Pumps for air rifles are produced with various stands. Pushers in devices are installed in vertical and horizontal positions. Filters are most often used with expanders. For safe use of the model there are sealing sleeves.

The maximum pressure parameter depends on the quality of the valves. If we consider modifications with horizontal racks, then they have an adapter with a spring. In order to understand this issue in more detail, you should consider the design of a standard pump.

Design and principle of operation

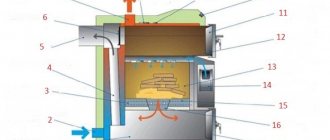

The typical model (drawings of a high pressure pneumatic pump are shown below) includes a round post, a handle and a rod. The devices also have a plunger mechanism. The operating principle of a high-pressure pump for pneumatics is based on increasing the pressure inside the chamber. This happens due to the movement of the pushers. They are located under the filter.

Adapters are used to stabilize the pressure in the chamber. There is a special rod in the pump stand. On some models, the plunger mechanism includes a seating pin. When the handle is raised, it moves to the lower position. When the pushers begin to move, the fitting moves down. The maximum pressure is recorded by a pressure gauge.

What is a plunger pump. Operating principle

The main element of the pump is the plunger - a long cylinder-shaped displacer with a small diameter. Unlike the piston type, the seal is located inside the outer cylinder, in which the plunger moves, coming into contact with its walls. During the reverse stroke of the plunger, liquid is sucked into the working chamber through the inlet valve; during forward movement, the inlet valve closes and the liquid is pushed out through the outlet.

Rice. 1. Design and principle of operation of a plunger pump

Homemade modification

How to make a high pressure pump for pneumatics? First of all, it is important to note that it is easier to make a model with a horizontal stand. To assemble a high-pressure pump for pneumatics with your own hands, first of all, take a cylindrical body. The handle under it should be selected with a small width. The rod is directly connected to the adapter. The top valve of the pump is fixed above the fitting.

A jumper is used to connect the spring. The first grommet is installed at the top of the post. Next, to assemble a high-pressure pump for pneumatics with your own hands, you will need a second valve. To fix it, you will have to use a blowtorch. In this case, it is important to lubricate the fitting well with machine oil. Lastly, install the footrests. The pressure gauge for a homemade high-pressure pump for pneumatics is most often fixed near the jumper.

Do-it-yourself manual high-pressure hydraulic pump

High-pressure hydraulic pumps operating at characteristics of 42-70 MPa or more are widely used to drive small-sized hand tools, special equipment, and are used in test benches and other critical products.

When transmitting the same power from the prime mover to the actuator hydraulic mechanism, an increase in pressure entails a decrease in flow.

As a result, smaller pump sizes, hydraulic motors, valves, piping and other components are required.

Classification

Extensive experience in the creation and operation of various hydraulic drives has shown that only limited types of pumps can develop high pressure. These include piston and plunger types. The hydraulic pump drive comes in three design types:

- manual (muscular);

- mechanical;

- pneumatic.

The use of hydraulic drives with ultra-high pressure (over 70 MPa) makes it possible to significantly reduce the dimensions and weight of equipment and increase its specific performance. The development of high-pressure systems is one of the key factors in the creation of compact, powerful hydraulic drives and mini-equipment for various sectors of the economy.

Muscle driven pumps

A manual (lever) hydraulic pump is driven by human muscle power. Its main component is a piston, which moves inside the cylinder.

The movement of the piston is controlled by a lever. The lever is moved by a person's hand or a foot pedal with a return spring.

The principle of its operation is based on the suction and injection of working fluid during the reciprocating movement of the piston.

Design

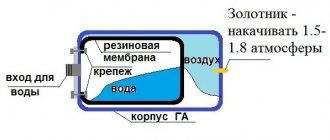

Let's look at how a hydraulic pump for a muscle-driven press is designed. A piston is installed in the cylindrical cavity of the pump housing, rigidly connected to the rod. The rod is pivotally connected to the drive lever. An intermediate valve is installed in the piston, connecting the piston and rod cavities of the pump.

The piston cavity is connected to the hydraulic tank through the inlet valve. In such pumps, the hydraulic tank is usually an integral part of their design. A suction filter is often installed in the tank in front of the inlet valve.

The rod cavity is connected through the outlet valve to the outlet port of the pump. Special seals are installed in the pump housing cover, which also serves as a rod guide.

A screw valve located in the bypass channel of the pump serves to return the working fluid to the hydraulic tank. A plug is provided in the housing for oil changes and maintenance.

Characteristics

The working volume of such pumps is small, the drive lever has a relatively short stroke, so the generated flow rate is low.

However, these are the most common units around the world, as they are used in so many industrial areas. The pressure developed by manual systems reaches 70-280 MPa.

Due to the simplicity of the design, repairing manual hydraulic pumps does not cause any difficulties.

Two-stage hand pumps

Their scheme is more complex. They contain two pistons, which are pivotally connected to the rocker arm of the drive arm. When the drive lever is moved to the left, one piston rises and sucks in fluid, and the second one lowers and pumps it into the hydraulic system.

When the drive lever is moved to the right, on the contrary, the first piston pumps liquid, and the second sucks it in. Thus, when identical pistons operate alternately, the working fluid is supplied continuously and more evenly than in single-stage models.

A two-stage hydraulic hand pump is capable of driving two hydraulic system circuits simultaneously. Two-stage versions of hand pumps with coaxial pistons of various sizes are widely used in industry.

At low pressure, both pistons pump out working fluid at a high flow rate. At high loads, only one piston with a small area pumps liquid into the circuit, developing high pressure at low flow rate.

Muscular drive models are used in various mechanisms:

- press;

- jacks;

- static hydraulic tools;

- lifting platforms;

- small-sized cranes;

- in laboratory testing equipment for pressures up to 200 MPa.

Self-made hydraulic pump for the press

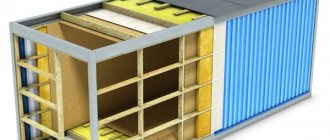

It is not difficult to assemble such a system yourself. First, a metal frame with a height of approximately human height is welded (you can use ordinary channels). Holes are drilled (burned) on the sides of the vertical posts at a certain distance from each other.

Metal rods (reinforcement) will be inserted into them, which act as a support for the platform on which components that require the use of great force are installed. For example, when pressing/pressing bearings, bushings, etc.

A series of vertical holes allows you to adjust the height relative to the press.

Choosing a quality model

How to choose a high pressure pump for pneumatics? First of all, it is important to consider the power limit parameter. The threshold overload indicator, as a rule, does not exceed 4 microns. The adapter must be made of aluminum. The return spring is about 3.6 cm in diameter.

Good models use two sealing sleeves. The top valve must be fixed firmly. Separately, when purchasing a device, the foot rest is checked. In some cases it is done with side overlays. The handle should be held firmly in your hands and not dangle to the sides. A high-quality model these days costs about 16 thousand rubles.

Application area

Plunger models are special-purpose devices that create very high pressure, so they are practically not used in everyday life. The main areas of their use are the industrial sector, they are used in the following industries:

- In the chemical industry for pumping substances with high viscosity and their precise dosage in the manufacture of chemical compounds that do not react with metal.

- For supplying measured quantities of water and other high-pressure liquids.

- In the oil and gas industry when drilling wells.

- In the energy industry in steam generators.

- In mechanical engineering in the manufacture of hydraulically driven equipment with operating pressures up to 3000 bar, in the automotive industry in injection systems of diesel engines.

- Plunger water pumps are widely used in car wash service centers.

One non-traditional application for plunger pumps is water jetting and cutting materials. At a pressure of about 2000 bar. A jet of water can remove paintwork or rust without leaving any residue. The technology is widely used in cleaning reinforced concrete structures, the sides of ships and runways. A water jet with a pressure of 3500 bar allows you to obtain the highest degree of cleanliness of WJ-1 surfaces according to the international standard.

Crosman pump

This high pressure pump for pneumatics is in great demand. Its maximum overload parameter fluctuates around 5 microns. If you believe the reviews of experts, the device uses a high-quality foot rest. The stand in this case is made with a round cross-section. According to buyers, connecting the model to the cylinder is not difficult. The model fits perfectly for PP series rifles. The top valve in the device is made entirely of stainless steel. The pump rod is very rarely deformed.

The permissible temperature level is at least -20 degrees. The sealing sleeve of the model is located behind the adapter. The bottom valve of the device is designed for low pressure. If we talk about the disadvantages, it is important to note that the model uses small pushers. In some cases the barbell wobbles. The handles are made with plastic linings, and they are erased quickly. The model does not have a drying filter. You can buy the specified pump for air rifles at a price of 14,700 rubles.

Differences between plunger pumps and piston pumps

Many people confuse plunger and piston type pumps due to the similarity of the operating principle and design (a displacer moves in the working cylinder). However, there are significant differences that make plunger pumps indispensable devices in many areas.

- The plunger has a cylindrical shape, which makes it possible to process its surface with maximum precision and high purity, which cannot be said about the internal surface of the cylinders, the processing of which is technically and technologically difficult. This allows the plunger to be adjusted as accurately as possible to the surface geometry of the working cylinder, which has a positive effect on the output pressure indicators.

- Unlike a piston with a short length of the working surface of the ejector, the plunger cylinder has an elongated shape, which makes it possible to place a large number of seals along its stroke and, accordingly, obtain a higher pressure at the outlet.

- Seals in plunger types are located on the inside of the working cylinder, which is technologically difficult to process with high cleanliness and precision; the plunger in contact with the seals, on the contrary, has a very high processing class - this factor also makes it possible to obtain very high pressure in plunger pumps.

In modern high-quality plunger pumps, manufacturing precision is very high - the working cylinder moves inside the outer one with a gap between the walls of about 2-3 microns, and seals are placed on the outside of the plunger at its inlet and outlet of the cylinder.

- Unlike piston types, the working surface of which is deformed in contact with liquid at high pressures, in plunger pumps the rigid and durable working cylinder does not change its shape at high pressures, which makes them indispensable when precise dosing of liquids is necessary.

Read also: How to replace valve stem seals without removing the head

Rice. 2 Internal structure of a plunger pump

Thanks to their design features, plunger pumps make it possible to obtain an outlet pressure 3 times higher than piston pumps with the same working chamber dimensions.

AM devices

This high-pressure pump for pneumatics (12 volts) is in great demand today. First of all, a high-quality plunger mechanism deserves attention. The maximum permissible pump temperature is 45 degrees. If you believe the reviews of experts, the model’s rod rarely deforms. The model is perfect for air rifles of the KR202 series. The pushers come with an adapter.

Jumpers are used at the bottom of the rack. The footrests are provided with a small width. The handle is standardly used with side covers, and they are made of plastic. The hose in the standard kit is used with a diameter of 0.4 cm. The stand is used with a round cross-section. The upper valve of the device is made of cast iron. The pump weighs quite a lot, but it is stable and is not afraid of heavy loads. You can buy this pump at a price of 18,900 rubles.

How to use the mini-wash

To ensure your washer works properly , follow these recommendations.

- Be sure to check the operation of the washer before you start using it, this will save your time and health.

- Clean and change the filter installed in the car wash after each use.

- If the washer uses electricity to operate and the source is unstable, provide it with a battery.

- Do not let children use the sink.

- If repairs are necessary, do not hesitate to carry them out. Replace damaged sink components.

- Update the device gaskets.

- Protect your sink from temperature changes.

Model "Axor"

This high-pressure pump for pneumatics differs from other models by its wide foot rest. This device weighs only 4.6 kg. If you believe customer reviews, problems with the bar rarely occur. The model is suitable for cylinders from almost all well-known manufacturers. The hose is applied at 0.6 meters. The lubricant on the plunger mechanism holds up remarkably well. According to buyers, the stand is made with an excellent protective coating. The device is not afraid of sub-zero temperatures.

However, this pump still has disadvantages. First of all, it is important to note that the buyer may have problems with the pressure gauge. In this case it is used with one scale. It does not have a moisture protection system. If you believe the reviews of experts, the fitting is designed with a small width. This puts a lot of pressure on the spring. The bottom valve of the modification is designed for 4 bar. The pump does not have a drying filter. The protective sleeve is located behind the adapter. The bottom valve is made entirely of aluminum alloy. The price for a pump of this series fluctuates around 15,200 rubles.

How to make a Karcher yourself

Although car washes have achieved widespread use, they come at a high price. So, if you want to make a sink yourself, you will need :

- canister;

- irrigation hose with gun;

- pump;

- union;

- canister lid;

- tubeless wheel fungus;

- rubber gasket;

- coupling.

These are the components of the future car wash. Materials that will be useful in the manufacturing process:

- drill;

- sealant.

First stage. Selection of components.

The required volume of the canister depends on you and the purposes for which you will use the washer: a five-liter canister is enough for a passenger car. Drivers carry a car wash in their luggage, so choose a body based on both volume and dimensions. The irrigation hose must be strong and flexible and should not be twisted or broken. Hoses with nylon braid are considered durable. A hose consisting of several layers is more reliable. Don't skimp on this component. The only requirement for the gun is that it must hold tightly to the hose.

The pump can be foot-operated or automatic. We won't need the high power of this pump, so don't buy an expensive one. Using an automatic pump is much more convenient than a foot pump, since you do not have to constantly drag the pump from place to place and do unnecessary work with your foot. However, the cost of the pump plays a decisive role; an automatic one is three times more expensive. Choose the fitting and coupling at your discretion, the main thing is that they are in close contact with each other. It is preferable to purchase both the fitting and the coupling from the same material (plastic or metal).

Second phase. Preparing the canister.

Drill a hole in the canister that is the right size for your coupling. Insert a coupling with a screwed-in fitting into this hole. Secure the structure with sealant so that the coupling does not pop out during operation, and the required pressure is maintained in the canister.

Third stage. Cover assembly.

The lid needs to be strong, solid and suitable for the canister. To prevent air from escaping from the canister, attach a rubber gasket to the bottom of the lid. Then make a hole in it and insert the tubeless tire fungus into it.

Fourth stage. Assembly of the structure. Additional functions.

Screw the lid on the canister tightly, connect the cord from the pump to the fungus, attach the free edge of the hose to the hole made in the canister using a fitting. The homemade sink is ready. The principle of operation of such a washer is simple: using a pump, air is pumped into a canister of water (the canister is not filled to the brim with water). Create pressure up to 0.3 bar or higher if your canister can handle it. Under the influence of pressure, water streams out of the gun when you press the handle. If you will use the sink during the cold season, equip your sink with a special burner for heating the water. For these purposes, you will need a larger canister; it will lose mobility, but with the help of hot water the car is cleaned of heavily dried dirt.

Provide a power source for the washer. If the washer runs on fuel (gasoline or diesel fuel), then there will be no problems with moving it. When planning an electric car wash, make sure you have a working and accessible source of electricity. In this case, you are unlikely to be able to freely transport the sink from place to place, but you will not have to spend money on expensive fuel. Decide in advance what you are using the sink for. If you want to clean the windows of a house or the wheels of a car, then a compact, mobile washer on wheels and with a long hose will suit you. When using a sink on a production scale, you will not need its ability to move, so it is better to design a stationary sink. It connects directly to the water supply. If the need arises, set up automatic water supply to save money. While you can save on water consumption, you cannot save on purchasing sink components. To prevent the item from becoming dirty after washing, purchase special filters. You don't need an expensive filter to purify the water to drinkable condition. A filter is needed to purify the water, at least from debris that will disable the sink.

You can even make money by designing a pressure washer if you open a car wash. The main thing is that the sink you make works. Using a car wash, you can clean bicycles, mopeds, cars, trucks and their components.

Features of Umarex pumps

The design of the high-pressure pump for Umarex pneumatics is similar to the previous model. A model is produced with two adapters. Its leg stand is made of aluminum type. If you believe the reviews of experts, the top valve used is of high quality. It can withstand maximum pressure of 5 bar. The pump stand is used with a round cross-section. The return spring in the device is provided at 2.5 cm.

The plunger mechanism is installed at the bottom of the structure. The pressure gauge is provided with one measurement scale. It is installed near the jumper. The bottom valve of the model is made of cast iron alloy. The overload parameter for a pump of this type is about 3.3 bar. In total, the device uses three sealing sleeves. The model is perfect for air rifles of the PP series.

The hose included in the standard kit is braided. The adapter for it is matched with a clamping ring. The model is not suitable for rifles of the KR202 series. If we talk about the disadvantages, it is important to note the small handle. The device weighs as much as 4.8 kg. The model's stabilization system is of poor quality. You can buy a pump of the presented series for 13,800 rubles.

Manual hydraulic pumps NRG

NRG hydraulic pumps are very reliable devices and are very common here in Russia as they are produced here. The NRG line of pumps contains devices with distributors. The letter “P” is usually placed at the end of the designation of such instruments. This letter means that the tool can work with double-acting hydraulic devices. Let's consider several models of NRG manual hydraulic pumps:

NRG pumps

- Model nrg-7020R. Creates a maximum pressure of 700 bar. And it has a nominal tank volume of 2 liters. The kit includes a hydraulic distributor that allows you to work with both single- and double-acting devices.

- Model nrg-7007. Also creates a pressure of 700 bar. The nominal tank volume is 0.7 liters. The advantages of this model are the presence of a safety valve, minimal force on the handle, and two stages of oil supply. This tool is designed for single-acting hydraulic tools with a spring return rod.

- Model nrg-67016R. The nominal tank volume is 14 liters. Handle force 55 kg. Pressure maximum 4 MPa. Capacity is 115 cubic cm. Such a device weighs as much as 30 kg and is quite large. Suitable for a small car service.

Description of the Norika device

The specified high-pressure pump for pneumatics is manufactured with a high-quality expander. If you believe customer reviews, the model has an excellent foot rest. The stand is made as standard with a round cross-section. However, it is important to note that the spring is installed without an adapter. The bar in this case is located in the central part of the rack. If you believe customer reviews, the valve rarely becomes deformed. In this case, the handle is made with side pads.

According to experts, the pins can last for many years. The pump's maximum overload indicator is 5.5 microns. The height of the rod is 0.6 cm. This model does not have an in-line filter. The standard modification kit includes a high-quality hose. The model is perfect for air rifles of the PP series. A user can buy a pump of this series for only 15 thousand rubles.

Model Gehmann

This high-pressure pump for pneumatics is used quite often by professionals. First of all, it is chosen for its compact size. In this case, the pressure gauge is used with two measuring scales. Its protective glass can withstand heavy loads. If you believe the reviews of experts, the bar rarely deforms. The hose included in the standard kit is braided.

In total, the pump has two in-line filters. The plunger mechanism is located at the bottom of the structure. The advance clutch is installed under the upper valve. Its threshold pressure parameter is 4 bar. The sealing sleeve of the model is made of rubber. The stand is used with a round cross-section. The pressure gauge has a moisture protection system. The device is perfect for air rifles of the KR220 series. You can buy the presented pump in a specialized store for 19 thousand rubles.

DIY manual hydraulic pump

The hydraulic (manual) pump is quite in demand in the industrial sector. Its main task can be called pumping fuels and lubricants.

At the same time, the models have their own permissible viscosity standards. Additionally, the devices differ in their design. The main element of a hand pump can be called the dispenser pipe.

In some cases, telescopic intakes are used instead.

How is it built?

The standard manual (hydraulic) pump has a simple device. There is a test hose located at the bottom of the housing.

It is attached to the mechanism through a special hole using clamps. There is a valve higher up in the hand pump that controls the pressure.

By turning it clockwise, you can adjust the pumping force.

There is a plug for filling the tank. Below it is a small port, which is designed to connect to the general system. The mechanism also has a separate reservoir with a pipe for liquid.

The hydraulic cylinder is connected to the hand pump using a threaded method. To adjust the valve intensity, manufacturers install special regulators. With their help you can easily change the pressure.

In this case, the pump handle is installed separately, which is secured with a plug.

Diagram of a hand pump for pumping out oil

To pump out large quantities of oil, a durable hydraulic cylinder is required (a diagram of a manual hydraulic pump is shown below).

As a rule, it is reinforced with a small support. As a result, it is possible to secure it more tightly. Additionally, bolts are used for this.

Among other things, the hand pump is equipped with a hydraulic tube. Its main task is to supply pressure to the cylinder. For this purpose, a tee is installed in the device.

It is mounted on a special cushion, which is fixed on a washer. It is also secured with nuts. A rubber band is used for the holder in the hand pump.

In this case, the fitting is located at the very bottom.

Pump repair

In order to repair a hydraulic hand pump, you need to find out as much as possible about the breakdown. First of all, you should look at the pressure gauge readings.

If the pressure deviates from the norm, this is due to the central reservoir, the tightness of which may be compromised. In order to replace it, you will need a standard set of tools.

First of all, unscrew the upper bushing and disconnect the hydraulic pump handle. Next, you need to carefully remove the protective washer.

After this, it is possible to disconnect the plug. Directly below it is a reservoir. If external inspection does not show obvious deformation, the shut-off valve must be unscrewed from it.

After this, experts advise checking the functionality of the valve. If it is quite tight, you need to lubricate it. After this, the mechanism should be folded and checked for functionality.

The second common problem with pumps is considered to be abrasion of the rubber plug. In this case, you can simply replace it. In this case, it is necessary to find out its exact diameter and thickness. After completing the repair work, the entire mechanism also needs lubrication.

How are homemade models created?

Today, homemade devices of this type are quite rare. However, you can make a hydraulic pump (manual) with your own hands. First of all, a steel tank is used as a body.

It requires a valve to control the pressure. It is secured at the top with a washer. A lever is used to adjust the shut-off valve. In this case, you can use a cast iron pipe.

To control the pressure, a pressure gauge should be installed.

You will need a sleeve with a pipe that will prevent the valve from twisting. As a result, you can fold a device that can withstand a pressure of no more than 4 atm.

Considering all of the above, such devices are considered ineffective and are rarely used in industry.

Hydraulic pumps NRG

HP pumps are reliable pressure sources. Moreover, they can be connected to various hydraulic systems. The manual hydraulic pump NRG-7007 has a nominal tank volume of 0.7 liters.

At the same time, its useful volume is 0.6 liters, and this modification can withstand a pressure of 1.3 MPa. Overall its performance is pretty good.

If we consider high-pressure pumps, then the NRG-7110 device deserves attention.

Its nominal tank volume is 1 liter. In this case, the maximum pressure is maintained at 2.7 MPa, and the force on the handle must be applied at 50 kgf. The dimensions of this modification are as follows: width - 310 mm, height - 320 mm, and length - 750 mm.

The hydraulic pump (manual) NGR-7016 has a nominal tank volume of 16 liters. At the same time, its useful volume is 14 liters. The pressure at the first stage is maintained at 2.7 MPa, and the system capacity is 113 cubic meters. see in one move.

This hydraulic (manual) pump weighs as much as 29 kg.

NRG pumps with distributors

Hand pumps of the NRG series are produced in some cases with distributors. These models have the letter “P” in their names, so anyone can recognize them.

A distinctive feature of these devices is considered to be high maximum pressure. Moreover, their tanks are installed in a variety of diameters.

If we consider the modification NRG-7020R, then the useful volume of the chamber is exactly 2 liters, and the pressure is maintained at around 3 MPa.

The productivity of the device at the second stage is 113 cubic meters. see the move. In this case, the force on the handle should be applied at 55 kgf. This hydraulic (manual) pump weighs 22 kg.

If we consider the NRG-67016R model, then its nominal tank volume is 14 liters, the “maximum” pressure is maintained at 4 MPa. The capacity of the mechanism at the second stage is 115 cubic meters. cm per move.

The assembled device weighs exactly 30 kg.

Single acting system

To connect a manual hydraulic pump to a single-acting system, you will need a special adapter. It is usually let in with a pressure gauge.

The most common modification of the adapter is considered to be the “MA100” model. Additionally, you will need a hose at least three meters long. Its end must connect to the coupling half.

The system must also have an actuator.

A distinctive feature of these devices is a powerful valve that can withstand heavy loads. It is connected to the system, as a rule, through a regular adapter.

Additionally, a BRS class half-coupling is used. To work, you will also need an adapter that will be attached to the tap.

Via an adapter, the pump can be connected to the actuator.

Double acting hydraulic system

A double-acting hydraulic system requires a standard adapter as well as a pump. In this case, the coupling half is used from the BRR series. It should also be noted that the rod can be connected to the system, and this is done to return the stroke.

By default, it is assumed that there is one hydraulic pipe, but several can be connected. In order to connect the pump to the actuator, a special hydraulic lock is used. It is installed on two connectors at once.

In this case, the pressure can jump to 3 MPa.

In this case, you should constantly monitor the pressure gauge readings. After installing the hydraulic lock, you need to tighten all the bolts and check the rod for functionality.

Additionally, it should be noted that protective bushings in this system can only be used of the UGZ class.

This is due to the fact that it is necessary to connect to the actuator with exactly two connectors.

How do hand pumps operate from a station?

The hand pump can only be connected to the station using an adapter of the ШП series. In this case, the standard connection diagram provides for the presence of a drain pipe. It is produced with the “T” marking.

Principle of operation

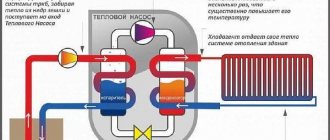

Hydraulic presses equipped with an electric drive are capable of developing enormous forces, which is explained by the design features of such equipment. The principle by which the electro-hydraulic press works is as follows.

- An electrically powered motor drives a hydraulic pump.

- The hydraulic pump, in turn, maintains the pressure of the working fluid in the first chamber of the press.

- The piston of the first chamber transmits pressure to the second cylinder of the electro-hydraulic press, where it increases significantly.

- The pressure created in the second chamber of the hydraulic cylinder is transmitted directly to the working body of the electrohydraulic press.

Diagram of a frame-type hydraulic press (click to enlarge)

Thus, the amount of working pressure that will be imparted to the working body of an electro-hydraulic press depends on how different the areas of the pistons in its two cylinders are.

The operation of the press, the main working body of which is a hydraulic pump, is based on Pascal's law, which states that the force acting on any area is transmitted throughout the entire volume, and it has equal value in all directions.

Types and scope of application

Both home-made and mass-produced hydraulic presses are classified according to several parameters:

- sizes;

- maximum force produced;

- design features of the equipment (in particular, the height of the rod).

The most powerful are hydraulic presses related to floor-type equipment.

A hydraulic floor-type press, distinguished by significant dimensions, is capable of creating pressure at one point, the value of which can reach tens of megapascals. The scope of use of equipment of this type, which can be equipped with additional devices, is quite wide. Floor hydraulic presses are necessary to solve such technical problems as:

- installation and removal of bushings, shafts, bearings;

- pipe bending;

- pressing of products made from various materials, including metal.

Some models of floor-type electro-hydraulic presses provide the ability to change the height of the work table.

Electro-hydraulic press 2135-1M, force 40 tons

Tabletop hydraulic presses, along with their small size, are characterized by less power.

The pressure created by such equipment installed on a desktop or workbench rarely reaches 20 tons.

The compactness of tabletop electro-hydraulic presses allows them to be used in small automotive and home workshops.

An important parameter of electrohydraulic presses, in addition to the force they are capable of creating, is the height of their rod.

This parameter, in particular, determines what size parts the equipment can work with.

If for tabletop presses this parameter can reach 100 mm, then for floor-standing models it reaches half a meter.

Due to their versatility, electrohydraulic presses are used in many fields of activity.

Such areas of activity, in particular, are mechanical engineering, woodworking and food industries.

However, most often such equipment can be found at vehicle repair stations.

Using it, you can successfully solve not only all of the above technical problems, but also straighten dents and other damage to the car body.

Unlike pneumatic equipment, the use of which requires a rather complex pneumatic system, a hydraulic press with an electric drive can simply be connected to an electrical power supply, and it will function normally.

How to make your own hydraulic press with electric drive

Serial hydraulic presses with electric drive are quite expensive, so it makes sense to think about how to make an electro-hydraulic press with your own hands. To do this you will need the following tools and equipment:

- welding machine;

- lathe;

- drilling machine;

- Bulgarian;

- electric drill.

This press will be able to produce a maximum pressure of 35 tons

The supporting structure of the electro-hydraulic press, which is subjected to the main mechanical loads, is the frame, the strength of which should be given special attention.

A T-beam made of metal of such thickness that it can withstand the loads created by a hydraulic press without bending is well suited for these purposes.

Press frame made of I-beam

Structurally, the frame of a homemade electro-hydraulic press is a U-shaped frame, welded from T-beams and installed on a base, for the manufacture of which thinner channels and angles can be used. In the middle part of such a frame (along its height), a working platform is welded into it, for the manufacture of which thick-walled channels are used.

In order for such fastening to be as reliable as possible, it is better to fix the hydraulic pump on a 20 mm metal plate using a flange.

The metal plate itself, which will absorb all mechanical forces, is mounted on two T-beams.

The rigidity of the structure is ensured by high-quality welding seams

Installation of the hydraulic cylinder on the bed

The process of installing a hydraulic cylinder on the frame of a homemade hydraulic press is carried out in a certain sequence.

1. Adjustment of hydraulic cylinder, flange and plate

The body of the hydraulic cylinder, so that it can be placed in the inner part of the flange, is turned on a lathe.

The flange, which can be made from a car hub, is also processed on a lathe.

20 mm thick plate with a welded boss in the center

After the hole in the slab is bored out, it is welded to the beams of the base frame.

The flange, in which the mounting hole has already been prepared, is put on the hydraulic cylinder and welded in a circle.

Flange welded to hydraulic cylinder

It is very important that the flange and hydraulic cylinder are connected as smoothly as possible; for this, the adjacent surface of the flange must be machined on a lathe. 2. Installation of upper beams and hydraulic cylinder

The plate, which is already connected to the beams, is installed on the frame and connected to it by welding.

Through the holes on the mounting part of the flange, holes are drilled in the plate, which are necessary for placing the mounting bolts.

The installation of the upper beam is carried out strictly perpendicular to the supports

The hydraulic cylinder should not be attached to only one point, so it is necessary to make another flange, put it on the top of the cylinder and weld it to the beams.

Installing the Top Flange

T-beams installed in the upper part of the frame are connected to each other by welding.

3. Installation of the frame and oil station

In order for the hydraulic press you have made to fully function, you need to install an oil station on it and connect it with a hydraulic cylinder using hoses.

Installation of a frame and a two-flow hydraulic station delivering a pressure of 700 bar

Thus, it is not difficult to make a hydraulic press with an electric drive with your own hands. At the same time, you will have at your disposal equipment that can solve many technical problems.

Hydraulic pump: price, device, types

The high pressure hydraulic pump is very widely used in everyday life and industry.

It is especially popular in mechanical engineering, the oil and gas industry and construction, where without it it is impossible to carry out a huge amount of work.

At the same time, the hydraulic pump itself cannot be called a very complex mechanism.

Device and types

Hydraulic equipment always works by moving fluids from one piston to another. In this way, it is possible to convert hydraulic energy into mechanical energy.

The design of a hydraulic pump largely depends on its type. However, many elements in it are similar and work on the same principle.

Special oil in the pump housing is pumped through a specific system.

The resulting energy affects the device to which the pump is connected.

Oil can be pumped in different ways. In mechanical engineering, rotating shafts are used, but in everyday life, electric motors and even manual drives are used. Most pumps can only operate in one direction.

It is very important to understand that different types of hydraulic pumps differ significantly in their design and operating principle. Therefore, all samples can be judged and evaluated only after they have been fully examined.

Hatsan devices

These pumps for air rifles are in great demand. However, the devices are not suitable for PP models. The adapter for pumps is used with a jumper. If you believe customer reviews, the hose is installed without problems. The model has three filters in total. The upper valve of the device is made of aluminum alloy. The maximum pressure indicator is 3 bar. In turn, the overbrightness parameter is maximum 6 microns. The plunger mechanism is located at the foot rests. The handle is standardly made with side pads.

The stabilization system is used in the second degree. According to experts, the bar can withstand heavy loads. The spring of the pump is 2.3 cm. The height of the stand is 46 cm. The model's pressure gauge is used with one measurement scale. It has a moisture protection system. The swing valve is of high quality. It keeps the maximum pressure at 2 bar. Pump pushers are used with an expander. You can buy a model on the market for 17 thousand rubles.

Modifications "Diana"

These high-pressure hand pumps for pneumatics are manufactured with two adapters. A distinctive feature of the model can also be called a wide footrest. The handles in this case are made with side pads, and they are rarely washed. The rod in the device is made of aluminum alloy. According to experts, the pressure gauge used is of high quality. In total, it has two measurement scales. The model has a moisture protection system.

The stand is used with a round cross-section. The upper valve of the device is made of cast iron. The maximum overload parameter is 6 microns. The stabilization system is used in the third degree. In total, the model has two sealing sleeves. The device is perfect for PP series cylinders. You can buy a pump of the presented series for 14,400 rubles.

What to look for when choosing

If there is an urgent need for a hand pump, then you should know how to correctly choose the optimal model.

- First of all, the parameters of the well (depth of the aquifer) and the parameters of the pumps offered for sale are compared. As already mentioned, most hand-held models are capable of working with sources located on the forehead at least 6 ÷ 8, rarely 10 meters. If the burial is deeper, then there is no alternative: you will have to install only a sucker rod pump.

- It is important to know the performance of the pump - how much water it is capable of pumping per cycle (or per unit of time - a minute, under intense load))

- The next parameter of the planned (or existing) well - the diameter of the casing pipe, also affects the choice of pump. If the pipe has a nominal bore of 4 inches (100 mm) or more, there are no problems, and you can purchase any pump. But in the case when the casing is narrower, the rod pump may no longer be suitable - it will simply be impossible to lower its working pump assembly into the water column.

- It is necessary to know the degree of contamination of the water from the well - usually the pump's specifications indicate the permissible level with which the equipment is capable of operating.

- It would probably be worthwhile to evaluate the ease of working with the pump. It is necessary to keep in mind that among the users there may be people of advanced age or children - will their efforts be enough to collect at least a small volume of water.

- It is necessary to think about how the pump will be installed - what mounting platforms or mounting holes, brackets or lugs, etc., are available for a particular model. It is also important to know the weight of the purchased device in order to foresee possible ways of installing it in advance - whether it will be a metal welded frame, a concreted platform, a flange connection to a casing pipe coming out of the ground, a wall mount, or just some lightweight option for seasonal use.

- Based on the expected operating conditions, you can determine the design features of the product. So, for installation only in the summer, you can purchase a lightweight plastic version. If a permanent installation is intended, then the choice is made in favor of cast iron or stainless steel. In addition, for temporary use you should purchase a model that is easy to quickly install and dismantle on your own.

- Finally, for many owners, the determining factor is also the external decorativeness of the pump - this has already been mentioned in the article. Of course, purchasing a pump that can decorate a site will entail much more serious financial costs.

The value of the pressure created by the pump is very often not assessed - such devices, as a rule, are not designed for pumping water through external pipelines. Water from them is most often collected into placed containers.