When heating private households or country cottages, combined boilers are often used to heat the house - they will ensure a comfortable temperature in all rooms, regardless of the presence or absence of a centralized gas supply or firewood.

A significant advantage of such units is the adjustment of cost estimates not only for heating the building, but also for supplying hot water. Besides, it’s very convenient to be able to use different types of fuel, don’t you agree?

The efficiency of combined boilers in the absence of access to a central energy supply system is confirmed by numerous reviews from their owners. The main task is to choose the optimal type of heating unit.

We will help you make the right choice. The article describes the features of operation, operation and maintenance of different types of combined boilers. We have outlined the main criteria for evaluating equipment and provided practical recommendations for choosing a heating unit.

What components does combined home heating consist of?

This system may include several components, namely:

- solar collector;

- Heat pump.

To achieve the desired effect, it is best to use a solar system in combination with another one, since when used separately, the collector is intended only for heating water, but in combination with another heating system, its service life reaches more than thirty years.

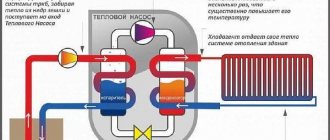

But the heat pump can already be used not only as an auxiliary heat source, but also as the main one.

The equipment that includes this device has the ability to extract energy from everything that is near the house:

Heat loss calculator

Calculator for the number of radiator sections

Heated floor calculator

- from the earth;

- of water;

- from the air.

Such a pump also lasts a decent amount of time, approximately 25 years.

Manufacturers, characteristics and design

Combined heating equipment on the Russian market is represented by products of domestic and foreign manufacturers. Some of the most popular are:

- Navien (Korea)

- CTC (Sweden)

- Hercules (Russia)

Let's start our consideration with Korean products. Gas-electric boilers from Navien are fully adapted for operation in Russian conditions. They easily cope with voltage drops in the network and do not react to a decrease in pressure in the gas main. The use of such technology allows you to save money on operation due to low gas consumption. They have a high degree of protection, and the circuits of electric-gas boilers make them completely safe to use. The operating modes of the device are set in software and can be selected independently.

The boilers of the Korean company have an optimal balance between price and quality. The presence of a special chip in the package that protects the device from voltage surges significantly extends the life of the device and also prevents its breakdown. The operation of this boiler is configured in such a way that it adapts to the conditions in a particular room, which saves fuel. The presence of a remote control allows you to control the operation of the device from a distance.

An electric-gas boiler from a Russian manufacturer under the Hercules brand can be used to heat rooms up to 300 m². The company's products are represented by a wide range of models. It includes samples with different configurations, depending on the energy carrier and functional features of the device. They have two circuits and are capable of not only heating the room, but also supplying residents with hot water, without connecting additional gas water heating burners. The DHW circuit in such boilers has a protective coating that increases its service life.

The device from the Swedish manufacturer has a power of 45 kW and is capable of heating rooms up to 500 m².

The gas-electric boiler STS is a model that can operate on any of the existing types of fuel. Its distinctive feature is that it is equipped with heating elements with a power of 15.75 kW. The presence of an internal automation system allows you to maintain the water temperature at a constant level. If necessary, boiler circuits can include programming devices that allow operation to be adjusted depending on the outside temperature.

The presence of a heat exchange unit in the configuration allows you to prepare up to 730 liters of water per hour.

The advantages of this device are:

- Easy access for cleaning smoke ducts

- Overtemperature control

- Possibility to turn off the pump and burner if necessary

Having considered the capabilities of three models of combination boilers from different manufacturers, you can make the right choice. It should be based on the size of the room, its thermal insulation properties and the availability of the required amount of funds.

Combined fuel boiler

This boiler model is a universal device that allows you to use several types of fuel at once. The most popular combinations that are in demand among consumers are the following types:

- diesel fuel in combination with gas;

- electricity combined with solid fuel;

- gas and solid fuel;

- electricity, diesel and solid fuel, gas.

Any of these options is selected individually for each home, taking into account multiple factors and features, such as the location of the house in relation to gas mains and water supply and climatic conditions.

A four-component boiler is an ideal option for cottages that are located far from the amenities of civilization and there are no utility lines nearby and frequent power failures. Also, the above heating options are in great demand. Electricity combined with solid fuel is an economical option and quickly pays for itself on equipment investments. Solid fuel heating uses not only wood, but also coal and coke. Heating is an integral part of any home, apartment or industrial facility. Therefore, heating systems and equipment are constantly being improved, allowing us to find new and more acceptable options for the consumer. Our company provides installation services for combined heating at home and guarantees the high quality of the work performed.

Our specialists have mastered the latest developments in the installation of modern home heating and are professionals in this field.

By contacting our company you will receive high-quality and decent service at reasonable prices.

Operating modes

The presence of an electric heater for hybrid boilers is optional. Such an additional heating source does not serve the purpose of smoothing out interruptions in the supply of fuel or reducing the cost of the generated thermal power. However, heating elements are very ergonomic in terms of temperature control, which means they can be used for precise heating of coolant without a complex automation circuit, controlled dampers and pressurization.

In most cases, it is important for the consumer to mitigate the disadvantages associated with low gas pressure and its high cost. The main heating occurs due to the combustion of solid fuel, while the gas burner is switched on only to achieve the set temperature. This may be required both due to the low energy intensity of wood, and at times when the next supply of fuel is exhausted.

You should know that the most effective operating scheme is when water from the “return” flows first into the gas combustion chamber. There it is heated exactly to the extent that, after passing through the solid fuel firebox, it acquires exactly the specified temperature value. In this case, the most complete absorption of heat from the most expensive type of fuel occurs. At the same time, water enters the heat exchanger of the solid fuel chamber already heated, which makes the formation of tar and soot less intense.

The inclusion of heating elements in the work occurs according to a slightly different principle. Naturally, if necessary, electric heaters can play the same role as a gas burner. However, usually electricity is just a safety net for solid fuel boilers: electric heaters only maintain the temperature of the coolant above the freezing point if all the fuel is used up.

Installation of water supply heating systems Klin, Klinsky district

Heating cost calculation

The cost of repairing heating systems

Cost of installation of water supply

Similar services:

- Combined heating from a gas holder Every owner of a private building located outside the city faces the problem of heating the house with hot water. Combined heating from a gas holder is suitable if...

- Boiler room and heating of a wooden house - Portfolio Until recently, heating in a wooden house was organized on the basis of a brick stove. It was this that was the main source of heat and...

- Heating a country house options and prices Autonomous heating of a country house in various options at prices below average - we provide these services in Moscow and Moscow region...

- Heating of a private country house Heating of a private country house: steam is used mainly as central heating for apartment buildings. To implement this type of heating it is necessary…

- Heating for the home Installation of a heating system for the home. This approach ensures unity in the actions of the team, a common vision of the heating installation scheme and eliminates the occurrence...

- Heating and boiler room Heating of the house must be thought through before the construction of the house itself begins. Especially if this house is not just an easy home for a summer resident,…

- What is private heating? The desire to plunge into the silence of country life, to be closer to nature, to breathe clean air prompts the idea of building a country house...

- Heating a house with a warm baseboard When installing a traditional heating system, problems with radiators constantly arise. I want to hide them somewhere away so that they don’t stand out and...

- Choosing a heating system for a country house When choosing a heating system, as a rule, we focus on our finances, the size of the heated area and the quality of the manufacturer. With that, let's begin...

- Types of water heating systems for suburban heating These systems are of open type with natural circulation (gravity) and closed type with forced circulation. System with natural coolant circulation…

- Heating of houses Modern heating systems, heating of houses with any type of fuel. We have been designing and installing heating systems of various types and complexity since 1999...

- Heating a house with antifreeze Recently, more and more often, owners of private houses with an autonomous heating system use antifreeze as an energy source. Antifreeze is essentially......

- Installation of heating systems Solnechnogorsk Choosing a company that will prepare a competent project and then carry out high-quality installation is a key task in the construction of heating systems at home. Long…

- Radiators for home heating Traditional pipe heating systems have three main components: a source of thermal energy, pipes for coolant circulation and heating devices: radiators, convectors...

- Heating a house with warm floors A private house is a home that many people dream of. Life here is distinguished by its calmness and tranquility. The main thing is to be able...

- How much does heating cost? The cost is determined individually for each customer. Turnkey heating of a country house is calculated taking into account the following factors: selected equipment and components;…

- Installation of heating systems Installation of heating systems for buildings in our country is traditionally carried out using water heating systems. Carrying out heating installation work is a pressing task for…

- Installation of a heating system for a house in Istra In order for the installation of a heating system in Istra to go smoothly, a heating diagram for a private house is needed. This article collects and describes in detail…

- Turnkey installation of a boiler room Turnkey installation of a boiler room for heating a private house. Installation of boilers, boiler automation, pipelines, piping of the hot water boiler and boiler, installation of pumping…

- Diesel heating of a house Diesel heating of a house You have bought yourself a luxurious house high in the mountains. The cleanest air, virgin nature, what else is needed for real......

Installation Features

Combined fuel boilers belong to the class of massive and dimensional heating devices. The weight of boilers for heating residential buildings with an area of 250–300 m2 can reach 500–700 kg. Because of this, a reinforced pedestal made of reinforced concrete and lining of walls located closer than one meter to the boiler body with fire-resistant materials are required.

There are also difficulties with organizing the chimney. Hybrid boilers, including those with separate fireboxes, have a common exhaust of combustion products with rather strict requirements for the speed of natural draft in the chimney. Problems with the formation of carbon monoxide can be guaranteed to be avoided by installing smoke exhaust fans, or by following all the requirements when installing a vertical segment of the chimney. This mainly concerns a sufficient lifting height (about 2–2.5 meters) above the roof ridges of adjacent buildings, compliance with the required throughput and the use of insulated composite pipes.

The rules for installing boiler room ventilation are separately regulated. Bi-fuel boilers are installed only in non-residential premises, mainly attached boiler rooms without insulation of the enclosing structures. Equipment from leading European manufacturers can be designed for complete isolation from the internal environment with permission for installation in unattached rooms without their own general ventilation supply. In this case, air is taken from the street, which has a good effect on saving energy resources.

rmnt.ru

Model selection

When starting to select boiler models, you need to know that the power level for certain types of fuel will be different.

House project with combined heating

This is necessary to determine the main type used for heating purposes. One more information - in foreign boilers the rated power is indicated, and in Russian boilers the maximum power is indicated. This will give a significant difference in performance, so you need to be careful. Combination boilers for private homes have different power levels when changing fuel.

Solid fuel + electric boilers

The combination of a solid fuel and electric boiler will reduce the severity of the energy supply problem. The electric boiler can be turned on at a reduced rate from evening to morning if a two-tariff meter is installed. Firewood is used when it is possible to regularly put it in the firebox and remove the ash. This combination is suitable for houses where there is no gas.

At the beginning of the process it is worth using a solid fuel boiler. After reaching the required temperature, you can configure the system to automatically turn on the electric boiler. As a result, you will get quick heating and save money.

Device prices: summary table

In order for the buyer to quickly choose an option that suits his needs and income level, the offer of trading enterprises is as follows:

| Model | Number of circuits | price, rub. |

| Teplodar Kupper OK 15 | single-circuit | 19 900-21 200 |

| Karakan 20 TEGV | double-circuit | 22 500-25 000 |

| STS V25 FG | double-circuit | 330 000-500 000 |

Restrictions and standards when installing a warm water floor

Let's start with the fact that water heated floors do not belong to high-temperature heating systems. According to the standards, the coolant temperature cannot be exceeded or heated above 55C.

In practice, heating occurs to a maximum of 35 or 45 degrees.

However, do not confuse the temperature of the coolant and the temperature of the floor surface. It can range from 26 to 31 degrees maximum.

where you are constantly (living room, bedroom, kitchen) - it’s 26C

in rooms with temporary stay (bathroom, separate hallway, loggia) - 31C

Also, don't forget about the circulation pump. A warm floor is still a separate independent circuit. The pump can be either built into the boiler or mounted outside it.

With the help of a pump, it is easier to fulfill another requirement regarding temperature differences. For example, between supply and return, the difference should be no more than 10 degrees.

Knowing all these limitations and recommendations, let's move on directly to the schemes themselves.

Minimum required power

For an average house in the climatic zone of the Moscow region, with 2 bricks and a ceiling height of 2.7 m, the minimum required power is calculated using a simple formula: 1 kW for every 10 m2. We also recommend setting aside a power reserve of 20-30%.

For example, for the average house described above with an area of 100 m2, the minimum required power of heating equipment is 100/10 * 1.3 (30% reserve) = 13 kW. Boilers of this power are not found on the market, so we round up to the nearest higher value - 14 or 15 kW.

When choosing a double-circuit boiler, it is recommended to add another 10-15% to the result, since when heating hot water, the heating circuit is not heated.

Connection diagram for batteries and one TP circuit

The TP can be inserted into the supply line through a tee. A mixing unit must be installed.

Often heated floors are combined with conventional radiators. Let's consider how to connect a water heated floor to a common circuit if we have only one circulation ring. In this case, we do not need to convert the two-pipe heating system to a radial (collector) heating system. The TP can be inserted into the supply line in the same way as radiators, that is, through a tee. The return line is cut in the same way.

To reduce the temperature to the required level, you need to make a mixing unit. In this case, a pump is not required, since it will be either in the boiler or in front of it on the return line of the general system (after the expansion tank). No flow meters, air vents or other control elements are needed. It is enough to install a three-way thermostatic valve and, of course, like on every radiator, shut-off valves.

First launch of TP

Warm floors are very convenient.

All that remains is to figure out how to turn on the heated floor. The first start can be carried out only after the screed has completely dried - this is about a month. First, the system is filled with water. This is done manually using a pressure test pump or through a pre-installed connection to the water supply circuit.

The technique is as follows:

- all air vents and all shut-off valves open;

- the circuit is filled with coolant;

- when water begins to ooze from the air valves, they close;

- the temperature regime is set at the mixing unit;

- then the boiler turns on.

As the coolant heats up, air will come out of it, so it will need to be vented. After several cycles of heating the coolant, the system will stabilize and you will only have to adjust the hydraulic resistance on different TP circuits using flow meters. As you use it, you will make adjustments to the coolant temperature.

Insertion into a one-pipe system with an additional pump

This connection option even has its own special name - “Leningradka”. Its use requires installation of a pump and self-assembly of the mixing unit.

In order for the finished system to function without interruption, it will be necessary to take into account the compliance of its parameters with the following requirements:

- the distribution line in internal diameter corresponds to DN25 or more;

- no more than 5 radiators are placed on the ring;

- the heated floor loop is connected to the return pipeline after the batteries;

- the return and supply insertion points are located at a distance of more than 30 cm from each other;

- the degree of heating of the circuit is regulated by a mixing valve (three-way, simplified design).

Layout drawing for underfloor heating and single-pipe heating with radiators

In this system, a valve is necessary to prepare water at the required temperature, and a pump is necessary to move the coolant through the circuit. There is almost no practical use of such a scheme, since it functions unstably, and the radiators lose balance due to changes in water flow caused by the operation of the pump.

Varieties by number of circuits

This is the main technical feature of any boiler. The choice of model and method of operation of the equipment depends on it.

Single-circuit

This technique is intended only for heating water circulating in the heating system. Its power is enough to heat a large home.

To organize hot water supply, you will also need to buy and install a boiler.

Dual-circuit

An additional heat exchanger installed in gas-electric boilers solves the problem of supplying the house with warm water. If the power of the unit is sufficient, then several water points can be installed. To avoid a decrease in the temperature of the liquid during transportation, the taps should be installed close to the heater.

Such a boiler has several advantages:

- Low gas and electricity consumption.

- Simultaneous heating of water for heating and water supply.

- The cost is lower than that of a single-circuit device and a boiler combined.

- Installation in a separate room, as well as in the kitchen, is allowed, subject to installation rules.

Some of the inconveniences are:

- the need to balance the consumption of gas, water and electricity;

- if the liquid pressure decreases, then the released heat is spent on heating, i.e. the air temperature in the room rises;

- when the pressure changes, the equipment needs to be reconfigured;

- due to the scale that forms, periodic maintenance of heating elements is required;

- When using hot water for a long time, its temperature drops.