Material device

To understand the difference between a house made of brick and a house made of reinforced concrete products (RCC), you must first understand what kind of material it is. It has one difference from ordinary building concrete - steel “insides”. During the casting process, steel reinforcement is added to the product. It improves the properties of reinforced concrete such as load resistance and increases its bending ability.

Thanks to improved physical properties, it became possible to produce ready-made blocks from the new material, from which multi-storey buildings and private cottages began to be built according to standard designs.

How to connect wall panels and ceilings

The structures are made at the factory, so all geometric proportions are maintained, the panels fit together, and at the construction site they are simply assembled in the required sequence. Of course, you will need equipment and a good construction team, and control over all stages of work - construction is construction.

BENPAN panels are assembled using bolts and anchor rods from Hilti. BENPAN+ and BENPAN Premium - by welding embedded contact pads.

Vasiliy

It's like a construction set, just bring up the slabs.

In terms of strength and durability, both options are similar. The welded version has greater torsional rigidity, but this is only relevant for earthquake-prone areas.

id291650501

These are no longer Khrushchev’s sockets, a completely different technology. The houses are warm.

Advantages and disadvantages of panel houses

“Typicality” has become the main argument of opponents of the construction of residential buildings from reinforced concrete panels.

The process of constructing a panel private house

In their opinion, such a house will not be original. However, practice has shown that reinforced concrete can be successfully used to build the most original cottage in the world.

Other disadvantages of reinforced concrete houses include the following:

- poor thermal insulation;

- low noise insulation;

- heavy weight of the slabs.

But all these arguments were relevant 20 years ago. Currently, so-called composite materials have begun to be used instead of steel for the manufacture of reinforcement. These are polymers that improve the physical properties of reinforced concrete panels while reducing the standard weight of the slab.

To protect the surface of the concrete itself, manufacturers use special coatings that protect the material from water, the so-called penetrating waterproofing of the house, as well as reducing heat loss and sound transmission. But this is not the main advantage that reinforced concrete buildings have.

An example of installing reinforced concrete panels in the frame of a house

The main advantage is the speed with which you can build a cottage from such material. In addition, houses made of reinforced concrete structures have no equal in terms of durability and strength. As builders joke, such a house can withstand hurricane winds and withstand the force of a small explosion.

The advantages of reinforced concrete products also include:

- the ability to build at any time of the year;

- variety of layout options;

- the possibility of exterior finishing of houses with any material;

- fire protection;

- cheap materials.

Now let’s look at all the stages that go through the construction of reinforced concrete cottages.

Improved layout or (UP)

An improved layout is called a residential building of the 80s, 20th century. The main advantage of such houses is the spacious kitchen and large rooms and the fact that each room is separate. Houses with an improved layout have not only separate rooms, but also bathrooms. The most common series of UP buildings are: series 141 with many entrances and one entrance, and series 137. So, series 141 is a panel residential area with 9 or 10 floors and many entrances, and residential buildings of 12 - 16 floors with a single entrance . In these houses the ceiling height is 2.5 meters. In many entrance buildings, the layout of the premises is similar to the Pentagon; each landing accommodates 4 apartments, an elevator shaft and a garbage chute. Houses of these types have a loggia, its placement is spread over all floors, it is two windows long, usually flat or semicircular in shape, the area of the loggia reaches 6 square meters. meters. Apartments in buildings of the 141st series with one entrance with an elongated loggia with an area of 9 sq. m. m. and located on one kitchen window and one window in the room. The kitchens have electric stoves. There are two types of elevators: passenger and freight, and there is also a fire escape, called “cold” and passing through each loggia.

Houses of series 137 have one entrance, with 12-16 floors. The semicircular balcony and loggia are located no lower than the third floor. Their depth (width) is about one meter. The layout of such buildings partially coincides with the location in series 141, with one entrance. There are the same elevators and fire escapes, called “cold” ones. Electric stoves are installed in the kitchens; in the apartment of series 131 the ceiling height reaches 2.5 meters. The entrances are equipped with garbage chutes.

Stage one: design

The first step is the most important. Because in the process of drawing up estimate documentation and calculating the dimensions of the future house, the number of parts that will be required for its construction is also calculated.

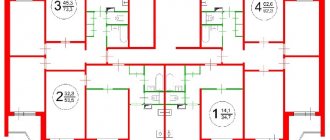

Layout of all floors of a private two-story house made of reinforced concrete panels

In this case, everything is taken into account, including external walls, window and door openings, horizontal ceilings and interior walls. This method is good because it protects the owner of the future home from unscrupulous builders. When building a brick house, there is always the possibility of writing off building materials as “overexpenditure.” With reinforced concrete products, such a trick will not work for clever foremen. Most builders offer standard house designs to customers.

But the variety of parts produced by manufacturers allows you to create a unique, one-of-a-kind structure.

Thanks to this, many modern cottages made of reinforced concrete components have a unique look. The presence of standard projects frees developers from worries, who see their future home as simple and practical.

Prefabs

Prefabs are a type of modular houses that are distinguished by modern avant-garde architecture, a desire for autonomy and environmental friendliness. The name of the technology comes from “prefabricated houses” - “prefabricated, pre-fabricated houses”; all labor-intensive processes of making a house are carried out at the factory.

At the construction site, the foundation is poured and installation is carried out. The most common option for such houses is modules, but these can also be wall panels made of various materials, with insulation, sound insulation and electrical outlets, sometimes even with inserted windows. They are usually one-story. Such houses are ideal for views of plots in very beautiful places. In Russia, this area is poorly developed - for objective reasons.

spacewalkerFORUMHOUSE Member

The forecast is pessimistic: there is no reasonable price offer. Either a bungalow at an exorbitant price, or an outright semi-finished product.

Stage two: foundation

As noted above, reinforced concrete components of houses are characterized by significant weight.

The process of laying the foundation for a cottage made of reinforced concrete panels

Therefore, the foundation for them must be made solid, capable of withstanding heavy loads. For the construction of objects of this type, a strip foundation with a significant recess is erected. Steel reinforcement is introduced into concrete for greater resistance.

The height of such a foundation is on average 180 cm, of which 140 cm are located below ground level. The width of the base is at least 40 cm. Before pouring concrete, a sand cushion is laid at the bottom of the trench, which acts as a drainage and shock absorber. Its thickness is 20 cm. Coarse river sand is used for the pillow.

Scheme for installing a foundation for a house made of reinforced concrete panels

The foundation itself is cast from concrete grade M250 and higher, into which steel reinforcement is inserted. For ventilation, during the manufacturing process of the foundation, blank holes for air vents are made above the ground surface.

Experienced builders note that the time of year does not affect the quality of work on pouring the foundation for a house. However, in rainy weather it is better not to build the foundation of the house. And if the work is carried out in the summer, in the heat, then as the concrete hardens, it is recommended to moisten it with water. This will prevent it from cracking due to high temperature.

Full-length apartments (LM)

The type of such houses is called Stalinka. This name was assigned to them due to the fact that they were built during the time of Stalin, in 1930-1950. But, in the real estate community, these houses are mostly called Full-Length. Stalinka or PM were built in quite large sizes, they also have practical breading, are distinguished by a high ceiling height and spacious kitchen areas. At that time, luxury residential buildings were built, with comfortable apartments with offices, children's rooms and libraries; these apartments had huge bathrooms, kitchens with a garbage disposal, as well as servants' quarters. But you can still find another type of Stalin films - full-length films.

Full-length apartments are apartments with small rooms with long corridors - so to speak, an economy option. These houses were built to special order and the apartments were used as dormitories or communal apartments. Full-length buildings also have high ceiling heights, which is typical for all buildings of the Stalin era. The indisputable advantage of full-length buildings is the large width of the walls. In the period from the 30s to the 50s, brick and cinder block houses were built, thanks to which living quarters had excellent sound insulation and insulation. Apartments in Stalin buildings are often designed differently and differ in size. The ceiling height can vary from 2.7 to 3.2 meters. Buildings built during the war period and earlier were built with 2–6 floors with wooden floors. But post-war buildings were erected using reinforced concrete floors - these buildings are practically “immortal”. The disadvantage of Stalin buildings is the age of these houses; they are old, dilapidated and require investment in expensive repairs. The wooden floors in them are very fragile and fire hazardous, which does not correspond to fire safety. And the garbage disposal in the kitchen has not been relevant for a long time.

Stage four: insulation and finishing

Depending on what type of slab construction was chosen for construction work, the question of whether the cottage needs to be protected from water, frost and sounds is decided.

The process of insulating a house from reinforced concrete panels

The technology of prefabricated buildings, popular in Europe, offers a new design of wall blocks. In cross-section, it resembles a layer cake: first there is reinforced concrete, then insulation, and the whole thing is completed with a layer of finished plaster. Therefore, builders do not even have to waste time on interior wall decoration. All that needs to be done after construction is completed is to seal the seams between the blocks.

By the way, slabs for horizontal floors are made using the same technology.

As for the style of the façade of the building, some owners leave it unchanged. But if you really want to decorate the outside of the cottage, then there are practically no barriers to the flight of fancy. Houses of this type can be faced with natural and artificial stone, painted almost every month in a new color, finished with wood siding or some other material. Reinforced concrete cottages do not require preliminary finishing or putty; they are ready to be decorated in any style. Knowing all this, you can become the owner of your own new home in just six months.

Small family type (MS)

Quite often you can find a type of real estate - small family. In principle, this is practically a hostel. In Soviet times, such housing was often provided under social contracts. rent, and small families were dormitories where one family was given a separate room without sharing neighbors. It turned out that one family or resident officially received a living. The area is only one room. Nowadays, the concept of a small family means that the owner has a home with one room or more, possibly divided into sections, with a separate kitchen and bathroom, in general, absolutely any living space. area in the dormitory, registered as private property. Such dormitories can be corridor types or block-sectional. Corridor-type dormitories imply the arrangement of living rooms along the entire corridor, with doors on both sides, bathrooms are often located at two ends of the corridor, one on each side, and in the center of the corridor there is a single kitchen. The block-sectional type is slightly more compact in size, there are fewer rooms, but also a shared kitchen and bathroom.

Conclusion. This article discusses the general characteristics of each type of residential building, which are for informational purposes only. All of the examples of buildings given have their advantages and disadvantages. The final choice will be made based on the wishes and requirements of the buyer, and will also depend on the financial side of the issue and the purpose of purchasing a home. You can also make remodeling in such apartments, which will help to visually increase the space, or make the premises to suit your needs.

Prices for houses made of reinforced concrete panels in the Moscow region

The range of prices for reinforced concrete houses in Moscow is quite wide. The cost depends on the area, complexity of the project, delivery of materials. The price is also affected by the segment in which construction is planned: premium, business or economy.

The most important requirement for the construction of country real estate is the quality of both materials and work. The home should be warm, breathable and comfortable. Modern technologies and professional construction organizations will create a comfortable environment for the whole family in a country house.