A foundation made of reinforced concrete slabs is considered one of the most economical options formation of the foundation of structures.

Its use has certain limitations caused by the shallow depth of burial and insufficient load-bearing capacity.

However, in a number of cases this option is considered as the most optimal design in terms of cost and reliability.

When choosing this type of foundation, you should proceed from the actual loads and soil conditions (see other types of foundation).

Criteria for choosing material for base insulation

The insulation under the foundation slab is subject to special strength requirements.

The insulation applied to a monolithic slab is part of a critical structure, so there is a specific list of requirements for this product:

- High thermal insulation properties must be ensured with a relatively small thickness. It is important that the dew point in winter is not located in the middle of the reinforced concrete and does not perform destructive work, but is shifted to the insulator.

- The density of the heat barrier must be sufficient to withstand the load not only of a multi-ton screed, but of the entire building. In this case, the uniformity of the structure plays an important role here - shrinkage should occur evenly.

- A hygroscopic structure, which freely allows moisture to pass through itself, is not suitable for thermal insulation under the base. In this case, the concrete will become damp and fungal formations will begin to develop in it.

The world practice of building buildings using Swedish technology has shown that it is best to insulate a monolith from below with polymer structures - industrially manufactured sheets of foam polystyrene or polyurethane foam. For similar tasks, a special type of this product was developed, called penoplex.

Turnkey construction price

Average market prices for slab reinforced concrete foundations (construction on a turnkey basis) are reflected in the table . The given values are indicative, because the final cost in each specific case must be calculated separately by a specialist.

| Height of the foundation slab, m | Cost of turnkey installation, rub./m3 |

| 0,20 | 4000–4200 |

| 0,25 | 4100–4500 |

| 0,30 | 4400–4800 |

| 0,35 | 4900–5100 |

| 0,40 | 5500–5700 |

Prices for monolithic slabs for foundation construction are presented in the table:

| Plate length, mm | Slab width, mm | Slab height, mm | Slab price, rub. |

| 2010 | 2010 | 200 | 12500 |

| 2010 | 1500 | 200 | 9300 |

| 1500 | 1500 | 200 | 7000 |

| 1900 | 500 | 200 | 2500 |

Why is it necessary to insulate a slab foundation?

About 10% of heat is lost through a floor laid on the ground without insulation.

Several aspects of the positive effect of insulating the foundation of a house on its design and operation can be highlighted. The first and most important thing is protection from mechanical damage to the load-bearing parts of the building. It lies in the fact that under the area of the insulated box, freezing of the soil does not occur so intensely, so its deformation is minimal, since the soil is drier and the building area itself does not allow frost to penetrate deeply or spread under the entire plane.

The second question concerns freezing and getting wet of the foundation. If concrete freezes, this leads to disastrous consequences: it begins to crack, burst and flake off under the influence of the expansion forces of water, because it is still present in its thickness. Getting wet adds another negative corrosive effect that moisture has on the reinforcement frame, and the formation of mold and fungi, which thrive in a humid environment. The thermal insulator eliminates this by shifting the dew point beyond the supporting structure and creating an additional waterproofing barrier.

Another important point concerns the heat loss of the building. Any surface of a building conducts heat in one way or another, including the floor. The better the insulation of a monolithic slab, external walls, and roof is organized, the less energy is required to heat the space to the desired temperature. The concrete floor of a one-story building without additional measures to insulate it will take on 15% of the total heat loss.

Extruded polystyrene is a structure that has some elasticity, so it will play a certain role as a buffer in case of possible swelling of the ground underneath it.

general information

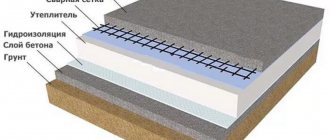

The design of the slab base consists of layers:

- geotextile is covered with overlapping strips on the sand layer, the joints are taped;

- pour crushed stone in a layer of 15-20 cm;

- pour a leveling layer of cement mortar, 5-10 cm thick;

- be sure to isolate the structure from moisture using rolled or coating materials;

- arrange a heat-saving layer;

- cover with plastic film in stripes overlapping by 20 cm;

- lay the reinforcing mesh;

- poured with concrete.

Installation and insulation of a slab monolithic foundation is expensive due to the high consumption of building materials. When the soil freezes to a great depth and a significant deepening of the strip foundation is required, installing a slab will be cheaper and less excavation work will be required.

Pros and cons of thermal insulation

The use of insulation prevents the appearance of cold bridges.

The use of polyurethane foam as an insulator gives the homeowner the following advantages:

- low thermal conductivity of the layer, the thickness of which may not exceed 5 cm;

- exceptional adhesive properties to any type of surface - there is no need to use adhesives, since the polymer itself adheres well initially;

- a continuous layer of insulation, since the polymer is continuously sprayed, eliminating the possibility of cold bridges;

- there is no need to use additional waterproofing.

One of the important disadvantages of this method of insulating a foundation slab is the need to use specialized equipment that needs to be delivered to the site. Only a qualified specialist can spray the polymer correctly and evenly onto the surface. In a liquid state, the material is hazardous to health, so the requirements for the use of personal protective equipment during surgery are increased.

Extruded polystyrene foam due to its strength characteristics is suitable for insulating a foundation slab

When installing a warm sole made of polystyrene foam, you can get the following benefits:

- Laying the polymer is not particularly difficult and does not involve the use of special equipment. This speeds up the process of forming the insulator many times over.

- The sheets are lightweight and easy to deliver to the site, unload and carry.

- The insulation under the foundation slab is perfectly uniform over the entire plane.

- The material itself has high densities and is absolutely non-hygroscopic.

- In terms of thermal insulation properties, this is one of the best polymers.

Among the disadvantages is the need to install additional waterproofing under the polystyrene foam against eroding groundwater, since it can still penetrate into the cracks between the joints. The heat barrier must be glued to the waterproofing base and to each other to prevent the sheets from spreading when pouring concrete or moving the soil. The polymer belongs to the category of expensive coating.

How to pour correctly

To independently erect a slab, it is necessary to evaluate the soil composition and groundwater level (GWL); compaction of the sand backfill with water and a vibrating plate plays a special role. Next, you should definitely initially plan communications with duplication, for problem-free drainage (gutter). For a floating slab, plantar and ring drainage is provided. The insulation is ordinary dense polystyrene foam.

Work technology

Expanded polystyrene is laid on the ground in front of the reinforcement and concrete platform.

When installing a shallow Swedish slab, its base is insulated with a heat barrier using the following technology:

- A non-woven geotextile fabric is laid on the surface of a leveled pit, filled and compacted with a layer of sand, so that when the soil moves, the laid rectangles do not diverge, they do not tear, and cold bridges do not form.

- A layer of waterproofing is made from a special polymer membrane.

- Expanded polystyrene sheets 10 cm thick are laid as the first layer under the entire area of the foundation. Be sure to glue the joints with mounting foam adhesive.

- Along the perimeter of the resulting layer, formwork is installed from the same insulation to the height of the future screed. It is reinforced with external timber formwork.

- Having stepped back from the formwork by 40-50 cm along the entire perimeter, they drive the second layer of polystyrene foam insulation. It is important that the joints of the first and second layers do not intersect in any way. Here you also need to glue each sheet with the previous and underlying ones.

The last step is laying the waterproofing base on top of the heat insulator. Its main role is to prevent moisture from concrete from entering the cracks between the joints, which can significantly worsen the thermal insulation properties of the equipped heat insulator.

You can use insulation with special locks on the end of each sheet. Milled grooves greatly simplify installation and also contribute to better joining and smaller gaps.

When laying sheets of polymer on bitumen waterproofing materials, the latter may contain various solvents that can corrode the material. Therefore, after installing such waterproofing, you need to wait some time for them to evaporate.

Differences between an insulated monolithic Swedish slab and a video about its construction

As mentioned earlier, the insulated slab under the house developed by Swedish builders is energy-saving. During its construction, permanent formwork made of extruded polystyrene foam is used. As a result, heat leakage into the ground is minimal. The second fundamental difference is the water heated floor system built into the slab.

Since engineering systems are poured deep into concrete, it requires accurate and competent calculations. High demands are also placed on execution. Even small mistakes are critical. You can make USP yourself, but it is better to order the project. See the following photo for an approximate breakdown of costs. The amounts are no longer relevant, but the percentages are correct. The cost of the foundation project is about 1%.

Approximate percentage of costs for a monolithic slab foundation

In the following videos you will see the stages of making a Swedish stove for a specific house. Many useful devices are described that will make work easier, and explanations are given for some of their features.

And look how the Germans pour such a slab. There are also many useful nuances.

Well-known brands of thermal insulation products

TechnoNIKOL is a well-known domestic brand of insulation for concrete.

URSA is a well-known brand in Europe. The manufacturer specializes in the production of polystyrene foam, expanded polystyrene and extrusion versions of the product. The products are of high quality in terms of uniformity and thermal insulation characteristics.

TechnoNikol is an industrial giant of insulation in the domestic market. The plant produces expanded polystyrene and a wide range of other insulation products. The production facilities have their own laboratories where new types of insulators are developed.

Elit Plast is a manufacturer of Ukrainian origin. It produces decent polymer insulation materials that meet all environmental global standards.

Rules for installing heating pipes

When installing USHP, heating pipes are used. There are the following rules for their installation:

- More dense pipe laying allows for higher room heating temperatures.

- The distance between external walls and pipes should not exceed 150 mm. Closer to the center, the laying step can be increased to 250 mm.

- To minimize hydraulic losses, the length of one loop should not exceed 100 m.

- Do not lay pipes closer than 100 mm from each other.

Heating pipes must not be installed at the junction of monolithic slabs. In this case, it is better to lay two circuits. The pipeline crossing the joint is insulated with steel sleeves 30 cm long.

You can see how to make an insulated Swedish slab with your own hands in the video: An insulated foundation slab allows you to reduce heating costs during operation and helps reduce the level of frost heaving in the soil. Thanks to this, the life of the foundation is extended, and living in the house becomes more comfortable.