A water pump is a device that is almost impossible to do without when living in a private house or cultivating a summer cottage. In cases where it is not possible to purchase a serial model of such a device, you can make a water pump yourself, spending a minimum of financial resources. A homemade water pump is made from materials and parts, most of which can be found in any home workshop or garage, according to one of the design schemes proposed below. Using such a low-cost device, you can solve many household and economic problems.

Manual water pump

Water pump

In order to make a simple and useful unit for working in the garden or vegetable garden, you will need:

- Tubes and hoses.

- Bottle necks with cork.

- Stationery knife.

Making a water pump:

- There is a thin gasket in the plug. You need to take it out and remove a 2 mm strip from the edges, leaving a small section 3 mm thick. The result will be a circle with a protruding petal.

- In the center of the lid you need to drill a hole with a diameter of 1 centimeter. We insert the cut gasket into place and screw the neck. As a result, the neck should press the petal to the lid.

- The resulting valve must be installed in the rod tube. A skirt made from a cut bottle is connected to it.

- An outlet hose is connected to the other side.

A device made in this way will allow you to get rid of some debris on the site.

Design and principle of operation

Screw rotors rotating inside the stator displace liquid, increasing its pressure. The liquid is pumped by moving it between the screw grooves located along the axis of the screw and the housing. To improve the quality of the design and reduce the number of leaks, conical and cylindrical elastic casings are used. The spring presses the conical screw quite reliably, and the fluid, due to the pressurized pressure, helps reduce the number of leaks. If it is necessary to withstand heavy loads, metal cases are used instead of elastic ones.

water pump

The classic pump scheme, which has been used for several decades in many villages and towns without running water.

The simplicity of the design allows it to be used in disadvantaged areas without extra costs. An excellent option for a plot of land that has a well.

The following components will be needed:

- PVC pipe 5 cm in diameter with plug and elbows.

- Check valves 0.5 2 pieces.

- PPR pipe 2.4 cm in diameter.

- Rubber gaskets and several pairs of bolts with a 6-8 mm nut.

- Additional details.

Let's make a pump.

In order for the structure to work, it is necessary to ensure the reliability and tightness of the structure. The handle is connected to a piston, which creates pressure in the working chamber. Under the influence of increased pressure, water passes through two valves and reaches the outlet. If you do not ensure the reliability of the housing and the tightness of the gasket, your efforts will be in vain

What types of concrete pump designs exist?

The concrete pump is a structure consisting of the following parts:

- Frame with one or two-axle chassis - a welded frame designed for compact and stable placement of the main parts of the installation.

- The power unit is a diesel or electric asynchronous motor.

- Hydraulic system - pumping station, distributor, hydraulic cylinders and cooling system. This system, used in piston concrete pumps, is designed to drive the working parts of the unit - pistons moving in concrete supply cylinders.

- A loading hopper with a mixer is a container in which the concrete mixture loaded from the mixer is additionally uniformly mixed into a homogeneous mass and supplied to the pressure chamber.

- Pressure chamber - this unit in various types of concrete pumps consists of two cylinders with pistons moving in them, a rotating rotor or auger. In this unit, the concrete mixture is compressed under pressure of 200 atmospheres. Such a high degree of compression is necessary for continuous and uniform supply of the mixture over a distance of up to 1000-1500 m and a height of up to 200-300 m.

- Sleeves or pipes for supplying concrete - having a large diameter, flexible concrete pipelines through which the mixture under pressure is supplied to the pouring site

- Control panel for concrete pump operation.

Also in many modern models of concrete pumps there is

a flushing system consisting of a compressor and a water tank (receiver). With the help of this system, upon completion of concrete work, the units in contact with the concrete mixture are washed - concrete pipelines, pressure chamber.

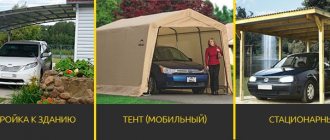

Depending on the size and possibility of transportation, these devices come in the following types:

- stationary – trailed concrete pumps mounted on a single-axle chassis with a hydraulic or electromechanical drive. They are used in the construction of high-rise buildings and cottages.

- mobile (mobile) – concrete pumps installed on the frame of a truck. In such installations, the car engine acts as the power unit. Such powerful and high-performance concrete pumps are used in the construction of high-rise buildings and cottages.

- small-sized - small installations used in private housing construction.

Hand pump

Assembling a homemade bicycle pump is actually quite simple. In order for it to work properly and not require an excessive amount of effort, you need to carefully select the dimensions of the working parts.

What you will need for assembly:

- Pipe up to half a meter long, of arbitrary diameter.

- The metal disk is 2 mm narrower than the diameter of the pipe.

- Valve.

- Schlag.

- Thick reinforcement.

It will be more of a stationary pump. If desired, it can be made smaller and from lighter materials.

DIY fan: how to make a homemade powerful fan. Basic parameters and properties of fans (130 photos)- Why do you need a security alarm, what functions does it perform?

How to choose winter workwear and not make a mistake - recommendations from the pros

On one side the pipe needs to be soldered. A reinforcement of a convenient length for use is welded into the center of the metal disk. A hole is drilled through which air will be pumped. A valve is installed in it.

In order for the disc to move in a strictly vertical direction slightly above the valve, it is necessary to add a bearing that will control the movement. On the side of the pipe, near the sealed end, a hole is drilled for the air outlet hose.

If desired, you can install a cross from the bottom for greater stability of the unit. If air leaks occur around the round disc, you can use a rubber or silicone gasket.

How do rod units work?

This hand pump for a well or well, although it contains the principles of a piston device, is slightly improved. And this opens up the possibility of pumping liquid from a depth of a maximum of 30 m. The peculiarity lies in the special design of the piston, equipped with a special rod (and the name comes precisely from this modification).

Rod unit for pumping liquid from depth

As always, increasing the complexity of the design leads to a decrease in strength. The main disadvantage is the frequent breakdown of these same rods. Here, however, everything depends on the manufacturer, who is responsible for selecting high-quality materials and careful assembly. The second negative point is that the design of the pump itself is quite cumbersome, and this causes certain difficulties during installation.

This unit works in exactly the same way as a piston unit, but the difference is that it is not the pipeline through which water flows that is inserted into the well, but the entire pump body to the level of artesian waters. That is, the reservoir holds much more liquid than a simple piston pump, and water can be drawn from a greater depth. This means that the presence of harmful impurities entering the water at shallower depths is excluded.

Pool water pump

In order to make a device that allows you to fill the pool in the shortest possible time, you will need:

- Motor from a washing machine.

- Reed valve.

- Cork.

- Hose.

- Separating transformer.

Using a plug, you need to close one hole in the valve.

Before you make a pool pump with your own hands, you need to purchase a reed valve. It needs to be connected to a hose and lowered into a water source. The second end of the hose is connected to the pump.

How to choose an air conditioner for your home or apartmentDo-it-yourself bait - composition, application features and storage methods (115 photos and videos)

DIY sliding gates - how to build simple and automatic gates. Schemes, drawings and review of the best ideas (90 photos)

After the entire structure is filled with water, you can connect the engine to the transformer.

Creation of an airlift

Pumping water from reservoirs and underground sources can be organized without the help of standard pumping equipment. To do this you will need an original device called an airlift. To make such a simple but quite effective water pump with your own hands, you will need two pipes of different diameters, one of which will supply compressed air, and the second will pump out water, and a regular air compressor.

Operating principle of an airlift pump

The operating principle of the airlift, which was invented 200 years ago, is as follows. If you place two tubes in the water column, one of which will supply compressed air, this will lead to the formation of a mixture of liquid and bubbles. Such a mixture, having a lower density than water, will begin to rise up the second tube.

To see how such a water pump works, you can conduct a simple experiment by placing two tubes in a bottle of water, one of which is connected to an aquarium compressor powered by a low-power motor. When the compressor is turned on, water will begin to pour out of the second tube. The efficiency of such a water pump, usually not exceeding 70%, directly depends on several parameters - air flow, immersion depth and the total height to which the pumped water must be raised.

Photo instructions on how to make a pump with your own hands

Answers to frequently asked questions

How can you save money when making a pressure washer?

When making a high-pressure washer with your own hands, you can save money by using inexpensive, used, but serviceable parts from disassembly of various machinery and equipment. However, what you should not save on is the pump. If you take a low-quality or already worn-out pump, it will quickly fail.

Why does a pressure washer lose pressure over time?

A drop in the performance of the MVD is a sign that the pump was chosen poorly and is quickly wearing out. When the washer pumps normally when cold, but as it operates it begins to supply water worse, this indicates overheating and the need for additional cooling of the units.

Does water hardness affect the pressure and service life of the sink?

Mineral particles dissolved in water can act as an abrasive, gradually scratching the friction surfaces, deposited on device parts and accelerating their wear. They can also clog the spray gun nozzle.

What to do if the assembled sink does not produce the required pressure?

If the washer pumps weakly, despite the suitable parameters of the pump and motor, you need to make sure that the motor develops sufficient power. Three-phase electric motors on a 220 V network operate only at 30%, and this may be the problem. If the engine is at fault, it needs to be replaced with a more powerful one or repaired (if we are talking about an internal combustion engine).

Homemade for a small stream

Homemade diagram for a small stream.

2 buckets are rigidly connected through blocks. The drainage system is made of galvanized steel. A leash with a cable is attached to a metal product. To reduce wear, a polymer gasket is used.

The principle of operation is based on pouring liquid from one bucket to another. A crank mechanism is used to transfer energy to the pump.

American or spiral type

The use of river flow energy is the basis of the principle of operation of a spiral pump. For normal operation, the water flow must move at a speed exceeding 15 m/s at a depth of at least 0.3 m.

For manufacturing it is necessary to prepare materials according to the following list:

- rubber hose d 50 mm;

- clamps of the appropriate size;

- a piece of plastic pipe with a cross section of 150 mm;

- pipe reducer from a recycled sewer truck;

- wheel, supplemented with blades for efficiency.

The water intake, made of a polyvinyl chloride product with a diameter of 150 mm, is connected to 1 end of the flexible hose. The opposite edge is put on the gearbox. It is allowed to use industrial equipment.

The hose pipeline is fixed to the wheel with clamps. It is recommended to fasten in a spiral manner.

The liquid enters the intake and moves along a spiral path, providing the required pressure. The lifting height is determined by the speed of the water flow and the immersion depth of the water intake pipe.