Home » Building a house » Premises » Bathroom

BathroomReviews and RatingsFinishing MaterialsFloor

Svetlana Shevtsova 04/30/2020

3794 Views

SavingSavedRemoved 1

The best floor covering is comfortable for bare feet, aesthetic in appearance, durable in service life. When it comes to a bathroom, it is necessary to add resistance to a humid environment, temperature changes, and water resistance to the list. We suggest you find out whether there is a laminate for the bathroom that meets the listed parameters.

Introduction

Water and humidity are the main enemies of such flooring.

This coating will be an excellent alternative to boring tiles that are slippery and cold to the touch. It gives the room coziness and elegance. Although laminate does not seem like a suitable type of floor for a bathroom, modern developers of building materials, thanks to new technologies for processing boards, have managed to improve its moisture resistance.

So, if you choose the appropriate type of product, carry out installation according to all the rules, carry out careful maintenance, and correct operation, the floor will delight its owners for decades .

Let's look at the types of corresponding floor boards and review the most popular brands on the market. We’ll also look at recommendations for laying the coating yourself.

Useful video

Until recently, laminate was used exclusively as flooring. But times are changing and now designers are actively expanding the scope of its application, offering to also cover walls with it. This is a rather interesting solution, but we still recommend that you consider its properties and installation options in more detail.

Types of laminate

A room with a wooden floor looks very cozy

A typical high-quality laminate consists of at least four layers:

- The stabilizing substrate is a layer of thick paper (kraft cardboard) impregnated with paraffin or resin. It is laid under the base to provide the structure with moisture resistance and protection from curvature.

- The base is the thickest layer, which is responsible for the strength, resistance to deformation, and durability of the board. Connection locks are machined in this part

- A decorative element is a picture on paper that imitates a natural coating. The most popular images are wood, marble, granite, mat, leather, metal, ceramics

- A protective resin coating that protects the design from abrasion, gives it a glossy shine, and emphasizes the relief texture

Some manufacturers include an additional layer in the form of a special film that provides barrier protection against fungus and mold.

The product, which is suitable for installation in the bathroom, differs from ordinary boards in its higher moisture resistance characteristics. It does not swell, does not get wet, and with high-quality installation, water does not penetrate inside through the seams of the locking joint. There are two laminate options suitable for installation in bathrooms.

Moisture-resistant coating

Moisture-resistant board is afraid of prolonged contact with liquid

The base material used here is compressed wood fibers HDF (the English abbreviation means high-density board). There is a thick substrate treated with paraffin; locks and grooves of structural elements are also impregnated with it. All layers are connected with a special waterproof epoxy glue, and the top coating is made of a polymer film - it protects against abrasion, repels liquid, and holds it on the surface.

Such a floor is quite capable of withstanding short-term contact with water, but if an accident occurs and the room is flooded for a long time, the liquid will be absorbed through the joints and penetrate into the wood layer. As a result, the floor covering will swell, bulge, and become deformed. Also, the board gets wet over time due to frequent changes in humidity - so a moisture-resistant laminate is more suitable for a hallway, kitchen, or toilet that is not combined with a bathroom.

Waterproof coating

Here the base is made of durable, safe PVC plastic, which is absolutely insensitive to water. Even if the room floods in the event of a water pipe break, and the liquid sits for many hours, the board will not be damaged.

The weak point here is the seams, so all the ends and locks of the boards, in addition to the wax coating, are treated with a special silicone sealant

During installation, it is recommended to additionally coat the joints of the lamellas with an additional sealant. It will not hurt even if, according to the manufacturers of the chosen brand, the board has already been treated with a similar composition.

Most often, the plastic base consists of two levels, which are connected by vertical plates - as a result, a cellular air layer is formed inside, which provides reliable thermal insulation. The lamellas are more durable, resistant to damage, and durable. The plastic base is covered with decorative paper with a textured pattern, and the front layer is made of acrylate resin with the addition of corundum.

Corundum is a transparent mineral that has high hardness, resistance to acids, moisture, and temperatures. It is also called stone glass substitute.

The ends of the laminate are treated with silicone, the back side of the base is treated with wax. The top polymer film does not conduct static electricity. All levels are glued with a special waterproof glue.

Kinds

Vinyl laminate is easiest to immediately divide into two types: by installation method and by composition .

The installation method can be of two types: using glue or a locking system.

Adhesive

Not the most popular type of laminate. It is rarely found in stores, installation is extremely difficult, there are no special devices, and the glue itself is also a rare find for such purposes. But if you still find and use good glue, it will adhere so tightly that such a coating is no longer afraid of moisture and damage.

The coating becomes perfectly smooth and durable.

But there is a catch here too. If one laminate panel is damaged, it cannot be replaced . Replacing the panel will cause damage to other areas of the floor, the edges will be damaged and all this will ultimately lead to the need to replace the entire floor.

The demand for the self-adhesive type is small, so it is more profitable for manufacturers to completely abandon supplies with adhesive joints.

Castle

Much more popular than adhesive and is the most common. First of all, because such a floor can be disassembled or restored many times if one tile is damaged.

Installation does not require a large number of tools, usually these are:

- roulette;

- square;

- pencil;

- hacksaw;

- circular or carpenter saw;

- hammer and electric drill.

Everything is the same as when laying the adhesive coating.

Material with a locking system can have click and lock connections .

The first is a collapsible lock, and the second consists of latch locks. Compared to adhesive, locking is susceptible to moisture .

A laminate with an increased level of strength is quartz-vinyl laminate . Quartz gives this coating a special hardness.

Its production occurs through hot pressing, which contributes to a more dense laying of all layers, the top of which is an aesthetically pleasing polyurethane .

Based on the manufacturing method and composition, vinyl laminate is also divided into vinyl-PVC . In addition to layers of vinyl, resin, stabilizers and plastic, such tiles contain an additional layer of PVC that protects the floor from a variety of damage and environmental influences.

Advantages of plastic laminate flooring

It's nice to step on this floor with bare feet.

So, we came to the conclusion that a product that is characterized as waterproof is more suitable for the bathroom. It is also called vinyl. What advantages does it have?

- It does not absorb moisture at all and does not allow it to pass through.

- The coating is durable, wear-resistant, does not swell, does not delaminate

- It is not afraid of intense loads and increased use

- Tolerates room temperature changes perfectly. It can be laid on uninsulated loggias and balconies, where the temperature can vary from -20°C to +50°C

- Mold does not grow in plastic and fungus does not spread

- Easy to care for, just wash

- The material is considered environmentally friendly and safe for health. It does not emit harmful fumes or toxic compounds into the air

- PVC lamellas are low-flammable products; when exposed to fire, they melt - which means they do not contribute to the rapid spread of flames

The disadvantages include the high cost - it is an order of magnitude higher than a regular board, and is priced a little more expensive than the moisture-resistant variety. The range of the latter, by the way, is much wider, so we will also consider the lower availability of waterproof laminate as a minus.

T-Lock

Developed by Tarkett. It requires two people to work, since first the lamellas are connected along the length, and then only attached to the already laid row. An assistant will help you lay the long assembled row in places where the room has ledges or niches. For example, pipes or bay windows. The connection is tight, smooth, and does not form cracks.

Based on this connection, Tarkett subsequently created the modernized TC Lock laminate lock. Due to unobtrusive changes, TC Lock will better eliminate cracks, the connection of the lamellas has become much stronger and more airtight.

Since manufacturers Klassen and Tarkett are the most popular in Russia, the question often arises: which lock is better - Megalock or TC Lock.

T-lock locking connection developed by Tarkett

Board class

More details about class

Laminate flooring is usually distinguished by class categories. It should be noted that at present this concept is considered relative, because each manufacturer independently assigns a position to its products. The indicator is calculated based on the impact resistance, wear resistance, moisture resistance, and sound insulation of the product.

The higher the marking, the more expensive the price, the stronger the physical characteristics. Depending on the installation location, there are two groups of laminates: for home (domestic needs) and for commercial needs (products suitable for installation in premises with intensive use). The class of the former begins with the number “2”, and the latter with “3”.

The second number is responsible for the wear resistance of the load-bearing layer and the strength of the lamella as a whole, respectively, when it comes to choosing flooring for the bathroom - the higher the number, the better. Currently, classes 21, 22 and 23 are gradually disappearing from stores, since developers prefer to produce only categories 31, 32, 33, 34 - they are better sold out, because the product lasts much longer.

When assessing the quality of a laminate, there is another marking - the durability of the top, protective layer. It is designated by the letters AC and numbers from 3 to 6. That is, two lamellas of classes 32 and 34 can be approximately the same in terms of wear resistance if the front layer has a higher rating than the second.

5G system locks

The laminate lock, made using the 5G system, was designed to simplify the installation of laminate flooring without compromising the quality and quality of the connection.

The idea behind the creation is to lay the laminate with one click. The short side automatically snaps into place when the lock on the long side of the slat is connected. This is provided by a special “moving tongue”, which is located at the end of the board. By simply pressing the slats are fastened to one another.

There are a huge number of options for 5G system locks, since many manufacturers have developed and perfected their own type of such a lock, naturally patenting their results.

Further information will be presented in more detail about the most famous laminate locks produced by recognized leaders in this field.

How to choose

Hundreds of colors, brands, varieties await you in the store

We have determined that a waterproof or plastic (vinyl) laminate with markings 33-34 and AC 5-6 is more suitable for the bathroom. What else should you pay attention to when purchasing?

- Study the packaging - products with good water-repellent properties always have the designation “aqua”

- Pay attention to the country of origin - European goods are usually of higher quality than Chinese ones. Often 32 class Belgian laminate turns out to be more reliable than 34 eastern edition

- Find out in advance the prices for the same laminated boards in different stores - waterproof products are expensive, so even a slight reduction in cost can help you save a lot

- Directly ask the construction department to show how the locks work - are there any gaps left, does the mechanism snap easily

- Avoid products with a smooth face layer to avoid falls due to wet feet and how many floors. It is better to choose a corrugated texture

If you decide to buy a moisture-resistant coating, additionally check the swelling coefficient and the density of the wood fiber base. The first should not exceed 18%, and the value of the second should be as high as possible.

Laying features

Before starting installation, you should study the installation rules and select the appropriate tool. A laying scheme is drawn up, according to which consumables are purchased, and its optimal quantity is determined. In case of a defect during installation, it is recommended to take a small supply.

Let's start with the general provisions.

- To calculate the required number of planks, first draw up a floor plan. It is necessary to calculate the floor surface area. It must include niches, ledges and other obstacles.

Note:

According to the recommendation of specialists, the volume of purchased material should be approximately 10% more than calculated. The excess will be needed in the future for repair work.

- The room temperature during the day and for a couple of days after installation is maintained within 18–28 degrees.

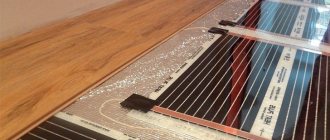

- The finishing coating for the heated floor is turned off a few days before installation.

- The lamellas are kept for 24 hours in this temperature range, preferably in a horizontal position.

- The adhesive smart tape can become dirty, which can affect the quality of the future floor, so the planks should not be removed from the packaging before the installation itself begins.

Now let's move on to the most important points of laying various types.

- Modules equipped with a locking system are laid using a technology similar to the installation of laminate flooring.

The differences are few, but they are significant:

- no substrate needed;

- optional waterproofing device;

- modules can be mounted on old coating;

- the base does not need to be leveled if the height difference is no more than 3–4 mm, since the vinyl slats are elastic.

The price per m2 is much higher than the cost of any floor covering, including laminate. However, if we add in all the expenses that need to be made, for example, when installing a conventional laminate:

- dismantling the old floor,

- preparatory work,

- leveling mixture

- backing and more

then this difference is significantly reduced, not to mention the fact that it will take several days to install a standard one, and only a few hours for vinyl.

- The assembly of elements with a self-adhesive base or adhesive, in contrast to locking modules, is carried out on a previously prepared floor surface.

- Adhesive modules are placed on a concrete screed or any rigid, non-sagging base. These can be sheets of plywood or GVLV boards. In any case, it must be leveled and cleaned of dust, dirt, grease stains or oil paint.

Sealing seams, cracks and other screed defects also has an economic component, since it reduces the consumption of adhesive solution.

- The elements are first laid out on the floor “dry” and determined with the starting point for laying. There are several ways of laying: diagonally, from the center, pyramid, etc.

- After trying on, remove the protective film from the bottom of the self-adhesive lamellas and apply it to the base. The main subtlety is the accuracy of the fit. Re-gluing should be avoided, otherwise installation will be less effective. That is why certain rules are followed during installation. First, a thin strip (no more than 20 mm) of the protective film is removed along the side of the joint, the elements are joined, and only then the rest of the protection is removed. All that remains is to glue it tightly onto the surface.

- Adhesive models are installed quite similar to linoleum. Although there are some nuances here too. The strip cut to size is rolled up towards the starting point near the axis and pasted as it unwinds.

- When choosing an adhesive composition, pay attention to the time required for its polymerization.

- The glue is applied with a rubber spatula with V-shaped teeth. Air bubbles are removed by running a spatula over the panels, and any exposed adhesive is also removed. The joints between the planks can be easily adjusted before the glue begins to harden.

- Having completed the installation of the coating, they pass over it with a special rolling roller so that there are no uneven or loosely connected elements left in it.

Watch the video:

The question often arises about vinyl tiles or laminate - which is better and easier for installation? Installation of roll material is carried out only on a perfectly flat surface. For tiles, an increased value of the floor level difference is possible. The technology for installing roll coverings is different from tile ones. Main installation steps for the last option:

- Surface preparation. The technology depends on the floor material, its area and operational features. It is important that the above conditions are met.

- Adaptation before laying vinyl laminate. To do this, it is necessary for the material to lie at room temperature for 1 to 3 days.

- Installation begins from the corner of the room. The adhesive edge that will be adjacent to the wall is cut off.

- If the floor has significant differences, you can use an industrial hair dryer to soften the coating. However, the exposure temperature should not exceed the standard specified by the manufacturer.

- After installation is complete, you need to walk over the floor with a special roller. This way you can avoid the appearance of gaps between the plates.

All vinyl laminate manufacturers recommend turning off the heated floor system before installation. This is necessary for better gluing of surfaces. After laying and rolling, the floor can be used. But at the same time, it is important to comply with all the conditions, which can be found on the manufacturer’s website or obtained in advance from the seller.

Advice

During installation, the room temperature should be from +15°C to +25°C with normal humidity.

Review of manufacturers

European manufacturers are the key to reliability and quality

Products manufactured in Europe are considered more reliable; their performance characteristics are far superior to those from China.

The best brands of plastic laminate

Aqua Step - waterproof board with perfect wood imitation

Let's take a look at the leading vinyl laminate manufacturers on the market:

| Name | Country of issue | Characteristic |

| Dumaplast | Belgium-France |

|

| AquaStep | Belgium |

|

Manufacturers of moisture-resistant laminate flooring

Choose a good coating so you don’t have to worry about a brand new renovation

Sometimes moisture-resistant laminate is also used for installation in the bathroom. Let's look at the best brands.

| Name | Country of issue | Characteristic |

| Quick Step | Belgium |

|

| Classen | Germany |

|

| Kaindl | Austria |

|

| Kronotex | Germany-Russia |

|

Product line from Quick Step

Disadvantages of the material

Despite the abundance of advantages, vinyl flooring for the bathroom has a number of negative qualities.

The waterproof coating on the bathroom wall is very delicate. It reacts to household chemicals that are used to clean dirt. The protective film may deteriorate from exposure to chemicals or become less durable.

To completely remove all stains from the surface, it is advisable to use a light soap solution or wipe with plain water.

This material is not cheap. Of all the floor and wall coverings on the market, vinyl is one of the most expensive.

In order to begin fixing the coating, you need to make sure that the coating on which the parts will be applied is smooth and without flaws, since only under this condition will the panels hold tightly.

The advantages of vinyl coating include absolute moisture resistance

DIY installation tips

If you are afraid, trust the installation to a professional

It is difficult to describe how to lay laminate within one small section - separate articles with a larger volume are devoted to this. Here we will mention important subtleties, knowledge of which will protect you from incorrect actions:

- The quantity of the product is calculated based on the area of the room. Always buy 10% more to have extra in case of damaged or damaged items

- The purchased laminate must rest in its premises for at least 3 days (we open the packaging)

- It is important to prepare the floor surface: cover up cracks, level it, treat it with a primer for better adhesion

- The evenness of the floor is checked using a building level

- Consider additional waterproofing of the floor (not necessary, but recommended)

- Laying can be directly perpendicular to the walls and diagonal. The first one is much easier to do with your own hands.

- Before starting work, do not be lazy to draw a laying diagram

- Don’t forget to purchase a backing for the laminate – polystyrene foam layers

- Check the distance between the bottom of the door and the floor so that after laying the laminate, it does not turn out to be touching the coating when opening. If necessary, the door is removed from its hinges and shortened

The coating helps give the room a stylish look

Laminate that is suitable for installation in a bathroom must be resistant to moisture and must not allow water to pass through. These are the two main criteria for an ideal product that will last for many years without changes in appearance. Purchasing a waterproof or moisture-resistant board is an individual choice for each buyer.

Carefully study all the characteristics of potential applicants, consult with a repair specialist or, at worst, with a manager at a hardware store. We recommend choosing a laminate from a European developer, marked 33-34, preferably with a plastic base. If you are still inclined to choose a board made of super-durable fiberboard, purchase a collection specifically designed for rooms with changes in humidity.

Watch a video that clearly explains how to properly install laminate flooring in a bathroom:

Laminate for bathroom walls: features of selection, installation and care

Moisture-resistant laminate is an ideal material for finishing interior walls of rooms with a high content of water vapor in the air. Many people prefer to choose it because of the wide variety of colors, textures and patterns. With proper care and taking into account all the nuances of installation, such a finish will not be destroyed by dampness or direct contact with water. Let us consider in detail the features of choosing a finishing material for bathroom walls, methods of its installation and maintenance requirements.

SmartLock by Pergo

This is technically a simpler lock. However, the joints of this lock also have moisture-resistant impregnation.

Installation of laminate with SmartLock is quite simple, it can be carried out at any angle and at the same time the coating is of high quality and can withstand heavy loads. The lamellas are attached as follows: the insert ridge is independently fixed in the groove when pressure is applied to the end of the panel. They are fixed firmly, which eliminates the deformation of the floor.

PressXpress by Balterio

This type of laminate lock belongs to the 5G system. Installation of the laminate flooring is carried out using normal pressure. Reliable fixation is guaranteed by a groove located inside the lamella; it ensures reliable fixation and the appearance of the coating without traces of seams that catch the eye.

Megaloc by Classen

This is probably one of the strongest laminate locks located at the end of the panel.

An unusual solution from a technological point of view made it possible to release an excellent version of the lock. It is reliable and at the same time easy to install. The slats are connected using a tongue and groove.

Classic version

Bathroom floors require that the products used have a special laminated coating. However, classic laminate does not meet these requirements, so its use in a shower room is not recommended. This material does not tolerate high humidity, as well as direct contact with water. As a result, its use is limited to living space or kitchen. Otherwise, you risk losing a significant amount, since deformation of the laminate occurs after a short period of time.