Modern gas stoves are simple and easy to use. Just press the auto-ignition button, turn the power knob, and the burner lights up. However, sometimes users suddenly discover that the burner is not working.

Housewives usually face the following situations:

- The burner lights up, but as soon as you release the handle, it goes out.

- The burner does not turn on with automatic ignition, but if you take a match the old fashioned way and light it, everything works as it should.

- The burner does not light at all: neither from electric ignition nor from a match.

We’ll tell you in our material what could have happened to a previously properly working gas stove, and how to restore the equipment’s functionality.

Not enough charge

When you open the water, you observe a normal flow, when you turn it on, there is a characteristic click, a spark is formed and everything is generally visually good.

But there is one noticeable point: the burner itself in the gas water heater does not ignite. If you look through the window, there is no flame. This is the reason why there is no hot water. The owner does not have hot water, which causes a lot of inconvenience. This reason must be eliminated as soon as possible. The reason for the malfunction and lack of hot water lies in a completely simple phenomenon. When the batteries stop working, the speaker stops functioning. It does not heat up and therefore the hot water supply stops.

The battery charge in the final stages is only enough to produce a spark. Therefore, visually you observe a spark, and there is also a noticeable click. But the battery energy is not enough to ignite the burner itself.

Replacing the batteries yourself is not difficult. To do this, you need to open the box with the batteries and take them out. Next, you should replace it with new, high-quality, powerful batteries.

More about batteries

Polarity in batteries matters. If you insert batteries without taking into account their polarity, the column will not light up. Batteries can sometimes get stuck in the pack, so keep an eye on them.

Replacement with new functioning batteries is carried out if two main criteria are met:

- The polarity of the batteries must be taken into account;

- The box intended for batteries must be closed until it clicks.

The batteries used in geysers must be standard D (in other words, barrel batteries). Salt options are not suitable because they have the ability to quickly fail. In most cases, alkaline batteries are used for geysers. They are otherwise called alkaline batteries.

There are often cases when a person purchases batteries, but they do not light the column. Here, too, several questions arise as to why even new batteries cannot cope with their functions. At this stage, the owner may also become confused and look for a completely different reason. In order not to find yourself in such an unpleasant situation, you need to wisely choose batteries for the operation of the gas water heater. There are a few tips to keep in mind...

Tips for choosing batteries

It is not advisable to choose too cheap ones. In this case, it is recommended to choose more expensive batteries (normal ones cost about 200 rubles). If you buy cheap ones, they most likely will not work properly, which means that in the future you will need to overpay

Therefore, initially purchase good quality expensive batteries; Pay attention to the expiration date of the batteries; As for brands, Duracell and Energizer brands are preferred. The battery must be alkaline or lithium.

It will be more informative to use a specific multimeter tester that accurately determines the charge. Anyone can use such a tester; it won’t be difficult. This method is convenient and practical to use, and you can purchase a battery tester at any store.

What if the equipment is still noisy?

If, after these manipulations, the gas water heater still ignites with a bang when you turn on the water, then it is better to stop further independent research. In such situations, you will have to seek help from qualified specialists.

They will carry out competent diagnostics of the equipment, will be able to clearly determine what is causing the cotton and, based on the data obtained, will be able to provide you with options for solving the problem.

In certain cases, independent repair is impossible, then cooperation with qualified specialists will be a rational solution.

Eliminating the problem

Temporary. To reduce the temperature in the room, you can open the window slightly. At the same time, due to the decrease in temperature, the relay protection against overheating will stop turning on and the water heater will not go out.

Final. You can completely get rid of the problem only by replacing the bad relay.

Malfunction of the ignition system.

One type of ignition system for geysers is a pilot burner. But more modern models are equipped with an electronic ignition system for switching on. To create a spark, there are two options: using batteries (batteries); using a piezoelectric element, which is turned on by a device in the form of a turbine placed in a water system.

water heater

If batteries are used to generate the spark, then perhaps they should simply be replaced. Despite manufacturers' assurances of trouble-free battery life for a long time, experience shows that they have to be replaced approximately every year.

Weak or completely absent cold water pressure.

To start a gas water heater, sufficient pressure of cold water entering its system is required. When the cold water pressure decreases, the Oasis heater will simply go out. The protection will work, turning off the column, as if the tap is closed and the column will go out. In this case, you should find out the cause of the problem. Open any cold water tap:

- If the water pressure is weak there, then you will not be able to do anything, since such pressure comes from the city system.

- If water flows normally from the tap, the filter will probably need to be cleaned or replaced. If the problem is not in the filter, then you will have to clean the gas water heater radiator.

The procedure looks like this:

- Close the gas supply valve;

- Unscrew the pipes;

- Remove the water heater from its hinges;

- Turn it upside down and, in this position, place it on the table;

- We draw the washing liquid previously purchased from a specialized store into a syringe and inject it into the column;

- Leave in this state for two to three hours;

- After this, drain the liquid, rinse with water and install in the reverse order.

Some models are equipped with a special handle that regulates the amount of water passing through. If the water pressure in the tap is good, but it is not enough to start the water heater, then the handle is moved to the extreme left position and moved to the right until the water heater turns on. As a rule, the flow has to be adjusted once during startup.

Membrane damage.

One of the reasons why a gas water heater does not ignite is a faulty membrane. If it has mechanical damage or has lost elasticity, then normal operation of the column becomes impossible.

This fault falls into a more complex category. To determine whether the membrane is faulty, it must be disassembled, remembering the location of all parts. To do this, you need to remove the water block from the water heater, disassembling it to remove the membrane. When purchasing a new membrane, you should opt for the silicone version, since such parts have a longer service life.

Care tips and advice

For long-term operation of the gas water heater, you need to follow the important recommendations of experts:

- Monitor the temperature of the heated water so that it can be used without diluting it with cold water in the mixer.

- To purify cold water from hardness salts, it is enough to install a water filter in front of the column.

- Carry out regular, annual cleaning of the column and flue ducts from soot.

- It is not recommended to disconnect the speaker's electronic systems from electricity during periods of inactivity, such as at night. Frequent power outages lead to disruptions in electronic circuits. This is why false protection and device shutdowns occur when there is no spark at the gas water heater or it goes out.

Effective and durable operation of equipment depends on its correct selection and proper installation. However, even with this, the speaker user may encounter malfunctions, which most often occur due to prolonged operation of the unit, and there is nothing to worry about, you just need to know what to look for.

Sources

- https://sovet-ingenera.com/otoplenie/vodonagrevatel/remont-gazovoy-kolonki-oazis.html

- https://www.tproekt.com/gazovaa-kolonka-oazis-zagoraetsa-i-tuhnet-priciny/

- https://cosmo-frost.ru/gazovye-kolonki-i-kotly/neispravnosti-gazovye-kolonki-i-kotly/pochemu-gazovaya-kolonka-oazis-ne-zazhigaetsya-net-iskry-ne-vklyuchaetsya/

- https://newades.ru/portativnaya-akustika/the-automatic-gas-column-does-not-turn-on-why-does-not-the-gas-column-oasis-there-is-no-spark. html

- https://www.samaragas.com/neispravnosti-gazovoj-kolonki-oasis

- https://ks5.ru/otoplenie/kotly/gazovye/oazis-neispravnosti.html

- https://cosmo-frost.ru/gazovye-kolonki-i-kotly/neispravnosti-gazovye-kolonki-i-kotly/remont-gazovoj-kolonki-oazis-neispravnosti-i-ix-ustranenie/

- https://myguru.ru/services/remont-gazovih-kolonok/oasis/

Sources of accident

There are several reasons for burner failure, the main ones being the following factors:

1. Lack of traction.

For any model, be it Neva, Oasis or Vector, the flame goes out or does not light up due to the fact that the chimney is often clogged with dust, dirt and foreign objects. In modern equipment, in this case, a safety valve is activated, shutting off the fuel supply to the gas column automatically. This happens because combustion products are not removed in full and in accordance with technical requirements.

To verify the malfunction, you need to check the traction. To do this, open a window and bring a lit match or a sheet of paper to the pipe. If the chimney is clogged, the wind will not be felt, so the gas water heater will not light. Specialists are engaged in cleaning the combustion waste removal system

It is important not to miss this moment, as exhaust gas enters the room, which can lead to serious consequences

An ingenious way to almost NOT PAY for electricity! A cunning meter that saves electricity Pays for itself in 2 months!

Sometimes the automation is triggered when a nearby hood is on, and the flame goes out or does not appear. If the device has high power, it interferes with the removal of waste, so you should never install two units in one place, especially in small rooms.

2. Sensor malfunction.

If the pilot flame goes out, it is necessary to inspect the device that controls the exhaust of gases. To do this, disconnect the wires and check the resistance using a special device. The indicator must be indicated in the passport; if it does not reach the optimal value, the sensor will have to be replaced. The burner goes out if the thermocouple breaks down. In this case, the geyser does not ignite due to low voltage, the optimal parameter of which is 10 mV.

3. Discharged batteries.

The main function of the batteries is to keep the valve open during operation. The service life of the elements is no more than a year, so manufacturers of gas units such as Neva recommend changing batteries on time. In addition, the reason that the burner does not ignite may be a malfunction of the piezoelectric element or the power cable. It is necessary to disconnect the wires and check them for internal and external breaks. If there is still no spark, the column does not turn on, then the source of the problem is different.

4. Interior clogged.

If dirt and soot get into the gas supply tunnel from the fittings to the burner, the flame goes out or does not ignite. The injectors need to be cleaned. If the fuel pressure is not adjusted, a characteristic whistle will be heard, the flame will come off, and then it will disappear. Also, a burner of the wrong diameter can create such a malfunction. In this case, you need to adjust the gas supply or replace the elements. When aired, the gas water heater ignites, but immediately goes out. To eliminate the defect, you need to unscrew the nut on the fitting and bleed the air, then return the mount to its place, fix it and check whether the burner goes out.

5. Deformation of elements.

If the water is too hard, scale appears in the pipes, which gradually clogs the filters, so the gas unit goes out or does not turn on. The grate is removed and thoroughly cleaned. If it has become damaged due to deposits, it is better to replace it.

The membrane of the water supply unit often breaks, so the column does not turn on. To determine its condition, remove the top cover of the case. The plate should not have cracks or breaks, have the correct shape, smooth and even. In case of the slightest deformation, it will have to be replaced. It is better to choose a part made of durable and elastic material that is resistant to temperature fluctuations and the influence of scale. The membrane must be installed carefully, pressing the fasteners around the perimeter.

6. Water pressure.

As in the situation with draft, the automation blocks the gas supply; if the supply is poor, the burner goes out immediately. It is worth contacting the utility services to find out the reasons and turn off the unit until then. You can use the column only if the water pressure is normal. In private homes, pressure is increased using a compact station and regulator. If the column turns on and works normally, but the water still comes out cold, the device may not have enough power, the parameters are noted in the passport.

Here's the secret to saving water! Plumbers: You'll pay up to 50% LESS on your water bill with this faucet attachment

Radiator leak

Heat exchangers made of copper and copper-containing alloys have the greatest risk of leakage. The reason is that manufacturers often use alloys in which the percentage of copper is lower and lower.

During operation, as a result of corrosion and mechanical damage, small holes begin to appear, violating the tightness of the radiator. These are the so-called “fistulas”. In these places, the heat exchanger begins to let water through.

By the way, even a high-quality copper heat exchanger is not protected from rapid destruction.

Corrosion occurs under the influence of stray currents that arise in the water supply when the dispenser is not properly grounded or when other operating rules for gas-using equipment are violated.

Elimination: you can replace the heat exchanger with a new one, but this will cost a third of the price of the column. Often this is not justified; it is much easier to solder it without disassembling the entire column and removing the radiator.

Before you start soldering, you need to drain all the water from the radiator, otherwise heating the pipeline will be problematic.

To do this, you need to turn off the water supply to the column, disconnect the incoming pipe from the pipe, place a container under it, and open the hot water tap.

When the water has drained, it is necessary to blow through to remove residues. You can use a vacuum cleaner or compressor. If such devices are not at hand, you can blow through with your mouth.

To do this, you need to select a rubber hose of suitable diameter and fit it tightly onto the coil, strengthen the connection by crimping.

Soldering can be done in two ways: with a gas torch or a soldering iron.

Gas burner:

- For soldering you will need a torch with a gas cartridge, a sponge, flux paste containing tin and copper, and solder.

- Start by heating the leaking tube to evaporate any remaining water. Clean the soldering area with a sponge. Apply flux paste. Heat again until the flux color changes from gray to silver.

- To prevent flux residues from leading to corrosion, it is necessary to remove them with a damp cloth.

Soldering iron:

Prepare a powerful soldering iron of 100 W or more, POS-50, POS-61 or other solder with a melting point of at least 200 degrees.

Flux: rosin or solder fat, you can also use aspirin tablets. Using a hair dryer makes warming up much easier.

The soldering area must be cleaned with a zero polish until all traces of corrosion are removed from the metal surface. Then degrease it with alcohol or solvent.

Heat the soldering area well with a soldering iron. Additional heating with a hair dryer gives excellent results. Tin the soldering iron tip with a piece of solder.

Apply a small amount of flux to the soldering area and immediately tin the metal surface with a soldering iron. Try to maintain the fluidity of the solder by adding flux from time to time. Bring the solder thickness to 1-3 mm.

With good heating, a thin layer of solder is enough to reliably eliminate a leak and prevent destruction of the pipeline at the soldering site.

Scale on the heat exchanger - how to fix it

The need to clean the heat exchanger is usually caused by the following reasons.

- The water takes a long time to heat up.

- Poor water pressure.

- The overheating sensor is triggered and the column turns off.

If the above happens to the column, this means that it is necessary to clean the heat exchanger, since a large amount of scale has formed in it.

Step-by-step instruction

Cleaning the heat exchanger consists of the following steps.

- It is necessary to shut off the water supply to the heater with the valve and dismantle the heat exchanger, disconnecting it from the water pipes. If cleaning is carried out infrequently, it is recommended to use a lubricating spray for dismantling, which makes it easier to unscrew the oxidized nuts. After treating the nuts with a spray, you need to wait 15-20 minutes and start unscrewing them.

- After dismantling the heat exchanger, you can begin cleaning it. To clean scale, you can use a solution prepared at the rate of 100 grams. citric acid per half liter of hot water. Using a watering can, the solution is poured into the heat exchanger and left there for 12 hours.

- Afterwards, you need to drain the solution and rinse the part thoroughly with clean water. It is necessary to thoroughly clean the heat exchanger from any remaining scale, as it can clog the tubes, blocking the flow of water. This can be done using pressurized water or compressed air.

- The final stage at which it is necessary to install the heat exchanger in place in the heater after first changing the sealing washers.

Incorrect pipe connection

The Oasis gas instantaneous water heater, whose malfunctions are caused by the fact that the device was installed incorrectly and the inputs and outputs of hot and cold water were mixed up, will not work. Oasis devices work in such a way that the cold water pipe is connected to a water block, on which a mechanism is installed that adjusts the pressure and speed of fluid flow. There is also a safety valve and a water drainage unit for carrying out repair work or relieving excess pressure.

The next important unit for the movement of the medium is the copper heat exchanger, which is located above the collector and consists of a curved finned pipe. The structure takes heat from the exhaust flue gases and transfers it to a moving stream of water entering through the water unit. The heated water exits through the outlet pipe to the water tap. A temperature sensor is installed on the pipe to protect the device from overheating. Therefore, if the input/output of the water medium is mixed up, then there will be no water circulation.

The lineup

The company's product range is quite wide. Classic, chimneyless and turbocharged models, varying in their power, operating principle and appearance, are presented to consumers. The most popular are the mid-price columns, which provide an uninterrupted supply of hot water for very little money. Among them there are a number of models, the customer reviews of which are most common.

“Oasis Glass 20 VG” is a flow-through device that requires a chimney and has a unique design. Thanks to its small dimensions of 34x59x14.5 cm, the speaker fits harmoniously into small rooms, does not clutter up the space and does not spoil the interior. The model is powered by batteries, which ensures complete energy independence of the unit and makes its operation independent of power outages. The dispenser starts automatically immediately after opening the hot water tap at a pressure in the water supply pipes of at least 0.02 mPa. The dispenser is equipped with an RCD, thermostat and anti-freeze function, and the presence of the “Winter-Summer” mode allows you to save up to 70 cubic meters of gas per year. The model’s productivity is 10 l/min, which with an optimal power of 20 kW is quite enough for the bathroom and kitchen. The efficiency of the device is 90%, and the cost varies from 4 to 4.8 thousand rubles.

“Oasis TUR-24” is a device from the “Turbo” series that operates from an electrical network and does not require regular battery replacement. The gas burner is ignited synchronously with the opening of the tap. The model does not require the installation of a chimney: combustion products are removed forcibly using an electric fan built into the housing. Exhaust gases are discharged to the street through a corrugated pipe.

Column productivity is 12 l/min. The turbocharged model is equipped with a liquid crystal display that allows you to monitor the temperature and overheat protection that automatically turns off the device if the permissible temperature is exceeded. The dimensions of the column are 33x62x18.5 cm, the cost is 9 thousand rubles.

“Oasis B-12W” is a miniature flow-through chimneyless model with dimensions of 29x37x12 cm and a capacity of 5 l/min. It is usually installed on one of the intake points, which is due to its fairly low power, not exceeding 11 kW. Ignition is carried out using replaceable batteries. The device is equipped with a copper heat exchanger, overheating protection and a display. The cost of the column is 4 thousand rubles.

“Oasis 20-OG” is an economical, energy-independent device designed to operate on liquefied gas from cylinders and used in homes that are not connected to central networks. The model is equipped with a “Winter-Summer” function, gas control, thermometer and ionization sensor. The heater productivity is 10 l/min, the power is 20 kW, and the cost does not exceed 5 thousand rubles.

Peculiarities

High consumer demand and popularity of Oasis geysers are due to a number of undeniable advantages of these devices:

- The high safety of using the units is explained by the presence of protective sensors that turn off the device in emergency situations.

- The ability to provide stable heating of the coolant, regardless of pressure drops in the water supply system, makes the operation of the dispensers simple and comfortable.

- The location of the main module away from the hot water pipe increases the safety of the device and protects important structural components from overheating.

- The presence of a mesh filter protects the system of pipes and pipes from clogging and rust accumulation.

- Economical fuel consumption is due to the presence of “Winter-Summer” modes. This allows you to automatically regulate the fuel supply and significantly save on water heating.

- The presence of a heat-resistant alloy in the radiator eliminates the formation of scale on the internal walls of the device.

- High efficiency rates and long service life distinguish Oasis speakers from other devices available in this price category.

- The presence in the product line of turbocharged models capable of forcibly removing gas combustion products. They allow you to use the water heater without installing a chimney and make its operation even safer.

- The modern and aesthetic design allows you to install speakers in kitchens and bathrooms without the risk of spoiling their appearance.

- All Oasis models are equipped with a liquid crystal screen and a control panel, which makes using the device simple and convenient.

Why does the speaker turn off during operation?

If the gas water heater lights up normally, but for some reason goes out during operation, this may indicate that the device’s security system is functioning properly.

The column design has a sensor that is triggered when the internal temperature rises. There are two plates inside the system that repel each other, stop the power supply, and turn off the column. This happens when your core temperature rises quickly and uncontrollably.

The gas water heater automation system includes three sensors: draft, flame, overheating. Plus two valves: gas and reset. They ensure safe operation of the device

You can check the sensors by resistance. A working part shows an infinity sign. When a different value is displayed, we call a technician.

If the device works for a long time and then turns off, check the settings. Sometimes users accidentally set it to turn off automatically after a certain time.

What else causes the shutdown:

- poor water or gas pressure;

- broken contact between the thermocouple and the solenoid valve (you need to clean the contacts and tighten the connections);

- oxidation of the power supply contacts, when the device clicks but does not light up.

It is also useful to check the batteries. Standard replacement of power supplies is carried out every six months. Batteries hold a charge longer.

Traction is poor or completely absent

The accumulation of combustion products is most often associated with clogging of the chimney with soot, soot, and debris. When there is no traction or it is insufficient, the work is not carried out.

To check the draft, you need to bring a burning match or lighter to the control window of the column. If the flame deviates to the side, there is draft. It remains to burn evenly - it’s gone

It is important to remember that the flame can go out due to external factors - gusts of wind, for example. The draft in the shaft increases or decreases under the influence of a draft

You can clean the chimney through the “pocket” located 25 cm below it. If such manipulations do not help, call the utility company.

Soot accumulation on the heat exchanger

During operation, the heat exchanger accumulates soot, soot, and scale. When it becomes clogged, the color of the flame changes from yellow to blue.

How to clean the heat exchanger:

- We remove the casing.

- Unscrew the screws holding the casing.

- We turn off the water supply.

- Open the faucet to drain hot water.

- Disconnect the heat exchanger thread and tap. You will need a stand as water may leak.

- Prepare a solution of hydrochloric acid (3-5%).

- Take a pipe with a diameter of 1/2” or use a hose.

- We connect one end to the input, the other to the output.

- Pour the solution into the funnel. If foam appears when washing, this is normal.

- As soon as a strong pressure appears at the outlet, we stop the procedure.

While working, be sure to wear gloves. After descaling, you need to thoroughly rinse the heat exchanger to remove acid residues.

If during the cleaning process defects were noticed on the tubes, then the heat exchanger will have to be repaired.

To clean the heat exchanger from scale, you can use citric acid (80 g of powder is needed for 700 ml of water). Boil the radiator in the solution for half an hour, leave until cool and rinse

It is recommended to carry out cleaning work once a year. Regular maintenance will help the device function properly.

Clogged shower head and hose

It happens that the gas water heater turns on and for some reason immediately goes out when switching to the shower. This may be due to clogged holes in the watering can.

You need to unscrew the watering can, clean and rinse the holes. Soaking metal elements in a solution of citric acid is also effective.

Scale on the watering can forms due to the increased hardness of tap water in some regions. To prevent this from happening, install filters or buy a faucet with a shower equipped with a built-in anti-scale system

The next part that can cause the wick to go out is the shower hose. If it gets tangled or clogged, the pressure power decreases and the column goes out.

The mixer can also break or become clogged. You need to disassemble it, check it, clean it if necessary.

At the entrance to the water supply unit there is a filter that retains small debris. It is also useful to clean it periodically. To do this, unscrew the screws, remove the element, rinse, and clean with a brush with citric acid.

Low water or gas pressure in the system

Errors in the operation of the water unit are quite common. This is due to the design of the unit. When heated water enters, the pressure begins to increase, acting on the membrane, bending it, thereby transferring pressure to the gas valve rod. It begins to move, acting on the spring valve, and the power supply to the control module is turned on.

Additional Information! It is clear that if this system does not work, the device will not start. Considering the complex functioning of the water unit, there may be several reasons for the failure. The water unit is dismantled together with the gas module, since they are a single structure.

During operation, the membrane, or as it is also called the “frog,” stretches, which causes similar malfunctions in the operation of the equipment; it must be replaced, since it will not turn off due to deformation. The repair is very simple and can be done by yourself. The size of this unit is small in size, and to get the “frog” you only need to unscrew 4 screws.

Reasons for column attenuation after ignition

When identifying the cause of a malfunction, it is important to pay attention to two points: how the igniter goes out (are any extraneous sounds heard); this happens immediately after ignition or already during the combustion process

Reason #1 - failure of the flame ionization sensor

If the device turns on and goes out, the ionization sensor is 70% to blame.

This element is constantly in contact with the flame. The ions produced during the combustion process are attracted to the sensor and produce a current. If there are enough ions, the device works. If there are few of them, the column does not function.

The ionization sensor is a thermocouple that is heated by a flame. It is also called a gas sensor because it prevents the device from leaking when the burner is turned off

Signs of malfunction:

- the burner went out 3-5 seconds after ignition;

- when restarted, the device operates longer;

- You just need to start the device several times and it is already functioning normally;

- problems appear only after a long break.

It is necessary to inspect the wiring that runs from the part to the control board. Why do we check all contacts? Then unscrew the holding screws and place the heating electrode at the hottest point of the flame.

This technique can extend the life of the sensor by another year. If everything is in order with the contacts and connections, the element needs to be replaced.

Reason #2 - the membrane of the water unit is worn out

A polymer part must have sufficient elasticity. Over time, this property is lost - the element becomes hard, cracks, and becomes overgrown with scale.

A water block or “frog” is a fairly simple device. The cover is held together with screws, by unscrewing which you can get to the membrane

If the element becomes unusable, the heater will go out. It is necessary to inspect and replace the membrane, if necessary, with a more durable silicone one.

How to choose a storage type gas boiler

There are several dozen different models of boilers on the gas water heating equipment market.

When choosing, experts recommend paying attention to several technical characteristics:

- Tank type - how to correctly calculate the volume of a storage tank is explained below. In addition to calculations, you need to decide on the choice of tank material. Manufacturers make tanks from the following types of metal:

- Stainless steel is the optimal material, characterized by long-term operation and corrosion resistance. The only drawback: high cost. Stainless steel has several classes. Only special food-grade stainless steel can be used for the storage device.

- With an enameled tank - there are several types of coating. Previously, the boiler tank was protected using ordinary enamel, which was used to cover dishes. Cheap water heater models still use this type of protection. Disadvantages: susceptibility to mechanical damage and thermal effects. The service life, even with careful use, does not exceed 5 years. Glass-ceramic coating is a modified enamel with good strength characteristics and heat resistance. Glass ceramics have a longer service life, up to 7-8 years of service.

- With titanium coating - the characteristics of boilers are similar to those made of stainless steel. The tank of a capacitive boiler will work freely for at least 10 years, and the durability is not affected by the intensity of water heating (as is the case with a conventional enamel coating).

- Burner type - there are conventional atmospheric and closed burner devices, with forced oxygen supply into the chamber. When choosing, they are guided by the technical conditions of the room used for installation. There are several types of storage tanks:

- Atmospheric gas boilers - they take air from the boiler room using natural circulation.

- Turbocharged storage water heaters with a closed combustion chamber - oxygen is supplied from the street (models with a coaxial chimney) or from the room, in a forced manner. Turbo boilers are economical. Disadvantages: noisy when turned on, volatile.

- Ignition type - not all water heaters work the same. Based on the inclusion principle, there are two main types of drives:

- Automatic ignition - runs on batteries or mains. Switching on occurs when the water temperature drops below the specified parameters. Water heaters with an electronic ignition system operate in fully automatic mode. The consumer is only required to set the heating temperature.

- Piezo ignition - in this case, a constantly working wick is provided inside the water heater. Ignition is done manually. The igniter flame is ignited by a piezoelectric element. The wick works continuously and lights the main burner.

- Fuel type - tank-type boilers operate on propane (bottled gas) and methane (from the central line). There are universal models. The latter can be easily converted to alternative fuel after changing the injectors and switching the mode. Water heaters with the ability to operate from a cylinder can be connected to a gas tank.

- Installation principle - the drives are designed in two solutions. The first ones are intended for floor installation. The volume of storage capacity is practically unlimited. Water heaters for wall mounting are limited in volume. The maximum capacity usually does not exceed 100 liters.

After selecting a storage tank according to the 5 criteria described above, we proceed to calculating the volume of the storage water heater. You can do the calculations yourself.

Manufacturer – Germany

JUNKERS (Junkers) BOSCH (Bosch)

| BOSCH Neckar JSD20 ⁄ 26 – B23 | BOSCH Neckar JSD20 ⁄ 26 – B31 |

| Installation and operating instructions for the JUNKERS BOSCH WR gas water heater | ||||||||

| 10-2B | 13-2B | 15-2B | 10-2G | 13-2G | 15-2G | 10-2P | 13-2P | 15-2P |

| Instructions for installation and operation of the BOSCH Therm geyser | |

| 6000 S | 8000S |

VAILLANT

| Instructions for installation and operation of the geyser VAILLANT atmoMAG | ||

| 14-0/0 RXZ | 14-0/0 RXI | 14-0/0 GRX |

| Installation and operation instructions for the VAILLANT MAG geyser | ||||||

| pro 11-0/0 XZC+ | OE 19/2 XZ-C+ | remium SOE 19/2-24/2 XIP | premium SOE 19/2-24/2 XI | premium OE 19/2-24/2 XZ | premium OE 24/2 RXI | premium OE 24/2 RXZ |

| Instructions for installation and operation of the geyser VAILLANT GEYSER MAG | ||

| 275/12 XZ | 350/12 XZ | 440/12 XZ |

Symptoms of a problem

Gas stove specialists, based on the collected statistics, have compiled an approximate register of common failures.

- When you press the burner control knob or a special separate button, electric ignition does not occur.

- The automation of the product in a gas stove works constantly, clicks are heard, but there is no spark - the gas does not ignite.

- After releasing the button or knob, the system does not turn off.

- The device constantly continues to fire, even when the button is not pressed.

- The circuit breaker in the apartment panel knocks out when starting up.

- The piezo ignition or electric ignition circuit of the stove is closed.

Exclusive designer series

In order to organically fit an electric water heater into the modern interior design of a room, Oasis presents the exclusive Q-form series, the boilers of which are aesthetically pleasing square-shaped devices with a perfect control panel.

The advantage of the Universal series is the possibility of different locations of the water heater (horizontal or vertical). At the same time, devices of various volumes from 30l to 100l are produced.

Appearance of the vertical model of the Oasis electric water heater from the Universal collection

Despite the comparative high cost of the equipment, water heaters of the Solution series combine all the advantages of the other Oasis lines in one device. They are characterized not only by a wide choice depending on the volume of the tank (from 30 to 100 l), but also by convenient and modern control of the water heating process, as well as the possibility of installation in both horizontal and vertical positions.

Based on the above, it follows that before purchasing Oasis electric storage water heaters, it is necessary to study and compare all models on the market in order to select the best option depending on the options, room conditions and the price of this or that equipment.

Manual gas burner with piezo ignition

This model of gas burner is a replacement stove for lovers of outdoor activities.

This item is indispensable for camping fans. Of course, you can try to challenge this fact by citing the classic example of making a fire. But in order to prepare soup or porridge, it is necessary not only to collect firewood, but also to wait until it burns out a little. For long-distance hikes, this is a significant waste of time; for resting at a rest stop, you can limit yourself to a short break. Another significant bonus is that in bad weather and in the pouring rain you can’t dream of a fire, but nothing prevents you from hiding under the crown of a tree and warming up with hot tea or porridge cooked on a gas burner. Piezo ignition eliminates the need to look for matches or a lighter, gas is consumed economically and one cylinder lasts for a long time. Advice! If you take a gas burner on a hike, make sure to store the cylinder; do not expose it to direct sunlight; overheating in the sun will cause the cylinder to explode. When putting it in your backpack, it is better to place the cylinder in the middle so that it is reliably protected from high temperatures. The gas is also sensitive to low temperatures; burners operate properly at temperatures down to -20. For more severe temperatures, it is necessary to purchase a cylinder of a gas mixture that is not sensitive to cold.

For gas burners, odorless liquefied gas is used, this adds a certain specificity to the use of the tool. Firstly, when using a burner, you should not turn it over or tilt it too much, the flame may get lost and lose staticity, becoming uneven

Secondly, you need to be careful when using cylinders. If there is a malfunction, a gas leak may occur, which cannot be felt due to the lack of odor.

You can check the cylinder for leaks using a soap solution; you can also immerse the cylinder in water for testing.

Oasis instantaneous water heaters

Gas instantaneous water heater Oasis SG-20

The instantaneous type of water heaters has become widespread. The key feature of this model is that water will be heated even at low pressure in the water supply system.

According to user reviews, the Oasis instantaneous gas water heater has a number of advantages:

- The device turns on only when the water is turned on. This helps save energy resources.

- Functions regardless of electricity, because its operation is carried out using replaceable batteries.

- Depending on the season, you can choose the heating mode.

- The device is designed according to a special design that helps reduce costs.

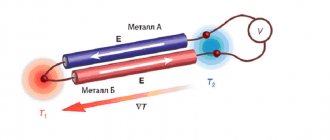

Oasis geyser device (with diagram)

The internal part of standard hot water gas equipment is presented:

- plate heat exchanger with a water tube;

- gas burners;

- exhaust gas collector;

- piezoelectric element or automatic electric ignition.

The electronics are powered through batteries, from the mains, or using a miniature built-in turbogenerator. The water temperature control in budget models is carried out by a water reducer or so-called frog, and in more complex and modern models - automatically via electronics.

Gas boilers are characterized by the presence of an open or closed combustion chamber, and the difference between models of the first type is represented by the intake of air masses directly from the room.

Exhaust gases are removed naturally through a chimney system, or using forced ventilation and a coaxial chimney.

The components and main components of flow-through gas equipment that require competent maintenance and explain the principle of operation are listed in the diagram.

Modern gas water heating equipment Oasis is equipped with protective automatic gas supply shutoff

Modern water heating equipment is characterized by the presence of protective automation, represented by flame control and a traction sensor, which allows you to shut off the gas supply automatically.

How to connect and configure

Gas water heating equipment is installed in the kitchen or any other non-residential but heated room in accordance with the gasification project and in accordance with the basic requirements of gas supply organizations:

- water heating equipment is connected to a chimney system that has good and stable draft;

- It is prohibited to install equipment above any open flame sources or heating devices;

- before installation, permission from gas service specialists to install equipment must be obtained;

- installation of the unit is carried out by the operating organization of the gas industry or other licensed companies;

- installation is carried out on non-flammable coatings, including brick, concrete and ceramic tiles with mandatory insulation with galvanized sheets and BTK;

- the protective layer of insulation should protrude beyond the body by at least 10 cm along the entire perimeter;

- the column is suspended using brackets attached to the wall, supplied with the gas equipment;

- all shut-off valves in the form of water supply to the gas supply to the unit are located in an easily accessible place;

- a filter system is installed in front of the water heating equipment to purify the water supplied for heating;

- to connect to the water supply, pipes or flexible hoses are used with an internal diameter of 13–14 mm or more.

Below is a standard connection diagram for a gas boiler.

Connected gas equipment must be registered

After installation and until it is put into operation, the water heater must be registered with the gas service.