drawing shows in detail the design of a pyrolysis boiler, which you can make yourself. It is recommended to strictly adhere to all dimensions specified by the developer

Typically, a 40 kW boiler is used for a private home. If this indicator needs to be increased or decreased, it is recommended to change the device parameters accordingly. The necessary data is presented in the table:

To make a pyrolysis boiler of suitable power with your own hands, you need to make elements of the appropriate size. The correct size ratio guarantees a successful result

A boiler with a power of 25-30 kW may be the best choice for a small house. Manufacturing a small unit will save both time and money.

Safety precautions

When installing a homemade boiler, we follow the following important rules:

- to install the heating unit, you need to allocate a separate boiler room;

- The boiler room must be equipped with an effective ventilation system. The minimum area of the air duct opening is 100 cm2;

- the distance between the unit and any other surfaces and objects must be more than 20 cm;

- Before firing the boiler, we lay a steel sheet with a thickness of at least 3 mm on the floor;

- we install the boiler on a pre-equipped brick or concrete base;

- The chimney must be properly insulated. Without thermal insulation, the formation of condensation, soot and other troubles will be more intense. This will negatively affect the efficiency of the equipment and its service life.

Finally, the boiler efficiency is checked. To do this, just do a test load of fuel. If the smoke coming out does not have a carbon monoxide smell, then everything is in order with the efficiency of the boiler and it can be used to heat the house without any fear.

What fuel to use

For economical and efficient operation of the pyrolysis boiler, you can use any solid fuel: firewood, coal, peat, pellets, and other combustible materials. The main condition necessary to maintain the pyrolysis combustion process is low humidity, no more than 20%. Wetter fuel must be specially dried to the required level. The ability to use waste from wood, clothing, oil mills and other types of production makes this oven even more profitable to use. The wood content must be at least 70%.

To operate a pyrolysis boiler, it is recommended to choose solid fuel

In conventional stoves, firewood needs to be added every two to three hours. Approximately 10 cubic meters of firewood are consumed in the winter. In pyrolysis boilers, wood burning lasts 12 hours, saving up to 40% over the winter. Coal burns much longer, up to five days, which saves not only fuel, but also time. There are models that are equipped with automatic feeding of fuel pellets, that is, they work in autonomous mode for a long time.

Expert advice on boiler combustion

Let's see what the professionals say regarding choosing the optimal type of fuel.

So, when burning wood, a lot of smoke will be generated. To get rid of the inconvenience associated with this, you need to place larger logs along the edges of the load, and put small kindling in the center.

In densely populated areas, it is recommended to refrain from using peat, because... during its combustion, a large amount of carbon dioxide is released and various large particles are released into the atmosphere, which is unlikely to please the neighbors.

To effectively use anthracite, you need a strong hearth. The power of a pyrolysis boiler is usually not enough to completely burn such fuel. To reduce costs, sift out large surviving fragments from the ashes and reuse them.

Thus, having mastered welding skills and following the recommendations given, you will be able to independently make an effective, reliable, safe and economical pyrolysis boiler.

Boiler operation

Good luck!

Video - DIY pyrolysis boiler

Assembly

It is necessary to assemble the structure with your own hands according to the drawings and at the site of operation. After laying the foundation, the internal walls and ash compartment are installed. Structural elements are assembled using welding.

Pyrolysis oven in nature

The heat exchanger, chambers, and grates are being assembled. External stiffeners and walls and a top plate are installed. Water tanks are being installed. Sand is poured between the walls (it is pre-calcined to get rid of organic components), which will accumulate heat and prevent overheating of the structure.

Primitive design of a pyrolysis furnace

The chamber doors are installed. Connection is made to the circuits of the water container. The metal structure, made by hand, is ready for use.

Scheme of a pyrolysis furnace

DIY pellet burner: drawings

For the purpose of self-assembly, it is necessary to prepare a competent project in advance, as well as drawings, all materials and standard working tools. The drawings must reflect all components and parts, including the combustion chamber, represented by a metal pipe with a round or rectangular cross-section, as well as a fuel loading hopper, a screw-type conveyor and a fan.

The frequency of maintenance of a boiler operating in automatic mode directly depends on the volume and size of the loading hopper being manufactured.

Pellet boiler drawing

The electronic control unit is designed to independently regulate the operation of the fan blower and control the air supply intensity, which has a direct impact on the combustion time of the loaded fuel pellets.

System assembly

The assembly of the pyrolysis combustion furnace is done directly at the installation site, so as not to bother moving the large device.

— The foundation must be laid from heat-resistant bricks.

“Then the inner walls of the boiler are installed around the perimeter, and a compartment for ash is placed at the bottom. The inner walls are connected by welding.

— When the housing is ready, proceed with internal installation. The chambers need to be welded, as well as the heat exchanger and grate bars along the previously attached guides.

— Stiffening ribs cut from the profile are attached externally by welding in a vertical position.

— Finally, the outer walls and top plate are installed. Water tanks are installed on the plane.

— Clean sand is poured into the device between the walls, which will perform a universal function: it will protect the chamber from burning out or overheating and additionally accumulates heat.

At this stage, the chamber doors are sealed. A container of water is connected to the circuits. That's it - the metal homemade pyrolysis oven is ready.

The boiler is lit with solid fuel, then the fire is secured with a door. Smooth combustion can only occur with a regulated air supply to the chambers. To do this, it is necessary to attach a special system consisting of valves and levers.

Types of burners

Pellet burners have several types. Reviewing them will allow you to decide which one is best suited for certain conditions. In most cases, a pellet burner requires electricity to operate, which powers the pellet feed mechanisms. Is there anything that can be done if it often disappears?

With forced fence

Such pellet burners are considered one of the best in terms of fire safety; they are used, for example, in Teplodar boilers. But for a burner with such a mechanism you will have to pay a considerable amount, which easily reaches 3 thousand US dollars. Burners with forced intake have several mechanisms through which pellets are supplied. One of them involves the use of a pneumatic system, and the second - an auger. Safety is ensured due to the fact that the channel through which the pellets move goes from bottom to top. Fire is known to move in the opposite direction, so it is unlikely that it will enter the bunker. The pneumatic system for the pellet burner has maximum safety. This is true, because the pellets are supplied in portions and do not remain in the pipe through which they move. For burners with a pneumatic feed system, large hoppers can be installed, which are loaded no more than once a month.

Screw feed mechanisms for pellet burners, for example, Teplodar, consist of two main units. One of them is an auger, which takes pellets from the bunker. He pours the material into another receiver, from which another auger lifts the pellets directly into the burner. In this case, the fire from the burner still reaches the mass. This is due to the fact that the pellets are located along the entire length of the auger. To further secure the mechanism, engineers make a unit that fits the burner from a material that melts and self-extinguishes. It acts as a fuse to cut off the path of fire.

One of the disadvantages of forced-feed pellet mechanisms, such as Telpodar, is their dependence on the availability of electrical energy. If it disappears, the supply of pellets will stop and the heating system may fail. Two electric motors have to be powered. If there are no problems with power fluctuations in your area, then you can purchase additional air boost. It allows you to increase the efficiency of pellet combustion, and accordingly increase the efficiency of the entire system. Mechanisms with a retort are becoming more common. The Fire Chalice has shown to be problematic when it crashes. In this case, the bowl itself became clogged and frequent cleaning was required. In retort burners, the combustion of pellets and pyrolysis gas occurs in the burner itself.

Gravitational

The gravity feeding device of the pellet mechanism is much easier to use. Also, such a device can function without electricity. The bottom line is that the pellets fall under their own weight. Domestic manufacturers of such burners are Pelletron and Begemot. You can start the product from Pelletron and Behemoth by simply adjusting the supply damper and the draft regulator on the chimney. But the disadvantages of the burners from Behemoth and Pelletron are the high probability of ignition of the pellets that are in the bunker. This is due to the fact that the hopper itself is fixed to the hole through which pellets are supplied to the burner. The efficiency of such pellet products is less than that of those with forced feeding.

To solve the fire hazard issue, manufacturers try to install special thermal dampers on such pellet appliances. If a flame escapes from the hearth and moves towards the bunker with pellets, then the heating triggers a special gateway, which simply blocks the movement corridor. Another interesting method of protection is the double grate. It is a simple mechanism. Its upper part approaches the hopper and takes the required number of pellets. After this, it moves to the combustion zone with pellets. The second part at this moment dumps the ash into the receiver, from where it can be cleaned.