If you need a prefabricated, inexpensive and warm garage, pay attention to sandwich panels. This material is lightweight, which allows you to make a lightweight foundation. In addition, it comes immediately with a paint coating inside and outside, so finishing work is also not needed. It is assembled on a metal, or less often a wooden, frame in a few days (provided there is a ready-made foundation). So a sandwich panel garage is a good option.

The garage of their sandwich panels is warm and looks solid

Sandwich panels: general concept

A garage made of sandwich panels belongs to the category of frame buildings.

This is the name of a multilayer material characterized by ease of installation. Manufacturers produce panels for walls or roofs. All of them consist of 3 layers: a middle insulating layer and 2 outer protective ones.

The cladding is made of PVC, OSB or magnesite sheets. It can be profiled or smooth. There are materials that imitate corrugated sheets, siding, and brickwork.

The thermal insulation layer is made from:

- foamed polyurethane;

- polystyrene foam;

- mineral wool.

Properties

The thickness of the slab is 6-25 cm, width - 1-1.25 m, length - 2-12.5 m. Such characteristics help to build prefabricated buildings with a minimum number of horizontal joints. It is worth ordering slabs with a length that matches the height of the walls of the building. The panels are placed vertically, connecting using the tongue-and-groove method. Structures built from sandwich boards retain heat, so additional thermal insulation is not required.

Benefits of use

The positive qualities of the material in question include:

- ease of installation;

- possibility of use in any climatic conditions (when choosing slabs with an appropriate heat insulator);

- light weight, facilitating the transportation of material to a construction site or warehouse;

- minimal load on the foundation, reducing the required strength of the foundation being laid, making it possible to erect buildings on any terrain;

- attractive appearance, helping to avoid cladding the facade of the building;

- hygiene;

- low moisture absorption coefficient;

- good noise insulation properties;

- low cost of material (a garage from SIP panels can be built on a limited budget).

The advantage of using the material is ease of installation.

Prices

If you build a garage yourself, its construction will cost the owner much less than using standard materials, and the building will last from 30 to 50 years.

The average price for sandwich slabs varies from 920 rubles. up to 4200 rub. for 1 m2 . The greater the parameters of the elements (thickness, width, length), the higher the price. This cost must be multiplied by the area of the garage walls and subtracted from it the sizes of windows and gates. Roofing panels will cost about 2000 - 4000 rubles.

To the costs you also need to add the price of the foundation, fastening elements (if they are not included in the package of the panels), gates, windows, tools for work.

Factors affecting the performance of building materials

The properties of sandwich panels depend on their composition, thickness, and installation method.

Insulation material

The middle layer of the slab may consist of:

- Glass wool, which is rarely used due to the complexity of construction work. The insulation contains fibers that irritate human skin. Work must be carried out in gloves, a protective suit, and a respirator.

- Basalt wool, sensitive to the influence of steam and moisture. Increased demands are placed on the quality of sealing of building joints. However, it is impossible to ensure proper sealing during the construction of a utility block.

- Polyurethane foam that retains its properties at any humidity. The insulation is resistant to pathogenic microorganisms.

- Expanded polystyrene is a lightweight, practically non-flammable material.

Additional insulation can be glass wool.

Sheathing and polymer coating

When constructing cabins, summer cottage sheds and other outbuildings, sandwich panels treated with galvanized steel, which is insensitive to corrosion or mechanical stress, are used. A facing polymer coating is applied on top of the metal layer.

Companies offer building materials covered with plywood or particleboard. They are used less often in the construction of garages.

Product thickness and types of connections

Multilayer slabs for different purposes differ in size and shape. The thickness can reach 26 cm. However, in the construction of utility structures, thinner sandwich slabs are used. The connection of the wall panels is made end-to-end, the roofing slabs are laid with an overlap.

Advice from the experts

- When installing panels, you can slightly improve the quality of the locking connection. To do this, a tape of insulation (you can use polyurethane foam) is placed in the groove of the mating part, preventing the joints from blowing through and condensation or freezing appearing on them.

- If a horizontal type of installation is used, it is recommended to lay a strip of foam plastic under the first panel. This will help retain heat in the room, seal the joint and prevent rain or melt water from entering through the cracks.

- Before cutting the panels, it is necessary to determine what type of insulation is inside. If there is mineral wool, you have to cut it in a respirator. If it is glass wool, glasses, gloves, and closed clothing are required.

Garage Project Options

When designing a building made of sandwich panels with a metal frame, the car owner is faced with the difficulty of choosing the layout of the future building. It is worth studying ready-made plans for utility units, which are used when creating your own drawings.

Single-story

The building consists of a single room where the car and everything required for its maintenance are stored. You can see what an assembled one-story garage made from sandwich slabs looks like in the photographs.

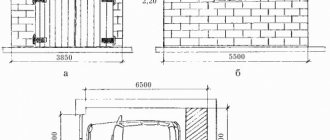

Drawing of a one-story garage.

Two-story

Similar projects are often used by car service owners. On the ground floor of the building there are boxes for car repairs, and in the attic there are administrative premises.

Table: pros and cons of choosing material

| Advantages | Flaws |

| Does not require the construction of a capital foundation. | If you use mineral wool as insulation, then do not forget to take care of good ventilation or use panels with expanded polystyrene. |

| You can work with this material in any weather and at any time of the year. | Uninsulated areas (joints) may freeze slightly. |

| There is no need to involve specialized dimensional equipment. | The coating is quite fragile and unstable even to scratches. |

| There is nothing difficult in constructing the structure; even a beginner can handle it. | |

| There is no need for large financial expenses. | |

| The panels do not require additional finishing. | |

| This is a fireproof material, it stably maintains the temperature inside. | |

| Environmentally friendly material. | |

| If the building is built correctly, it can last quite a long time (up to 30 years). | |

| When moving, the material can be disassembled, transported to a new location and reassembled. If there is a good metal frame, the entire garage can be transported. | |

| Thermal insulation is initially built into the panel. |

Construction technology

Before calculating the number of sandwich panels and drawing up an estimate, they select the technology for constructing a prefabricated garage and make a drawing. This eliminates mistakes when purchasing materials.

For the construction of utility blocks from metal structures and multilayer slabs, 2 technologies are used:

- Finnish way. In this case, all elements of the building are built from SIP panels: roof, walls, floor and ceiling. The design is based on a metal frame.

- Russian method. Domestic builders recommend logs and boards for forming floors. The base is made of metal or wooden elements. In the latter case, the frame construction method is used.

The metal base of the building is assembled from:

- beams and racks produced in the same factory as the panels;

- profiles, corners (when constructing 2-seater buildings, I-beam elements are used).

The Russian method is used for the construction of utility blocks.

The first option is easy to install, since the factory elements of the metal frame have the required dimensions and are numbered according to the project.

Profile pipes are cut by hand.

When using any technology, the metal elements of the frame are held together by:

- electric or gas welding;

- bolts.

The panels are attached to the metal frame with long self-tapping screws.

Choosing a size

The size of the garage is determined by the size of the area allocated for it. On a plot near a private house, you can afford a larger garage if there are any plans for it - for example, equipping a workshop, a paint booth, etc.

There is another factor that influences the size of the garage - the number of cars. The standard size traditionally used for the construction of such buildings is 6 m by 4 m; for 2 cars they usually build 6 m by 6 m.

NOTE!

Practice shows that, if possible, building a more spacious garage is always very useful - who knows what kind of car will be parked in it tomorrow, maybe a very large one?

Recommendations for DIY construction

Work begins with calculating the number of panels and other materials and choosing the location for the construction of the utility block.

Preparatory activities

When constructing a prefabricated building they use:

- concrete mixer;

- sand, crushed stone, cement;

- containers for preparing the solution;

- reinforcing bars with a thickness of 8 mm;

- boards for formwork;

- shovel;

- building level;

- drill;

- drill;

- bolts and screws;

- welding machine (when working with the metal base of the building);

- silicone sealant.

A concrete mixer is used during construction.

To count the number of slabs you need:

- calculate the area of the roof and walls;

- divide the resulting number by the quadrature of 1 slab;

- round the value up.

An important stage of construction is laying the foundation. Before it starts, the volume of concrete and the amount of reinforcing material are calculated. The garage is built on a slab or strip foundation. The first is laid around the perimeter, the second - in a continuous way. To calculate the volume of concrete, the length of the foundation is multiplied by the width and height. The base of the utility unit is reinforced with thick metal rods. Their number is calculated as follows:

- the width of the building is divided by 0.15 (the number of rods is obtained);

- the value calculated at the previous stage is multiplied by the length of the wall (this helps to express the amount of reinforcing material in linear meters);

- repeat the calculation, calculating the number and length of the rods that are placed along the long side;

- double the number obtained at the previous stage.

Foundation

The best option for a utility block is a shallow slab base. A solid foundation provides the following advantages:

- refusal to arrange the floor;

- stability of the garage during soil vibrations;

- insensitivity of the building foundation to high loads.

A slab shallow base is the best option for a utility block.

The construction of a slab foundation for a garage includes the following steps:

- Site preparation. Determine the installation location of the utility unit. They break up the surface using corner and intermediate stakes. A rope is pulled between the elements.

- Digging a pit. According to the previously completed markings, the soil is removed with an excavator or shovel. The walls of the pit are compacted and leveled.

- Formation of a sand cushion. The material is laid in a layer of 7-10 cm, leveled, compacted. Gravel is poured in the same way.

- Formwork assembly. If there are no boards, the pit is lined with roofing felt. If lumber is available, the walls are reinforced with shields and crossbars.

- Installation of fittings. A metal frame with a cell of 20 cm is welded from rods. Wire can also be used to assemble the structure.

- Pouring the solution. It is recommended to use factory-mixed concrete, each layer of which requires compaction. No voids should form in the thickness of the foundation slab. At the last stage, the surface of the monolith is leveled with a board.

Construction of a metal frame

After the concrete has hardened, the installation of the base for the panels begins. The frame is built from wooden beams or metal corners. In the first case, elements with a cross-section of 10 x 10 cm are required; before installation, they are impregnated with an antiseptic composition. Metal corners are used for connections.

The frame installation process involves placing vertical posts.

The installation process of the utility block frame includes:

- Assembling and fixing the lower belt on the foundation. Using a building level, check the horizontalness of the frame.

- Placement of vertical posts - in the corners and every 3 m.

- Mandatory installation of frame posts at the gate locations. A distance of 50 cm is left between the elements.

- Installation of the upper belt.

Nuances of laying panels

Before installation, holes are made in the elements for fasteners that secure the casing to the racks. The self-tapping screw should be located at a distance of more than 5 cm from the edge. All fasteners are inserted perpendicular to the surface. Corresponding holes are also formed in the frame elements.

When installing panels, observe the following rules:

- Before installing the slabs, remove the film at the points of attachment to the frame. It is completely removed after the construction of the wall is completed.

- When using horizontal technology, the slabs are laid starting from the bottom. The vertical method involves installing the element in the corner part of the frame.

- When using the horizontal method, the panel is laid with the groove down. This ensures that water drains quickly in rainy weather.

- The installation of wall elements of the building is carried out with constant control of verticality.

- The connections are sealed with silicone compound, applying it with a construction gun.

- Before installing the roofing elements of the building, a support platform is installed. The slabs are lifted using a manipulator or a self-clamping mechanism.

- The shaped elements are installed after the walls and roof are assembled.

When laying panels, it is important to follow the rules.

Garage sheathing is carried out in any weather. However, it is worth considering the operating temperature range of sealing materials.

It is not advisable to work with mineral wool-based slabs in rainy weather.

Finishing work

Sandwich panels do not require additional cladding. However, at the final stage you need to install windows, gates and a partition. The dimensions and quantities of auxiliary elements are selected at the design stage.

Windows and gates are ordered from specialized companies; the partition can be assembled from leftover panels.

Frame installation

The frame is the basis of the entire structure

The vertical posts of the frame are the basis of the structure. Supports are installed in two ways:

- partially buried in the ground;

- secured to the foundation using an anchor connection.

Depending on the material chosen for installation of the frame, the elements are connected in different ways:

- with screws;

- self-tapping bolts;

- special anchor locks;

- gas or electric welding.

Features of premises operation and care

A cottage, garage or shed made of SIP panels is durable and reliable, however, in order for the building to last longer, it must be carefully looked after. To do this, perform the following actions:

- Every six months, inspect the walls and roof for cracks or other defects.

- Do not allow excessive loads on the panels or impacts. This helps avoid dents and damage to the insulation.

- Heavy furniture modules, ladders or mechanisms are not attached to the panels.

- The roof is equipped with a drainage gutter. In winter, the roof is regularly cleared of snow.

- The facing coating of SIP boards is cleaned with a detergent that does not contain abrasive substances.

- If the protective layer of the panel is damaged, repair paint is used.

Walling

The walls are installed from prepared panels, for which they are cut to length and width (if necessary).

Installation can be done in horizontal or vertical direction. If a horizontal installation is used, then the locking parts should be positioned in such a way that flowing water cannot enter the joint, otherwise it will freeze and expand and begin to destroy the joints of the material . Vertical installation is carried out from the corner; the direction of the lock in this case does not matter.

NOTE!

The panels are cut using metal scissors. It is strongly not recommended to use an angle grinder for this, as it heats the metal and causes the protective coating to peel off, which causes corrosion of the metal.

Examples of finished buildings

An unusual and interesting garage made from American-style panels. This utility unit is designed for 2 cars. The first is located indoors, the second is under a canopy. Such a garage is convenient for storing country equipment that is used regularly. The attic is designed for storing small equipment. There is a separate door next to the gate.

Sandwich panels are initially ready-to-use material.

Sandwich panels are very popular.

A garage made of sandwich panels will not be too heavy.

An equally good option is a garage attached to the house. The correct selection of panel tones helps the utility unit fit harmoniously into the overall ensemble. The gate faces the street, so there is no need to drive the car into the yard.

Roof installation

The roof can be flat or pitched. For areas with heavy snowfall, it is better to build a sloped structure, but you should not make it too high, as the wind load will increase . In this case, you need to assemble the rafters and install them one by one on the upper points of the frame trim.

Then they are connected by purlins and longitudinal strips, on which the roofing panels will subsequently be installed.

Negative aspects of a prefabricated structure made of sandwich panels

The disadvantages of prefabricated buildings include:

- the need to organize a forced ventilation system, without which the air humidity in the garage increases;

- low load-bearing capacity of long sandwich slabs;

- the impossibility of hanging heavy structures on the walls of the utility block;

- the need for careful processing of joints between slabs.

Sandwich panels are an easy-to-install, inexpensive material for the construction of auxiliary buildings. Step-by-step instructions help you accurately complete all stages of the work. It is important to assemble and sheathe the frame correctly. Then installing gates and windows will not cause problems.

Garage Doors

An important detail is the garage door. They provide safety and comfort of use. Gives a completed look to the building.

Popular types: — Roller shutters — Sliding — Swing — Sectional

All options have insulation in the form of foam filling. This gives additional heat and sound insulation properties. You can choose almost any color, in combination with the main one.

Can be equipped with automatic remote opening. Only in swing gates this will be more difficult to implement.