Induction cookers are in great demand abroad, but the Russian market is still wary of them. Is this justified? We have already dispelled five popular myths that stop you from buying: “Induction hob: 5 myths.” However, induction has objective disadvantages and advantages, which we will discuss in this article. Let your choice of stove be informed!

Doesn't heat up, but works

Unlike any other type of stove except gas, where the surface heats up and transfers heat to the cookware, in induction technology only the cookware is heated - this happens due to the electromagnetic field. You can rest your hands on the induction hob, place spatulas and spoons, and escaped liquids will not stick tightly to the surface. There are many fascinating photos on the Internet with half-melted frying pans and half-melted food on them. Here are a few similar ones, it’s really surprising when you’re not used to it:

And even a video to really get into it:

There is a caveat here: the stove underneath can heat up the hot dishes. Therefore, it is better not to touch the burner itself, on which the pan was just boiling, although you still won’t get a serious burn from such a temperature, and the surface will cool down extremely quickly. You can clean it almost immediately after turning it off. Speaking of cleaning: induction cookers are the leaders in terms of ease of cleaning.

What problems do you often encounter with gas stoves?

Some popular problems in the performance of the device that are significant are highlighted. Their repairs should only be carried out by specialists. These problems include:

Gas flows poorly to the burner or is absent altogether. Usually this problem is not affected even by fully opening the tap, since in any case there is an extremely weak flame, and often there is no flame at all. For repairs, you have to remove the burner, in which the nipple is cleaned. If this does not lead to the desired results, you have to turn to gas workers. The plug turns tightly. Also, when it returns to place, there is no special click, so the pin does not fit into the corresponding recess. Usually the reason here is that the lubricant used for this element thickens, so turning the plug becomes difficult and tight. Also, the recess often becomes clogged with various products or oils. Here you will have to disassemble the tap, and the general flow of gas will certainly be blocked. To remove the tap, the handles and decorative panel are dismantled. Next, the pins will open, which act as a holder for the plugs in a special protective housing. All parts are removed and thoroughly cleaned in a special solution. Then they are dried and inserted into place. Since you have to work with complex elements in a gas stove, it is best to entrust the process to specialists. An unpleasant smell of gas appears during operation of the equipment.

In this case, it is important to completely stop any activities with the gas stove and contact a gas specialist.

Thus, problems with gas stoves are considered quite frequent and popular. Some of them are complex and specific, so they must be trusted to specialists

Simple and standard problems can be solved on their own, for which it is important to know the cause of the breakdown, which can be easily eliminated, after which the ease of using gas equipment for its intended purpose is ensured

Saves energy and time

Induction cookers have a very high efficiency: about 90% of the total heat generated directly heats the food. This concentration allows you to save time: the frying pan heats up faster than on an electric stove, therefore the dish is cooked faster. If the stove operates for a shorter period of time, then less energy is consumed.

To prove the heating rate, we conducted an experiment: we boiled half a liter of milk at the same temperature on gas, electric and induction stoves. The results are as follows: electric stove - 5 minutes 32 seconds, gas - 4 minutes 48 seconds, and induction - 4 minutes 10 seconds. So for those who do not want to give up gas hobs with protruding burners in favor of smooth glass-ceramic hobs just because of the heating speed, this issue has now been resolved.

Sound source

Despite the fact that the kitchen, by definition, cannot be the quietest room in the apartment, the creators of kitchen appliances have always strived to make their devices as “silent” as possible. But sometimes careless operation or manufacturing defects can cause various malfunctions in the operation of the stove. A direct consequence of these disturbances may be a dull sound, vaguely reminiscent of the hum of the turbines of an airplane flying above you.

If your electric stove is humming, check out the main causes of various unpleasant sounds:

- The “Booster” function, as a rule, forces the heating elements to work in forced load mode, so you should not be surprised by the appearance of additional sounds;

- The burner may be clogged or deformed. Such damage usually results in a cracking sound due to vibrations on the surface;

- Large metal parts of the housing expand when heated and contract when cooled. This process may be accompanied by a soft cracking sound or the sound of a metal sheet bending;

- The tubular electric heater (TEH), which is the main heating element of electric stoves, can become loose and hum, as the vibrations it creates have a wider amplitude;

- If the sound comes from the oven, the reason may be due to the operation of the fan involved in convection;

- The fan cooling the front panel may move off-axis or even lose its blade, resulting in rattling noise;

- Sometimes noise is a consequence of the interaction of magnetic coils and the material from which the cookware is made. The volume of the hum depends on the thickness of the walls, the characteristics of the material from which the dishes are made, the smoothness of its bottom, weight and tightness of fit to the surface;

If the induction unit is operated with a wet pan bottom, a cracking sound (or whistling sound) is inevitable.

Automation and security

Another advantage of induction cookers: the burners only work when there is a cookware on them. We removed the frying pan and the induction stopped working. In this case, the burner will not begin to heat an object smaller than a certain diameter, even if it has ferromagnetic properties (more about them below): if you accidentally put a fork on the active burner, it will remain cold. Therefore, even a switched on stove will not harm children and pets.

This is interesting: The best kitchen aprons: types and ratings of materials

Automation also allows you to select different cooking programs and precisely adjust the desired heating temperature. If you need very fast and strong heat, which is used to boil water or cook a dish in a wok, many models have a Power Booster function: the selected burner will draw the power of the others for its needs.

—

Major breakdowns

There are several characteristic damages that can cause a loud clicking sound:

- The regulator relay is broken. The relay turns the current flow to the plate on and off. It is this part that turns on with a click when the burner operates in pulses. If the relay is damaged, worn out, or the contacts near it have oxidized due to water ingress, the device will click and not heat up. Or you will hear frequent loud bangs, and then the device will completely stop turning on. In both cases, the relay needs to be replaced, and at the same time the wiring nearby must be cleaned. To do this you need to contact the service. Self-repair of Hansa, Gorenje, Bosch and Zanussi equipment is prohibited by the manufacturers and is extremely dangerous.

- Fan. Another case where the induction cooker clicks louder than usual is related to the cooler. If one of the blades is deformed, dirt has stuck to it, or the cooler has moved off its normal axis, it will begin to rotate with a louder sound, it runs “heavier” and generally becomes more noticeable. Most often, this part cannot be repaired; the blades will definitely have to be replaced. The Ariston, Indesit and Kaiser brands recommend using only original spare parts.

- Thermal sensor. This is a sensor that monitors the temperature on the surface of the burner. In normal mode, it is this sensor that transmits information to the control module that the relay should turn the current on or off. If the temperature sensor is broken, it will constantly send random signals to the control unit. This failure can quickly lead to regulator failure and even serious damage to the copper coil. Most often this problem occurs in the Gefest technique.

Do not restore the stove's functionality yourself. Call a specialist so you can be sure that the repair will be successful. LenByt issues a guarantee for all types of services. To submit an application, call or use the online feedback form.

Requirements for dishes

Not all cookware will be heated by a magnetic field. The bottom of suitable frying pans, pots and other containers must have ferromagnetic properties. However, in practice, this excludes only three popular materials: glass, ceramics (namely the base, not the coating) and aluminum. At the same time, aluminum frying pans are often made with a layer of steel or copper, which is sufficient for compatibility.

You can find out if the dish is suitable using a magnet: bring it to the bottom. If you are attracted, there will be no problems. Cookware for induction cookers can be bought at any store; at most you will have to give up a couple of old saucepans in favor of new ones. Or, as an option, buy special removable bottom attachments that will ensure compatibility.

Why do tiles make clicking noises?

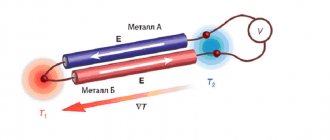

All induction panels operate on magnetic field energy. At the base there is a copper spiral to which energy is supplied. It is covered with a glass ceramic sheet. An eddy current flows through it to the bottom of the pan and heats it, and not the surface of the tile. There are several components in the design of electrical induction technology that can click during operation:

- Pulse regulator. Electric induction technology allows you to control the cooking temperature down to a degree. But it is difficult to achieve such accuracy, given the heating of the dishes, so the device has a pulse-periodic mode. For example, if the system is set to “low fire” parameters (power 2-3), the temperature is maintained by turning the device off due to overheating and turning it on again using the regulator. In this case, the user will notice that the device operates jerkily and will hear clicks every 3-7 seconds. If the settings are set to use pulse mode, clicking is normal.

- Cooling Fan. The plate itself does not heat up, but the high temperature from the bottom of the pot or pan is transferred to it through the hob. To maintain the temperature and maintain the serviceability of the most important part, a fan is installed that cools the plate during operation. In many models, it spins while the tile is on and for a few seconds after it is turned off.

If from the first day of use the device clicks and works, especially on low heating modes, there is no need to worry. But if the sound becomes louder or a new crackling sound appears, grinding or clicking becomes more frequent, perhaps some part has failed.

The stove is humming

The operation of an induction cooker is not silent: it hums or even hums evenly - this is the sound of working induction coils when interacting with the cookware. This may annoy some people, which is why this item is included in the “cons” section, but in general, any cooking is a rather noisy activity, and the hum will very quickly be drowned out by the sounds of frying or water pouring from the tap. In new models, noise is becoming less and less, and specialized cookware helps reduce it to a minimum: it costs more than usual, but manufacturers promise an almost complete absence of buzzing in addition to improved thermal conductivity and a perfectly flat bottom surface.

Troubleshooting

Immediately after purchase, you should carefully inspect the unit and find out whether all its visible elements (door, switches, grilles, etc.) are securely fastened in place. After this, you should connect the unit to the network and run some kind of gentle program “idle” - this way you can find out whether there is a manufacturing defect.

Most often, owners of electric stoves from the following manufacturers face the problem of extraneous sounds: Gorenje, Indesit, Gefest, Zanussi, Hansa, Kaiser and Electrolux.

Price issue

The first thing that frightened many people about the new product that appeared on the market was the price. But against the background of prices that have increased during the crisis, the difference in the cost of conventional electric stoves and induction ones is not so noticeable. Of course, the price also depends on the functionality, so you can simply abandon the bells and whistles that are unnecessary for you in favor of induction technology.

The most popular are Bosch induction hobs. We monitored many sites and realized that they have the largest number of positive reviews. The second most popular brand is Electrolux. If you compare these two brands in terms of cost, it is almost the same.

The hob turns off automatically

The hob should be turned off automatically in the following cases:

- if the user did not perform any actions with the panel for ten seconds;

- if the burners were turned on more than two hours ago;

- if the timer shutdown function is activated.

In all other cases, turning off the panel indicates its failure. In these cases, it is necessary to call a specialist who is professionally involved in the repair of modern hobs, who will find out the exact cause of the breakdown and replace the burner unit or control unit.

Installation of a gas stove with electric ignition

Darina, Hansa, Ardo – so different and at the same time the same. The repair of gas stoves by Hephaestus is exactly like the repair of Ariston; gas stoves are made up of standard units. It is enough to look at a single device to understand the circuit. Have a reference book to help you properly maintain gas pressure. When set correctly, the flame is even and blue. Orange flashes indicate an imbalance in the fuel mixture. If the settings are incorrect, the flame will fail (especially typical for carob ovens).

For those who have read the reviews of the VashTekhnik portal regarding gas instantaneous water heaters, independent repair of gas stoves will seem like child’s play! You cannot do it yourself, but you can clean the device. The technician will have to clean candles, combustion sensors, burners, and sometimes nozzles. There are a lot of interesting things inside the gas stove. Anyone learning how to properly clean equipment should understand what we will see inside. Under the gas stove table:

- Burners. They are often bolted to the gas stove table. Each burner consists of a lid, a divider, and an injector (nozzle). They are not rigidly fastened under the table; each is fitted with a steel or copper tube; the fastening is carried out like an American one. You will need a key of approximately 13 to remove the products. It is more convenient to clean if something is clogged inside. Beware of tearing off the head or thread - you will have to replace it. After assembly, check the tightness by washing. The procedure involves applying foam to the disputed nodes.

- There are two candles around the perimeter of the burner. One serves as ignition (due to a piezoelectric element or an electronic circuit), the second is a thermocouple, included in the combustion control circuit. It's quite easy to distinguish. The high-voltage spark plug is covered with a ceramic caftan so that the spark does not strike below a predetermined level. When the arc flows, you can see: the tongue of the discharge licks the body of the burner. Gas stoves with electric ignition will be properly grounded by a technician. Beware of using plumbing connections or connectors pierced with metal threads. During installation, the hoses are separated from the riser by special gaskets. Failure to follow the rule will easily provoke an explosion in favorable situations. We wrote in more detail, we remind you again. The candle with a thermocouple is covered with a bronze caftan that conducts heat. The faster the semiconductors cool down, the flame goes out, and the protection that cuts off the gas supply will work more reliably.

- Most often there is a collector under the table. A thick tube from which a line goes to any burner. The gas flow is controlled by solenoid valves. The number is usually equal to the number of burners. When the burner flame goes out, the rest will burn. The expediency of the decision can be challenged, but this is how it is done. Each solenoid valve contains an inductor. The thermocouple heats up, an EMF (tens of millivolts) appears, keeping the devices open. Complete activation procedure: turn the gas supply regulator, press down. We press the piezo ignition button, or the electronic circuit performs a set of procedures independently. We hold the handle for a fixed time. The thermocouple warms up, an EMF begins to be generated, the electromagnetic valve is held open due to the phenomenon discovered by Seebeck. As soon as the gas goes out, the sensor plug cools down and the gas supply stops. The process is inertial, we believe that the day is not far off, flame ionization sensors will begin to be used in gas stoves, allowing the protection to operate instantly.

- Similar to the gas manifold, there is a distribution valve panel inside. Single high-voltage wires run to each ignition electrode. Another way to distinguish a thermocouple: two wires with a thinner cross-section stretch to the sensor. The spark breakdown goes to the housing, the second ignition wire is superfluous. If the gas stove is deprived of grounding, we have a chance of getting an electric shock. Fatalities are possible - an additional reason to entrust the installation to a professional. The collector is connected via connectors. There is protection against incorrect orientation of the plug; you can easily mix up some places. When you open the burner, a spark will jump on another divider. It’s not very pleasant, a flash of flame is possible.

If the charge is generated by an electronic circuit, you will find a simple thyristor, diode, capacitor, and fuses inside. The circuit operates, powered by a capacitor charge with a subsequent burst of energy from the spark gap of the spark plug. Repair of electric ignition of a gas stove concerns the listed elements. The fault is easy to notice. Burnt elements are black or similar in color.