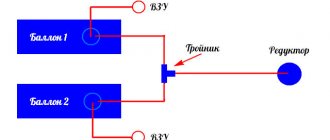

We tell you how to make a universal oven from a gas cylinder with your own hands. Suitable for heating a room up to 70 sq.m., and for cooking.

To make such a homemade stove, you will need:

- two gas cylinders (propane) with a volume of 50 liters;

- steel strip;

- round pipe;

- some scrap metal.

For work we will use a welding machine, a grinder, a hand hacksaw and other metalworking tools.

You might also be interested in reading how to make a potbelly stove from rims.

The basic principle of the work performed

A do-it-yourself long-burning potbelly stove, like all wood-burning devices, consists of elements such as

1. The blower is a special channel, which is usually located at the very bottom of the furnace body. It is through this channel that air is usually supplied, which is the main catalyst for fuel combustion. This element is usually equipped with a door, which is used to effectively regulate the intensity of the combustion process. It simply closes or completely opens the channel from time to time. At the same time, the internal space of such a blower can be used as a special container designed to collect ash.

2. Firebox, that is, the combustion chamber of the fuel used, located strictly above the ash pit. This element is part of the channel through which air is supplied. It is separated by special rods, which are known as grates. The firebox must have its own separate door, which is required for loading fuel.

The ignition process, as a rule, is carried out strictly with the door of the combustion part open and with the door of the existing blower completely closed. All unburned parts of the fuel usually fall through the grate into the mounted ash pit. They can also fly out through a special exhaust channel.

3. The chimney is an exhaust duct used to remove combustion products from the stove. A view, that is, a special wedge-shaped shutter, is mounted in the body of the chimney. It was originally intended to completely close the entire exhaust duct. Using it, you can seriously slow down the overall process of efficient fuel combustion, while simultaneously increasing efficiency parameters.

Do-it-yourself stoves made from a gas cylinder usually involve placing two structural elements in a metal container body: a firebox and a high-quality ash pan. The chimney of this stove can be mounted separately.

- Such a potbelly stove works based on the following principles:

- The blower supplies air to the combustion part;

- The firebox usually burns coal or wood;

- A part of the stove, such as the chimney, removes gas and all unburned elements, that is, soot;

- The combustion control process is carried out by means of a throttle valve. It, in turn, is inserted into a short fitting and a special wedge-shaped view, pre-installed into the body of the chimney;

- Fuel is loaded into a special door cut into the body of the cylinder.

In fact, everything is relatively simple and clear. All that remains is to figure out how to correctly place the combustion part and the blower in the cylinder. It is important to understand how to connect a special chimney duct to it. All this can be found out by studying the information below.

Scheme and principle of operation of a potbelly stove

The history of these heating units goes back to the beginning of the last century, when they were used to heat rooms in houses and even apartments. This popularity is explained by the primitiveness of the stove design and ease of manufacture. But this same simplicity negatively affects the efficiency of its operation, because the efficiency of a traditional potbelly stove hardly exceeded 45%. Therefore, today it is used mainly for periodic heating of cottages and garages.

Initially, the heater was a metal body with a door at one end for storing firewood and an ash pan, and a chimney pipe was welded to the back. There was no grate, the fuel burned directly on the bottom (hearth). At the same time, the lion's share of the heat left the room through the chimney, since the hot combustion products entered there directly from the firebox. To understand the structure and operating principle of such a potbelly stove, it is worth studying the following diagram:

As you can see, hot flue gases containing a large amount of heat immediately leave the body of the furnace and are not used to heat the room. Later, the design was modified by unknown craftsmen in order to take away this heat, as a result of which the following types of wood-burning potbelly stoves appeared:

- stove with grate and smoke circuits;

- long-burning heater, where the process of burning wood occurs from top to bottom.

Note. To additionally extract heat from the chimney pipe, they began to install a samovar-type water heat exchanger on it, which will be discussed below.

The two-pass wood stove, shown below, has a grate and 2 baffles that force the flue gases to make a tortuous path inside the body before venting out. Thanks to this, the potbelly stove becomes more economical, since combustion products have time to exchange heat with the surrounding air through the metal walls of the unit.

There is also a variant of a round stove with one smoke circuit, where pyrolysis gases are burned. This potbelly stove is designed for burning sawdust and small wood waste. Here there is a double-walled design and a lower location of the chimney pipe, since gases must travel from the firebox from top to bottom in order to give off heat. The operating principle of such a homemade potbelly stove is shown in the diagram:

Another design, where solid fuel is burned from top to bottom, is not so economical, but it works much longer from one fill. The firewood here is set on fire and burns from above, pressed down by a weight with a pipe through which air enters. How such a long-burning potbelly stove functions is shown in the diagram:

For reference. People call this unit nothing more than the “Bubafonya” oven.

Classic steel stove

We propose to weld the wood-burning stove shown in the photo from iron sheets 3-4 mm thick. Externally, it is similar to a classic rectangular potbelly stove with low efficiency (up to 40%), but inside the design has been modernized. To make it more economical, two smoke teeth are installed above the combustion chamber, like brick fireplaces.

The partitions inside the body, shown in the drawing, block the section of the firebox in the horizontal plane and leave a small passage 10 cm wide for combustion products. The flow of heated gases through two smoke circuits increases heat transfer by 5-10%, which is much better than factory cast iron stoves.

Advice. The dimensions of the heating unit indicated in the drawing are not an axiom; you can change them at your discretion. The main thing is to maintain the size (height) of the flues. We do not list the required materials, since their list is obvious - sheet metal, cuttings of pipes for the chimney, and rolled metal for grates and legs.

The manufacturing procedure is as follows:

- Weld the body of the potbelly stove, starting with the bottom sheet. The primary assembly of parts is performed using tacks.

- Cut and install 2 partitions. For the lower one, located above the flame, it is worth taking thicker iron - 5-6 mm.

- Make a grate and place it on supports made from corners welded from the inside to the side walls of the firebox.

- Attach a cover and chimney pipe, install simple doors with locks.

- Finally weld all seams.

If you plan to heat your potbelly stove with small fractions of coal or sawdust, make a grate from steel corners with the profile facing downwards. Make the distance between them minimal - 5 mm.

What and how to make doors from

Doors for potbelly stoves can be purchased cast. You will need a small height for the ash pan and a larger one for storing fuel. There are ready-made blocks - a flow door with a blower in one design. In this case, a frame made from corners welded to size is welded into a hole cut to size, and the casting is already bolted to it. To prevent air from blowing in from the cracks, a small edge is welded around the perimeter of the cutout under the door - a 1-2 cm strip of metal.

How to attach a cast iron stove door to a gas cylinder

You can not buy doors, but use a cut piece of a balloon wall. Then you will need some kind of hinges or replacement parts. It’s clear with the hinges: mark the places, weld them. There is an interesting version of homemade loops: several links of a thick chain.

The hinges on the door can be made from several links of steel chain

A latch will need to be welded to such a door.

How to make a chimney for a potbelly stove

For stable operation of this kind of homemade stoves, it is important to ensure good traction. To do this, the cut of the chimney pipe of a potbelly stove made from a cylinder must be at a height of at least 4 m above the level of the grate. When connecting the gas duct sideways, the minimum length of the horizontal section should be 400 mm, and at the bottom of the vertical part it is necessary to organize condensate drainage, as shown in the figure:

At the same time, it is desirable to take measures to effectively remove heat from the flue. There are 2 proven ways to do this:

install a horizontal section of the chimney from the potbelly stove at an angle of 30-45°, running it along the wall. After this, the canal turns up and goes out onto the street;

a purchased or homemade samovar-type water heat exchanger is installed on the chimney.

A pipe coming out of the stove at an angle and passing through the entire room will have time to transfer a significant amount of heat to the internal air, causing the overall efficiency of the stove to increase and the consumption of firewood to decrease. In turn, a chimney with a water circuit will allow you to install 2-3 small radiators in your dacha and provide them with heat. The device is quite simple to manufacture: a water jacket with two pipes is made in the flue section.

Advice. It is better to provide circulation in the water circuit mounted on the chimney of the stove by force, using a circulation pump.

With grates or without?

In the simplest version, no grates are provided. If the cylinder is small or stands horizontally, then selecting a part inside is problematic. In this case, the design of a potbelly stove made from a cylinder is quite simple: the body is placed on legs, one door, and a pipe for connecting the chimney is welded in the upper part. All. The whole stove.

The internal structure of a potbelly stove made from a horizontally located cylinder is quite simple: only a door for loading fuel/unloading burnt coals and an exit for the chimney

The photo above shows examples of such simple ovens. In order to improve heat transfer, metal strips are welded to the outside of the body. In the upper part, in addition to the smoke pipe, there is another outlet - a lid is installed on it, and this outlet is used as a stove for cooking food and heating tea.

If you still want to make grates in a potbelly stove from a horizontally installed cylinder, you will have to weld a tray for collecting ash from below. Below there is a drawing and photo of the practical implementation.

About the top burning potbelly stove

To make this type of stove, you need to assemble its internal part - a weight with a pipe for air supply. It should be round in shape with a diameter such that it fits freely inside the cylinder. Usually this is thick sheet metal (at least 10 mm) with a hole in the middle where the pipe is welded. On the bottom side, for better distribution of air in the combustion chamber of the stove, several ribs are attached, this is clearly shown in the photo:

As in the previous version, you should cut off the top part of the cylinder and make a hole in the middle for the pipe to pass through. In order for the future lid to close tightly, it must be scalded all around with a steel strip. The chimney pipe cuts into the side, in the upper part of the stove body. How to properly make a long-burning potbelly stove, where the process goes from top to bottom, is described in detail in the video:

Technology for making a stove from a conventional gas cylinder

First of all, it is necessary to clarify that a do-it-yourself long-burning potbelly stove is constructed from a special 50-liter container. It was originally designed to store propane mixtures. These containers are usually used in everyday life to power autonomous gas stoves, as well as in industry, in particular, for the efficient storage of fuel used for a conventional gas cutter.

The process of careful preparation of the container

- The oven assembly process begins with preparing the base. It is done like this:

- The gas is completely removed from the cylinder, for which you just need to open the valve and wait for a sound such as a perfectly audible hiss. This process is carried out strictly on the street;

- After this, it is recommended to completely get rid of the smell of odorant or mercaptan fragrance. It is this that is usually added to the container to determine if there is a gas leak. To completely get rid of it, simply rinse the bottle with a special bleach solution that contains acid. Any sediment present can be effectively washed off with a 10% soda ash mixture. After washing is completed, you can use the container to perform a long-burning oven.

The choice of furnace design is carried out

It is worth knowing that a potbelly stove can be vertical and horizontal. In other words, the cylinder can stand in its usual position, that is, with the valve up and at the same time resting on a special stand in the form of a ring. Also, the base can simply lie with the valve to the side, while it rests on the legs welded to the base.

A horizontal potbelly stove is usually constructed much faster, but the disadvantage is that the device takes up quite a lot of free space. A vertical stove can be placed in any corner without any problems and the draft will be much better.

Vertical oven assembly process

- A vertically positioned potbelly stove can be made with your own hands according to the following instructions:

- The existing hole for the valve, located in the end part, should be slightly enlarged, to about 10 cm. At the same time, a metal plate, that is, a collar, the thickness of which is 5 cm, should be welded along the ring. Such an element will play the role of a pipe intended for chimney;

- A small hole is cut approximately 5-10 cm from the very bottom; it will act as a door for the installed blower.

- A little higher there is a hole for a small firebox door. The parameters of these holes can be completely arbitrary, but the parameters of the door, which plays the role of a vent, are in no way less than the total area of the chimney system;

- Between elements such as the firebox and the ash pan, shelves are welded in order to then place grates of rods and grates;

- The doors can be fixed on special hinges, and they can also be equipped with special latches.

This version of the stove is installed on a sheet of steel, the dimensions of which are 60-70 by 100 cm. Installation is carried out strictly taking into account the need to install a special “broken” chimney. This design makes it much more difficult to discharge a large volume of heat through a special exhaust duct.

We increase the efficiency of the furnace

A potbelly stove can heat a room in literally a matter of minutes. Moreover, you can throw whatever comes to hand into the firebox: since it does not have an extensive network of chimneys, and the smoke in it comes out “directly,” you don’t have to worry about them getting clogged.

But if a conventional heating stove installed in premises for permanent residence has an extensive network of chimneys that retain heat, in a potbelly stove it goes directly into the pipe, so its efficiency is not very high. That is why it is too “gluttonous” and requires a lot of fuel.

To reduce fuel consumption, you can use the following tips from experienced stove-makers: • door to the firebox and vent

in such an oven must be as airtight as possible;

otherwise, the air supply to the potbelly stove will increase, and the fuel will burn out too quickly; • to regulate the output of warm smoke in the chimney, it is advisable to provide a damper

;

• next to the stove, you can provide side metal screens

at a distance of 5-6 cm from the stove, in which case it will heat the room not only through heat radiation, but also through convection (circulation of warm air); • a potbelly stove, “clad” in a metal casing, will help retain heat much longer;

Potbelly stove in casing

Round furnace with afterburner and casing with heat gun

• to retain heat in the room, elbows should be built up in the pipe; however, soot will be retained in them, so it is advisable to create a collapsible structure; • the pipe can also be given a stepped shape: arrange the elbows in stages, making a 30° turn with each step; in this case, each of the elbows must be securely attached to the wall with rods;

Stove with chimney elbows

• chimney capacity

should be less than the productivity of the furnace itself, in which case hot gases will not go into the pipe immediately;

its diameter should be only 2.7 times larger than the volume of the firebox, for example, with a firebox volume of 40 l, the diameter should be 110 mm; • you can increase the efficiency of the stove by blowing the chimney with a fan

- this will turn the stove into a kind of smoke cannon;

• to reduce air circulation, firewood in the stove

should be stacked as tightly as possible;

if it is heated with coal, the resulting ash should be stirred up as little as possible; • to regulate the air flow, the door to the ash pit can be made adjustable by providing it with vertically located slots and a valve

that will block these slots;

• to increase the heating area, it can be ribbed, that is, strips of metal

;

• if you place a couple of buckets or a metal box with sand

, they will accumulate heat and store it even after the stove goes out;

sand backfill or a heat accumulator made of stones

can also be sewn inside the metal body of the furnace;

Scheme of a potbelly stove with sand backfill, the stove is made of a pipe with a diameter of 500 mm, its length is 650 mm

• oven lined with 1-2 layers of brick

, will retain heat much longer;

Brick screen

• the volume of the furnace also matters: the larger the area of its walls

, the more heat they will release into the room;

• bricks or metal sheets

on which the stove is installed will help not only protect the room from fire, but also retain heat.

Related video: Do-it-yourself potbelly stove stove

One of the simplest and cheapest ways to heat a dacha or garage is heating with wood, for which homemade long-burning potbelly stoves are used. These are primitive metal stoves with some modifications to increase the efficiency of burning solid fuel. In this article we will tell you how you can make such a potbelly stove with your own hands from a gas cylinder, as well as correctly install it and connect the chimney.

What do you need to prepare?

From the tools you need to collect:

- welding machine (200A);

- grinder – “grinder”, preferably with discs with a diameter of at least 180 mm;

- electrodes;

- circles for grinding and cutting metal;

- hammer cleaning slag from welding;

- a brush with metal bristles;

- folding meter, tape measure, chalk or marker for marking;

- drill and drill bits of the required diameters;

- chisel, regular hammer and pliers.

From materials, in addition to one or two gas cylinders, you must purchase:

- a sheet of metal, at least three millimeters thick - it is useful for constructing a hob and ash pan;

- ready-made cast iron doors, or you can also make them yourself from a metal sheet or a piece of metal cut from a cylinder;

- chimney pipe;

- corner or thick reinforcement - they will be needed for the manufacture of legs and grate. The latter can be purchased ready-made (from cast iron) or constructed using holes drilled in the bottom of the cylinder.

It should be noted here that both a standard gas cylinder and a small cylinder are suitable for the manufacture of such a stove.

Materials and tools

To create a potbelly stove you will need: • metal with a thickness of 3±0.5 mm: thinner sheets will quickly burn out, in addition, under the influence of high temperature they can warp, and the stove will become shapeless; thick-walled metal will take a very long time to warm up; • chimney pipe; • rods 16 mm; • a sheet of metal with a thickness of 0.3 mm for constructing a box for collecting ash; • tape measure, ruler, chalk; • welding machine 140-200A; • grinder for cutting metal; to make round holes it is more convenient to use a gas cutter; • metal brush for cleaning welding areas; • emery wheel for adjusting doors; • drill and drill bits.

Choosing a quality barrel

To make a potbelly stove, you can use any steel barrel used in the petrochemical, paint and varnish, chemical, and metallurgical industries for storing and transporting technical products:

- bulk - oils, solvents, paints, diesel fuel, sodium liquid glass;

- pasty - thick lubricants, bitumen;

- bulk - caustic soda, various plasticizers.

They are produced in two types - with an open and closed top; they also differ in the thickness of the bottom, lid and shell.

Any of these containers can be used as a potbelly stove if you first thoroughly clean and rinse its inner surface. However, the thinner the walls of the container, the faster they will burn out and the stove will fail. Therefore, for a potbelly stove you need to choose a product with a metal thickness of more than 2 mm.

Well, the best option is a stainless steel barrel. High-alloy stainless steel is most resistant to high temperatures in the fuel combustion zone, which means a stove made from it will serve for a longer period.

Calculation of parameters: drawings and recommendations

You should start with the selection of source material. A 50-liter gas cylinder is ideal.

Its dimensions: 300 mm in diameter, 850 mm in height with a 4 mm metal wall.

These cylinders are commonly used in a variety of applications, from stove fuel to industrial applications.

Main parameters and features of stove manufacturing:

- the chimney is usually made of a pipe with a cross-section of 100–125 mm with a wall of 3-4 mm;

- place it vertically, perhaps with a slight deviation, 25-350;

- the firebox and ash pan are equipped with doors, which must be locked to improve heat transfer during fuel combustion and for fire safety purposes; in addition, the doors are used to regulate the air supply;

- it is important that the firebox must have sufficient depth for firewood of a convenient size;

- grates are needed for storing fuel and separating ash and coals during the combustion process;

- It is better to weld them from the most durable and heat-resistant material, for example from reinforcing bars with a thickness of 12-15 mm;

- their length must correspond to the inner diameter of the cylinder body; this grid usually has a mesh or a gap with a pitch of 10–15 mm;

- In order for your wood-burning “potbelly stove” to heat and fire properly, it is built according to the principle of a conventional wood-burning stove.

Chimney device

• To prevent precious heat from escaping through the pipe too quickly, it must have a special design. Such a device has two main parts: vertical

1.2 m high, installed at an angle of 90° above the stove and an inclined part, called

a hog

, 2.5-4.5 m long or more, in which the smoke burns out. It is the hog that provides up to 1/4 of the heat of the entire oven.

Chimney Hogs

• A tall person can touch the heated pipe, so the hog must have a protective mesh cover. To avoid burns, the distance from the floor to this pipe should be 2.2 m. The vertical part of the pipe coming from the stove is additionally wrapped with thermal insulation.

Important!

The pipe should be located away from plastered walls at a distance of 1.2 m. The distance from wooden structures is 1.5 m.

Advice.

Laying pipes through a wooden ceiling and roof is a rather labor-intensive process. It is much easier to bring it out through a hole in the wall or window.

Exhausting smoke through the window

Manufacturing of a two-chamber pyrolysis stove

The photo above shows a potbelly stove made from a gas cylinder. This version of the potbelly stove is more compact and economical. Instead of two 50 liter propane cylinders, we will need 1 24 liter propane vessel and 5 pipes with a diameter of 57 mm and a length of about 400 mm.

The operating principle is as follows:

- The first propane cylinder is similar to the previous option. The only difference is that instead of grates, there are slits cut on top of the cylinder itself.

- There is an opening on top of the cylinder. 5 heat exchanger pipes fit there. Through these pipes the smoke rises into the secondary chamber. Following this path, the heated air releases some of the heat into the room.

- Additionally, warm air is supplied to the secondary chamber through a separate channel. A pyrolysis effect is created - the smoke burns out in the fuel chamber and releases additional heat. And only after that they finally come out.

The power of such a horizontal stove can reach up to 5 kW. This is enough to heat 50 m2 of usable area.

Making a pyrolysis (long-burning) two-chamber stove is not much more difficult. It is more compact, but has less power. In the same way, we will prepare tools, materials and you can make the necessary drawings.

Materials and tools

You will need the following materials:

- electrodes

- cutting wheels

- 1 gas cylinder 24 liters

- sheet 2 mm thick

- corner for making “legs”

- fittings with a diameter of 20 mm

- pipe diameter 57 mm

- pipe diameter 20 mm

- other

You will need the same tools:

- portable welding machine

- "Bulgarian"

- drill

- drill

- other tool.

Below is a drawing of a potbelly stove made from a 24-liter gas cylinder.

Step-by-step instruction

Diagram of a two-chamber pyrolysis stove

Your actions should be like this:

We cut a hole for the stove measuring 260x200 mm in the bottom of the propane cylinder. Make an ash pan and weld it to the bottom. Weld the supports. Make a grate. We make a heat exchanger according to the drawing above. We cut the pipes in a checkerboard pattern

It is critical to maintain all distances. We weld a pipe with a diameter of 20 mm for an additional supply of warm air, having first bent it at a right angle. We cut a hole in the cylinder and weld the heat exchanger. Now let's make a secondary chamber with a chimney. We use a blank cut from a cylinder as a cover for the chimney. It is needed for longer burning.

The main stages of making a potbelly stove

1. All the details are marked on a sheet of metal: 6 steel rectangles for the walls of the oven, 1 rectangle for creating a smoke reflector, plates for the grate and latch for the door. 2. Cut

sheet metal can be found at any metal depot. The guillotine, unlike the grinder, allows you to cut (chop) it more accurately. In this case, there will be no need to straighten the sheets. 3. The furnace body is made in the form of a rectangle. Their sides are joined together at an angle of 90° and welded together.

Welding the box

4. To avoid mistakes, the furnace box is first only tacked by welding in several places, and only then, after checking its horizontal and vertical positions, its seams are welded.

Important!

All connections in the body are thoroughly welded;

To check the seams

for leaks, you can coat the joints with chalk or kerosene.

5. Welding seams are cleaned with a wire brush. 6. The internal space of the potbelly stove is divided into three parts: the firebox, the smoke circulation chamber and the ash pan. To separate the firebox from the ash pan, a grate is laid between them, on which the fuel will be placed. To do this, at a height of 10-15 cm from the bottom of the stove, 5x5 cm corners

, on which the grille will be located.

Advice.

It is better to make the grate from 2-3 detachable parts. Otherwise, when replacing a burnt grate, it will be difficult to remove it from the firebox.

7. The grate is welded from thick steel rods or strips 30 mm wide. They are attached to 2 stiffeners - rods with a diameter of 20 mm. Since the grates burn out over time, it is better to make such a grate removable.

Manufacturing of grate

8. At a distance of 15 cm from the top of the box, two strong rods are welded, on which one or two removable reflectors

– thick-walled sheets of metal that will delay the flow of hot gases and send them for afterburning. However, they should not completely block the oven. To allow hot smoke to enter the chimney, an indent of about 8 cm is made from the front (for the first sheet) and back of the stove.

Diagram of the passage of gases in a simple potbelly stove and stove with an installed reflector

9. Next, the upper part of the box is welded, and then a hole for the pipe

.

Pipe hole

10. The front part of the stove with holes cut in it for the firebox doors and ash pan is welded last. 11. The size of the firebox door must be sufficient to allow fuel to be added and grates to be changed without effort. The hole for the ash pan is made a little smaller. 12. The hinges are welded first to the door, and then to the body of the potbelly stove. They can be bought ready-made or welded from two tubes of different diameters. Door handles can be made from a strip of metal or rod.

Welding the door

Important!

When attaching the doors, you should

fit them to the body

as tightly as possible; To do this, they are straightened (leveled) and cleaned with an emery wheel. The wedge latches that close the doors are fitted to the body as tightly as possible.

The final part of the work

We cut four identical pieces of round pipe and weld them to the bottom of the stove - we get support legs.

We make a locking mechanism so that the door can be closed while the oven is operating. We scald the door itself on all sides with steel strips.

At the last stage, all that remains is to clean all the welds with a grinder and paint the stove with heat-resistant paint.

The step-by-step process of making a homemade stove from a gas cylinder can be found in the video below. The idea belongs to the author of the YouTube channel DIY Projects.

Trial fire

After the potbelly stove is made, you need to test it in action. The first fire will show all the defects. The oven must be heated before painting. The test is carried out in the following order:

- We light the stove with a small amount of fuel. The first stage lasts 30-40 minutes.

- If smoke is not visible anywhere, next time we make a full load and heat the stove. Our goal is to fade the old paint.

If smoke gets in somewhere, these places need to be sealed. After testing, the oven must be coated with heat-resistant paint.

Advantages and disadvantages

The positive aspects of homemade stoves include:

- excellent thermal conductivity (provided by the thick metal walls of the cylinder);

- convenient dimensions (can be made to fit your garage);

- ease of manufacture and maintenance;

- availability of consumables and fuel.

Among the few disadvantages, one can highlight only the ability to use a limited number of types of fuel (wood, coal, fuel briquettes), and with a vertical design, there is also the need to adjust the size of the logs to the length of the firebox.

Safety precautions

Precautions when operating a structure made from gas cylinders:

- The stove should be installed away from the passage to avoid accidental burns. It is also advisable to provide good lighting at the installation site. There should be no flammable objects near it on the floor and walls of the garage.

- The walls of a homemade garage oven made from a gas cylinder heat up very quickly to a high temperature. Sometimes the metal glows red. Careless touching will result in severe burns. To increase safety, the structure is fenced with one or two screens.

- The first start-up of the stove is accompanied by an unpleasant odor from paint burning on the surface of the gas cylinder. During this time, ensure good ventilation in the garage.

Important! The screens around the stove not only provide protection from burns, but also work as deflectors: they direct the flow of cold air from the floor along the hot walls, ensuring quick heating of the garage.

Safety precautions when working with equipment differ little from the recommendations when using a welding machine, grinder and other tools. We need protection for the eyes and skin of the hands, and care when handling fire and hot metal. The only thing you need to pay attention to is the preparation of the gas cylinder. Here, in addition to caution, you need to follow simple requirements - working in the open air, away from fire, i.e., taking smoke breaks over a cylinder that has not yet been filled with water is an unwise decision.

The design of the stove and its principle of operation

Heating a garage with gas is prohibited, because if the house has long been connected to the main gas pipeline, but the cylinder remains, it can be used to create a stove. Depending on how many cylinders are available and what fuel the owner plans to use, the design of the stove is selected.

Stationary equipment in the garage includes all kinds of boilers, stoves, and fireplaces. Their installation is possible with permission from the relevant authorities, but many neglect this rule. For safety reasons, it is strictly forbidden to install a gas heater in the room where the car is parked.

The basic requirements for the room include the distance of the stove from flammable materials, a normal level of ventilation, the presence of a chimney, the presence of water containers in the room for emergency fire extinguishing, sheets of metal or concrete within a radius of 0.5 meters at the base of the chimney and the unit itself.

Manufacturing recommendations

The topic of making various wood-burning stoves from gas cylinders is very popular and here’s why. Firstly, this is an accessible material that can be found at any scrap metal collection point. Secondly, such a tank is an actual finished furnace body with fairly thick walls. All that remains is to modify it yourself and you will get an excellent potbelly stove for heating a garage or cottage. Moreover, the design can be either vertical or horizontal.

Advice. Most of all, a standard propane cylinder with a capacity of at least 50 liters is suitable for making a homemade heater. Using tanks of a smaller volume will not give the desired effect, the stove will be heavy, and the heat exchange surface area will be small.

A vertical potbelly stove made from a cylinder, made by yourself, is more compact and takes up little space in the room. But the wood in it will not burn for a long time, no matter how you limit the air flow, since the flame will begin to cover the entire volume of fuel.

Another thing is a horizontal stove, in which the flame moves from beginning to end, gradually burning the wood. But with it there is more work; you need to arrange an ash chamber outside, since inside it will take up too much useful volume. The structure of this potbelly stove is shown in the drawing:

Now about how to make a horizontal potbelly stove at home. To do this, you need to carefully cut off the top of the cylinder with a grinder, where the gas valve is screwed on. Naturally, the valve must first be unscrewed, and the container must be filled to the top with water in order to displace all the propane vapor that could remain inside the tank.

Otherwise, you risk causing an explosion, the consequences of which are unpredictable. The next sequence of actions is as follows:

- cut a strip in the side wall where the ash chamber will be welded. Another option is to drill many holes, as seen in the photo below.

- make and weld an ash pan from metal 2-3 mm thick to the cylinder. Place a homemade door or damper in front to regulate the air supply;

- The loading door should be cut into the front end. It can be made in a round or square shape, or you can purchase a finished product;

- in the back you need to cut a hole for the chimney duct. You shouldn’t make it too big; it’s enough to take the chimney diameter as 100 mm, maximum 150;

- weld the pipe;

- make a stand from any available rolled metal and also weld it to the body.

Making a vertical oven from a cylinder is a little easier. To make such a potbelly stove with your own hands, you need to cut openings for the doors in the side wall, and the cut pieces of metal themselves can act as doors. You just need to attach loops to them, for example, from several links of a thick chain, as was done in the photo:

But you will have to tinker with the grate bars. Not only do you need to make a grid (preferably from periodic profile reinforcement), but you also need to somehow install it inside the cylinder. Here you will have to cut off its top or bottom part - at your discretion. After installing the grate, the cut part should be welded in place, and a pipe should be attached on top to remove combustion products.

Note. Instead of a cut-off hemisphere, it is easier to put a flat lid made of a sheet of iron. However, the pipe does not have to be attached from above. It can also be embedded into the wall of the potbelly stove at the top.

Heater made from car rims

The advantage of the rims is the decent thickness of the metal. If you make a potbelly stove from them, it will not burn out for a long time, although such a product cannot be called beautiful. Let's give some recommendations for production:

- The more old wheels from a car of the same size you have at your disposal, the larger the furnace firebox will be. Only the middle part of the disks needs to be cut out (preferably with a gas cutter; using a grinder is inconvenient).

- It is easier to make a horizontal stove - weld several wheels with a cut out core and place the structure on legs. Attach a door in front, and a blank wall with a chimney hole in the back.

- To make cleaning the horizontal model easier, place a sheet of metal in the firebox.

- The vertical version is made in the same way, only the door is cut out in the side wall of the housing, and the chimney is cut out on the opposite side.

Bottom line

A homemade stove based on gas cylinders is an inexpensive and high-quality heating unit that will last for many years. Of course, the efficiency level of such a stove is not the highest, but welding experts are working to improve it.

A potbelly stove based on cylinders, when properly welded and designed, copes with its task much better than other heaters running on electricity or gas. What type of stoves do you think is the most effective? Share your opinion in the comments!

Sources

- https://gidpopechkam.ru/pechki/burzhujka-iz-gazovogo-ballona.html

- https://cotlix.com/kak-sdelat-burzhujku-dlitelnogo-goreniya-iz-gazovogo-balona

- https://teplowood.ru/burzhujka-iz-gazovogo-ballona.html

- https://oboiman.ru/ingeneer/burzujka-iz-gazovogo-ballona-svoimi-rukami-instruktaz-po-izgotovleniu.html

- https://stroy-podskazka.ru/postrojki/garazh/pech-iz-gazovogo-ballona/

- https://sdelairukami.ru/pech-iz-gazovogo-ballona-luchshij-variant-dlya-garazha-i-masterskoj/

- https://kachestvolife.club/otoplenie/kak-sdelat-piroliznuyu-burzhuyku-iz-gazovogo-ballona-2-luchshih-sposoba

- https://dekoriko.ru/postrojki/garazh/pech-iz-gazovogo-ballona/

- https://vdome.club/bez-rubriki/pech-v-garazh-iz-gazovogo-ballona-kak-sdelat-svoimi-rukami.html

- https://VseProGarazh.ru/kommunikatsii/otoplenie/pech-dlya-garazha-iz-gazovogo-ballona/