If a well is dug at a summer cottage as a source of water, then today you can easily organize a small water supply system. To do this, you will have to buy a pump for the well, install it and run a pipe from the device to the house. And already inside, at your discretion, install piping throughout the premises to plumbing fixtures. This is the simplest type of plumbing. The main thing is to choose the right pump, because there is a huge range of them on the market.

What is the difference between a surface pump and a submersible pump?

But if you look at these units from a purely operational position, they can be divided into two groups: submersible and surface. The first ones are lowered into the well shaft and immersed in water. Hence, in principle, their name.

Scheme of operation of a submersible pump.

The latter are placed at the edge of the hydraulic structure, and a pipe or hose is lowered into the water, at the end of which a mesh filter is installed.

Scheme of operation of a surface pump.

There are surface models of small mass, which are sometimes lowered into the well itself, where a platform or float is installed. The pump is attached to this device. This is done specifically in order to operate the device in winter. After all, the temperature inside the well is positive even in severe frosts. Let’s consider the two designated positions separately.

Comparative characteristics of three types of devices

Determining the model of the necessary equipment without special knowledge is not easy. After all, it is not always clear what will be better for certain operating conditions; a surface or submersible pump will cope with your task faster. A table with technical and operational characteristics will help you quickly navigate and see the main differences between a submersible pump and a surface pump.

| Submersible device | Surface aggregate | Semi-submersible pump | |

| Device mobility | It can be quickly moved, assembled independently and installed on any base. | Can be easily mounted on a frame. Borey pumps are already installed on a lightweight trolley. | Special fastenings for installation and lifting mechanisms are required. |

| Pump maintainability | Practically absent. If the device breaks down, you need to wait a long time for special spare parts. The pump must be removed from the liquid. All this significantly increases time costs. | Good. If a breakdown occurs, there is no need to dismantle the device. Russian-made parts and seals are excellent for repairs. | High. In case of breakdowns, dismantling the device is not required. Domestic parts are suitable for repairs. |

| Reliability of units | Not tall. The motor as well as the mechanical seals experience chemical wear. As a result, liquid may enter the motor. | Sufficient. Requires only standard maintenance from the manufacturer or service organizations. Operation according to the manufacturer's instructions significantly increases the service life of the pumps. | High. Important elements do not come into contact with water; the likelihood of liquid getting into the motor is zero. |

| Immersion/suction depth | Not limited. | Within 8–9 meters. If a long horizontal pipe is used or the sampling point is located at a considerable distance, then the indicator is reduced. | Up to 6 m, deeper submersible pumps are made to order. |

| Max. innings | No more than 7000 m3/h. | Up to 1200 m3/h | No more than 90,000 m3/h. |

| Power consumption | ≤ 0.75 kW | ≥ 0.9 kW | 245 W |

| Noise | Less than superficial. | More than submersible. | Moderate. |

You can ask questions and get detailed characteristics of each type of equipment from our specialist. To do this, leave a question in the comments or write to the chat. We'll be happy to help!

Surface pump

It should be noted right away that these pumps have a small water intake height. It does not exceed 8 m. That is, if the water level inside the trunk is within 6 m, then this is a normal indicator for this type of pumping equipment. Because the water intake pipe with the filter must descend into the water layer itself by at least 2 m. And it should not reach 1 m to the bottom.

If the depth of the water layer is below the specified parameters, and the choice fell on a submersible pump for the well, then you can change the depth of water intake by installing a special device in the pipe (hose) network - an ejector. But this device reduces productivity. Therefore, you will have to choose: either water intake from the depths, or a large water supply.

Pros and cons of surface pumps

The biggest advantage of this type of pumping equipment is that it is located on the surface. It is visible, easy to look after, maintain and, if necessary, repair. But this is also a minus. Open to “all winds”, it is exposed to the negative effects of precipitation and temperature changes.

If you operate the pump only in the summer, then there are fewer problems. A small canopy solves them completely. If the water supply continues to work in winter, then the unit will have to be moved to an insulated or heated room: a basement, barn, utility room inside the house.

And it would seem that the problem is small. But here you will have to carry out a number of additional measures:

- Dig a trench for the pipe, in which the latter must be laid with insulation.

- Install the pump, preparing a solid and level base for it. For example, a reinforced concrete slab or metal structure.

The surface pump also has other negative qualities. Firstly, it makes noise during operation. And if you install it inside the house, the degree of comfortable living is sharply reduced. Secondly, if the installation is carried out incorrectly, the device begins to vibrate, which will affect the quality of the joint between it and the pipe.

Diagram of an insulated surface pump.

Types of surface pumps

Based on purely design features, surface pumps are divided into two groups: centrifugal and vortex. They differ from each other only in the impeller, or more precisely, in the shape of the blades of this part.

Centrifugal blades are located perpendicular to the axis. Due to this, water is pumped under the action of centrifugal force, which pushes it towards the walls of the housing where the outlet pipe is located. It is the centrifugal force that creates the pressure of the water column.

In vortex models, the impeller blades are located at an angle with a slight bend. When rotating inside the chamber, a vortex is created, which pushes the liquid in a spiral, driving it into the outlet pipe.

Attention! All surface pumps used for water intake from wells and boreholes are self-priming units. That is, it is necessary to pour a little water into them during the first start so that it fills the chamber where the impeller is located. When the latter rotates, a vacuum is formed inside the chamber, which draws water from the source.

Criterias of choice

The main criterion is engine power. For a family of 3–5 people, you need to buy a unit capable of producing 3–5 cubic meters of water.

The depth of the well or well is taken into account. If the water is always at approximately the same level, you can take the station. But if the well becomes empty in hot weather, you will need a submersible pump operating at a depth of up to 50 m, so as not to be left without water in the summer.

The height of the water column is important when the equipment is located far from home. The indicator is calculated using a formula, only then they go to select a device with the given parameters.

Submersible pump

In those hydraulic structures where the water is below 8 m, it is necessary to install a submersible pump for the well. It is lowered into the water column, so the unit itself is made of materials that are not subject to rust. In this case, the device is assembled with the maximum degree of tightness.

But it should be noted that submersible pumps are much inferior to deep pumps in terms of the depth of water intake. In this regard, there is such a difference. Submersible can pump water from a maximum depth of 30 m, deep ones 200-300 m.

Submersible units are presented on the market in a wide range of models. They differ from each other in the method of pumping water and the design of the drive. In the second case, these are rod and rodless devices. The first are pumps in which the electric motor is located on the surface of the hydraulic structure, and the water intake chamber is inside the water layer. Both parts are connected to each other by a rod - a metal rod that transmits rotating moment from the motor to the impeller.

Rod models are not household, so rodless pumps are used in the country. That is, those in which the electric motor and the water intake chamber are located in the same housing.

There is another classification of submersible pumps, in which the distinguishing feature is the working element. Here the devices are divided into two groups: centrifugal and vibration.

In what situations should you choose a pump?

If the store does not have a pumping station with the required characteristics or operating principle, or its manufacturer does not inspire confidence, choose a pump. If these are German, Italian or Danish manufacturers, there is a chance that the units will last at least 7 years without repair.

If in the summer the whole family moves to a fully equipped dacha, where it is planned to include plumbing fixtures and kitchen appliances, you will need a pump, which can be dismantled and hidden in the house with the onset of autumn.

If the house already has a stationary device, and the pump is needed for street work or a garden located near a reservoir, there is no need to overpay for the station.

In addition to drinking water, you can pump sewage or drain lowlands. For such work, drainage or fecal pumps with a completely different operating principle are suitable.

If the pressure of the pumping station located in the house is not enough to water the area, you need a second copy - more powerful, which will work from a different water intake. Dismantling and moving the station is long and inconvenient. A small pump weighs much less.

Centrifugal pumps

Here, as in the case of surface ones, the main working body is the impeller. It is located in the lower part of the pump housing after the suction pipe. Rotating at high speed, the impeller draws in water, throwing it towards the walls. This is where high pressure is created, which pushes the liquid up through the chamber where the electric motor is located. No water gets into the motor itself; the chamber is sealed. But this is how cooling occurs.

Advantages

- Minimum amount of noise during operation

- Longer service life than other submersible pumps

- Sand that can get in with water is not scary

- Can work at very great depths and easily transports water through a pipeline system

Flaws

- Complex design, therefore maintenance and repair are expensive

- High price of equipment

- If the liquid medium is dirty, the service life will be significantly reduced

Video review of the Aquarius submersible centrifugal pump

Important characteristics of the water source:

A well is distinguished from a well by its depth and shape. Water from the well can be taken manually using a bucket, this is inconvenient and time-consuming. The well is narrower and deeper, and is not designed for the use of a bucket.

Wells and manholes have the following key parameters on which the choice of pump depends:

- static water level - the distance to the surface at rest, that is, when the water has not been pumped out for at least 2-3 hours;

- dynamic level - the distance to the surface of the water during intensive use. This is the minimum level that can be achieved if water is withdrawn without stopping. During pumping, the water level decreases faster than it can be restored to a static value. Recovery occurs within a few hours. However, in some artesian wells the static and dynamic levels practically coincide;

- depth – distance from the surface to the bottom of the well;

- pipe diameter;

- flow rate - the maximum volume of water that can be pumped at one time.

It is recommended to select a pumping installation only after obtaining accurate information about the source.

But first, let's figure out how well pumps differ from pumping stations?

Vibrating Submersible Pumps

This well pump is very different from the previous one. Firstly, there is no impeller in its design. It is replaced by a rubber membrane (diaphragm), which moves up and down, creating a pressure difference in the chambers it separates.

The membrane itself cannot vibrate like that. To do this, an electromagnet is installed inside the pump, connected to a piston. It is the latter that pushes the membrane. The vibration speed of the electromagnet, and accordingly the piston and membrane, is 100 vibrations per second. This is enough to create a pressure difference.

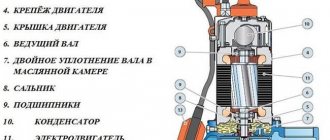

Submersible vibration pump device.

Many manufacturers make pumps of this type. One of the most popular is the “Malysh” brand. Its suction valve is located at the top. The outlet pipe is also located nearby. That is, it works according to this principle:

And since this all happens quickly with a frequency of 100 times per second, the amount of water supplied outside will be sufficient to provide the house with domestic needs. The performance of the pump in this case will depend on the volume of the suction chamber. The larger it is, the more water it can hold.

Installation diagram of a submersible vibration pump

It should be noted that the electromagnet is located at the very bottom of the housing, in a sealed chamber filled with a special compound. The latter provides protection against leaks. In addition, the water surrounding the housing cools the electromagnet.

Today, manufacturers equip submersible vibration pumps with float switches. With their help, the water level in the well is controlled. As soon as it reaches a critical value, the float drops to its lowest point, disconnecting the unit from power. The well begins to fill with water, the float floats up, and the lever attached to it raises the limit switch, turning on the power to the device.

Advantages and disadvantages

The vibration submersible pump has a whole list of disadvantages that we should briefly talk about:

Among the advantages, it is worth highlighting the low price, the ability to maintain high pressure in the pipeline, simplicity of design and high level of reliability.

Pros and cons of pumping stations

Their positive aspects are the following factors:

- Ease of installation and maintenance during equipment operation;

- Possibility of automatic operation of the equipment, the unit turns on as the water level in the storage tank (hydraulic accumulator) decreases, turns off when filling;

- The cost is 10-20% lower than similar submersible devices.

But the equipment also has enough disadvantages:

- It makes a loud sound during operation; when installed inside the house, noise insulation costs will not be unnecessary;

- When installing in a separate shaft before frost approaches, you need to take care of its insulation;

- When taking liquid from a depth exceeding 8 meters, an ejector is required;

- The electric motor is cooled by the pumped water, so it can turn off due to overheating protection;

- Replaceable filters must be used to ensure that the efficiency of the equipment does not decrease.

Pumps with hydraulic accumulators - why are they used?

What is a hydraulic accumulator? This is a tank, inside of which there is a rubber bulb filled with air under pressure. It connects to the pump, the latter pumps water into it.

Scheme of operation of the hydraulic accumulator.

That is, water entering the hydraulic accumulator compresses the bulb, which itself presses on the water. It turns out that the liquid inside the tank is under pressure. This is done to ensure that water is always under pressure inside the autonomous water supply network. That is, I opened the tap, and it flowed, as usual, under pressure. And this is with the pump turned off.

As soon as the water pressure in the accumulator drops to a critical point, the well pump turns on, which again pumps it into the tank. Such tanks are sold today in all hardware stores. They are blue in color and come in different sizes. The latter is selected based on the water consumption in the house and the number of plumbing fixtures.

Attention! Today, manufacturers offer surface pumps with hydraulic accumulators as part of a surface unit. They are called pumping stations. Submersible models do not have such design features. You will have to purchase a separate tank for them.

What is better to choose

When deciding which pump or pumping station is better, it is necessary to take into account both the technical characteristics of the units and consumer needs. This way two important points must be balanced. The first is the level of water consumption at a specific facility during the day. The second is the water intake performance of the installation. That is, the equipment must cope with the user's needs to the maximum extent.

The next point is the state of the water in the source. This refers to its level. In a well, unlike a well, the indicator can change. That is, when using a pump, the depth is not terrible, but its immersion must be monitored. Experts recommend focusing on the following recommendations for choosing devices for pumping drinking water:

- up to 8 meters - surface type pump for a well or pumping station;

- 8-21 m – pump plus injection device;

- 10-81 – submersible device or powerful deep installation.

Example of a deep well pump Source prom.st

Selection by technical characteristics

All pumps have only two main parameters: performance and pressure. They are accepted when the task of choice is faced.

Productivity depends on how many people live in the house. After all, one person consumes up to 200 liters of water per day. For example, if there are 4 residents, then 200x4 = 800 l. Accordingly, the pump performance should not be less.

But this value does not take into account watering plants in the garden and vegetable garden of a summer cottage. Here you will have to add 3-4 liters per 1 m2 of watered area. True, everything will depend on the watering season. Therefore, experienced summer residents recommend installing two pumps in the well: one for domestic needs, the second for irrigation.

Now, as for the pressure. This parameter means that the well pump must pump water with a certain constant pressure, raising the liquid to a certain height. The latter depends on the depth of the hydraulic structure. In this case, it is necessary to take into account that the pressure (pressure) loss is in the following ratio: at 10 m of depth, the pressure drops by 1 m.

But that's not all. Part of the water supply is a horizontally laid pipe. So there is also a drop in pressure, but only slightly. The ratio per 10 m length is 0.2 m pressure. If the well is a short distance from the building, this indicator will not greatly affect the performance of the device. But if the distance is significant, then the pressure will drop significantly.

Why Borey?

We produce industrial pumps of various capacities, which makes them accessible to both large and small companies.

Our equipment is fully adapted to work in Russian conditions.

We not only produce pumping units, but are also ready to offer spare parts and components for similar models. In addition, you can rent a motor pump if we are talking about single contract work. Our specialists are ready to select the necessary pump for any task of draining a site or draining groundwater.

What to pay extra attention to when choosing a pump for a well

An important criterion is the price of the equipment. Today it is not a quality benchmark. There are a huge number of well pumps on the market, especially from domestic manufacturers, which perform their functions perfectly because they are adapted to Russian operating conditions. Their cost is much lower than that of foreign analogues.

It is necessary to pay attention to whether the pumps are equipped with an automation system. It is this that makes it possible to extend the life of the units. Although its presence means an increase in price. Therefore, manufacturers offer simple systems such as the float switch indicated above. Or more complex ones in the form of blocks that are responsible for dry running and overheating of the electric motor.

And the third criterion is the material from which the devices are made. It is better to give preference to stainless steel rather than plastic

Features of the use of submersible equipment

Such installations operate under the surface of the water; the permissible depth is indicated in the characteristics. An example is the GRUNDFOS systems. The downside is the variety of designs and diameters. And the well must exactly match the size of the pump, which complicates the selection of equipment. In addition, you will need to equip the well with neck protection. Installing and removing the device yourself is problematic because it requires a whole range of work.

Advantages of HDPE pipes over steel analogues

The pipes that connect the submersible equipment to the surface centrifugal pump deserve special attention.

When choosing material for this area, you need to consider the following:

- Pipes must be easy to transport.

- Their installation should not be particularly difficult.

- You need to choose a material that is durable and abrasion-resistant.

- Products must be elastic and not lose functional characteristics when deformed.

- The absence of toxic substances in the material and safety when transporting clean water are the main conditions.

All of the above criteria can be found when studying the characteristics of low-density polyethylene pipes. In addition, they are not subject to corrosion like steel water pipes. On average, the operational period of HDPE pipes is about half a century.

When deciding to purchase pipes made of low-density polyethylene to supply water from a well, you should give preference to high-quality products with appropriate markings. The pipes must be marked with the type of product, outer diameter, wall thickness, nominal and maximum pressure.

Pipes that are planned to be used to lay a water supply from a water source must be labeled “drinking.” For use in a summer cottage, pipes with a diameter of 32 mm and a wall thickness of 2.4 mm are suitable. Pipes for pumping water have a blue stripe (for information, pipes for transporting gas have a yellow stripe).

Thermal insulation of external water supply

The location of the pipes below the freezing level of the ground allows you to avoid measures to insulate the main line. However, not all areas can boast a sufficiently low groundwater level, which completely eliminates the possibility of digging deep trenches. In this case, the solution to the problem is to lay pipes at a shallow depth and properly insulate the external water supply.

Relatively recently, the only way was to wrap external communication pipes with thermal insulation material and plastic film to protect them from water.

Modern methods, materials and technologies make the insulation process simpler and significantly increase the efficiency of heat conservation. Modern methods of insulation include enclosing pipes in a hard polystyrene foam shell at one of the production stages.

A heating cable stretched along the main and attached to the pipe is the most effective option for a water pipe with a diameter of 32 mm. However, this option has one significant drawback - the need to connect to the power supply network. This problem is not of particular importance for owners of suburban housing who constantly live off-grid. In case of a power outage, they have an alternative option - a generator running on gas, gasoline or diesel fuel.

It is recommended to perform independent installation and connection of a pumping station only if you have experience in installing, replacing or repairing pumping equipment. A simple home craftsman without the necessary knowledge and skills should resort to the help of a professional craftsman or, as a last resort, carry out the work under his supervision.