Here you will learn:

- Design Features

- Principle of operation

- Making homemade Buleryan

- Drawing for assembling the furnace, materials and tools

- First steps

- Making an afterburner

- We complete the assembly of the base

- Making a chimney

- Final stage

Buleryan solid fuel stoves continue to gain popularity. They are characterized by high efficiency and the ability to quickly warm up rooms. Consumers can purchase ready-made units or try to assemble a Buleryan stove with their own hands. There is nothing complicated about this, because in its design it resembles the most ordinary pyrolysis potbelly stove. The only differences are in the housing, which is equipped with efficient tubular convectors.

Design Features

Assembling a Buleryan stove with your own hands is really very simple. But only for those who know how to handle tools and iron, and also have an understanding of the structure of solid fuel stoves. There are no particular structural difficulties here, but you need to remember that working with iron requires special care - it is not as malleable as wood. But as a final result, you should get an excellent heating unit that will delight you with quick warm-up and long-lasting combustion.

The Buleryan stove, assembled with your own hands, is a traditional solid fuel unit that runs on wood using a gas generator circuit. That is, the wood burns here, releasing pyrolysis products, which are sent to the afterburning chamber and burn there with secondary air. Combustion products go up the chimney, escaping into the atmosphere and partially falling out in the form of condensation - we will tell you how to get rid of it with just one movement of the hand.

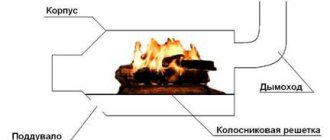

Our Buleryan potbelly stove consists of the following parts:

- The main combustion chamber is spacious, roomy, the firewood lies directly on the convection pipes;

- Afterburner chamber - located above the combustion chamber, it is a perforated or solid sheet of iron that separates the upper quarter of the entire internal volume;

- Tubular convector - a set of curved pipes, most of the area of which is in direct contact with firewood, coals and combustion gases;

- A loading door with a small blind flap through which firewood is loaded into the Buleryan oven, made by hand. It also allows you to regulate the access of oxygen to the combustion chamber;

- A chimney with a slide damper and a chamber for collecting condensate - ensures the removal of combustion products and collects condensed combustion products for their subsequent removal.

Also in the design of the furnace there are tubes (injectors) for supplying secondary air - it is needed in the afterburning chamber for combustion of pyrolysis.

It was the simplicity of the Buleryan convection oven (also called the Breneran oven) that gave it its well-deserved popularity.

Operating rules

A homemade long-burning boiler, Buleryan, has a simple structure, but to achieve better results in terms of efficiency and long service life, you must adhere to some simple rules:

- Only dry fuel is used for combustion: briquettes, pellets, firewood, wood chips, etc.

- After operating the stove, the ash should not be completely removed each time; its layer protects the bottom from burning.

- Do not use wet firewood; plaque forms on the walls of the boiler and chimney, which reduces the efficiency indicator.

- To achieve maximum efficiency indicators, you need to close the damper throttle and the blower door to enhance the convection process.

Principle of operation

It is this unusual appearance that makes the Buleryan stove so extremely effective.

In order for you to experience all the delights of the Buleryan stove, we will tell you about its operating principle. We have already said that the pyrolysis reaction is used here. The burning of wood with a limited supply of oxygen looks like smoldering with the release of pyrolysis products. Entering the upper afterburning chamber, they ignite and burn, releasing a large amount of heat - combustion is supported by small injectors built into two convection pipes.

The blower and gate valve are responsible for maintaining the pyrolysis reaction. They are responsible for limiting the supply of oxygen and slowly removing combustion products. Thanks to this, the heat is almost completely sent to the heated rooms.

Many users are wondering whether a potbelly stove or Buleryan is better and what to give preference to. The efficiency of a potbelly stove, including a pyrolysis one, will be lower. To increase efficiency, it will be necessary to retrofit it with additions that create convection. But the potbelly stove still won’t be able to catch up with the Buleryan stove, no matter how hard you try. Buleryan is the most efficient and advanced stove today, with an extremely lightweight design.

Buleryan during mining is not a solid fuel stove. But you can assemble it yourself, using a similar scheme, by building a homemade burner into the loading door (we wrote about assembling such a burner in our reviews). It is also possible to purchase a ready-made burner. But such a scheme will be justified only if you have access to inexpensive supplies of this simple fuel.

Water bullers

Buleryan water boiler

Is it possible to adapt such a really good stove for water heating? It is possible, and water buleryans are produced by industry. But, looking at this (see figure), one inevitably recalls the statement of an outstanding Soviet submarine builder about the project of a giant nuclear-powered missile submarine of the Akula type, also known as the Typhoon: “This is a vivid example of the victory of technology over common sense.”

The authors of “water bullers” forget, or ignore, based on market demands, that buleryan was originally created as an air furnace. And the heat capacity of water is 800 times greater than that of air. In order for the exhaust gases to transfer their heat to it, they need to be entangled in the labyrinth of the water heating register. But in a buleryan with its side-heated heat exchanger, this is basically impossible, otherwise you will have to create a completely different furnace.

The only way to heat water for heating with a boiler is to intensify the combustion in the firebox. But at the same time, as discussed above, the efficiency will inevitably drop.

However, it is very simple to adapt any Buleryan for hot water supply. Let's say we have 2 batteries with 4 pipes each, and the whole furnace is 10 kW. As can be seen in the thermal image (see the figure on the left below), even with intensive heating for rapid heating, the air temperature in the battery nozzles is not higher than 160 degrees.

Thermal image of the Buleryan stove

Now let’s put the most ordinary metal hoses on two pipes and connect them to the pipes passing through the DHW boiler. Horizontally, vertically – it doesn’t matter. 2.5 kW will go into the water. If an 80-100 liter tank is insulated with 40-50 mm thick EPS, then in half an hour the water in it will heat up to 60-70 degrees, and then this temperature will be maintained. For comparison: 3.5-5 kW heating elements are installed in household 100-liter electric boilers.

This system is also good because without any automation, boiling of water is absolutely excluded. Let's remember the school physics problem for the especially (without quotes) gifted and savvy: how to heat water exactly to 100 degrees without letting it boil?

The answer is: take a pan and put wooden blocks in it for thermal insulation. Place another, smaller pan on them. Pour water into both pans and put on fire. The water in the outer pan will boil, but its temperature will not rise above 100 degrees, because... the heat of the fire will be used to transfer the latent heat of evaporation of water to the water.

The water in the inner pan will also heat up to 100 degrees, but there will be no temperature difference between it and the outside, and the heat required to evaporate the water will not be able to transfer to the inner pan. The water in it will heat up to exactly 100 degrees without any signs of boiling.

In the case of a “water buller”, in air with a temperature of 140 degrees there is no reserve of heat to ensure boiling of water. When its temperature approaches 100 degrees, the air in the heat exchanger will rapidly cool, the temperature gradient will approach 0, and the water will never boil.

Making homemade Buleryan

This furnace has a wide range of applications. It is suitable for heating residential buildings, country houses and utility rooms. If you need a good stove for the garage, Buleryan will be a worthy solution - fast-acting and effective. Literally 15-20 minutes after ignition, a comfortable and warm atmosphere will be established in your garage.

The Buleryan stove, made by yourself, will delight you with its ease of operation and unpretentiousness to fuel. However, the logs for it must be dry (preferably no higher than 15% humidity), otherwise the pyrolysis reaction will occur with difficulty. Increased humidity of firewood also leads to a large amount of condensation. Let's see how to assemble it with your own hands.

Installation site requirements

If you make a mistake when installing such a heating device, this may cause damage to the building or a fire. Therefore, you must follow the instructions carefully. It is best to install the buleryan lower. This is how the oven heats the cold air, which enters through the bottom of the tubes located at the edges of the body.

It is prohibited to place the stove on a wood or plywood floor, as this violates fire safety regulations.

Buleryan is most often installed in private homes. A private house is a secluded place for the whole family. Warmth, comfort, fresh air in the yard are the key to a healthy and good atmosphere in the family. Some people like to spend time passively, but residents of houses usually choose a more active position.

The vegetable garden is the main place of activity for all residents of private houses. When harvesting every year, you must remember that the soils are depleted and must be fertilized periodically. You can buy fertile soil price in the Agrogrunt online store. It is fully prepared for planting both in greenhouses and in open areas.

Installation of equipment on the floor can only be carried out if there is a certificate of use. The stove must have fireproof legs that cannot be removed. It is also necessary to have a catch pocket in front of the ash pan.

As a base, you can use a steel sheet with a height of at least 1.5 mm. It should be on an asbestos pad. The optimal radius is about 1.2 m in relation to the doors. The stand should protrude 25-30 cm along the edges of the stove. Place the back side of the buleryan 1-1.5 m from the wall. If you first cover it with fire-resistant plaster, you can reduce the distance to 0.8 m.

Drawing for assembling the furnace, materials and tools

We present to you a drawing with dimensions that we will use as a guide when assembling the Buleryan stove with our own hands.

Detailed diagram of the Buleryan stove.

During the development process, you can make your own changes if they seem necessary to you. For example, nothing prevents you from fitting a ready-made door here, so as not to have to worry about assembling it yourself. Along with the drawing you will need the following tools:

- Hydraulic or manual pipe bender;

- Welding machine;

- Angle grinder for cutting steel;

- Grinding disc for correcting welds.

Next we prepare the materials:

- Pipe with a diameter of 60 mm for the manufacture of a convector (heater) - the drawing shows pipes with a diameter of 50 mm, but then the convection will not be so intense. In this case, we advise you to focus on the area of the heated room;

- Sheet steel with a thickness of at least 4 mm - from this we will cut intermediate plates, as well as the front and rear walls;

- Chimney pipe with a diameter of 100-130 mm;

- Metal pipe to create a choke (blower) on the loading door;

- Hinges for the loading door, as well as a secure lock with a secure handle for opening and closing it;

- Materials for creating a slide damper - another handle with a small piece of sheet steel to block the chimney clearance;

- Metal pipe with a diameter of 15 mm for injection pipes.

An asbestos cord is also useful to seal the door. Don't forget to choose good electrodes for welding metal parts.

You will also need thick cardboard, from which it is very convenient to make patterns for later cutting out metal - this way you will save time and nerves. By the way, some craftsmen make Buleryan stoves with their own hands from a square pipe. It turns out a little scary, but overall it works.

About heating a private house

Okay, the reader may say, but you need to warm up! Yes, but stove heating is used mainly in private households, and there water heating is pure prejudice, a stereotype of “centralized” thinking. For the efficiency of a central thermal power plant, indeed, the heat capacity of the coolant is of paramount importance, otherwise it will cool down before it reaches subscribers.

What about in a private house? What, should we run a line from the kitchen or furnace around the entire area to the living room/bedroom? Isn’t it easier to disperse the warm air through the rooms, which the bubbler gives, as they say, from the top? Judge for yourself:

- Air ducts can be made with a simple tool from cheap materials: tin, plasterboard, plywood, just cardboard, but pipes are expensive, they need to be bent, boiled, soldered.

- No registers, expansion tank, fittings, or automation are needed.

- You can forget about fistulas and leaks once and for all.

- Ductwork with fans and louvers does not require a design or permit. It is enough to calculate for yourself which section should go into which room.

- Heat transfer into the walls (and this is up to 15% of heat loss through water) is zero; here the poor thermal conductivity of the air works to our advantage.

- Install adjustable blinds at the exits - here you have easy, quick temperature control in rooms. It’s better not to compare it with setting up water heating.

- If you place the exit blinds on the walls farthest from the window above the floor, then the air will give up its heat to the room by the time it gets to where it can heat the street. And everyone knows how batteries in window sills increase the entropy of the Universe.

- The same technique will also provide a warm floor without any additional costs or work.

- The walls are straight, there are no deformities in sight - design the interior as you please.

Video: Buleryan and garage heating

First steps

First, we need to make the frame of our entire Buleryan stove - it is an interweaving of curved pipes that form an air heater and the future firebox. Use a pipe bender and bend them to a radius of 225 mm. The length of each pipe is 120 cm - this is more than enough. The pipes are welded together with metal strips to create a stable base for our stove. There should be no holes on the sides, otherwise smoke will penetrate into the heated rooms.

Technical points

The chimney can be placed inside or outside the building. External installation is used when installing a heating unit in a ready-made house. This technique involves venting the chimney through the wall of the room.

Experts include the following advantages of this technique:

Design and operating features of the unit.

- significant space savings;

- quick and easy installation;

- there is no need to remove this unit through the interfloor ceiling and roof of the building.

The disadvantages include:

- presence of a horizontal section;

- carrying out thermal insulation work;

- unoriginal appearance.

The internal placement of the chimney involves the passage of its vertical sections of stainless pipe inside the building. In this case, the chimney is installed near the internal walls and partitions. It is discharged through the interfloor covering and the roof using special pipes and roof penetrations. To do this, you will need the following tools: hammer, hammer drill, drills, hammer.

Due to the low weight of stainless steel structures, installation work is carried out without installing an additional foundation. The difficulties of such a procedure include ensuring its safe passage through the ceiling, including a safe and sealed chimney exit through the roof.

https://1popechi.ru/youtu.be/utZ2NxxLm84

Experts include the following advantages of this technique:

- presence of good traction;

- providing additional heat from the chimney itself.

The disadvantages of the internal placement of the chimney include:

- carrying out complex installation;

- occupied usable area;

- ensuring the tightness of the chimney passage through the roof;

- provision of additional fire safety measures when the chimney passes through the interfloor ceiling and roof.

Making an afterburner

The next stage of making a Buleryan stove with your own hands is creating an afterburner chamber. To do this, you need to take sheet iron and make partitions from it with recesses for the air heat exchanger.

Next, we weld the partitions from the inside to the pipes so as to separate about a quarter of the internal volume (or as indicated in the drawing). Please note that these partitions go to the rear wall, and they do not touch the front wall (secondary air injectors are welded into the first two pipes).

Pyrolysis products will end up here. And the combustion products will go to the back wall, where the chimney of the Buleryan stove is located.

Let's move on and check all the welds - they should ensure the tightness of the entire structure.

Bullers without pipes

Professor Innokenty Nikolaevich Butakov (not to be confused with Alexander Vladimirovich Butakov, also a professor, but a lawyer) actually invented the Buleryan back in the 20s of the last century, attaching an afterburner to the top of a potbelly stove with a heat shield. Nowadays, stoves such as “Butakov”, “Professor Butakov”, “Student” in modern design (see figure) successfully compete with Buleryans on the domestic market. Their technical characteristics and principle of operation are similar, like identical twins, but making “Butakov” yourself is much easier, as can be seen from the figure.

Convection oven Butakov

We complete the assembly of the base

Now we need to cut two pieces from sheet iron that form the back and front walls of the Buleryan stove. But don’t rush to weld them - they still need work. In the back wall we make a hole for the chimney, focusing on the diameter of the chimney pipe.

After this, we move on to the front wall - here we need to make a hole for the insert. The door is made from a piece of pipe with a diameter of 350 mm. And here you will have to suffer.

The whole point is that the door should tightly close the inlet of the firebox. We weld a part of a pipe with a diameter of 350 mm to the front wall of our Buleryan stove, which we assemble with our own hands - it protrudes slightly, as in the picture. Next, we make the door itself - it will be double-layered, the inner part will go inside the loading hole, and the outer part will cover it from the outside.

We make a hole in the door of the Buleryan stove for the choke. Its dimensions are indicated in our drawing. It is a small section of pipe in which a damper rotates on a metal loop - it should completely block the gap. To prevent the loop from rotating under its own weight, we press it with a spring. It is also necessary to make a reliable lock to secure the loading door.

Fiddling with doors, throttles and dampers when assembling a Buleryan stove with your own hands is the most problematic, because working with small parts is always more difficult than working with large ones. But if your hands grow from there, you will cope with the task relatively quickly.

A little history

In Canada, forests are felled not in blocks, but selectively, and teams of lumberjacks lead a nomadic lifestyle. Logging is carried out more in the cold season, when the vegetation does not vegetate, life in the forest comes to a standstill and the damage to forest biocenoses from logging is minimal.

The climate in the Canadian taiga is even harsher than the Siberian one, and even with a 4-hour shift, workers froze into icicles. Comfort and civilization in general in the wilderness is zero. Therefore, lumberjacks needed a heating stove that could be carried with them without cluttering the body, and could be carried into a residential trailer by hand. And this stove was supposed to heat up a housing of 20-30 cubic meters in a maximum of 20 minutes. Waste fuel: branches, wood chips. The firebox is large enough to fit pieces of thick, gnarled logs into it. Operating time from one fill of fuel is at least 8 hours. Where to get up at night and heat it up, when during the day your bones have been broken to the point of pain.

Depending on the weather and season, the heating power must be adjusted. The adjustment should be simple so that it can be performed by an untrained person or after a one-time introductory briefing.

At the same time, the stove had to be inexpensive and quite technologically advanced. Electronics requiring power supply, and automation in general, were excluded: the slightest breakdown in the taiga could cost the lives of an entire brigade. The use of expensive and special equipment-requiring special alloys was also excluded: Buleryan had to be available for production in any mechanical repair shop.

Additional requirements were put forward for operational safety. Firstly, the formation of waste must be excluded under any combustion mode and under any regulations of regulatory authorities. Secondly, the body temperature of the stove should not exceed 60-70 degrees, so that if you accidentally bump into it while asleep and “out of a hangover,” you will not get burned to the point of losing your ability to work. They say that Canadian lumberjacks know how to distill moonshine from pine cones. It's called sterno.

Making a chimney

If you think that the chimney for the Buleryan stove, assembled with your own hands, is a piece of pipe, then you are completely wrong. We will make a T-shaped chimney with a slide damper for our stove.

Unlike a throttle, the gap here is not completely blocked, but only 3/4 of the maximum diameter of the chimney - this is exactly the damper that will need to be cut out and installed in the outlet (horizontal) pipe.

We weld a vertical section to the horizontal chimney pipe of the Buleryan stove. Smoke will escape through its upper part, and condensation will accumulate in the lower part (it will definitely happen). To make getting rid of it more convenient, weld a ball valve to the bottom. Just one movement of the hand - and all the accumulated condensate will drain into a previously placed container, as we promised earlier.

About pipe batteries

With a thermal power of up to 20-25 kW, the pipes in the batteries are made in the form of technologically simple semicircles, as on the left in Fig. In this case, the diameter of the pipes is 60-100 mm, and their number is 3-4 per battery.

Buleryan stoves of low and high power

With a higher thermal power, it is impossible to increase the diameter of the pipes proportionally; due to the low thermal conductivity of the air, the efficiency will decrease. It is necessary to increase the “tube” of the batteries. But with batteries of 6 or more pipes, the efficiency also drops; this is where the square-cube law applies to fuel loading.

Up to a power of 100-120 kW, designers get out of the situation by making pipes curved in the form of sinusoidal arcs and slightly inclined with the top of the arc downward. In this case, the firebox acquires a drop-shaped or ovoid cross-section, as on the right in Fig. With even greater power, computer modeling of the Buleryan with optimization is required, and a positive result of long, complex and expensive work is not guaranteed.

Heat distribution

To keep the whole house equally warm, you need to place the buleryan in the central room. There should be a short path from it to other rooms.

There are several options for the role of the stove in heating:

- Auxiliary. You won't be able to give up gas heating, but you will be able to reduce consumption. If your region does not have very cold winters, you can completely heat your home with a stove. To do this, set the gas to the minimum setting so that condensation does not accumulate on the windows.

- Basics. Only for small houses with no more than 5 rooms. If the heated area of your home is more than 70 m2, additional measures will be required to allow air to be distributed throughout the home.

How to remove condensation ↑

There is another known problem that is associated with the operation of Breneran. Its smoke pipe, as you know, is located on the wall of the stove at the back. A tee is mounted here - a chimney pipe is connected to it. At the bottom there is a glass plug for condensate. This design does not have the required tightness. And this is a problem, because condensation inevitably and steadily enters the air, which is not good. Some craftsmen adapt their own solutions, making sealed containers to collect condensate, while others remove it from the room using pipe devices. In short, we have to innovate as best we can, because the market, alas, does not offer ready-made solutions.

Best models

Original Bullerjan models are capable of efficiently heating rooms from 100 to 1200 cubic meters:

- Klondike HB-100, capable of heating rooms up to 100 cubic meters. Price – from 10.5 thousand rubles;

- Klondike HB-150, designed for heating rooms up to 150 sq.m. Price – from 13.5 thousand rubles;

- Klondike NV-200 stoves provide heating of 200 cubic meters of air. Price – from 14 thousand rubles;

- Klondike HB-400 on one tab for 8-10 hours and heats a room with a volume of up to 400 sq.m. Price – from 19.3 thousand rubles;

- Klondike HB-500 effectively heats a room with a volume of up to 500 sq.m. within 10 hours. Price – from 23.7 thousand rubles.

HB-100 is ideal for garages up to 100 sq.m.