Gas stoves have a relatively simple design, which ensures durability of components and operation. A number of brands are improving their models, including the installation of electric ignition. If a part breaks, no spark is supplied to the burner or the stove constantly clicks. This leads to inconvenience and discomfort in using the technology. To repair problems and restore serviceability, contact the service center.

Repair of gas stoves in Moscow is carried out at the client’s home every day from 7:00 to 23:00. The visit of the masters is offered by appointment or urgently if the application was submitted before 12:00 of the current day. You can use the services on weekdays, weekends, and holidays. We accept applications by phone or online by requesting a call back. If necessary, managers will advise on issues of interest and prices. The final cost is determined after diagnosis.

Main types of repair work with gas stoves

There are several problems that are most common with these devices.

Therefore, the repairs usually required are the same. The most common repair work on gas stoves includes: Burner repair. It is these elements of equipment that most often fail, so it is necessary to carry out certain repair work on them. As a rule, the flame begins to weaken, after which it appears only on one or two sides of the burner, and then disappears completely. The reason for this deterioration in the operation of the burner is clogging of the burners or dividers. Some people, when cooking with a gas stove, allow food to get on the burners, which leads to clogging of the elements. Even when cleaning the stove from dirt, a small amount of detergent can get into the burners, causing the elements to become clogged. This problem is solved quite simply, since you need to remove the burner, after which it is disassembled into its component parts. The nozzle and divider are thoroughly cleaned, which ensures that the cause of the blockage is eliminated. They can be cleaned with various specialized tools or improvised means, which include a regular needle or knitting needle.

Oven door repair. Another popular problem with a gas stove is certain obstacles that arise when opening the oven door of the appliance. The door begins to jam or does not close tightly. This problem usually occurs after several years of equipment use. It does not allow you to fully use the oven, so there is an urgent need for repair work. To repair the element, the door is removed, for which the screws that secure it are unscrewed. You should not unscrew them completely, as you only need to loosen them a little. Next, the door swings slightly in different directions, which will ensure that the door fits on the hinges. This adjustment will lead to solving problems with opening or closing the door.

Valve thermocouple repair. This element belongs to the gas leak control system, therefore it is considered an important and complex product that must work without interruptions and problems. It is precisely due to the thermocouple of the solenoid valve that the possibility of gas leakage if the flame accidentally goes out is prevented. The safety of using the gas stove itself, as well as the safety of living in the house in which this equipment is located, depends on it. Often problems with this element arise when, after igniting the burner and releasing the button, the flame goes out. A thermocouple is a special metal pin with one side pointed. This element is located next to the burner and acts as a temperature sensor. As soon as the flame dies out, the temperature next to the burner drops, so the gas control cuts off its flow. Therefore, even if the burner is turned on, gas will not flow into the room. If there is a problem with the burner constantly going out unnecessarily, then the thermocouple should simply be cleaned of adhering deposits of fat and food residues. Standard sandpaper works great for this. If even this process does not lead to the desired result, then you will have to disassemble the device and replace it with a new element.

Thus, simple repair work related to the gas stove can be carried out on your own. However, they should not concern the direct connection of the device to the gas main. In these cases, you should definitely seek the help of specialists, since there is a high probability of making irreparable mistakes. This endangers not only the apartment owners themselves, but also other residents of the apartment building.

Basic steps

What to do if the gas water heater whistles? The first step is to calculate the source of the sound. Turn off the gas. Open the mixer in the hot water position. If the problem is not serious, the gas unit immediately stops whistling.

If the whistling gets worse, pay special attention to the water path. Study its components: pipes and maintenance, and its components. They could get clogged

A particularly common situation is the accumulation of scale on them.

They could get clogged. A particularly common situation is the accumulation of scale on them.

And scale often accumulates if the set water temperature parameters constantly exceed 60 degrees.

The measures here are simple - thoroughly clean these components. How to do this effectively? Start the reverse flow of water. It will remove all the blockage from the pipes.

Back pressure should only be applied after turning off the gas and water. You also need to unscrew the liner at the inlet section.

The easiest way to carry out this operation is to use a faucet in the bathroom. The shower switch must be set to the neutral position. The taps should be opened slightly.

To remove lime deposits, use a descaling agent. You can also work with folk remedies: acetic or citric acid. They are diluted in the correct proportions. The resulting composition is poured slowly into the water path. It is added according to the degree of sound attenuation. Then repeat this procedure three more times.

This is a good method when the gas water heater whistles due to a clogged duct.

And when you open the tap and there is no whistle, the problem could be hidden in the gas path. This means that there is possible damage to the valve for adjusting the flame power.

This is the most common answer why the unit does not stop whistling. The problem is especially pronounced when achieving the optimal ratio of gas flow dynamics and valve clearance width. This ratio may have different values in different columns.

If the gas water heater whistles when operating in high power mode, you need to adjust the regulator until the annoying sound disappears completely. Turn it smoothly, now in one direction, then in the other. The dynamics of the gas flow will decrease. It is not enough to produce sound. If it is increased, the valve clearance will expand, and the unit may start whistling again.

If these measures do not give the desired effect, it means that the gas path is clogged. The device will whistle even louder. It urgently needs to be disassembled, the problem area identified and thoroughly cleaned.

If your geyser is still under warranty, contact service immediately. You will have to contact them if the warranty period has expired and you cannot solve the problem on your own.

Solving the dilemma on your own is possible when you have the necessary knowledge and skills. The task comes down to cleaning this tract. Scale or winding elements could be stuck in it. If this is the case, the speaker will begin to whistle very powerfully.

Common electrical ignition problems

A typical electric ignition circuit consists of wires, contacts, an electric spark plug and a start button. All of them require careful handling and maintenance. Here are the most common breakdowns to look for when the stove clicks:

- Contacts are oxidized. This often happens when exposed to water or simply in a damp room. Typically, when oxidized, the module turns off. But sometimes, on the contrary, if the circuit closes, it will work indefinitely. This failure is indicated by sparking in all burners.

- The button is broken. The key is the most vulnerable point because it is mobile. If you press too hard or sharply, or twist the handle at an angle, the button may mechanically break. It cannot be repaired, it must be replaced.

- The ignition unit is broken. This fault is diagnosed by elimination. If all the previous reasons did not help to correct the situation, you will have to install a spare part. Some elements in it are damaged due to a power surge or natural causes and cannot be repaired. Most often, owners of Gorenje, Indesit, Gefest devices request this service.

How to fix the problem?

The first step is to disconnect the device from the network and close the gas valve. Afterwards you can proceed to the following actions:

- remove excess moisture from outside and inside the stove;

- if there is a lot of liquid, remove the button and blow with a hairdryer;

- Carefully disassemble the parts and dry the button.

It is worth inspecting the internal parts of the structure and, if necessary, cleaning them.

@absoluteappliancesrepair.com

If none of the options discussed above work, contact a home appliance repair specialist for help. Your own intervention often leads to even more serious consequences.

If cracking or clicking sounds are periodically heard from the gas stove, it means that the auto-ignition system has broken down. Fixing the problem is not difficult; you just need to follow simple recommendations or, if necessary, replace the failed part.

The most important piece of advice that will help you avoid such a disaster is proper care of your burners. Timely cleaning and care will allow the device to serve for a very long time.

Benefits of contacting us

"Remontano" has extensive experience in the field of slab repair and a formed team of highly specialized professionals. They also choose us for other reasons:

- Positive reputation in the service market, a lot of feedback from clients.

- We work throughout Moscow. Travel to the region is possible.

- Extended work hours from 7:00 to 23:00.

- Performing services of any complexity at the customer’s home.

- Official cooperation with registration of a guarantee.

Please note that independent intervention often leads to additional defects, which increases the cost of eliminating the consequences. Choose the services of professionals and you will receive documented confidence in the serviceability of household appliances. Call the phone number and we will send an employee to the specified address with the necessary tools, equipment and spare parts.

What to do if the piece constantly clicks on its own

The most important thing in such a situation is to find the source of the problem, and then simply follow the instructions for eliminating it. If you discover a breakdown, do not panic and strictly follow all safety rules, try to make repairs, guided by our advice. Remember - most of the causes of the problem, in this case, are absolutely safe and can be eliminated independently, without resorting to the services of specialists.

How to fix the problem without the help of a specialist

The following actions can help in dealing with the malfunction:

- If the cause of the breakdown is water, and its constant contact with the stove, then there is only one way out - dry it thoroughly, first turning off the auto-ignition from the outlet. Let the stove stand unconnected to the power supply for several days - during this time it should dry thoroughly and the clicking will stop on its own. If such a “repair” does not help, it’s time to call a specialist and entrust the repair to him. When drying, one important point must be taken into account - you cannot dry the stove using a working oven - otherwise moisture, on the contrary, will accumulate in the appliance in huge quantities and the situation will only worsen. Therefore, be patient and let the device dry naturally.

- If the ignition button does not work well, the reason is the accumulation of dirt, dust or congealed grease under it. Clean it. For better cleaning effect, use a brush dipped in soapy water. After cleaning, let the stove dry. It should be noted that this method is not always able to return the button to its previous functionality. There is always a possibility that due to the low landing, it will not press completely. If cleaning does not help, consider replacing the auto-ignition button or its entire mechanism.

During prolonged use, the auto-ignition unit may fail. If only one burner does not work, then the reason is most likely due to damage to the wire located in the channel of the block. But do not forget that the burner itself may also be faulty, and in this situation, independent repair is not only unacceptable, but life-threatening. To accurately diagnose the cause of a non-functioning burner, you should contact a specialist who can not only identify the actual cause of the malfunction, but also replace the damaged element.

The main thing is that no matter what happens to your favorite stove, do not panic and act thoughtfully. Remember, thoughtful repairs can fix almost any damage.

Household appliances Stove

Why does clicking occur and features of the problem?

The problem occurs on equipment with electric auto-ignition. Piezo ignition installed on older devices is not prone to developing defects with regular clicking.

If the plate clicks, the reasons are:

- Natural wear and tear. After prolonged use, the button mechanism became worn out and became stuck in the on position.

- Manufacturing defects. Occurs on devices in the first year of service after purchase or connection. The occurrence of a malfunction is possible on domestic and imported equipment, including Hansa, Gorenje, Bosch.

- Human factor. Improper use and care. Mechanical damage to the button or moisture penetration into the ignition key.

The exact source of the problem when the gas stove clicks is determined by specialists through diagnostics using special equipment. To ensure an inexpensive and high-quality restoration, we recommend that you do not attempt self-repair.

Problems with burner control knobs

Gas supply handles for the burner are one of the most necessary parts; without them it is impossible to use the stove. Behind the outer skirted flag, which you turn, there is a gas tap, which can have a gas control sensor built into it.

Electric ignition built into the handle is rare on Hephaestus stoves - it is usually located with a separate button.

Over time, the knobs may stop turning, become stuck, or become loose. We'll tell you what to do about it later.

The handle is difficult to press and turn

This problem is not uncommon; if you start it, the handle may stop turning completely. The cause is usually grease that has accumulated between the flag, skirt and front panel of the cooker.

Hot, it splashes during cooking and easily flows into all the cracks, and then cools, thickens and turns into a kind of glue.

Carefully pry up the skirt and handle with a knife, screwdriver or other flat object. Do not use too much force - you may damage the enamel or plastic.

To get rid of the problem, the flag with the skirt must be removed from the stem and washed thoroughly. The handle needs to be pulled towards you - it is simply pressed tightly onto the rod, without latches or other fasteners. For convenience, you can grab it with pliers, preferably through a non-slip cloth, one of those sold for cleaning.

The skirt usually comes off on its own after the handle is removed, but if it does not turn with the flag, it can be secured with a latch. In any case, you can pick it out with a knife. Remember its position so that when assembling, the latches close to the panel or flag.

Many models have a reinforcing metal plate in the handle; do not lose it. After washing all the parts, as well as the front panel under the handle, put everything back in place. Don't forget to install the spring if you had one.

The checkbox scrolls or jumps off

This problem is rare with Hephaestus slabs, but it does happen. The reason is usually that a metal plate has fallen out of the flag and is lost, which clings to the recess on the rod.

You can cut such a plate from a metal preservation lid and insert it into a special groove, or buy a new flag. If the handle on your model is completely plastic and its inside is licked off, only buying a new one will help.

The handle turns hard

It happens that even after the flag and skirt are perfectly washed, the handle still turns tightly. The reason is that the lubricant on the gas taps has run out.

It is better to invite a specialist to carry out preventive maintenance, because mistakes during such repairs can lead to leakage or clogging of gas supply pipes

If you decide to lubricate the gas taps yourself, buy a special graphite lubricant for this. Turn off the gas supply to the stove. Then remove the handles and the front panel - we described how to do this above.

In Hephaestus slabs, the stem is fixed in the tap with a flange connection; to remove it, simply unscrew 2 bolts on the sides. Immediately wash the stem from grease and dust.

Then the spring and the tap plug are removed - the last one needs lubrication. This is a cylindrical part with a through hole and a cut on the side, through which gas is supplied to the burner. You need to lubricate the cork very little; the layer should be invisible, but noticeable to the touch. It is more convenient to put a little lubricant on your finger and rub the plug.

After assembling the faucet, do not rush to replace the front panel. First, put the flag on the stem without it, open the gas and apply a soap solution to the tap. If no bubbles appear anywhere, wipe everything dry and reassemble the stove.

Why does the electric ignition on the hob not work?

Increased dampness inside the panel.

Excess water that gets inside the structure after extensive washing or boiled-over food can create increased humidity. As everyone knows, water is a good conductor of electricity, so when it hits the contacts of the power button, it closes them and thereby activates the electric ignition of the hob. What to do in this situation? Such a malfunction is not dangerous for residents; it cannot lead to irreversible consequences, the only thing is that the constant clicking drives them crazy. As soon as the water evaporates, the clicking of the hob will immediately stop, so to help the water evaporate, you should turn on the oven for 30 minutes or turn off the power to the stove for 2-3 days. Before taking these steps, wipe the stove burners and entire worktop dry. If after a while the problem does not disappear, you should contact our repair shop and order hob repair.

Fat and food on control buttons.

Grease that has accumulated over time on the electric ignition buttons can jam it. In the design of the button, a conventional metal spring is installed to open the contacts, which, when the handle is released, returns to its original quiet state. The fat that gets into all the cracks of the button slows down the sliding mechanism and it is difficult for the spring to overcome such tension. Repeated activations may lead to jamming or complete breakage of the button. If the ignition switch breaks, the electric ignition unit will continuously generate an electrical spark - even after the burner has ignited. In this situation, only qualified gas stove repair will help you.

The ignition unit is faulty.

Like all household appliances, the hob has its own service life. With prolonged use, natural wear of parts appears, for example, over time, the electric ignition unit may close, which leads to constant clicking of the hob. In this situation, the right decision would be to invite a technician to your home to repair the electric ignition, or rather, replace the entire unit.

How to remove handles from gas stoves of different models

The operating principle of this technique is almost the same. Plates from well-known manufacturers such as:

Each device is equipped with gas supply power regulators. On some models they are very easy to remove. It is enough to use only the tip of the knife and pry off the element. Other slab models require disassembling almost half of the surface of the structure and the presence of tools such as:

- pliers;

- multi-format screwdrivers;

- kitchen knife.

Removing handles on devices such as Hephaestus, Darina, Hansa does not require the intervention of specialists or contacting service centers. They are simply removable, you can easily clean them and even replace them with new ones yourself. There are gas and electric stoves on which the regulators are welded to the internal parts. Such devices are called stationary, on which it is impossible to remove the handles at home. In this case, you need to turn to professionals.

Regulators on the stove

How to remove handles from a Hephaestus gas stove

Many housewives do not know how to properly remove all the handles from the Hephaestus gas stove in order to wash its surface. The Hephaestus device contains several types of handles responsible for activation:

- main surface burners;

- ovens;

- mechanical timer.

Regulators on the Hephaestus stove

To light the burner, the valve on Hephaestus must be pressed down and turned. As practice shows, removing such regulators is not at all difficult. But you should not forget about the safety rules:

Close the gas supply valve. Make sure all controls are off and turned all the way. Take the knife and pry up the handle

It is very important to do this together with the circle on which the marks are drawn. Apply force and pull up. If the efforts made are not enough and difficulties arise, experts recommend using WD-40 (liquid key)

Now you can clean these parts from grease and other contaminants.

How to remove the handles from Darina's gas stove

The regulators of the Darin model are very similar to Hephaestus, in which ignition of the burners requires pressure. Instructions for dismantling parts of this brand are as follows:

First of all, turn off the gas. Next, disconnect the hose that is connected to the device. Check all control valves

Make sure that they are turned off, otherwise it may damage the plastic parts (they may burst). Wrap the regulator with a piece of cloth, pry the edges with a knife and remove it with pliers. Instead of pliers, you can use two knives, where one of them will serve as a lifting lever

You need to remove the rotary handle on devices very carefully so as not to damage fragile components: springs, nozzle washers, cylinder

Instead of pliers, you can use two knives, where one of them will serve as a lifting lever. You need to remove the rotary handle on devices very carefully so as not to damage fragile components: springs, nozzle washers, cylinder.

Removing the rotary regulator

How to remove handles from a Hans gas stove

The Hans model is characterized by ease of operation and good performance. As on the two previous kitchen devices, the handles on Hans are removable and do not require much effort. The main thing is to be careful and not forget about safety. Before work, be sure to turn off the gas. The regulators are removed using a small thin screwdriver, with which you need to pry the washer with the adjustment marks and pull it towards you.

Hans gas stove

Usually the process of removing the handles is straightforward, but sometimes fat under the control elements can slow down the process. In such cases, housewives use a variety of soap solutions, which they first wet the parts with, and only then begin to remove the parts. As practice shows, control valves can be easily removed after treatment with liquid wrench. But you should not get carried away with this tool, otherwise it will reduce the performance of the rotating mechanism of the handles.

Share on social media networks:

One of the most common problematic issues among housewives is how to clean the handles of the stove from old grease, because this is not the easiest task, although there are enough cleaning products on the modern market. And first of all, you need to find out how to remove the handles from a Hephaestus gas stove or any other brand. General rules and useful tips on cleaning this part of the hob can be found in this article.

Correct connection of a stove with electric ignition

If a regular stove only needs to be connected to a gas supply system, then models with automatic ignition also need to be connected to a 220-volt AC electrical network. To do this, each device is equipped with a three-core cable with a cross-section of at least 1.5 mm and a grounding plug. The outlet into which the equipment is connected must also be equipped with a grounding circuit. It is advisable not to use additional extension cords, adapters and tees, but to connect the device directly to the outlet.

A separate circuit breaker and additional protective equipment for connecting household appliances with ignition are not required, since the electricity consumption during its operation will be minimal.

Other causes of problems

In addition to electronics, other components also cause malfunctions.

If the oven operates with mechanical ignition, it is advisable to pay attention to the condition of the button located on the control panel. It is this that starts the process of spark formation and is powered by the voltage of the central network

Most often, the contacts melt due to a short circuit. The functionality of the unit is checked with a multimeter.

Breakage of spark plugs

Another reason for the breakdown lies in the breakdown of the burner spark plug. If you need to check the functionality, turn off the gas and press the ignition. If there is no spark, it is the spark plug that is faulty. The cause of failure may be contamination of the spark plug with grease, oxidation of the steel rod, or a violation of the seal. Interruptions in operation will occur if a crack appears on the element and a spark strikes to the side in the area of the violation. It is impossible to isolate or repair spark plugs; the only correct solution is replacement.

Electric stove clicks

Electric stoves do not have an automatic ignition system. Electrical components and components, including control relays and protective units, become sources of extraneous sound. In induction models, clicks may occur when heating, even if the equipment is in good condition. In other cases, we strongly do not recommend continuing to use the device due to the risk of a short circuit. This especially applies to apartments and houses that are not equipped with modern automatic protection systems.

Common electrical ignition problems

A typical electric ignition circuit consists of wires, contacts, an electric spark plug and a start button. All of them require careful handling and maintenance. Here are the most common breakdowns to look for when the stove clicks:

- Contacts are oxidized. This often happens when exposed to water or simply in a damp room. Typically, when oxidized, the module turns off. But sometimes, on the contrary, if the circuit closes, it will work indefinitely. This failure is indicated by sparking in all burners.

- The button is broken. The key is the most vulnerable point because it is mobile. If you press too hard or sharply, or twist the handle at an angle, the button may mechanically break. It cannot be repaired, it must be replaced.

- The ignition unit is broken. This fault is diagnosed by elimination. If all the previous reasons did not help to correct the situation, you will have to install a spare part. Some elements in it are damaged due to a power surge or natural causes and cannot be repaired. Most often, owners of Gorenje, Indesit, Gefest devices request this service.

Why does the hob keep clicking?

.

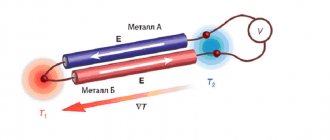

Water got on the power buttons; . A lot of fat on the power buttons; . The spark generation unit is closed; . The power button burned out and melted; . Increased dampness; . Button contacts stuck together; . Oxide on contacts. To eliminate the causes in the electronic ignition system of gas stove burners and hobs, it is important to know the theoretical foundations and operating principles. When you press a knob or button, an electric spark appears at the spark plug, which ignites the gas. The electric spark is generated by the ignition unit. After the gas has ignited, you continue to hold the knob pressed for a few more seconds to magnetize the gas control system. When you turn on the burner, we hear characteristic clicks, which stop when the handle is released.

Reasons for automatic ignition switching on

As it turns out, taking into account practical experience, spontaneous clicks of a gas stove lighter in most cases have nothing to do with the electronic circuit of the ignition unit.

One of the many designs of gas stove lighter buttons. Traditionally, a plastic case and a metallized contact group are ideal conditions for the formation of oxide junctions. However, there are better, but more expensive designs.

The reasons for the appearance of an uncontrolled spark lie elsewhere. Often the place where such a defect occurs is the inner area of the ignition control button.

Reason #1 - moisture inside the control button

Surely owners of gas stoves have had to deal with uncontrollable ignition clicks on the gas stove after washing and cleaning household appliances.

Most likely, during the washing process, some amount of water got on the ignition control button, as a result, some of the moisture penetrated inside.

View of one of the lighter button designs from the inside. With this placement of conductors, even a small amount of moisture, soot, soot, etc. enough to create a short circuit between the contacts

Considering that a high discharge voltage is supplied through the ignition button circuit, a small amount of moisture is enough to cause an uncontrolled spark to appear on the gas stove's spark gap.

Typically, the defect of an uncontrolled lighter spark in such cases disappears after some time. The moisture inside the button dries out, the short circuit factor disappears, and accordingly, spontaneous clicks stop.

The picture shows a simple way to get rid of the defect of spontaneous sparking of the ignition system caused by moisture. Warming up the device for some time with all burners helps get rid of uncontrollable clicks.

Often, correcting a short circuit defect due to “water that has entered after washing” is helped by lighting all the burners of the gas stove for about 15-30 minutes.

Reason #2 - formation of a junction

The solders that form inside the ignition button can take different shapes. The formation of a junction can be facilitated by the same moisture that gets inside the button after washing. Typically, such a “water” junction is formed due to periodic penetration of water.

Over and over again, deposits accumulate and eventually an oxide junction forms. In addition, grease, soot, and dust can accumulate inside the button housing. All of these are also harbingers of a short circuit between the contacts.

If this happens, you will have to disassemble the gas stove:

- remove the top panel;

- open the front subpanel;

- remove the ignition button(s).

Or in the case of more modern designs of gas stoves, it is necessary to get to the designs of disk control devices, which simultaneously perform the functions of a button and regulator of gas supply to the burners.

A variant of the mechanism for turning on auto-ignition and adjusting the burner flame level, which combines two functions in one design. Such systems are more difficult to remove for cleaning or repair than a separate button

After removing the part from the body of the gas stove, the deposits are cleaned, after which everything is assembled in the reverse order. However, this work is the prerogative of gas company specialists. It is not recommended for a user of a gas stove who is inexperienced in such matters to disassemble the device on their own.

Reason #3 - mechanical connection of the contact group

The mechanical connection of the contact group of the ignition button of a gas stove should also be classified as a reason associated with a short circuit. Such a defect, as a rule, can occur on slabs that have been in use for quite a long time. True, the same malfunction cannot be ruled out on new devices, where the quality of components leaves much to be desired.

A mechanical connection is formed by any of the button contacts, which simply breaks off, for example, due to physical wear. The broken part moves away from the attachment point and forms an electrical connection with another contact. In essence, it creates the effect of the ignition button being turned on - that is, the spontaneous activation of electric ignition on the burners of a gas stove.

In case of such a malfunction, the only way out is to completely replace the component.

The electric ignition of the gas stove does not work, what should I do?

The electric ignition system for a gas stove operates from an AC electrical network at 220V. When using a gas stove, a fault in the electric ignition may occur in one of the component elements. Since the work is being carried out, the electric ignition is turned on by pressing the ignition button. In modern models of gas stoves, the ignition button is located under the handle located on the stove panel; by turning the handle, you activate the ignition system.

The circuit closes and high voltage pulses are emitted from the ignition unit from high-voltage coils, which are supplied through wires to the spark plug. Which in turn produces a spark, thus charging and igniting the gas. Each burner of the stove has a built-in ceramic candle; the gas coming out of the burner is ignited by an electric spark from the candle. When the electric ignition button is pressed, a spark comes out of all the spark plugs, but only the open burner ignites, from which gas comes out of the burner.

Since sometimes there is a decrease in alternating current in the network or a short circuit, the electric ignition starts to click, since it operates at 220V. A short circuit and a decrease in current cause the ignition to break down. What are the signs to determine if the electric ignition of a gas stove is faulty?

The ignition does not work when the button is turned on; The burner ignites poorly or does not ignite at all; constant clicks in the ignition; the candle sparks even when the burner is turned off; the ignition continues to work even if the handle is released; The machine in the electrical panel constantly knocks out.

High-quality repairs of gas stoves in Kyiv are carried out by the service center servicecenter.co.ua

If the electric ignition on a gas stove stops working, you need to find out the root cause and eliminate it. If there is no spark, or if a ceramic spark plug is constantly sparking, the most common cause may be contamination of the mechanism with grease. Because during cooking, the fat from the frying pan splashes across the stove. Sometimes after washing the stove, detergents remain on the surface of the mechanism, which also interferes with its operation. After the button has been cleaned and all components of the stove contaminated with grease accumulated during operation have been dried, the malfunction will be eliminated.

One of the reasons for failure or poor ignition performance may be a violation of the seal of the spark plug or possible oxidation of its steel rod. In this case, the malfunction will be eliminated after replacing the damaged spark plug with a new one. This problem with spark plugs occurs due to contamination during operation. If the ignition unit malfunctions, the electric ignition on the gas stove does not work. Since when turning the handle, no impulse is sent to the spark plug and there is no spark, it is necessary to replace the unit, since it is impractical to repair it.

Sometimes, when cleaning and washing a gas stove and hob, even with care, water and detergent penetrate the wires or contacts of the ignition button. With constant contact, liquid from the heat received from the exhaust burners of the stove oxidizes the contacts. Therefore, the contact joints become rougher, causing them to break or stick together and therefore jam. In this case, the malfunction is eliminated by technical washing and subsequent drying of the electric ignition mechanisms.

When cleaning, it is important to remember that the entire gas stove system is under 220V voltage, so before washing and cleaning it is best to unplug the plug from the socket to comply with safety precautions. After you make sure that all the parts are dry, in order to avoid a short circuit, you can plug the plug back into the socket to supply current to the ignition.

If the electric ignition on a Hephaestus gas stove does not work, then you need to pay attention to the ignition button, since this is the most common drawback in the models of these gas stoves. It is important that the ignition button and the high voltage transformer match each other. When replacing a transformer, it is important to connect the electrical wiring correctly, since if the connection is incorrect, the ignition button will not work. This is a very common cause of malfunction of the hephaestus plate.

It is necessary to check the gas burners, because if the burners malfunction, the ignition does not turn on. When the burner is turned on, it should burn steadily and evenly. If this does not happen and the gas in the burner burns on one side, or the flame is yellow and inhomogeneous, spasmodic, the violation must be corrected. Sometimes if the burner is flooded with water, it will not work again when the ignition is turned on. Therefore, if the electric ignition on a gas stove does not work, you need to take corrective action.

In this case, you need to clean the nozzle and then reinstall the divider.

A very common cause of breakdown is the failure of the ignition unit, due to possible fluctuations in the electrical network or the occurrence of a short circuit. It can only be eliminated when the unit is completely replaced, and in the future, to prevent a similar problem from arising, it is necessary to make grounding. A very common replacement when the electric ignition is faulty is to replace the resistors. Since inside the ignition block there is:

Transformer; capacitor; diode; resistor.

The ignition block may contain other elements, since each gas stove model is significantly different. But the basic principle of operation of the unit is the supply of charge through a diode. Therefore, if a resistor fails, first of all, you need to turn off the electricity. Then inspect the printed circuit board, electronic unit and high-voltage unit and conductor protection circuit, usually a silver strip, which is varnished on top.

During operation of the stove, contamination or damage to the board occurs due to a short circuit; after cleaning off carbon deposits and degreasing with alcohol, the damaged microcircuits are restored. If the capacitor is damaged, you can see it immediately; it swells. By replacing it, you will restore the operation of the ignition unit.

The Ariston gas stove does not have electric ignition; when repairing the electric ignition and after inspecting the electronic boards, you should pay attention to the transformer and replace it if it malfunctions. Since the transformer is one of the main elements of the block. Therefore, a malfunction of the transformer prevents the entire unit from functioning, since a spark does not occur.

Almost all malfunctions that may occur in the electric ignition system do not pose a danger to the user. But the gas stove system itself has a potential danger, since gas leakage is possible due to unexpected depressurization of the gas supply connections to the burners. Therefore, specialists do not recommend repairing the gas stove and elements of the electric burner ignition system on their own. Be sure to call a professional to avoid a dangerous situation in your home.

- Why is electric ignition needed?

If you have been thinking about replacing your outdated stove for a long time, but want to avoid the hassle of finding matches, then purchasing a gas stove with electric ignition would be an excellent option. It is this useful feature that will allow you to forget about buying matches forever.

Let's consider the advantages of this technique, as well as how the process with electric ignition occurs.

Gas hob repair

In a gas hob, you can only repair the electric ignition and gas control system yourself. In principle, the main problems arise with them. Since a gas hob with electric ignition is also connected to electricity, in case of general problems with the electrical part (piezo ignition does not work at all), first check the presence of power in the outlet and inspect the integrity of the wire. If everything is fine here, you can go deeper.

You can repair your gas hob yourself

The electric ignition button does not work (no spark)

Electric ignition is a convenient thing, but periodically the spark stops “jumping” and the fire on some burner does not ignite. You can light it by pressing the button of another burner. They are connected in parallel and when you press one, there is a spark on all burners. But this situation is abnormal and the spark must be restored. Repairing the hob in this case is not very difficult. There are several reasons:

- The candle is clogged with grease, dirt, and detergent residues. It must be thoroughly cleaned and wiped dry.

- Check the power wires that go to this spark plug. To do this, you need to remove the burners and the top panel. If it is glass-ceramic, it can be placed on a sealant; we trim it and remove the front panel. If it is metal, unscrew the fixing bolts. Under the front panel we are interested in the power wires. It is necessary to check for an insulation breakdown to ground (to ground). To do this, you can press the ignition button several times; if there is a breakdown, a spark will jump in that place. If there is no visible damage, we test the wires with a multimeter for integrity and for breakdown with ground. We replace the found faulty conductors with similar cross-sections.

- If the conductors are intact, the contacts are normal everywhere, the problem may be in the button. We disassemble it, clean it, put everything back in place.

- Another reason is problems with the electric ignition transformer. O has two windings, each of which powers two burners. If you measure the resistance between two opposite burners, it should be about 600 Ohms - this is the resistance of the transformer windings. If it is lower, most likely the reason is a stuck (dirty) button. We disassemble them, clean them, and put them in place.

What else can be done is to check the contacts and soldering. If necessary, tighten the contacts or clean them from dirt, solder them, if cold ones are found, re-solder them. How to determine if a solder is cold? If you pry the tin with something hard (the end of a multimeter probe, for example), it moves or flies off, and there may be cracks in it. In this case, heat up the soldering iron and melt the solder again.

After ignition, the flame on the burner goes out

Many modern gas stoves or hobs have a gas control function. Near each burner there is a sensor that monitors the presence of a flame. If there is no flame, the gas supply stops. The function is useful, but sometimes problems arise - after ignition, when you release the power handle, the flame goes out. The fact is that the sensor - thermocouple - is dirty or faulty and “does not see” the flame.

Where is the thermocouple located in a gas stove?

First you need to try cleaning all the sensors. During use, they quickly become overgrown with grease, so they require periodic cleaning. First, turn off the power, remove the burners, remove the handles, and unscrew the front panel. We find a thermocouple on a non-working burner. This is a small metal pin located close to the gas burner. In some models of gas hobs it can simply be inserted, in others there is a lock. You need to remove the sensor from its socket and clean it of dirt. Use regular kitchen dishwashing chemicals or something stronger

It is important to achieve results. We wash the sensors, dry them, and put them in place. You can check your work

You can check your work.

Sometimes it happens that even after cleaning some burners do not work. This means that the thermocouple has failed. In this case, repairing a gas-powered hob involves replacing the thermocouple. You already know how to get to it, but it can be turned off simply: you need to remove the corresponding wires from the block. We take out the old sensor and install a new one. Reinstall the cover and check the operation. That's all, actually.

One important point: if your equipment is under warranty, you should not repair it yourself, otherwise you will be denied warranty repairs.

What to choose: mechanical or automatic electric ignition?

Like a car transmission, electric ignition is divided into two types: automatic and mechanical.

- A stove with a mechanical electric ignition function has a button that must be pressed after the switch has been turned. Thus, the high voltage circuit is closed, a spark appears, and as a result the burner ignites.

- If the stove has automatic electric ignition, then you don’t need to press anything. Simply turn the switch and lightly press it.

Return to contents

What conditions are necessary for such equipment to operate?

Of course, the main condition for the operation of a stove with electric ignition is the presence of electricity.

First you will need to connect the equipment to the electrical network.

For these purposes, you will need a grounded outlet and surge-resistant voltage.

If power surges occur in your home from time to time, before purchasing a stove with electric ignition, find out which models are most resistant to power surges.

In most cases, such slabs are produced by Russian manufacturers. These models best tolerate voltage fluctuations.

Return to contents

Will a stove with electric ignition work in the absence of electricity?

This question probably worries any person who decides to buy a stove with electric ignition. In fact, even if the lights are turned off, the stove will work. There is only one point: you will have to turn on the gas using the old, proven method, i.e. using matches or a lighter.

So you don't have to worry. If the power in your apartment or house suddenly goes out, you will not be left without a hot dinner.

Return to contents

What it is?

Electric ignition of a gas stove is a convenient innovation that can be seen on most modern stoves. Outwardly, this is an ordinary button, which is located on the front panel, near the handles that turn the burners on and off. Its task is to light the burners without using additional means in the form of matches, electric or gas lighters. Electric ignition can have two types.

- Automatic. The essence of auto-ignition is that, using special piezoelectric elements, the burner is ignited when the corresponding handle is turned.

- Mechanical. The mechanical version uses a button, which triggers the same reaction.

In order to clearly understand the essence of what is happening, it is necessary to understand the intricacies of the operating principle of electric ignition, which will look like this:

- pressing the button causes a reaction in the form of voltage, which is applied to the capacitor area;

- next includes charging the capacitor;

- the subsequent action will be to increase the level on the thyristor;

- upon reaching the desired limit, the process of discharging the capacitor starts;

- at the output you can observe the voltage that triggers the spark gap;

- the spark that results will be the factor that makes it possible to ignite the burner.

All stages occur instantly, so you can turn on the stove in just 1–2 seconds. The peculiarity of modern stoves is that voltage is supplied to the burner that turns on. Whereas in the old modifications the discharge went to all burners, and the one to which gas access was open was turned on. A pure gas stove cannot have mechanical electric ignition, since it runs on electricity, so modern stoves have a cord on the back that must be plugged into an outlet to create conditions for using the corresponding function. Having such an assistant seems like a blessing, but each device always has its own advantages and disadvantages.

Auto-ignition operating principle

To understand the cause of the auto-ignition malfunction, you need to know how it works. It is not difficult to understand the principle of its operation: the ignition mechanism is powered from the electrical network, and it is started by pressing a special button and turning towards the gas supply regulator, in the direction indicated on the arrow shown on the stove panel. The process of operation of this mechanism is as follows:

- When you press the ignition button, the spark is converted due to the flow of electrical impulses.

- When you turn the knob to open a certain burner, gas is supplied to the burner.

- The spark produced when the ignition mechanism is activated interacts with the gas, converting it into fire.

- The burner into which the gas was supplied begins to burn.

You can release the handle a couple of seconds after turning it - that’s exactly the time it takes for the system to magnetize. Of course, in reality, the entire arson process takes place much faster than it is described here. The burner lights up and a spark is supplied to it. The ignition button itself is located on the stove panel, next to the gas supply regulators.

In old-style stoves, the ignition process is slightly different from ignition of gas in new models. Its difference is that a spark is supplied to all burners at once, but only the one whose valve has been turned is ignited.

For both old and new models, for the auto-ignition mechanism to work, it must be connected to the electrical network.

Conclusions and useful video on the topic

A video about how to troubleshoot a geyser. A detailed overview of disassembling and repairing a gas water heater at home:

In case of any type of malfunction, as a result of which the gas water heater hums and crackles, you can try to fix the breakdown yourself. But there is no guarantee that you will not damage the device. Therefore, the best option would be to contact a specialist for servicing your gas water heater.

.

Would you like to supplement our material with useful information on eliminating the causes of excessive noise and crackling noise from a gas water heater? Or would you like to clarify a couple of diagnostic points? Ask your questions to our experts, leave comments, participate in the discussion - the feedback form is located below.

The operation of a gas water heater is always accompanied by certain sounds. Usually this is the sound of water running through pipes or the burning of a fire. But it happens that the device begins to make non-standard sounds: whistling, popping, clicking, etc. If this starts to happen, you need to quickly figure out why the gas water heater is making noise. The reasons may be different.

Conclusions and useful video on the topic

The first video contains information that will help you understand some of the causes of current leakage and understand how to deal with them:

The following video shows how you can independently detect the presence of a current leak:

The presence of a discharge on the body of the gas stove indicates that it is faulty or there are problems in the electrical network. The situation is complicated by the fact that “blue” fuel is flammable and explosive. Therefore, operation of the stove should be stopped immediately after the first signs of malfunction are identified. This will prevent accidents.

Your stove also recently experienced an electric shock, but did you successfully deal with this problem? Share your experience with other users, tell us what the problem was and how you managed to fix it - the comment form is located below this publication.

Why doesn't the electric ignition work and what should I do?

Even if this mechanism is assembled perfectly, it can still break someday.

Electric ignition may not work due to:

- Spark plug contamination. This malfunction can be easily fixed without leaving home and without resorting to the help of a specialist. To do this, you need to remove the fat deposits that have accumulated on the candle using a cotton swab dipped in alcohol.

- Power surges that occur on a regular basis.

- Incorrect handling of equipment. For example, you tried to ignite gas when the flame breaker was removed.

Separately, it should be said that in the first and second cases described above, you need to seek the help of a specialist.

Return to contents