Other Articles on this topic:

⇒ Ground heat exchanger for forced ventilation of a private house

The best solution for ventilation of a private house is a centralized forced supply and exhaust ventilation system with heat recovery.

The basis of the system is a ventilation unit equipped with fans, a heat exchanger - heat recuperator, control devices, filters, etc.

In a house with forced ventilation, air circulation occurs according to the same pattern as in buildings with natural ventilation. Fresh air from the street is supplied to the living rooms of the house. Next, the air is directed through the transfer holes in the doors to the kitchen, bathrooms, dressing rooms, and storage rooms. From these rooms the air is discharged into the street through exhaust ducts.

For more information about air circulation in the house, read: “How to properly make natural ventilation in a private house .

Each room of the house must be equipped with either an exhaust or a forced ventilation duct. In some cases, both channels are installed in the room.

The only exception is that ventilation of the boiler room , a fire hazardous room in which the gas boiler is installed, must be carried out using a separate isolated natural ventilation duct. This is due to the need to prevent the flow of flammable gases and fire through ventilation ducts from the boiler room to other rooms.

From the forced supply and exhaust ventilation unit (PFVV), fresh air from the street flows through the supply ducts into the living rooms of the house. Then the air flows into utility rooms - kitchen, bathrooms, dressing rooms and others. From the utility rooms, air is returned through exhaust ducts back to the PPVV unit.

Two air ducts are connected to the forced supply and exhaust ventilation unit (PPVV unit) from the premises of the house.

Fresh air from the street enters the PPVV ventilation unit through the air intake, and from there through the supply air ducts into the rooms of the house. Next, through the transfer holes in the doors of the premises, the air moves into the utility rooms - the kitchen, bathrooms, dressing rooms. From utility rooms, polluted air is returned to the PPVV unit through exhaust air ducts.

In winter, two air flows, warm from the premises and cold from the street, meet (but do not mix) in the heat exchanger - the recuperator of the PPVV block. The warm outgoing air transfers heat to the air entering the house. Fresh heated air enters the premises. A heat recuperator allows you to save up to 25% of the energy spent on heating a house compared to a system without a recuperator.

The ventilation unit is usually equipped with various devices for air preparation. Filters clean the air from dust, allergenic plant pollen, and insects. The air supplied to the house can be humidified, heated, and cooled.

A centralized system easily lends itself to automation of management and monitoring of its serviceability and operating mode.

Increasingly, air is taken into the system through a ground heat exchanger.

This is a pipe laid in the ground below the freezing depth (1.5 - 2 m).

One end of the pipe is connected to the air intake of the ventilation unit, and the other open end is brought above the ground surface. Passing through the pipe of a ground heat exchanger, air in winter is heated by the heat of the earth, and in summer, on the contrary, it is cooled. Heating and air conditioning costs for a home with a ground heat exchanger can be reduced by another 25%.

The design principle of a ventilation system recuperator. 1 - warm air from the room; 2 - air to the street; 3 — air from the street; 4 - heated air into the room; 5 - heat exchanger; 6 and 7 - fans.

The cost of a forced ventilation system with a heat recuperator is at least 4–5 times more than the cost of installing a natural ventilation system. The most expensive element of the system is the recovery unit.

The forced system constantly consumes electricity to operate the fans. There are costs associated with periodic filter replacement and cleaning.

However, saving thermal energy and saving heating costs pays off all costs. Moreover, the harsher the climate and the longer the heating season, the faster.

In addition, the increased comfort of life in the house is also worth something.

Centralized forced ventilation with a heat recuperator in a private house is a system:

- provides the necessary air exchange in all rooms of the house, regardless of atmospheric conditions;

- allows you to easily regulate and automate air exchange in a wide range of changes in air volume and depending on various indicators of the microclimate in the premises;

- carries out the preparation of fresh air supplied to the room: filtration, heating or cooling, humidification or dehumidification;

- saves a significant amount of thermal energy through the use of a heat exchanger - a heat recuperator for exhaust air;

- consumes electricity to operate fans;

- a complex technical device whose elements may fail;

- stops working in the absence of electricity;

- requires qualified installation and periodic maintenance;

- creates noise - requires special measures to reduce noise;

- carries out constant monitoring of the serviceability and efficiency of work (air exchange, temperature and humidity);

A modern energy-efficient home increasingly resembles a sealed plastic container.

To survive in such a container house, centralized supply and exhaust ventilation in the house is simply vital.

It's time for Russian developers to understand this too.

From the previous article on choosing a ventilation method in a private house, you can learn why a modern energy-saving house must be equipped with a forced supply and exhaust ventilation system.

Installing forced supply and exhaust ventilation in a house with a recuperator allows for effective ventilation of rooms and significant savings in heating costs for a private home.

Scheme of forced ventilation in a private house

Diagram of forced supply and exhaust ventilation of a two-story private house.

The PPVV unit is installed in the utility room on the ground floor. To ensure forced air circulation, a supply and exhaust ventilation unit is installed in the house.

The unit is equipped with electric fans for forced air movement and a heat exchanger - recuperator.

The flow of fresh air from the street through the air intake through the air duct enters the ventilation unit and is then distributed throughout the living quarters of a private house. In the diagram, the supply ventilation air ducts are indicated in blue.

The exhaust “dirty” air from the house is forcibly sucked into the exhaust ventilation ducts (in red in the diagram)

from the rooms where the greatest amount of pollution is released, this is the kitchen, bathroom, dressing room, boiler room (utility room), as well as from the space under the floor of the first floor.

The air, saturated with pollution, moisture and heat, also passes through the ventilation unit and is thrown out through the deflector on the roof of the house.

This air circulation scheme allows you to create some excess pressure in living spaces, which prevents the penetration of contaminants into the rooms,

both outside - for example, radioactive soil gas radon, and from other rooms and spaces inside the house.

The air supplied to the rooms moves into rooms with exhaust ventilation grilles through the transfer openings in the doors. This is usually the gap between the floor and the door.

In winter, in a heat exchanger - recuperator installed in the ventilation unit, the air exhausted from the house transfers part of the heat to fresh but cold air forced into the rooms.

In rooms in which a heating boiler or fireplace with an open combustion chamber is installed, using air from the room for combustion, both forced ventilation channels must be installed - supply and exhaust channels. The presence of only one exhaust duct is unacceptable, since the vacuum created in the room by forced exhaust can lead to the overturning of the draft in the chimney and the entry of combustion products into the room.

Kitchen hood pulls out money

When you turn on a kitchen hood, a large amount of warm air is thrown outside for the sole purpose of removing odors and other contaminants that form above the kitchen stove.

To avoid heat loss, it is beneficial to abandon a conventional kitchen hood. Instead of a hood, an umbrella is installed above the kitchen stove, equipped with a fan, filters, and odor absorbers for deep air purification. After filtration, the air, purified from odors and contaminants, is sent back into the room.

In addition, this solution reduces the performance requirements of the ventilation unit. This type of hood is often called a filter hood with recirculation. It should be borne in mind that the savings from lower heating costs are somewhat offset due to the need to periodically replace filters in the hood.

Results

If you are interested in how to make ventilation in an apartment so that your time and effort are not wasted, and the exhaust system works efficiently and without failures, listen to our advice:

- Mount the fan opposite the door. Installing it on the same wall as the door reduces air circulation.

- Before installing the fan, be sure to clean the ventilation duct.

- Widening the ventilation opening increases the intensity of the hood.

- During installation, the hood is completely deepened into the shaft, only its grille looks out.

- A sealant can act as an adhesive during installation. Additionally, it will improve sound insulation and reduce vibration of the operating fan.

Forced ventilation unit in a private house

| Forced ventilation unit with recuperator |

The supply and exhaust ventilation unit is a rectangular housing several tens of centimeters in size.

There are two electric fans in the housing

— supply and exhaust ventilation systems. Fans can operate at different rotation speeds, thereby ensuring a change in the intensity of air circulation.

For example, if there are a large number of guests, the maximum circulation mode is turned on, and if there are no people in the house, the ventilation can operate at minimum intensity.

Inside the ventilation unit there is a heat exchanger - a recuperator.

In ventilation units installed in private houses, a cross-shaped heat exchanger is most often used. The principle diagram of the operation of such a recuperator is given in the previous article (see the link at the beginning of the article).

Two filters in the ventilation unit -

one is installed at the entrance to the unit of fresh air from the street, the other - at the entrance of the exhaust air entering the unit from the house. The filter at the fresh air inlet retains fungal spores, pollen, dust, insects, etc. It cleans the air supplied to the house and, in addition, prevents clogging of the heat exchanger channels.

The filter on the exhaust air side serves only to protect the heat exchanger channels from house dust. In different block designs, filters can be replaceable or require periodic cleaning.

Recuperator frost protection system

— a mandatory element of the ventilation unit.

In winter, the warm and humid air leaving the house in the recuperator is greatly cooled and water condenses from it, as in an air conditioner. On frosty days, this water can freeze, the ice will clog and even destroy the recuperator channels.

To prevent this from happening, forced ventilation units use several methods to protect the recuperator from freezing:

- When fresh air with a low temperature enters the ventilation unit, the mode of intermittent supply of this air is activated.

The frequency and duration of breaks in the air supply are selected so that the water in the recuperator does not freeze. The method is simple, but interruptions in the air supply reduce the efficiency of room ventilation. - The ventilation unit is equipped with a bypass - a bypass air duct through which fresh cold air can pass in addition to the recuperator. During periods of low temperatures, the fresh air flow is divided: part of the air is passed through the recuperator, and the other part through the bypass.

The amount of air passing through the recuperator is adjusted so that the temperature of the recuperator allows the condensate to remain in a liquid state. - On frosty days, the cold air entering the ventilation unit is slightly heated using an electric heater

so as to only prevent the water in the recuperator from freezing. Heating the fresh air too much will reduce the efficiency of heat transfer in the recuperator.

The coordinated operation of all elements of forced supply and exhaust ventilation in a private house is ensured by a control and automatic regulation unit.

The ventilation system control unit allows the owner to regulate the amount and temperature of air circulating in the premises and monitor the serviceability of individual elements of the system.

More complex control units make it possible to program the ventilation operation in a daily and weekly cycle, automatically adjust the ventilation operation depending on the air temperature outside and inside the house, humidity and carbon dioxide content in the premises.

are built into more expensive ventilation units .

In winter, when the heating is turned on, the air in the house often becomes too dry. Home air humidifiers

allow you to provide comfortable air humidity in residential areas.

The temperature of fresh air after the recuperator increases slightly, but on frosty winter days it remains negative. The supply of such cold air to living spaces will cause a feeling of discomfort in people, especially those located near the supply ventilation anemostat. To eliminate this drawback, the ventilation unit is often equipped with an electric supply air heater - a heater.

The heater is turned on only at very low outside temperatures.

Air heaters connected to the home heating system are also used to heat the supply air. Typically, such a heater is installed as a separate device, outside the ventilation unit.

Where to install the forced ventilation unit

| It is most profitable to install a forced ventilation unit in the attic |

It is most profitable to install the ventilation unit in a non-residential attic. In this case, the length of air ducts from the premises of the house will be minimal.

Products for construction and repair

⇆

If this is not possible, then the block is installed in any other place. Usually this is a boiler room, utility room, garage or basement.

The requirements for the location of the ventilation unit are as follows:

- Free access to the unit for replacing filters, repairs and monitoring the condition of the unit.

- There are no additional requirements at the installation site to reduce the noise level from the operation of the unit.

- Minimum length of the main air ducts of the ventilation system. You should also evaluate whether it will be convenient to route the air ducts along the building structures of the house.

Bathroom fans: types

There are two categories of hoods on the market: axial and centrifugal. In design, they differ significantly from each other, although they perform the same function.

Axial

The design is simple - it is an electric motor with a bladed impeller mounted on its shaft. The blades are tilted inward towards the motor. They create pressure, generating a flow of air that moves along the axis of the device. Hence the name - axial.

Such models have great power and quiet operation. They are often installed in bathrooms and toilets.

Centrifugal

The operating principle of this fan is significantly different from the previous one. The design has an impeller, which drives air not along the axis, but across it, throwing it towards the walls of the housing. That is, everything happens under the influence of centrifugal force. Hence the name.

A flow is formed inside the device, which moves in a spiral, which is why these types are often called radial. A snail is added to the design of the hoods, facilitating the movement of air masses. The devices are not the most powerful, but they work quite quietly.

How to choose the right forced ventilation unit

The selection of a forced ventilation unit is carried out according to the following main parameters:

- Productivity, m3*hour

- the amount of air supplied to the house and removed from the premises per unit of time. - Pressure is the pressure required to overcome the aerodynamic resistance created by all elements of the ventilation system.

- The efficiency (coefficient of performance) of a recuperator is an indicator of the efficiency of heat transfer to fresh air supplied to the house from the air removed from the premises.

The minimum amount of air that the ventilation unit must circulate is determined by sanitary standards. Standard air exchange values for the premises of a private house are given in the previous article. The performance of the ventilation unit must be greater than the sum of the standard values for all rooms of the house.

In practice, to simplify calculations and create some performance reserve, another indicator is used - the air exchange rate. This is a value indicating how many times the air in the room should be changed within an hour.

According to Russian sanitary standards, the air exchange rate in a private house must be at least 0.35 times/hour.

For example, the total volume of all ventilated rooms in a house is 450 m3

.

Then the minimum required performance of the ventilation unit is 450 m3

x 0.35

1/hour

= 157.5

m3/hour

.

In addition, it is necessary to check that one more condition is met - the air exchange in the house should not be less than 30 m3/hour

per person living in the house. If this condition is not met, then the air exchange rate is taken to be greater than 0.35.

It is necessary to provide some reserve capacity for the ventilation unit to supply additional air to the heating boiler, fireplace, kitchen hood, or in case of receiving guests.

Therefore, in practice, the performance of a ventilation unit is determined by taking the air exchange rate in a private house within the range of 0.5 - 0.8

1/hour

.

It should be remembered that the ventilation unit, like any pump, has a curvilinear dependence of performance on pressure. The greater the pressure (aerodynamic resistance of the ventilation system), the lower the performance of the ventilation unit. This means that the shorter the air ducts and the larger their cross-section, the lower the requirements for the parameters of the ventilation unit - the cheaper the unit, and the lower the energy consumption for ventilation.

Calculating the aerodynamic resistance of a ventilation system and determining the required pressure is a rather complex task. It is better to entrust the decision to specialists.

The correct choice of ventilation unit parameters can only be made based on calculations. Often contractors do not bother with this and offer to install a ventilation unit that is obviously more powerful, and therefore noisier and more expensive.

The size of the reduction in heating costs directly depends on the efficiency of the recuperator.

The efficiency of cross-shaped heat exchangers does not exceed 60%. In some models of ventilation units, two such heat exchangers are installed, placing them in series one after another. The efficiency of the system increases by another 20%.

The most expensive ventilation units may contain even more effective solutions - rotary heat exchangers and even heat pumps (heat pipes). The efficiency of such devices reaches 90%. In Russian conditions, with relatively low fuel prices, it will not be possible to recoup the costs of installing such units.

When choosing a ventilation unit, you should also pay attention to other parameters that are significant for the developer:

- The noise level created by the ventilation unit.

If the block is placed on a wall or ceiling adjacent to the bedroom, you should choose a block with a minimum noise level or you will have to spend money on additional sound insulation. - The maximum electrical power consumed by the electric heaters of the ventilation unit may exceed the capabilities of the electrical network. Think about whether it would be more profitable to heat the air using a heat exchanger connected to the heating system.

- Assess the cost of replacing filters, the frequency of their replacement and their constant availability for sale.

- If fresh air will be taken in through a ground heat exchanger, then choose a ventilation unit equipped with a bypass.

Power

This value determines the level of performance: the higher the first value, the higher the second.

On a note. Calculate the required performance by multiplying the bathroom area by the number of users.

Usually, average power values (7-20 W) are selected; they are sufficient to ensure high-quality ventilation. A higher setting can cause drafts, and in winter it noticeably cools the room.

Air intake and deflector of the forced ventilation system

The air intake grille is usually located in the outer wall of the house or on the roof. The location of the air intake is selected based on the following:

- The distance between the air intake opening and the deflector through which air is exhausted by exhaust ventilation must be at least 10 m.

The same distance should be maintained from the chimney, sewer riser and other sources of odors and air pollution. - The air intake is placed at a height of at least 1.5 m

from the ground surface and 0.5

m

above the snow cover. - The air intake opening must be covered with a mesh to protect against the penetration of birds, insects, leaves, etc. into the air duct.

The air intake device through a ground heat exchanger is becoming increasingly popular.

Work safety

The main condition here is protection from moisture. This is provided by a special fan housing.

On the equipment you can find the letters IP and two numbers after them, they indicate the security level. The first number is protection against foreign objects, the second value is protection against condensation.

Important. For the equipment to work smoothly, the specified parameter must be at least IP45.

Ventilation ducts in a private house

In the forced ventilation system of a private house, round air ducts of standard diameters are most often used - 100, 125, 150, 200 and 250 mm

. Air duct pipes can be made of steel, aluminum or plastic.

How to determine the cross-section of an air duct

In order for the air movement in the air ducts to be silent, the flow speed in them should be approximately V = 2 - 4 m/sec. It is recommended to choose a lower value for branch ducts located within the living space, and a larger value for main sections located away from the bedrooms.

Based on the standard values of air exchange, the required productivity is determined for each point of air inflow and outlet, Q m3/hour.

Air duct cross-sectional area, A m2 = Q m3/hour / 3600 * V m/sec (taking into account that 1 hour = 3600 sec)

Knowing the required cross-sectional area of the air duct A , m2, you can easily calculate its diameter d , m (according to the formula A = π d 2 / 4), from which: d = 2√ A /π. It is recommended to choose a standard size air duct with a diameter larger than the calculated one.

Rectangular ducts take up less space, but have greater aerodynamic resistance than round ducts of the same area.

The ventilation unit is connected to rigid air duct pipes using flexible elastic pipes with a length of at least 1 m

. This solution prevents the transmission of sound vibrations from the ventilation unit through pipes into the premises.

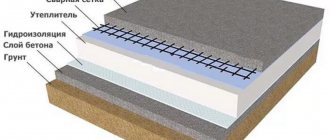

Ventilation ducts must be covered with a layer of thermal insulation.

Thermal insulation of air ducts prevents the condensation of water vapor on their walls, and also prevents the transmission of sounds through the pipe.

It should be taken into account that not only air moves through the air ducts in the house, but also sound, as well as rodents.

The walls of the air ducts, as well as the air inside them, serve as a conductor of sound. To reduce the level of transmitted noise, it is recommended to use air ducts made of elastic materials and cover the pipe walls with sound-absorbing material.

Sounds transmitted through the air are greatly attenuated as the length of the air duct increases and its cross-section decreases. Therefore, when designing the layout of air ducts and the locations of supply and exhaust openings, it is necessary to maximize the length of the air ducts connecting these openings in adjacent rooms.

To protect the ventilation unit and the premises of the house from rodents, metal grilles are installed at all inlet and outlet openings of the air ducts.

The diameter of the air ducts is selected in accordance with the calculation of the aerodynamic resistance of the ventilation system.

Air ducts of rectangular cross-section are less commonly used. Such air ducts fit more compactly into the building structures of a house, but they are less technologically advanced to manufacture and more difficult to install.

The ventilation ducts have a fairly large diameter. Therefore, even at the design stage of a new house, it is necessary to provide places in building structures for hidden installation of air ducts in the living areas of the house.

To accommodate ventilation ducts, niches are provided in the walls and channels in the ceilings.

Air ducts are hidden behind suspended ceilings, in the frame shell of walls and partitions.

In the premises, the supply air ducts end with anemostats, which serve to distribute air evenly and also allow you to adjust the amount of air supplied.

Air from the premises enters the exhaust ducts through conventional grilles.

Air balance

When calculating forced ventilation, a positive balance should be maintained. This means that the volume of supply air is greater than the volume of exhaust air.

The main rule: air moves from clean rooms (bedrooms, living rooms) to dirty ones (kitchen, bathroom).

If it is customary in the house to tightly close doors with baseboards, you need to equip them with grilles for ventilation. Then the air can circulate freely from room to room.

Air is supplied and removed mechanically into enclosed spaces.

The ratio of supply and exhaust in premises for various purposes.

| Purpose of the room | Innings | Outflow |

| Living room | 200 cubic meters/h | 200 |

| Bedroom | 250 cubic meters/h | 200 |

| Corridor | — | 50 |

| Kitchen | 100 cubic meters/h | 150 |

| Combined bathroom | 50 cubic meters/h | autonomous |

| Total (required minimum) | 600 cubic meters/h | 600 |

Products for home ventilation

Ventilation

Tips for the developer.

Why should the ventilation in your home be worse than in your car?!

Design a modern centralized ventilation system with heat recovery for your home.

When building a house, be sure to lay the air ducts and electrical wiring provided for in the project to the central ventilation unit. After construction is completed, this will be almost impossible to do.

If the construction budget does not allow you to purchase a ventilation unit with recovery right away, leave the purchase for later. Install a cheaper supply and exhaust ventilation unit without a recuperator.

Recovery units are quickly becoming cheaper over time, and energy is becoming more expensive. Soon, a moment will inevitably come when the price of the unit, the amount of savings on heating costs, the desire for comfort and your income will allow you to purchase a recovery unit and install it in an already prepared place.

Consider installing a ground heat exchanger. It can be more convenient and profitable to do it during the construction process and laying communications to the house than later, when the construction is already completed.

Monitor and manage the humidity in your home the same way you monitor and manage the temperature. You should also hang a device for measuring humidity on the wall next to the thermometer. There are inexpensive electronic devices available for home use that measure both of these parameters at once.

It would be a mistake to select a PPVV block without knowing the aerodynamic resistance of the system . In many cases, such a ventilation unit will have a very high power and use more electricity than necessary. But more often it turns out that it is too weak and cannot provide the premises with a sufficient amount of ventilation air.

After installing the ventilation system, request that the contractor take measurements of the amount of air passing through each supply and exhaust device. It is better to do this before you pay for installation. Measurements are taken with the windows and doors in the room tightly closed. The values obtained as a result of measurements should be close to the designed values. They will never be exactly the same as in the design - in practice, precise adjustment is impossible.

Model diameter

This parameter shows how much air the device is capable of passing through. In stores you can find indicators from 80 to 150 mm. For standard Soviet apartments, values of 80 and 100 mm are suitable. In modern bathrooms, 120 mm is preferable.

Installation care rules

Ventilation ducts must be cleaned regularly.

Do-it-yourself ventilation will serve the owners for many years if its prevention is carried out in a timely manner. Maintenance of ventilation equipment depends on its composition and location. In expensive kitchen hoods, for example, filters will need to be changed periodically, while maintenance of budget models boils down to washing them under warm water.

To avoid fan breakdowns, they should be cleaned of dust deposits and small particles of debris at least once a month. Bolted connections are periodically checked for strength and, if necessary, tightened. Competent and timely maintenance of ventilation equipment is a reliable guarantee of long service life.

Noise level

The noise level of a standard fan can be compared to a personal computer cooler. The sound of operation is audible, but does not disturb the person.

This indicator is determined by the shape of the blades and the speed of their rotation. For comparison, a device with a larger diameter and low speed makes less noise than a miniature and high-speed device.

By the way. When choosing, you need to focus on the figure of 30 dB: values equal to it or lower are considered the norm.

Hood installation

Built-in hoods are attached to the back of the bottom of the hanging cabinet or instead of it. The air duct is masked in the closet. In the case of a dome-type hood, the corrugation is hidden in a special casing, and the unit itself is attached to the wall.

On a note. If there are other communications in the area where the hood is installed that cannot be moved (for example, a gas pipe or a ventilation ledge), the device is mounted at a distance from the wall using plumbing self-tapping screws, which are used when installing sinks.

The valve system is sealed from the outside of the wall. Then an insulated galvanized channel pipe is installed and secured to the wall using clamps and dowels. Install the visor. Usually the pipe is connected to the roof.

Once the valve systems are sealed, the duct installation begins.

Informed choice of the appropriate option

Most often, wall ventilation exhaust valves are made of metal or durable plastic. Plastic products are not suitable for conditions of high temperature and humidity, for example, for a bath, but they have proven themselves excellent in less difficult situations.

When selecting a valve, you should take into account its cross-section: rectangular or round.

The most important indicator is the air flow speed for which the device is designed. The most common are models designed for a flow of 4-6 m/s.

To organize forced exhaust ventilation in an apartment or house, you can use a design consisting of a fan and a check valve

If the valve is selected for a natural ventilation system, it is very important that the damper damper elements respond sensitively to even small air flows. But for systems with low draft, the presence of an exhaust fan is mandatory, so such sensitivity is not needed.

But here it is important to choose a fan that is suitable in power depending on the volume of the room for which the device is selected. So, for a kitchen, the fan power is calculated using a multiplying factor of ten, and for a bathroom this figure can be seven units.

In multi-storey buildings, the exhaust ventilation pipe must be installed one meter above the roof so that unpleasant odors do not penetrate from the lower floors to the upper ones.