Adjusting the pump station pressure switch is a key stage in setting up an autonomous water supply system for a country house.

This operation is not particularly difficult, but to perform it correctly you need to know a few rules, which we will talk about later. Let's also consider the most common errors that can occur during adjustment.

Design

A pumping station pressure switch is an electronic-mechanical device that starts and turns off the pump at certain pressure values in the water supply network.

Relays produced by various manufacturers are structurally very similar; the differences, as a rule, lie in minor details. The pump is supplied or turned off by closing and opening the contact group - the main element of the relay.

In addition to it, the device includes a piston with a membrane and two springs, which in most cases have different sizes.

After connecting the relay to a special adapter of the pumping station, water pressure begins to act on the membrane, and that on the piston, which is connected to the contact group.

On the opposite side, a large spring acts on the contact group, the compression force of which can be adjusted using the appropriate nut.

If, due to water intake, the pressure in the water supply system drops, the spring overcomes the impact from the piston and the contact group closes, supplying power to the pump.

As the pressure in the pipeline increases, the piston will gradually shift the platform with contacts, overcoming the resistance of the spring. But the contacts do not open immediately, but only after moving a certain distance, which depends on the degree of compression of the second - small - spring. Like the big one, it is mounted on a rod with a nut. After opening the contacts, the pump is switched off.

Design of a typical pressure switch for a pumping station

Thus, by adjusting the compression force of the larger spring, the user sets the pump activation pressure or, as it is also called, the lower pressure - Pon. To set the shutdown pressure (upper) - Poff - a small spring is used, the compression force of which actually determines the difference between Poff and Pon.

At the pre-sale preparation stage, the manufacturer configures the relay. Pon is usually set in the range of 1.5 - 1.8 atm (or bar, which is the same thing), Poff - in the range from 2.5 to 3 atm. If the settings are not suitable for the user or they are incorrect, they resort to adjusting the relay.

However, before doing this, it is necessary to prepare a storage tank.

To organize an independent water supply in the presence of a well, it is necessary to connect a pumping station. Pumping station for a well - types and features, operating principle of the device.

What is a drainage pump and what are the advantages of float options, read here.

A caisson is a device that promotes uninterrupted water supply. Here https://aquacomm.ru/vodosnabzenie/zagorodnyie-doma-v/avtonomnoe-vodosnabzhenie/istochniki/kesson.html you will learn what types of caissons there are and how to install them on a well with your own hands.

Electronic models

Such devices usually cost 2-3 times more than their mechanical counterparts and have a number of advantages over them:

- More precise adjustment of RD parameters.

- Instant shutdown of the pump when water intake into the tank stops.

- Turning off the pump when there is no water flow in the pipes.

- Longer service life.

Mechanical taxiways are much more difficult to set up and take longer. If you need to reconfigure the parameters of the mechanical version, it will need to be disassembled, and unnecessary interventions in the mechanical system always increase the risk of its breakdown. The electronic relay can be configured much easier and without disassembling the device.

Prices for electronic models in this table:

| Model | Price |

| Extra IDR | ₽2730 |

| ARD-1 Whirlwind | ₽2250 |

| Extra IDR-P | ₽2500 |

| Danfoss KP1 | ₽1570 |

| Extra RDE-10M-1.5 | ₽3230 |

Preparing the storage tank

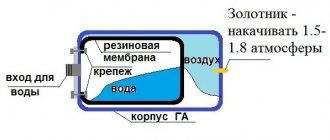

A storage tank or hydraulic accumulator is a sealed container with a rubber bulb located inside.

The latter is connected to the water supply, as a result of which it can be filled with water. Air is pumped into the space between the bulb and the walls of the tank using a conventional automobile pump.

This air spring compresses the bulb with water and maintains the pressure in the water supply network at an acceptable level for some time without turning on the pump.

The air pressure in the accumulator must be selected correctly, otherwise the system will not operate optimally.

If it is too low or high, the pump will turn on very often, which will negatively affect its service life.

In addition, with low air pressure, the accumulator bulb stretches excessively, as a result of which it also quickly fails.

Before pumping air, as well as before checking its pressure, water from the pipelines must be drained by opening the lowest tap. At the same time, the storage tank bulb will also become empty.

Now you can pump in air and check its pressure. It should be 10% less than Pon. If the system has not yet been configured and you have not yet decided on the switching pressure, the pressure is developed to the following values:

- 1.4 – 1.7 atm with a hydraulic accumulator volume of 20 – 25 l;

- 1.7 – 1.9 atm with a volume of 50 – 100 l.

The air pressure in the storage tank should be checked approximately once a month.

Do not leave the accumulator bulb without water for a long time. Its walls may stick together or dry out.

Connection diagrams

When connecting the water pressure switch for the pump, use the diagram shown in the figure below.

Pressure switch connection diagram Source ducepik.dysopu.ru.net

The grounding is connected in series to the water pressure switch and the pump, and the phase and zero are first connected to the power supply meter, then to the fuse (circuit breaker), then to the RD. The water pump completes the connection circuit.

Setting the pressure switch of the pumping station

If the air pressure in the storage tank is correct and all filters in the system are clear of blockages, you can begin adjusting the water pressure switch for the pumping station. To do this, you must adhere to the following sequence of actions:

- After disconnecting the pump from the network, you need to drain the water from the water supply through the lowest tap and remove the cover from the relay (for this you will need a regular screwdriver or a suitable wrench).

- Now you should turn on the pump, thus starting to fill the system with water.

- When the pump turns off, record the pressure gauge reading. This will be the current Poff value.

- Now you need to slightly open the tap located at the highest point of the water supply or as far as possible from the pump (with a single-level system). As soon as the network pressure drops to a certain level, the pump will turn on again. At this point, it is necessary to record the pressure gauge readings again, thus determining the current Pon value and the pressure difference to which the relay is set. At the same time, try to determine whether you are satisfied with the pressure with which the water flowed at that moment. Let us remind you that the test tap should be located above or further than all the others, that is, at the point where the water pressure is the least.

- If the pressure at the moment of starting the pump seems insufficient, the pressure Pon must be increased. To do this, turn off the power to the installation again, after which the largest spring in the relay is tightened with the appropriate nut. If you think that the pressure can be reduced, loosen the spring.

- Now you should set up the pressure difference Poff and Pon, which you have already calculated. Its optimal value is 1.4 atm. If you get a lower result, the water supply will be more uniform, but the pump will start more often, which will lead to a reduction in its service life. If the difference between Poff and Pon turns out to be more than 1.4 atm, then the installation will operate in a more gentle mode, but the difference between the maximum and minimum pressures will be much more noticeable. To adjust this parameter, you need to rotate the nut of the second – small – spring. By increasing the force of its compression, we increase the pressure difference and, accordingly, Poff. Weakening the spring will have the opposite effect.

- After adjustment, you need to check how correctly it was performed. The water supply is drained again, the pump is connected to the network and started. Then all actions are repeated in the same order.

Please note: the sensitivity of the second spring, responsible for adjusting the pressure difference, is greater than that of the first. Therefore, its compression force should be adjusted carefully by turning the nut at a small angle.

When automation needs to be reconfigured

Sometimes equipment breakdowns or errors occur. Here are the most common:

- the liquid flow is not powerful enough due to the large suction depth;

- the pump impeller is worn out;

- seals are cracked or dried out;

- difficulties when supplying liquid to the upper floors of a high-rise building or to a tank that is mounted too high.

SF-mix manual up to 0.8 m3/h

AMETHYST - 02 M up to 2 cubic meters/day.

Aeration unit AS-1054 VO-90

In such situations, you will need to change the settings set by the manufacturer.

Preparation for the process

What you need to do first:

- fix problems with all water supplies;

- check the indicators in the expander chamber, everything should be adjusted to the lower limit on the relay;

- if necessary, pump up the air - in this case, excess liquid may spill out, this is normal.

What characteristics should be changed?

You can change two parameters:

- RStart.

- Δ P, that is, the difference between the upper and lower limits.

If you do not change the factory value of ΔP (usually it is equal to 1 atm), then when you move Pstart, at the same time Pstop changes by the same amount. Here is a table with the most common problems and options for how to configure the water pump relay:

| Situation | What are we moving? | How |

| Excessively frequent station startup | Increase Rstop | Compress the spring ΔР |

| Pump on too long | The stopping limit needs to be lowered | We lower ΔР while maintaining the starting point |

| The pressure is too high | Reducing Rpusk | We weaken the large spring, and the lower pressure limit automatically tightens |

| Water flows into the taps in a weak stream | Raise Rstart, leave Rstop in the same place | To do this, compress P, weaken ΔP |

Setting up from scratch

Sometimes you have to deal with a relay whose springs are completely weakened. In this case, do this:

- By turning on the pump, the pressure in the network is pumped up to the level at which water flows from the most distant or highly located tap with acceptable pressure. Suppose the pressure gauge showed 1.5 atm. After this, the pump must be turned off.

- After disconnecting the station from the power supply and removing the cover from the relay, tighten the large spring until the relay clicks, closing the contacts.

- Having closed the relay, turn on the pump and increase the pressure to 2.9 atm (1.5 + 1.4).

- Turning off the pump again and opening the relay, tighten the small spring until the contacts open.

- Now the relay is set to Pon = 1.5 atm and Poff = 2.9 atm. It is necessary to close it with a lid and turn on the station to the electrical network.

Setting up the pressure switch

List of common breakdowns

Typical causes of automation problems include:

burnt contacts;- salt deposits on the coils;

- clogged and rusty hydraulic inlet;

- the entry of sand and other foreign particles into the membrane compartment and the formation of deposits;

- incorrect mechanical settings of the automation.

Another reason for a failure to pump water, which is not directly related to a malfunction of the relay itself, can be voltage surges in the electrical network.

Common Mistakes

Relay adjustment does not always go smoothly. Here are the situations that happen most often:

Small spring over-tightened

As a result, the shut-off pressure exceeded the maximum pump pressure.

In this case, the pump simply will not turn off.

What to do:

- Apply power to the pump and start it;

- as soon as the pressure on the pressure gauge stops increasing, the station must be turned off;

- open any of the taps and drain a small amount of water;

- making sure that the equipment is completely disconnected from the network, remove the cover from the relay and loosen the small spring until the contacts open with a characteristic click;

Now you can put the cover back in place and turn on the pump.

Poff pressure is more than 80% of the maximum permissible for this relay model

The relay of most pumping stations is designed for a pressure of 5 - 5.5 atm. This parameter is given in the product passport or on the packaging.

Therefore, the Poff pressure for such a device should not exceed 4 - 4.4 atm.

If this is not enough for a comfortable water supply, you will have to install a relay with a higher maximum pressure.

The Pon pressure is set so high (a large spring is overtightened) that the pump cannot overcome it and “get” to the operating range

In this case, the station will again not turn off.

What needs to be done: before starting the adjustment, study the pump passport and find the maximum value of the pressure it develops. It is usually indicated in meters of water column (mwst). To convert it to atmospheres, the given value should be divided by 10.34. Under all conditions, the values of Pon and Poff must be less than the maximum pressure that the pump is capable of.

Features of relays from some manufacturers

Some relay models may have additional elements, which often confuse inexperienced owners of pumping stations.

The most typical are:

- Lever of the dry running protection mechanism: most often found in expensive imported models that come with a complete set.

- An additional spring that prevents spontaneous turning of the nuts on the adjusting springs: such a device can be seen in the RDM-5 relays installed at pumping stations of the Russian company Gilex Jumbo.

The presence of these elements should not confuse you; perform the settings in accordance with the instructions provided.

It is also worth mentioning the features characteristic of the Marina and Pedrollo stations (Italy). For the former, the maximum pressure for the relay is only 3.2 atm and the springs in it have to be tightened every six months. For the latter, there is a manufacturer’s recommendation regarding the air pressure in the accumulator: it should be 0.2 atm less than the Pon pressure, which with standard settings is 1.4 atm.

Relays with tightly tightened springs wear out quickly. Try to select a model with sufficient pressure reserve.

In the private construction sector, there is often no possibility of central communications, including water supply. Submersible pumps for wells with automation are an excellent way to provide your household with water. Installation and assembly of the pump.

You can familiarize yourself with the technology for purifying water from iron in this material.

Briefly about the main thing

RD is a device that regulates the highest and lowest switching thresholds, which are responsible for activating the pump for forced pumping of water.

RDs can be mechanical or electronic. The latter are 2-3 times more expensive and have a number of advantages over mechanical analogues. In particular, electronic relays are easier and more convenient to configure, and they also have higher accuracy. Although the operating principle of both types of taxiways is the same.

Adjustment of the RD is carried out in accordance with the purposes for which the water supply in the house will be used. To take a bath, it is enough to maintain a low pressure level in the water supply system. To operate a Jacuzzi or hydromassage, you will need to maintain a high average pressure.

Ratings 0