How to connect a gas stove to a cylinder

When you are planning to connect a gas stove to a cylinder, you need to know how to do this correctly and with the help of what materials can be used to connect a gas stove to a cylinder.

At the very beginning of the article, it is worth mentioning that it is better to entrust the connection of a gas cylinder to specialists, or at least consult with them on this issue.

As for connecting a gas stove to a cylinder with a metal-plastic pipe, which is used for heating and plumbing, this is quite possible.

You can connect a gas stove to a cylinder with a reducer using:

- Metal-plastic pipe;

- Rubber gas hose;

- Using a rubber-polymer hose;

At the same time, it is worth understanding the level of danger, in principle, as when operating gas equipment connected by rubber hoses. In the event of a possible fire, the hose will ignite very quickly. Therefore, if there is such a possibility, then it is better to connect the gas stove to the cylinder exclusively with a half-inch metal pipe.

It is also very important to understand the direct purpose of the gas reducer. Without it, connecting the gas stove to the cylinder is strictly not recommended.

Household propane reducer - key criteria for the right choice

As is known, liquefied hydrocarbon gas (propane-butane) is stored in cylinders or gas tanks under a pressure of several bar. To reach the operating parameters of consumers (30-50 mbar), a special device is used in autonomous gas supply systems for private facilities - a household propane reducer . If we draw an analogy with an electrical network, this device acts as a stabilizer, that is, it reduces the pressure to the required value and automatically maintains it at the same level.

Gearboxes for gas burners: features of selection and use

- Characteristic

- Kinds

- Operating principle

- Choice

- Application

A reducer is a device that reduces and maintains gas pressure in various containers.

This manipulation can be performed automatically or manually. There are several types of gearboxes. The differences are in the color of the shell and the adjacent devices that are required to connect to the cylinders.

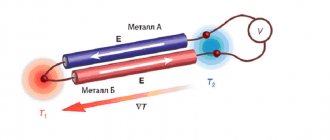

Design and principle of operation of the gas reducer.

Any propane reducer contains the following components:

- valve;

- working chamber;

- locking spring;

- compression spring;

- membrane

The throughput of this device depends on the degree of opening of the valve, which is influenced on one side by a membrane and a pressure spring, and on the other by gas and a shut-off spring. The higher the propane pressure in the cylinder and the lower the flow rate of gas-using equipment, the closer the valve is located to the seat. Conversely, as the pressure in the chamber drops and the flow rate increases, the valve opens more. The operating parameters of a household propane reducer are determined by the stiffness of the springs and the elasticity of the membrane. Some models are additionally equipped with a valve, the shaft of which is connected to a pressure spring, which allows you to manually regulate the gas supply within a certain range.

Operating principle of the device:

Modern propane reducers are sometimes additionally equipped with a safety mechanism that is triggered if the inlet pressure of propane-butane is exceeded. In order to increase the level of safety, such reducers are usually installed on gas tanks and group cylinder installations used for gasification of one or several houses. You can learn more about how autonomous heating is implemented in private households from the article: Autonomous heating with propane butane.

Klimovs-Travels

A few words to a small database of experience in dealing with gas gadgets and equipment...

The most important thing you need to remember if you are going to connect a gas cylinder to any gas equipment is not to use such a “Soviet reducer”. The quality of its performance is lame and what pressure it produces in the end and what it will produce after some time is absolutely impossible to predict.

When I installed a gas stove in a motorhome, I initially connected it to a regular steel cylinder using just such a reducer. The stove did not light up well, the flame was uneven, the system was constantly working, cutting off the gas supply when it died out

By the way, I use a DOMETIC SMEV PI8621RP gas stove in my camper and am very pleased with it. Having carefully studied the sticker attached to it, I found out that it requires a reducer with an outlet pressure of 30 mbar

This reducer (GOK reducer for a 30 mbar composite cylinder) has been working perfectly for almost four years with this stove. By the way, it’s not very expensive, so there’s definitely no point in saving here. Accordingly, if you are going to use it with a composite cylinder (and this is correct), then you need the one with the “KLF cylinder connection type”

By the way, a similar gearbox is also used on the Napoleon Grill gas grill, but it comes with a gearbox, so there won’t be any problems with choosing the right one. It differs from the above in the volumetric gas flow rate, which here is not 1.5 kg/h, but only 1 kg/h

Actually in this photo we see the same composite cylinder with a KLF connection

These connections also need to be dealt with. This is what this KLF looks like. Here I am demonstrating a slightly different gearbox (more on it a little later), but this does not change the essence - pay attention to the type of connection

If for some reason you want to connect a KLF reducer to a regular “Soviet” steel gas cylinder, which has a so-called CIS connector, then you will need a CIS-KLF adapter, which looks like this (in this photo the adapter is already screwed on)

After which you can safely connect KLF reducers to it without any unwanted gas leaks

But the variety of gearboxes does not end there, because in addition to conventional burners with +/- standard power, there are powerful and super powerful burners for cauldrons and woks

To connect a Wolmex gas burner with a power of 20 kW (this is where the cauldron is located in the photo above), you need a special gearbox that can provide this baby with normal “power” with an outlet pressure from 0.5 bar to 4 bar

Now it costs a little more, but unfortunately you won’t be able to save money here. Once I was forced to connect such a burner to the gearbox from a 30 mbar camping stove and this design, instead of melting the cauldron in a couple of minutes, had difficulty heating it up in 30-odd minutes

By the way, my new toy Dutch oven fits perfectly on this burner and works great on it in cases where the recipe does not require adding heat from above. This life hack was taught to me by Australian friends on Facebook, for which I thank them very much.

This concludes my story about the variety of gas reducers and how to connect and use them

Another useful post from a series of concentrated experiences on camper construction about water supply can be read here...

Add a comment Cancel reply

You must be logged in to post a comment.

How to choose a household propane reducer

The choice of a device for supplying a propane-butane mixture to gas-using equipment is based on two key parameters:

Sample passport for a gas stove

The operating mode of most household propane appliances is 30 mbar, 37 mbar or 50 mbar. Based on this indicator, the appropriate gearbox is selected. If its output pressure differs from the operating parameter of a gas stove, boiler or, for example, a grill, this may lead to improper operation of the equipment and even create an explosive situation.

The characteristics of the propane reducer can be seen on it - 3 kg/h and 29mbar

30 mbar, 1.5 kg/h (kg/h)

For stable and safe operation of the gas consumer, it is also important that its consumption does not exceed the performance of the gas reducer. In this case, the upper level of gearbox consumption is not standardized. That is, for a boiler with a power of 24 kW with a mass flow of 2 - 2.5 kg/h, it is permissible to install a gearbox with a capacity of 3 kg/h and higher - the automatic boiler or stove will still not allow “extra” gas to pass through.

0.45 m3 (for propane - butane)

1000 Pa - 1 kPa - 10 mbar

30 mbar - 0.03 bar

Some owners of autonomous gas supply systems make the mistake of purchasing industrial gearboxes instead of household ones, considering them more reliable. Firstly, such devices are an order of magnitude more expensive, and secondly, they are designed to work with more powerful gas equipment, so they are not always compatible with household appliances.

You should also pay attention to the type of thread of the device. Gearboxes designed to work with non-flammable gases are equipped with a right-hand thread, and with flammable gases they have a left-hand thread and a mark on the nut.

Rules for installation and operation of a gas reducer

To connect a propane reducer to gas-using equipment, two methods are used: using a herringbone fitting or using a threaded connection. The first option is considered the simplest and is often used to connect the cylinder to a gas stove. The second method is more reliable and aesthetic, in addition, it allows you to connect one propane tank to several consumers at once.

Connection via fitting

Whatever option is chosen, during the process of connecting the gas reducer and starting the system, you must adhere to the following instructions:

- Make sure there are no cracks or depressions on the housing, check the integrity of the pressure gauge (if equipped).

- Connect the device to the cylinder (gas holder). For better tightness of the threaded connection, you should additionally use flax or FUM tape.

- Connect the gas line to the outlet pipe of the reducer. When using a herringbone fitting, secure the pipe at the mounting location with a clamp.

- Slowly open the cylinder valve, then turn the tap on the gas consumer.

It is worth noting that the device is intended for use in temperate climates, so its use is permissible at temperatures from -15 to 45 degrees Celsius.

An example of connecting a propane reducer in a group cylinder installation

A high-quality household propane stabilizer can last for more than one year without major repairs. Only rubber materials that lose their elasticity over time are subject to periodic replacement. You should also inspect the bypass valve 1-2 times a year and, if necessary, clean it. The degree of clogging of the gas reducer directly depends on the purity of the propane-butane mixture used. For example, here you can familiarize yourself with the standard forms of delivery of this high-purity mixture in accordance with GOST. If you use high-quality gas, the service life of shut-off and control valves and gas-using equipment will significantly increase, and the likelihood of sudden failures of the autonomous gas supply system will be minimized.

Weight of an empty propane cylinder liters GOST – Theory of law

Made of high-alloy steel that can withstand external and internal loads without disturbing the original properties of the contents of the cylinder. It should be remembered that as the temperature increases, the pressure increases, so during storage and transportation, do not allow the temperature to rise sharply.

This is especially important in winter at low negative temperatures! Download the certificate Delivery in Moscow and Moscow Region Our store delivers using its own courier service, so orders are delivered on any day convenient for the buyer from Monday to Saturday between 13:00 and 18:00 or 18:00 and 22:00.

Free delivery within the Moscow Ring Road applies to some groups of products!

How much does a gas cylinder weigh?

The included accessories have a significant mass that must be taken into account. Average weight of the set: shoe - 5.2 kg metal cap - 1.8 kg ring - 0.3 kg The weight of a 40 liter oxygen cylinder is indicated in the table: Cylinder volume, litersWork.

Cylinder volume, litersWork. The weight of a gas cylinder is 50 liters without gas. The mass of gas in it is approximately the same as the cylinder itself weighs. That is, one liter of gas weighs a little less than half a kilogram.

There is a gas stove at the dacha, and every summer we have to replace the empty cylinder with a full one.

Important: A cylinder filled with gas weighs about 43 kilograms. This means that about kg of gas is filled into it. A liter gas cylinder contains a little more than 20 kilograms. If we assume that a propane-butane mixture is used for domestic needs and the content of How many kilograms of gas are in a liter cylinder?

Because there have been cases of explosions, even with fatalities, and now such refueling threatens serious trouble for the owners. They began to demand not only the presence of a plug, but even rubber rings around the body of the cylinder. Now to the essence of the issue.

Gas is filled into it. The total weight of the full cylinder is. I have these data: a kilogram cylinder contains approximately 20 kg of propane. Well, give or take the uneven filling. But a kilogram cylinder holds 11 kilograms of propane.

I thought about this question myself, because I myself want to buy a gas cylinder for my dacha and a gas stove to save on electricity. An empty 50 liter gas cylinder weighs about 22 kilograms.

The mass of the gas in nm is approximately the same as the weight of the cylinder itself.

The permissible mass of liquefied gas max is 5.3 kg 6.8 liters. The mass of the empty cylinder is 6.0 kg. The weight of a full cylinder is 11.3 kg. Propane cylinder 5 l with valve: Volume - 5 l.

The highest working gas pressure is 1.6 MPa. Dimensions - x mm. Wall thickness - 3 mm. The permissible mass of liquefied gas max is 2.2 kg. The weight of the empty cylinder is 3.1 kg. The weight of a full cylinder is 5.3 kg. Reply from 22 replies[guru] Hello!

Here is a selection of topics with answers to your question: How to determine by the weight of a cylinder with liquefied propane-butane how many atmospheres are left there? I have been working with gas since I was 15 years old, I started with my father, and now I have my own company. And please take into account that the density of the gas changes. How can you determine by the weight of a cylinder with liquefied propane-butane how many atmospheres are left there?

Important: the norms for filling cylinders by volume may differ at gas stations; the gas filling volume or weight must be clearly indicated by the gas seller when indicating the cost of filling a cylinder; in this case, the weight can be similarly recalculated according to the specified filling volume of a household gas cylinder. How many kilowatt hours are there in 1 kg of liquefied gas? The bulk of propane consuming devices - gas stoves, titaniums, welding torches, heating boilers - require reduced pressure.

To do this, the most common gearbox, BPO, is installed on the valve. A passport is placed on the upper part of the neck, on which the main technical parameters of the device are stamped.

These include: the name of the manufacturing plant, quality control mark, individual number, month and year of manufacture, inspection date updated every 5 years, volume, weight in empty and filled state. How many kg of propane are in 1 5, 12, 27, 50 liter cylinder? You can find this out in the product quality certificate or in the table below.

Here you can also find out how much a 5, 12, 27, 50 liter propane cylinder weighs. Volume 5 liters 12 liters 27 liters 50 liters Empty cylinder weight, kg Cylinders for technical gases.

Medical oxygen is used for medical purposes for breathing apparatus, oxygen cocktails, etc. Cylinders for technical gases manufactured in accordance with GOST can be designed for different types of gases.

They also differ in volume.

The cylinder must not have mechanical damage, traces of loose rust, or welding. All elements of the cylinder, the shoe and the neck, are attached to the shell using hot crimping.

The cylinder passport must be easy to read.

The service life of a cylinder produced since the beginning of the year, according to the order of Rostechnadzor, from the gas in the cylinder; Oxygen, argon, nitrogen, helium, welding mixtures: a liter cylinder at atm contains - 6 cubic meters.

Carbon dioxide: liter cylinder - 12 cubic meters. Important That is, one liter of gas weighs a little less than half a kilogram. A gas-filled cylinder weighs about 43 kilograms.

Source: https://teoriprava.ru/ves-pustogo-ballona-propana-litrov-gost.html

How to convert a gas stove to bottled gas

In general, setting up a gas stove for bottled gas is not difficult; to properly adapt the stove you just need to change the gas supply nozzles to the burners. This can be easily done with your own hands without hiring specialists.

Gas is supplied to the burner using a special hole in the nozzle, which is an integral part of any gas stove. The hole can be of different diameters, depending on the pressure in the gas supply system. Of course, the pressure in the central gas lines is noticeably higher than in a conventional gas cylinder, and accordingly the diameter of the hole in the nozzle should be smaller.

Often, complete with a gas stove, the manufacturer also includes a set of jets designed for different types of gas mixtures - natural gas, propane-butane, etc. But if they weren’t there or the stove was bought a long time ago, it’s okay, you can buy the necessary jets in the store.

Choosing a jet for bottled gas

Jets (other names: nozzles, injectors, nozzles, etc.) for gas stoves are not in short supply; they can be bought at specialized retail outlets - markets, shops. In appearance, the nozzle is similar to a regular bolt with a thread applied, but unlike the latter, it has a hole in the center through which the gas actually passes. As we said earlier, the hole can be of different diameters, and usually its value is stamped on the end of the product.

Before buying a jet, you should determine what diameter is needed. This is an important point, since incorrectly selected jets will not allow the stove to work normally, or even make it impossible.

It is not difficult to understand that the stove is working correctly after replacing the jets:

the flame should burn without hissing, without yellow impurities and red tongues;

When lighting the burner, no popping noises are allowed, and the flame should not suddenly go out.

The required diameter of the nozzle hole is indicated in the instructions for the gas stove; if the instructions are lost, then information about your stove and its manual can be easily found on the Internet.

We categorically do not recommend changing the diameter of the nozzle hole yourself by caulking or drilling - new nozzles are not expensive, and “reworking” at home can have a detrimental effect on the operation of the stove.

What tools are needed?

To configure a gas stove for bottled gas and then connect it to a gas container, you will need the following tools:

first of all, new jets;

7 mm wrenches, wrenches or open-end wrenches;

a new flexible hose, 1.5 meters or more in length. Serves to connect the stove to a gas cylinder;

seal and gas reducer with outlet pressure 30 mBar.

Decor

The design of a gas stove for a cylinder is nominal - there is no need to visit any authorities, the requirements are easy to fulfill. The first was announced - the distance to the cylinder is at least 0.5 meters. Second: there must be at least 2 meters to the main lines - water supply, sewerage, metal heating pipes. That's all.

There are two options for official registration:

- When you fill up a new cylinder at a municipal gas station (not for cars, but specifically for refueling household gas cylinders), the station employee will fill out the paperwork for you. You will need to provide the address (at least approximately) and explain where the stove is located and where the cylinder is located. Here you have to be careful, at least say that it is worth it according to the rules. Yes, the cylinder must be purchased at one of the Gorgaz stores and you will need the registration number of the car on which this cylinder will be transported.

Refill dispensers for gas cylinders

For many, a gas stove for a summer house under a cylinder has been standing for years even without such “design”. But in this case, you will refill the cylinder yourself, without using the services of municipal gas stations or exchange machines. Also, if it is necessary to repair or maintain the stove, or reconfigure it, you will need to somehow resolve the issue of design (usually there are no problems) or use the services privately.

We change the jets and connect the stove to the cylinder

Before starting work, the stove should be disconnected from the gas (if it is connected). Next, remove the burners; some stove models require removal of the top cover. After that, use a hex wrench to unscrew the old jet, and taking into account the size of the burner, immediately screw in a new one, and so on with all the burners.

The jets in the oven are changed in the same way as the burners - we remove the surfaces covering the burners, remove the burners and change the jets. For a more competent change, it is better to use the instructions for your stove.

Connecting the plate to the cylinder

For this operation, you need to screw a fitting onto the gas stove pipe, and put a previously stored flexible gas hose on it and secure it with a worm-type clamp.

We attach the second end of the hose to the reducer and also tighten it with a clamp, and connect the reducer directly to the liquefied gas cylinder using paronite gaskets. Fastening is carried out using an open-end wrench; we place the gearbox in a horizontal position - this is important!

If everything is done correctly, there should be no gas leaks, but it is better to check this personally. To do this, use the simplest method - applying a soap solution to the joints. If there is a leak, it can be easily seen by the inflating soap bubbles. In this case, it is necessary to change the gaskets, tighten the clamps, and if there is damage to the hose, replace it.

conclusions

It is not difficult to independently convert a gas stove to liquefied gas. But it is still strongly recommended to call a certified specialist from the gas service. The technician will quickly and easily change the jets, and will also check the stove and enter all the necessary data into the register. This will ensure that in the event of an emergency you will have all the necessary documents on hand, and responsibility can be assigned to the appropriate service.

Question

Write in the comments what you think - is it worth converting the stove to bottled gas yourself?

How to choose a reducer for a gas cylinder?

Why do you need a reducer for a gas cylinder? The easiest way to answer the question is by comparing a household reducer for a gas cylinder with a mains voltage regulator. For a thrifty owner, the use of an electrical stabilizer has long become the norm. A gas reducer for a cylinder is used for exactly the same purpose - to stabilize the pressure coming from the gas cylinder to our household appliances.

Reducing gas pressure to operating parameters that ensure stable operation of the equipment - this is the main task performed by a cylinder pressure reducing device. The characteristics of the inlet pressure are important for household appliances where the energy source is blue fuel.

It would seem that after we have found out why a cylinder reducer for propane and butane is needed, we can finish the article, say goodbye to the readers, and submit the work for publication. However, not everything is so simple, and it turns out that the gas reducer operates according to completely two different operating principles and is divided into two types of devices.

What is needed for installation and connection

- gas stove for a summer house under a cylinder (configured for the use of liquefied gas);

- gas cylinder;

- gearbox;

Gas stove for a summer house under a cylinder: connection rules when placing the cylinder indoors and outside

It’s already clear how to choose a gas stove; now we’ll figure out the rest of the components. Nothing complicated, but there are some peculiarities.

Cylinder material and size

First, let's talk about the material from which the liquefied gas cylinder is made. Until recently, there weren’t even such conversations. The gas cylinder was exclusively made of metal, and made of metal of decent thickness. Now there are also composite gas cylinders (also called Eurocylinders) and they are approved for use by gas services. If possible, it is better to buy just these. Why are they better? Here is a list of their advantages:

- 2 times lighter.

- They have a fusible insert that prevents explosion in case of overheating/fire.

- Allowed for transportation in regular cars.

- Do not accumulate static voltage.

Cylinders for liquefied household gas can also be composite (polymer)

The polymer cylinder has few disadvantages. The first is that it costs two to three times more than a metal one, but it is much easier to carry/transport. The second is that, with equal volume and dimensions, it is larger than its metal counterpart.

Now about the size of gas cylinders. The larger the volume of the gas cylinder, the longer the period between refills. But, on the other hand, larger volume cylinders have larger dimensions and weight, and are more difficult to carry/transport. In addition, it is easier to find a place for installation under a small cylinder.

In general, the choice is yours. Moreover, with the advent of composites, they appeared in different sizes - high and narrow, low and wide.

Gearbox

Why do you need a reducer on a gas cylinder? It performs several functions at once:

Stabilizes the pressure at the outlet of the cylinder.

- The gas in the cylinder is under high pressure; for a stove it should be lower. This is what the gearbox does.

- When there is little gas left in the cylinder - 5-10% - the pressure reducer increases.

Types of reducers for propane gas cylinders

So the reducer on the gas cylinder helps improve safety and stabilizes the operation of the stove. It is better not to connect the stove without it. In this case, the more you open the tap on the stove, the more powerful the gas flow will come out. In addition to the fact that this is uneconomical, it can create a situation where the balloon starts to jump. In general, it is better not to operate it without a gearbox.

Please note that different types of reducers are used for metal and composite cylinders. Therefore, when purchasing, check the type of cylinder and its volume

And most importantly, to work with a liquefied gas cylinder you need a propane reducer.

Beware of gearboxes made in China....

If we talk about manufacturers, it is better to take Russian or European products. It's better to avoid the Chinese ones. Even those that have passed certification are made of very thin metal and quickly fail (begin to etch). In addition, many cannot withstand the size of the fittings. When connecting, this becomes a problem, since the hose is not put on tightly, and you have to somehow seal the connection.

Hose for gas stove

You can buy it in city gas stores or in construction stores/markets. But be sure to specify that you need it to connect a gas stove. It is correctly called a “gas hose”. The internal diameter should be 16 mm, the external diameter depends on the type of hose, and there should be an inscription on the surface (in yellow) stating that the hose is gas.

There are such gas hoses:

Hoses for connecting cylinders to a gas stove look like this

To connect the cylinder to a gas stove, you need a hose about a meter long - to fulfill the condition about the distance between the cylinder and the stove of 0.5 meters and leave some room for freedom of movement.

On one side, a union nut with a gasket should be installed on the hose. We connect this end to the outlet from the gas stove. If you just buy a piece of hose, you can install the corresponding gas adapter yourself by tightening the fastening with a metal clamp (don’t forget about the thick silicone gasket for sealing). On the other hand, the hose is connected to the reducer - it is pulled onto the fitting, then tightened with a clamp (do not forget to put the clamp on the hose and then connect it to the fitting).

How does a cylinder reducer work:

1 Direct gearbox

An ordinary simple gas pressure reducing device consists of two chambers with an area of high and low pressure, separated by a rubber membrane. In addition, the “reducer” is equipped with an inlet and outlet fitting. Modern devices are designed in such a way that the bellows connection is screwed directly into the gearbox. Increasingly, you can find a gas reducer with a third fitting intended for mounting the monomer.

After gas is supplied through the hose and then through the fitting, it enters the chamber. The created gas pressure tends to open the valve. On the reverse side, a shut-off spring presses on the valve, returning it back to a special seat, popularly called a “saddle.” Returning to its place, the valve prevents the uncontrolled flow of high-pressure gas from the cylinder.

Membrane

The second acting force inside the gearbox is a rubber membrane that divides the device into high and low pressure areas. The membrane acts as an “assistant” to high pressure and, in turn, tends to lift the valve from the seat, opening the passage. Thus, the membrane is between two opposing forces. One surface is pressed by a pressure spring (not to be confused with the return spring of the valve), which wants to open the valve, on the other hand, the gas that has already passed into the low pressure zone presses on it.

The compression spring has manual adjustment of the pressure applied to the valve. We advise you to buy a gas reducer with a seat for a pressure gauge, this way it will be easier for you to adjust the spring pressure to the desired output pressure values.

As the gas leaves the reducer to the source of consumption, the pressure in the working space chamber decreases, allowing the pressure spring to straighten. She then begins to push the valve out of the seat, again allowing the device to be filled with gas. Accordingly, the pressure creeps up, pressing on the membrane and reducing the size of the pressure spring. The valve moves back into the seat, narrowing the gap, reducing the gas filling of the reducer. The process is then repeated until the pressure equalizes to the set value.

It should be recognized that gearboxes for direct type gas cylinders, due to their complex design, are not in high demand; reverse type gearboxes are much more widespread; by the way, they are considered devices with a high degree of safety.

2 Reverse gearbox

The operation of the device consists of the opposite action described above. Liquefied blue fuel is supplied to a chamber where high pressure is created. The bottled gas accumulates and prevents the valve from opening. To ensure gas flow into the household appliance, you need to turn the regulator in the direction of the right-hand thread.

On the back of the regulator handle there is a long screw, which, when screwed, presses on the pressure spring. As it contracts, it begins to bend the elastic membrane to the upper position. Thus, the transfer disk, through the rod, exerts pressure on the return spring. The valve begins to move and begins to open slightly, increasing the gap. Blue fuel rushes into the gap and fills the working chamber with low pressure.

In the working chamber, in the gas hose and in the cylinder, the pressure begins to increase. Under the influence of pressure, the membrane is straightened, assisted in this by a constantly compressed spring. As a result of mechanical interactions, the transfer disk lowers, weakening the return spring, which tends to return the valve to its seat. By closing the gap, the flow of gas from the cylinder into the working chamber is naturally limited. Then, with a decrease in pressure in the bellows liner, the reverse process starts.

In a word, as a result of checks and balances, the swing can be balanced and the gas reducer automatically maintains balanced pressure, without sudden jumps and drops.

Heating a country house with bottled gas

To create a high-quality heating system for a private home, gas boilers are usually used. Compared to alternative heating appliances, they are the most cost-effective and easy to use. But what about those who do not have the opportunity to connect a private home to a centralized gas pipeline? From this article you will learn whether it is possible to heat a house with gas from cylinders and how to properly set up safe heating with gas cylinders.

- What is more profitable - to use a convector or a cylinder?

- Proper storage is the key to safety

- Advantages of gas cylinder heating

- Disadvantages of heating with liquefied gas

Types of gas reducers

From the school course, the concept of non-flammable – inert gas – comes to mind. This broad group includes nitrogen, argon, helium, neon, etc. they do not support combustion and do not burn. It is widely used as a shielding gas during welding. On the other hand, there are flammable gases (butane, hydrogen, methane, propane, propylene, etc.), which either liquefy or compress and then move their cylinders. So, in order to prevent confusion, engineers, even at the production stage, suggested cutting versatile threads.

Advantages of purchasing gas reducers from ITS-Engineering LLC

The accuracy of regulation and stability of gas supply ensure the operating mode regulated by the equipment manufacturer, which allows us to guarantee constantly high quality of operation of autogenous equipment or other gas consumers. That is why a reliable and high-quality gearbox is the key to stable operation of the equipment and safety of work. You can choose and buy a pressure regulator for a gas cylinder or gas train at ITS-Engineering; our specialists are ready to provide advice on the correct choice of gearbox and offer the best prices based on the task, recommend the use of the necessary safety devices and protective equipment. We also have all the necessary spare parts (diaphragms, pressure gauges, seals) for service and repair of Messer gearboxes. The most popular models of industrial gearboxes of the CONSTANT 2000 and TORNADO series in single-stage and two-stage versions for oxygen, air, propane, acetylene, protective gases and gas mixtures are always available in our warehouse. We are ready to supply other series of gearboxes to order in the shortest possible time by placing an order in Germany. Please note that the scope of application of pressure regulators for gas cylinders is not limited to welding production and we will be happy to offer worthy use of Messer products in other industries for a wide range of gas equipment.

Reducer for gas cylinder

Since we are choosing a reducer for a gas cylinder, we consider it necessary to touch upon the topic of the container itself. The technological process and widespread introduction of new innovative materials are bearing fruit. You can increasingly find new composite cylinders on the market, replacing the old generation. Modern models, unlike outdated predecessors, have less weight and offer a greater level of safety. The latest manufacturing technologies undergo multi-level testing; at testing sites, the composite cylinder is subjected to an explosion, but even after such tests you will not find small fragments.

Composite cylinders are not subject to internal corrosion, are lightweight and comfortable. However, they do not know how to supply gas evenly on their own. A filled cylinder, of course, produces more powerful pressure than a half-empty one. A gas regulator will come to the rescue; its task is to regulate the pressure at the outlet of the composite cylinder and maintain it at the required level throughout the entire period of use.

Gas pressure reducers that have passed European certification show good collaboration with composite cylinders. Let's highlight one of these devices: the household gas reducer A300i-A310i IGT. The positive aspects include the following characteristics of the product:

- the presence of a nut that can be tightened by hand;

- service life of the control membrane increased to 10 years;

- the design ensures maximum sealing of the connecting elements;

- the gas hose on a fitting without a thread is clamped with a clamp.

Despite the fact that the importance of the device in creating conditions for the safe operation of a stove or other device is difficult to overestimate, household reducers for gas cylinders are usually sold at an acceptable cost. Despite the fact that the price rarely exceeds 300-400 rubles, these devices can protect not only your home, but also your life from dangerous situations.

Choosing a gas pressure reducing device is not a complicated process, but you should know and take into account such details as:

- The name of the gas passing through the device;

- Characteristics of the cylinder;

- Dimensions, type of flexible gas supply;

- Required flow and outlet pressure;

- Connection method.

What is needed for installation and connection

You will need:

- gas stove for a summer house under a cylinder (configured for the use of liquefied gas);

- gas cylinder;

- gearbox;

- hose for connecting a gas stove or copper pipes of suitable diameter.

- 2 clamps for attaching the hose (on one side - to the adapter for connecting the stove, on the other - to the reducer);

- gas tap (not required, but recommended).

It’s already clear how to choose a gas stove; now we’ll figure out the rest of the components. Nothing complicated, but there are some peculiarities.

Cylinder material and size

First, let's talk about the material from which the liquefied gas cylinder is made. Until recently, there weren’t even such conversations. The gas cylinder was exclusively made of metal, and made of metal of decent thickness. Now there are also composite gas cylinders (also called Eurocylinders) and they are approved for use by gas services. If possible, it is better to buy just these. Why are they better? Here is a list of their advantages:

- 2 times lighter.

- They have a fusible insert that prevents explosion in case of overheating/fire.

- Allowed for transportation in regular cars.

- Do not accumulate static voltage.

- There are polymer cylinders with transparent inserts. They allow you to control both the degree of filling and the availability of gas.

The polymer cylinder has few disadvantages. The first is that it costs two to three times more than a metal one, but it is much easier to carry/transport. The second is that, with equal volume and dimensions, it is larger than its metal counterpart.

Now about the size of gas cylinders. The larger the volume of the gas cylinder, the longer the period between refills. But, on the other hand, larger volume cylinders have larger dimensions and weight, and are more difficult to carry/transport. In addition, it is easier to find a place for installation under a small cylinder.

In general, the choice is yours. Moreover, with the advent of composites, they appeared in different sizes - high and narrow, low and wide.

Gearbox

Why do you need a reducer on a gas cylinder? It performs several functions at once:

- Stabilizes the pressure at the outlet of the cylinder. The gas in the cylinder is under high pressure; for a stove it should be lower. This is what the gearbox does.

- When there is little gas left in the cylinder - 5-10% - the pressure reducer increases.

So the reducer on the gas cylinder helps improve safety and stabilizes the operation of the stove. It is better not to connect the stove without it. In this case, the more you open the tap on the stove, the more powerful the gas flow will come out. In addition to the fact that this is uneconomical, it can create a situation where the balloon starts to jump. In general, it is better not to operate it without a gearbox.

Please note that different types of reducers are used for metal and composite cylinders. Therefore, when purchasing, check the type of cylinder and its volume

And most importantly, to work with a liquefied gas cylinder you need a propane reducer.

Beware of gearboxes made in China....

If we talk about manufacturers, it is better to take Russian or European products. It's better to avoid the Chinese ones. Even those that have passed certification are made of very thin metal and quickly fail (begin to etch). In addition, many cannot withstand the size of the fittings. When connecting, this becomes a problem, since the hose is not put on tightly, and you have to somehow seal the connection.

Hose for gas stove

You can buy it in city gas stores or in construction stores/markets. But be sure to specify that you need it to connect a gas stove. It is correctly called a “gas hose”. The internal diameter should be 16 mm, the external diameter depends on the type of hose, and there should be an inscription on the surface (in yellow) stating that the hose is gas.

There are such gas hoses:

To connect the cylinder to a gas stove, you need a hose about a meter long - to fulfill the condition about the distance between the cylinder and the stove of 0.5 meters and leave some room for freedom of movement.

On one side, a union nut with a gasket should be installed on the hose. We connect this end to the outlet from the gas stove. If you just buy a piece of hose, you can install the corresponding gas adapter yourself by tightening the fastening with a metal clamp (don’t forget about the thick silicone gasket for sealing). On the other hand, the hose is connected to the reducer - it is pulled onto the fitting, then tightened with a clamp (do not forget to put the clamp on the hose and then connect it to the fitting).

Gas reducers for gas cylinder, price and types

Let's try to choose a reducer for gas cylinders, from those popular types that are in greatest demand among consumers. Let’s take a look at the gas appliance market and find out what the price for a gas reducer for a cylinder was at the end of 2017.

Household gas reducer RDSG for propane stabilization

The leading position in the market, and among consumers in the country, is occupied by the RDSG-1-1.2 “Frog” device with a threaded fastening. The RDSG-2 Baltika gearbox equipped with a threadless connection is not inferior in popularity. Both leaders represent the simplest design. As a result, they can offer the lowest possible cost. Specifications: — inlet pressure from 0.7 to 15.7 Bar; — the output pressure lies in the adjustment range from 30 to 32 mBar; — device weight 310 g; — permissible operation in the range from -30 to +45 ±3 °C; — gas throughput characteristic — 1.2 m3/hour. You can buy a gearbox RDSG 2-1.2 Baltika or RDSG 1-1.2 Frog for up to 350 rubles.

vote

Article rating

Specifics

As already noted, gearboxes can be domestic and industrial. Also universal models.

Consumer versions may not be customizable.

These are simple models. They are used in everyday life and outdoors. RDSG products are installed together with household gas cylinders. They have a very simple design. Due to this, gas can only be used in household stoves. These products are inexpensive and very reliable. There is also a Frog type gearbox, there is the RDSG-1 model. They should only be used in cylinders with a volume of 12 - 50 liters.

The class of universal, customizable gearboxes has a more complex design and greater potential. This is an excellent option for domestic use and for work in the home workshop. The products are attached to the cylinders using a threaded method and are fixed securely.

They have a pressure gauge and an adjustment screw that allows you to vary the functional pressure within the range of 0 - 0.3 MPa. Their highest throughput potential is 5 m 3 /hour.

The category of professional models is created from the best wear-resistant materials. They have the highest build quality and settings: 0.4 - 1.6 MPa.

Some modifications have two pressure gauges. They reflect input and functional pressure.

Often, many summer residents and hikers ask questions such as: is a reducer needed for a gas burner? And is a gearbox needed for a gas stove in the country? Stable and safe operation of any gas appliances and in any conditions is always necessary. Even if there is no urgent need for gearboxes, it won’t hurt to be on the safe side. It remains to decide which gearbox is needed for the gas stove.

Since the stove and burner are propane based, a propane reducer is needed. You need to select these products by studying them and comparing their characteristics. The key ones are:

- Purpose of the device.

- Higher inlet pressure.

- Functional pressure.

- Higher gas consumption.

- Attachment method.

- Planned operational life.

- Price.

For example, if you plan to connect a desktop portable stove only on weekends, the gas consumption according to your calculations is 5 liters per month, then you need a 5 liter capacity and a Baltika RDSG-2 reducer.

For a static stove with an oven, a capacity of 27 or 50 liters is required. A suitable gearbox is the Frog RDSG-2.

Questions often arise here - what does a Frog gas reducer actually do? Why is it named like that? What is its purpose?

Why do you need a frog gas reducer? Its functions, like those of other gas reducers, are pressure stabilization, safety, etc.

Why frog? This device is direct. In it, gas flows through a fitting. The valve opens and is pressed against the seat by a spring. High pressure gas does not penetrate into the chamber. The diaphragm displaces the valve from this seat. The pressure gradually decreases to the operating values of the device to which the reducer is mounted.

The spring straightens. The valve is detached from the seat and does not interfere with gas flow. As the pressure increases, the spring presses the valve again, gas does not flow. This principle is reminiscent of frog jumping. And the device is similar in shape to it.

If it is necessary to connect a composite container to a thermal umbrella, it is better to use imported products with a KLF connector

The professional model BPO 5-3 Krass is optimally suited for gas welding in a home workshop. It guarantees a flow rate of a maximum of 5 m 3 per hour and allows you to adjust the operating pressure to 0.4 MPa. And for this task it has a flywheel and a pressure gauge. Thanks to the latter, it is possible to scrupulously assign pressure to the needs of gas welding equipment.