Impeccable compliance with standard requirements and practical recommendations during the calculation and construction of a boiler room for a cottage is a guarantee that the heating system in it will work flawlessly, and “living” heat will never leave your home.

Home boiler room: design

The design of modern boiler rooms used in private households may differ. Their features depend on the type of fuel consumed and the type of premises used. According to the method of location, the following types of boiler rooms should be distinguished:

- Built-in. The built-in boiler room is located directly inside the household. The location of the boiler room in a private house is quite convenient, but it is not suitable for every type of heating boiler. Thus, boilers that create a lot of noise (with a forced-air burner) are best used in isolated boiler rooms;

- Attached. They are located in an isolated room located in a special extension to the cottage;

- Freestanding. A separate boiler room for a private house is almost always located in close proximity to the house. It communicates with the main housing through various utilities (heating mains, gas pipelines, water supply and electrical wires).

A separate boiler room for a private home is a universal solution that allows you to install heating boilers of any design indoors, capable of operating on various types of fuel.

In rare cases, a boiler room is installed in the attic of a residential building. But this is the exception rather than the rule.

Alex720517 FORUMHOUSE user

I came to the conclusion that a free-standing boiler room, by all indicators and common sense, is better than a built-in one. Although its construction will cost more. Examples of boiler rooms separate from the house known to me show that heat loss during transfer is minimal (from the boiler room to the wall of the house - 5 meters) when using polypropylene pipes with insulation in a plastic sewer pipe. I’m generally silent about safety. Gas is gas. They don't joke with him. When using a separate facility, there are no boilers, boiler, tank or auxiliary equipment in the house. There is no noise, no unpleasant smell, space is freed up, etc. etc. There seem to be only advantages (except for the rise in price).

Yes, for boiler houses with high power (which can vary from 200 to 500 kW) and a large amount of equipment, it is better to make a separate room. It is convenient, safe and modern. Don't be afraid of the costs associated with building an additional house, as well as possible heat losses. It is worth building a separate boiler room; in this option you will always get more advantages than disadvantages.

If the project is not so cumbersome, then you can limit yourself to an extension to the house or even place the “stoker” in a separate room inside a residential building.

Here's what our user thinks about it.

Car Enthusiast FORUMHOUSE User

It makes sense to use a separate room if there is a large amount of equipment. For small boilers placed on the wall, it is better to install the boiler in the house. By the way, heat losses on the heating main can be quite significant - 20 kWh. On a winter day that’s 3 cubic meters of gas.

Where to place a boiler room in a private house - in the basement of a house, in a garage, in an extension or a special room - is up to you, but you should always plan its space correctly.

How to equip a boiler in private homes, photo.

Where to build a boiler room in a private house is up to you. But if the room could fit all the necessary equipment and there was enough space left for its maintenance, then the layout was done correctly. But we will return to this issue later.

Open and closed heating circuits

Typical boiler room circuits are divided into “open” and “closed”. An open circuit is cheaper to install, but operating costs are significantly higher. In a closed system, the coolant is heated directly in the system, and the pump circulates it.

The main difference between these systems is that in an open system, the coolant in the expansion tank comes into contact with air. This means that some of the heat is lost.

The closed circuit (the most common) is labor-intensive to install, but due to its tightness, heat loss tends to zero.

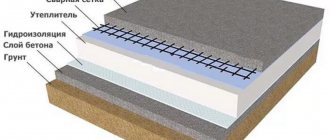

Arrangement of ceilings

We should not forget about the special function of the ceiling, which will protect the boiler room from the danger of explosion in an emergency. Under such circumstances, the ceiling acts as a valve, therefore, its design should be as light as possible.

Fears that such a ceiling will be cold are untrue. Insulation will be provided by a sheathed structure. This will require boards with a thickness of 30 mm. A layer of bituminized paper is laid on top of the filing. And ordinary sawdust is used as thermal insulation. 4mm heat-saving material is attached to the ceiling from the inside. The final stage is installation of the sheathing. Next we level the floor and plaster the walls.

The sheathing and boards should be treated with bio- and fire-retardant impregnation.

Specifics of constructing an extension for wooden buildings

For objects of this type, there is a strict sequence of various stages that must be followed without fail:

- The beginning of the production process is the construction of the foundation. An indispensable condition for a high-quality zero cycle is to allow the monolithic structure to settle and settle. It will take a year to ensure its reliability. This rule is especially important if it is adjacent to a wooden object that is easily flammable.

- Pay attention to the topography of the surrounding area. This will help you choose one of the foundation options, taking into account rainwater runoff and possible settlement due to the structure of the soil.

- In addition to concrete and brick walls, frame extensions to the house are also popular. This material is most easily connected to solid wood, and the rack bars ideally perform the functions of fastening. It is easy to nail wall sheathing to them later.

- The final chord is the construction of the roof. A hole is carefully made in it for installing a chimney.

What you can’t do without in a boiler room

Actually, the boiler itself, in which the coolant is heated. For large houses, you will need to install a collector that distributes coolant between separate groups of heating devices.

An expansion tank (tank), a water heater, a supply pipeline and shut-off valves that regulate the parameters of the heating system are also required.

Don't forget about automation to control the functioning of the system. Of course, the automation unit costs extra money, but these costs will quickly pay off.

Any heating system includes two interconnected systems - a chimney (removes exhaust gases) and ventilation (an influx of fresh air, which increases fuel combustion).

What is a “smart boiler”

To implement an automation scheme for a private boiler room, you need to invest additional funds. A simple thermostatic valve will cost very little, but programmable systems are many times more expensive.

Constant operation of a conventional boiler in one mode entails a large consumption of electricity and money. Therefore, the cost of purchasing an automation unit quickly pays off during operation.

Automation in a private boiler room guarantees the functioning of the heating system with maximum efficiency, which allows for comfortable conditions for residents living in the house.

By installing automation, the home owner can adjust the heating process according to his needs. Thanks to this, bills for consumed energy resources will be reduced by 2 times.

Controlling the boiler in automatic mode makes it possible to:

- Turn off the boiler in case of an unusual situation. Carry out automatic start or stop of the boiler in the current mode. Depending on the outside temperature, set the heating temperature.

- Manage the heating or water heating branches of a boiler with 1 combustion chamber.

- Regulate the temperature of water or other coolant.

- Make adjustments to the operation of the circulation or recirculation pumps if the heating system in the house is arranged in a closed circuit. In this case, the system cannot function without automation.

The most important element of the heating system is the thermostat. Its function is to regulate the temperature both in a separate room and in the entire house.

There are many types of thermostats - from simple mechanical to weather-compensated. The latter is the most technologically advanced, profitable, but also very expensive.

The heating control system consists of a temperature controller (1), an outside air temperature sensor (2), an actuator (3), a coolant temperature sensor (4), a display for connecting to an external control system (5), a circulation pump (6) , coolant supply (7), consumer circuits (8) (+)

The price of automation depends on the type of boiler used, the presence of heated floors, solar collectors, etc. In order not to spend extra money, you should analyze the features of all schemes and calculate the cost. It is quite difficult to do this yourself, but you can always turn to specialists with this problem.

Gas boiler houses

Increased requirements apply to gas boiler houses (instruction MDS 41-2.2000 and SNiP II-35-76), and gas boilers are subject to mandatory certification.

Remember that obtaining permits will require strict compliance with all regulations and standards. For example, the presence of a gas detector in the room.

Boilers less than 30 kW can be placed in the kitchen provided:

- have good ventilation in case of gas leaks. At the same time, the kitchen window area is at least 0.5 sq.m., and the width of the doorway is from 0.8 sq.m.,

- kitchen walls should be made of fireproof materials,

- The minimum room area is 6 sq.m. with ceilings higher than 2.5 m.

Solid fuel boilers - tips for choosing the best models and ideas for using boilers for heating (110 photos and videos)Screen for a heating radiator - a review of the best ideas and recommendations from designers for selecting screens for a heating system

- Chimneys for gas boilers - main types and step-by-step instructions for do-it-yourself installation (video + 100 photos)

For powerful gas boilers (exceeding 30 kW), you will have to allocate a separate building.

Features of premises for electric boilers

The most optimal heating unit from the point of view of safety is the electric one, which does not emit harmful combustion products. For this type of fuel, you do not need to install a ventilation system. The advantages include efficiency up to 99%, noiselessness and simple installation. Electric boilers are unpretentious in terms of maintenance.

Sergey Yurievich

Construction of houses, extensions, terraces and verandas.

Ask a Question

For heating an area exceeding 200 sq. m, you will need a unit with a power of 20 kW or more.

Solid fuel boiler room

According to building codes, there should be no solid fuel boilers in living rooms and kitchens. The extension should be correctly placed next to a blank wall, as shown in the photo of a boiler room in a private house. For high fuel power, independent buildings are built.

Components of an effective solid fuel heating scheme:

- corresponding heat generator,

- boiler piping, including a circulation pump, three-way valve, safety group,

- chimney,

- storage water heater,

- automation unit,

- fire extinguishing complex.

Coal, peat or firewood are solid fuels. In the case of coal, it is important to remember that coal dust in high concentrations is explosive. Therefore, it is important to protect the electrical wiring.

What documents need to be prepared

To begin adding to the building, you will need to obtain permission to begin construction from the architecture department and local authorities.

To do this, the owner of a residential building will need to provide the following documents:

- Standard application forms can be obtained from the architecture department at your place of residence.

- Documents confirming ownership of the house and land.

- Furnace design with calculations of heat loads, selection of equipment and connection diagrams for heating system pipes.

- Technical specifications from manufacturers of gas, water and electricity services.

- A passport for boiler equipment and a certificate of its compliance with Russian standards.

- Sanitary report on the sanitary safety of the facility for residents.

- Conclusion of the Ministry of Emergency Situations on the fire safety of the facility.

The furnace extension is allowed for the installation of 2 boilers with a total capacity of up to 150 kW.

Liquid fuel boiler houses

Installing such a boiler room in a house is much simpler than installing gas or solid fuel analogues. Such furnaces are placed both inside and outside the house.

High noise and specific smell usually exclude the placement of such a furnace in the kitchen. A reasonable solution would be to allocate a separate room with good sound insulation.

Double-circuit gas boiler: the best models, recommendations for choosing and installing a boiler with your own hands (105 photos)What does an inverter air conditioner mean: difference, myths

- Benefits of Drip Irrigation

An absolute plus is that no permits or approvals are required. All that is needed is free access for transport with fuel, as well as regular refueling of the boiler.

Selecting the energy carrier to use

It is very important to decide in advance what fuel the unit will run on. Taking into account the choice of boiler mainly determines how to properly install and equip the room. Mainly 4 types of energy carriers are used:

- From an economical point of view, let's use natural gas. Its use has another advantage - ideal environmental friendliness. The minimum amount of soot after combustion allows for much less frequent preventative measures to be taken to clean the chimney and boiler.

- The use of liquid fuel does not require permits from other organizations. The construction must be designed taking into account the free access of the tanker to fill fuel containers.

- The cheapest option is to use solid energy. The disadvantages include the manual method of loading fuel and the rapid clogging of the chimney.

- Electric boilers operate in waste-free mode and require virtually no cleaning. Disadvantages include high energy costs and the lengthy process of obtaining permits when connecting units with a power of more than 12 kW to a three-phase network.

Having selected the desired model, you can begin preliminary work.

Summing up

The legislative framework changes frequently, so already at the preliminary stage of designing a combustion chamber it is important to study all current standards and regulations. When planning to install a powerful furnace, it is wise to contact specialized organizations.

Believe me, saving on the work of professionals often leads to a significant overpayment during operation, as well as extremely unpleasant and dangerous consequences for the life and health of your household. Even if the boiler room is small, be sure to consult with specialists.

Application of finishing materials

A few simple tips will help you avoid problems when operating your equipment:

- Thermal insulation components are used for gluing the perimeter of walls. To ensure the presence of air gaps, bars are installed. PVC panels are subsequently attached to these elements.

- Many developers prefer to leave the cement floor. But laying porcelain tiles helps maintain cleanliness.

- Arrangement of continuous operation of a double-circuit boiler requires the presence of a hot water outlet to the house and a cold water supply to the equipment.

Compliance with all rules and requirements contributes to the serviceability of any unit and ensures the safe residence of the owners.

You can ask your question to our author:

Photo of boiler rooms in a private house

Ventilation

Ventilation in the boiler room is necessary for two main reasons. Firstly, heating equipment requires a constant supply of air: in order for fuel to burn, it needs oxygen. Secondly, ventilation installation is also carried out from a safety point of view: in the event of an emergency equipment malfunction, the combustion may stop, but the gas supply will not. A ventilation system will help cope with emergency gas leaks. Systematic ventilation of the boiler room does not allow carbon or fuel monoxide to accumulate in the room, which is produced during the combustion process and is dangerous to the health of residents. Thanks to the effective operation of ventilation in the boiler room, mold or dampness will not appear on the walls, and the heating equipment will last longer.

According to the method of air circulation, ventilation systems are divided into two types: natural and forced. With natural organization, there is a free inflow and outflow of air under the influence of wind. Two ventilation holes are laid in the wall - supply and exhaust. In order for draft to be generated, the minimum distance between the holes must be 25 cm. The disadvantage of natural ventilation is its dependence on wind and environmental conditions. When installing forced ventilation, there is no natural draft. The air supply is organized using special fans. The forced ventilation system is convenient to regulate and does not depend on weather conditions. The disadvantages include a higher installation cost than in the case of installing natural ventilation, and the possible appearance of noise during operation of the system.

The technology for installing a ventilation system in a boiler room of a private house has its own characteristics depending on the type of heating equipment.

Installation of a boiler room is a mandatory stage in the construction of a private house intended for year-round use. Since the heating system is associated with an increased risk of fire, the boiler room in a log house must comply with the standards and requirements from a safety point of view. It is important to seek help from specialists who will correctly select equipment and properly equip the boiler room, making it reliably protected from fire and easy to use. At Holz House, laminated timber houses are designed taking into account the layout of the boiler room. You can find out the cost and order the project from our managers.

Harness with hydraulic arrow

In complex multi-level heat supply systems, a hydromechanical distributor - a hydraulic switch or a manifold - is often used to balance fluid flows in various sections of the circuit with individual circulation pumps.

A similar scheme of a boiler unit involves turning on an indirect heating boiler through a pump NB and NR, radiator heating through a pump NK1 and NK2, and a warm floor through H1.

It can operate without a hydraulic module; in this case, balancing valves are installed to compensate for pressure drops in various “branches” of the system.

Complete set of thermomechanical equipment:

- Heat supply source – 2.

- Safety group, with air vent, safety valve, pressure gauge and expansion tank.

- Supply of coolant to heating devices.

- Coolant return from heating devices

- Heating radiators.

- Warm floor system.

- Indirect heating boiler

- Filter for coarse cleaning of boiler water from suspended solids on the return line.

- Check valve on the return line.

- Circulation pumps: through the main pipeline, in the underfloor heating circuit and indirect heating boiler.