In the absence of a central water supply line in private homes, water is drawn from a well or well using surface or submersible electric pumps. If the water level in the water intake source from the top of the earth is more than 9 meters (the operating limit of surface pumping equipment), a submersible pump is selected for water supply, which allows lifting liquid from great depths (200 meters in domestic artesian wells).

Models of submersible electric pumps from domestic and foreign manufacturers for collecting water from wells and wells are widely represented on the construction market. They are equally successfully used to work in any deep sources; some types for wells are structurally different from their borehole counterparts.

Fig.1 Deep pumps for wells

What is a submersible well pump, its advantages and scope of application

Unlike wells, wells have a low depth of up to 15 meters if concrete rings are used in their construction, and also a depth of up to 25 meters or more in the designs of plastic wells with walls made of high-strength corrugated polyethylene pipes (Corsis).

For water intake from wells with a distance of the water surface from the surface of less than 9 meters, surface water pumps or pumping stations of a centrifugal operating principle with automation are widely used, which are characterized by budgetary cost and ease of operation. If the static level of the water supply source is more than 9 meters, or it drops to a greater depth during water intake (dynamic level), it is necessary to use a submersible electric pump in the well.

The main difference between submersible types and surface ones is the water cooling of the electric motor; if the unit is not immersed in liquid, it quickly fails (the winding burns out) when there is no built-in overheating protection or automatic shutdown when idling.

The main parameter of submersible types is high pressure characteristics, which allow water to be supplied over long distances when the source is located remotely from the house.

Centrifugal electric pumps specially designed for water intake from wells are equipped with float switches that prevent their operation when the water level in the source drops to certain limits.

Fig. 2 Scheme of home water supply with water intake from a well using a Gilex electric pump

A submersible well pump for individual water supply systems for domestic use can perform the following functions:

- Collect water to supply a private home from depths of more than 9 meters, ensuring supply volumes within a wide range.

- To supply water to the surface for irrigation, it can be used to fill barrels, tanks and various containers with water, which, after warming up in the air, is used to water the garden. If drip irrigation is organized on the site, you can use a submersible electric pump to fill a large-volume tank and turn it off with a float switch installed on the walls of the tank when filling.

- A submersible well pump can be used to fill swimming pools, artificial reservoirs, ponds or pump water out of them.

- In critical situations when underground basements, garages, cellars and other premises are flooded during the spring flood, you can use an electric pump to pump out the water if it is not very dirty, or install a homemade filter on its suction pipe to prevent dirt particles from entering the working mechanism.

- Using a submersible electric pump, you can immediately fill the heating system with coolant directly from a well or barrel, with a pressure of about 1.5 bar necessary for its operation, or use it to fill an expansion tank located in the attic of the house.

- Some types of submersible pumps (vibrating, screw) are effectively used to combat siltation of water supplies - to do this, the unit is released into the well a short distance from the bottom and the turbid liquid is pumped out with its help.

Wells collect water from shallow water layers (overflow), and are designed to use mechanical means of supply using a gate and a bucket. If you plan to draw water from the site to constantly supply a residential building using an electric pump, it is much easier and cheaper to drill a shallow Abyssinian well (many people drill it with their own hands) and use it as a water source. The use of a well is justified only if there is no or frequent loss of electricity on the site.

Rice. 3 Submersible pump for water supply to a house from a well at the source

Overheating and dry running protection

If the vibration pump runs idle (without liquid), it will quickly overheat and burn out. To avoid this, use a thermal relay - it opens the circuit when it overheats and closes it again after cooling.

If shutdowns occur frequently, then it is necessary to clear the pipe and pipes of debris. But under no circumstances should you open the case yourself; there is a high risk of damaging the seal and completely disabling the mechanism.

Hose rings protect the housing from additional mechanical damage Source stroychik.ru 0 0 0

A plastic sensor monitors the water level; as soon as the lower threshold is reached, the electrical circuit opens Source outillage-online.fr

What are the types and types of submersible well pumps?

Before water intake from wells, household submersible electric pumps are used, which differ from industrial units in more modest technical characteristics. Since the depth of most wells does not exceed 15 meters, the pressure parameters are designed mainly to supply liquid in the horizontal direction and maintain the required pressure in the system.

The volume of supply by suction devices depends on their operating principle; most units are capable of delivering the required amount of water to a family of at least 3 people; the upper limit of household devices can reach the water supply of several families in a two- or three-story house.

Vibrating

Vibration pumps have been produced by domestic manufacturers since Soviet times, and since then they have not undergone significant design changes. All domestic models, their Chinese and Belarusian counterparts have absolutely the same design and technical characteristics.

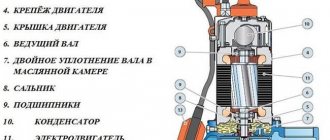

The exception is the Ukrainian Aquarius with a two-valve system (there are also three-valve models) and higher pumping volumes. The vibration pump is placed vertically in the water source, suspended by a cable; its main components are:

- Frame. Consists of two halves connected to each other with bolts and nuts. In the upper body part there is an outlet pipe and eyelets for fastening a metal cable; if a device with an upper water intake is used, it contains inlet holes and a central screw for fastening the check valve. With a standard bottom fluid intake, the suction ports and valve are located at the bottom end of the lower half of the housing. To seal the connection between the two body parts, an elastic gasket is placed between them, which simultaneously reduces the resulting vibrations.

- Electrical part. In the vibration model, the main actuator is an electromagnetic coil with a copper wire winding. It is assembled from steel plates (electrical steel), installed in the upper or lower half of the body (depending on the location of the water intake holes) and filled with epoxy compound; a massive steel anchor with a rod at the end is tightly adjacent to its ends.

- Pump part. The main element of the suction part of the electric pump is a check valve on the cover and an elastic piston located on the armature rod; the working chamber is separated from the electrical part by an elastic damper membrane.

Rice. 4 Submersible pump for water supply vibration

The principle of operation of the vibration pump is quite simple: when an alternating voltage with a frequency of 50 hertz is applied to the winding of the coil, the armature located at a small distance from its ends begins to perform reciprocating movements with the same frequency. Vibrations through the rod are transmitted to the piston disk, which, during the return movement, draws liquid into the working chamber through the inlet holes and an open check valve.

During forward movement, the liquid inside the working chamber pushes the elastic disk of the check valve in the same direction, and it closes the intake holes. Since the outlet of water to the source is blocked, it enters the outlet pipe under pressure and is supplied outside.

Vibrating devices are designed for pumping small volumes of liquid; in terms of performance, these are pumps for irrigation and household needs, their maximum limit is 1.5 cubic meters per hour with a liquid lifting height (pressure) of up to 80 meters.

Vibration pumps are mainly used in everyday life for the following household needs - watering, filling an expansion tank or pouring coolant into heating systems, filling and pumping water from swimming pools and artificial ponds. Thanks to their design, pumps can work with contaminated liquids with small particles; they are often used for drainage work, draining gray waste into sewers, cleaning well and borehole sources from silting, and pumping wells.

The main disadvantage of vibration pumps follows from their name - vibrations of the housing during prolonged use in water intake sources lead to silting and faster destruction of concrete rings of wells, and violation of the tightness of the casing in wells. Vibration pumps have a coefficient of efficiency (efficiency) of 30 - 40%, an average service life of about 5 years, although they can work longer after repair or replacement of the housing mounting bolts with stainless ones before commissioning.

This type of electric pumps has a good price (20 - 25 USD) and is produced by a wide range of domestic and foreign manufacturers; the popular brands Malysh, Rucheek, Aquarius, Zubr, Vikhr are widely represented on the construction market.

Rice. 5 Submersible pump for water supply, vibrating - device

Screw

Screw (screw) units operate on the same principle as a household meat grinder - liquid is supplied to the pressure pipe using screw blades or a serpentine auger. Industrial units have a simple design - a working screw is attached to the shaft of an electric motor placed in a sealed housing, drawing liquid through the end inlet hole, and water is pushed out through a side pipe in the housing.

Household samples are structurally arranged a little differently - water intake occurs through a mesh diaphragm placed on the side wall of the electric pump, while the electric motor is located at the bottom, and the shaft with a fixed auger is in the upper half of the housing.

The water entering the screw auger, as it rotates, is pushed into the outlet pipe located in the top cover of the device; there are also lugs by which the electric pump is suspended when lowered into the well. In many household models, the screw does not adhere to the walls of the case, but is located in a plastic cage, rotating inside which it pushes out water.

The efficiency of household screw pumps reaches up to 50%, they can work with viscous liquids (oil pumping in the oil and gas industry), therefore, for domestic use, many believe that screw models can pump water and sand without damage. This opinion is incorrect, sand scratches the screw and the plastic cage, leading to their rapid wear; if necessary, you can purchase a rubber cage that is less susceptible to abrasion in the retail chain.

There are not many screw models on the construction market from leading foreign manufacturers of pumping equipment; the most widely represented are domestic brands Belamos, Vikhr, Unipump ECO VINT, and imported ones Aquatica, Werk, Vodotok, Sprut. Screw types of household electric pumps can supply water with a volume of up to 15 cubic meters per hour. at a pressure of about 100 m.

How much does it cost to lay a winter water supply system per 1 linear meter?

installs water supply in:

— Moscow and Moscow region.

— St. Petersburg and Leningrad region.

The cost of laying a pipeline that can be used in winter depends on the region: in St. Petersburg the price of this service is 1000 rubles per linear meter, in Moscow - 1300 per linear meter. The difference in price is due to the difference in labor costs.

We dig water mains mostly by hand. This is cheaper for the client, and besides, the equipment does not damage the site. This is especially important if it is already landscaped.

Vortex

In vortex submersible pumps, water is taken in and expelled using a single impeller with blades, which is located in the upper part of a vertically suspended housing next to the outlet pipe. To reduce hydraulic losses, the design provides for a very small distance between the side edge of the vortex wheel disk and the working chamber - this makes it impossible for vortex devices to operate in an environment with sand particles.

A special feature of vortex types used in industry is the ability to pump liquids with a high content of gases; the efficiency of household units rarely exceeds 50%.

Vortex-type devices have good pressure characteristics (the height of liquid rise reaches 100 m) and average pumping volumes (about 5 m3/h).

Although vortex electric pumps are rarely used in everyday life, there are Belamos TM, Sprut, Vikhr, NeoClima, Pedrollo Davis models on the market.

Rice. 7 Vortex submersible pump for water supply - design and appearance

Centrifugal

Centrifugal types are the undisputed leaders in household use among other types of electric pumps; almost all surface models have a centrifugal operating principle; they are part of household pumping stations.

Centrifugal devices have achieved such widespread popularity due to the following properties:

- Their efficiency factor (efficiency) is the highest of all analogues; in large-sized industrial units it reaches 92%, in household models it reaches 70%.

- Structurally, the working chamber is designed in such a way that the liquid enters the central part of the centrifugal wheel and is pushed out through the side pipe. This makes it possible to make multi-stage centrifugal devices in which the ejected liquid is fed to the axle of the next wheel, which further increases its pressure. Thanks to the use of several centrifugal wheels with separate working chambers (stages), it is possible to obtain pressure parameters in the system that are several times higher than those of other pumping equipment (in household models, the pressure does not exceed 300 m).

- Centrifugal types are capable of pumping liquid in large volumes at high pressure; for domestic use, this figure rarely exceeds 20 cubic meters per hour.

- Centrifugal-type units are less susceptible to the effects of small sand particles on the working mechanism; they are widely used in sand wells, choosing a model to work with the appropriate particle size specified in the passport.

- A significant advantage of centrifugal types is their high level of automation; the world's leading manufacturers of pumping equipment (Grundfos, Pedrollo, Speroni, Dab) equip their devices with units with frequency control of the impeller rotation speed. This innovation allows not only to significantly save energy when operating the electric pump (up to 50%), but also to significantly increase its service life.

If we list all the manufacturers of centrifugal pumps that present their products on the domestic market, the list will be quite lengthy, so we will limit ourselves to the leading global manufacturers listed above. Among the domestic brands, the most famous are Aquarius, Gilex Vodomet, Vikhr, Belamos, Caliber, Unipump.

Rice. 8 Centrifugal submersible pumps - design and materials using the example of Grundfos SBA

How to choose the right one and what to look for when buying a pump

When deciding which pump is best to install in a well, the following factors must be taken into account:

- Price. The cost of equipment is the main indicator when choosing a suitable model; the minimum price for Grundfos wells is 300 USD; domestic Gilex with similar parameters can be purchased several times cheaper (80 USD).

- Material of manufacture. Basically, well pump bodies are made of stainless steel or high-strength polymers, and their impellers are also made of high-quality plastic - this reduces the weight of the device. When purchasing, you should pay attention to the Chinese manufacturer - the fact is that in their products, the Chinese use sputtered aluminum - a mix - instead of copper windings. This leads to the fact that during operation, due to the higher resistance of aluminum, losses in the winding increase, heating of the housing increases, and efficiency decreases. Some Russian manufacturers are closely associated with Chinese companies; for example, equipment under the Vikhr brand is manufactured at Chinese enterprises and has an aluminum electric motor winding.

- Purpose of the pump. The main areas of use of pumping equipment in a suburban area are provision of permanent or temporary water supply and irrigation. When used for gardening purposes, it is better to choose a vibration electric pump - its cost is lower than all analogues, it is unpretentious to the quality of the working fluid, and temporary use for a short period will not cause significant damage to the well or well. In some cases, vibration models can be used for temporary water supply, but for permanent water supply, special submersible centrifugal pumps with a float switch for wells are used.

- Source parameters. The model must be selected in accordance with the flow rate of the source - the supply volume of the pumping unit should not exceed the natural replenishment of the reservoir with water. All models of submersible electric pumps indicate the depth of immersion under the water surface. Since the submersible pump is located in a well or borehole at a minimum distance of about 0.5 m from the bottom, the thickness of the water layer above it should not exceed the parameter specified in the technical passport.

- Pressure The pressure indicator for direct water supply is determined by calculation using simple formulas; it depends on the length of the horizontal and vertical sections of the water main and losses in the line; the part that goes to maintaining pressure in the system is also taken into account.

- Particle size. All models of submersible pumps are designed to draw clean drinking water; if the liquid contains fine sand, a modification is selected that allows operation with a certain particle size specified in the technical data sheet.

Fig.9 Submersible pump for water supply Gilex - technical characteristics

- Temperature. The manufacturer supplies the domestic market with installations for pumping water with standard parameters: working fluid temperature up to +35 C., ambient temperature up to +40 C. - it is clear that such a water temperature cannot be in a natural water supply source and any pumping equipment is suitable for these parameters.

- Model. For wells, special models of pumps with a float switch have been developed that turn off the power supply to the device when the water level in the well drops below the suction filter or at a certain mark (the depth of operation of the float can be adjusted). This device duplicates the dry running relay in the system, which can be installed at the request of the consumer. Well models from leading manufacturers (Grundfos) are equipped with a float water intake - this allows you to supply clean, unclouded water from the surface of the source, and not from the bottom area with a high content of sand particles, and there is no need to clean the water at home from sand.

- Other options. Less important factors that you should pay attention to when choosing a device are the length of the power cord, the presence of a built-in check valve, weight and overall dimensions, the length of the warranty period, the availability and location of the nearest technical service centers.

Electric pumps designed for drawing water from wells should not be used in wells, even if they meet the parameters. The fact is that well pumps are designed to draw water from shallow depths (their maximum pressure rarely exceeds 50 meters), and if you use a well pump with high pressure characteristics at low pressure, thereby increasing the volume of water supply, its efficiency will be unacceptably low.

Features of winter water supply

To install a winter water supply you need:

- The source of water is a well or borehole, where water is available all year round. Before purchasing a plot, be sure to check this point with sellers or neighbors.

- Drain (preservation) system. With its help, water is drained from the entire system during conservation. For example, if you are planning to leave home for a long time. If the trip is planned to be short - for example, for the New Year holidays - then more and more often the water supply is not preserved, but the temperature in the room is left above zero - +5-+10°C.

Why do you need to drain water from pipes?

We all know that water turns into ice at low temperatures. At the same time, the ice expands and begins to put pressure on the walls of the pipes from the inside. They become deformed and connections begin to leak. In addition, the pipes will have to be heated until the ice completely melts. That is, you won’t be able to use the running water for several hours (or even days), and this is inconvenient.

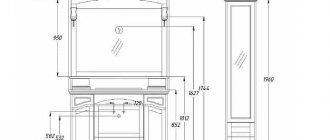

Submersible pump for water supply - connection diagram

The well pump is lowered into the source strictly in its center to avoid the float touching the walls; it is tied to a rigid transverse pipe, angle, or metal profile inserted into the punched hole in the walls along with the pressure pipe of the water supply. The second option - hanging the pump on a transverse support located on top of the well walls - is simpler, but to connect to a water supply line located underground, you will still have to go down into the well. The calculated point for installing the pump from the surface of the earth is the depth of soil freezing in winter; the entire water supply system is deepened to a distance of about 0.5 below this mark.

To supply water to the house, pipes made of low-density polyethylene (HDPE), specially designed for use in water supply systems, are usually used. The pressure pipe is connected to the electric pump with a plastic fitting; its further connection to the water supply line is also made using an adapter corner plastic coupling; when supplied to the house using HDPE fittings, the line is easily connected to the internal water supply system.

Pumping equipment is connected according to a standard scheme using a pressure switch, pressure gauge, hydraulic accumulator (allows you to maintain pressure in the system), using special fitting plumbing fixtures (five-inlet fitting). Unlike downhole types, the dry-running relay can be excluded from the control automation - the submersible unit is protected from winding burnout by a float switch.

Rice. 10 Connection diagrams for a well electric pump

Cleaning a heavily silted well

It is difficult to clean such wells with a household drainage pump: it quickly becomes clogged with sand and cannot cope with the job. Professional equipment would have been more useful here, but the craftsmen found a way out.

First, preliminary work is carried out. Need to find:

- barrel with a volume of 200-300 l;

- surface pump or budget vibration pump;

- sand filter.

The container is installed near the well.

First, clean water is pumped out so that as little of it as possible remains, about 1 m. It is sent through a hose beyond the boundaries of the site or found another use. Now you can start cleaning the source from sludge.

The technology is as follows:

- A drainage pump pumps muddy water into a barrel.

- From there it is fed under pressure back into the well. But it is already clean - the filter does not allow sand to pass through.

- The sand is washed away by a strong jet, the drainage pump captures the muddy liquid and delivers it upward.

The process goes on almost continuously. They stop only to lift the device and rinse with clean water any deposits in the water channel, which can lead to equipment failure.

Submersible pump calculation

When purchasing a submersible pump, its main indicators are the lift height and the volume of pumped liquid. The volume of water that the pump must pump is associated with two parameters - the flow rate of the source and the needs of the consumer. The volumetric parameters of the pump should not exceed the speed of the natural inflow of water in the well, otherwise the dynamic level will drop to critical and the float switch will turn off the pump, stopping the water supply. You need to understand that too much excess of water supplied by the pump before consumption is ineffective and economically unprofitable - the operation of a powerful device will lead to frequent water hammer, a decrease in the time between on-off cycles and the service life of the device, and unnecessary waste of electricity.

Calculation of a well pump for irrigation

It is rare that anyone uses expensive submersible well electric pumps designed to ensure a constant water supply only for irrigation; they usually choose budget vibrating units that have the same characteristics. Since the choice is limited, it makes no sense to calculate the parameters of a vibration pump when choosing a suitable model if their characteristics are the same.

Upper and lower water intake, difference and features of use

The main mechanism of action has been described previously. But on the market you can find models with upper and lower water intake. The only difference between them is the location of the suction valves. The upper intake is holes with valves on top, the lower intake is at the bottom of the vibration pump.

The design of a vibrating submersible pump with a bottom water intake is more appropriate to use for flushing fresh wells. The lower location of the valves allows you to suck in more water and debris and pump out more efficiently.

In wells and reservoirs, it is more effective to use models with an upper fence; the holes are 30 cm from the ground and do not trap debris and sand. This design feature significantly extends the service life of the mechanism.

“Malysh” pumps have models with upper and lower intake Source horodom.cx.ua

Calculation of a well pump for water supply at home

When calculating a well electric pump for constant water supply to an individual house, the main results of the calculations obtained are the height of the water column and the volume of pumped liquid. The initial data is the estimated or calculated volumes of water consumption using tables or using online calculators.

Consumption volume

There are two main methods for calculating the volume of water consumed: the first is to calculate the water consumption of each resident, the second is to calculate the total water consumption of plumbing fixtures. In both cases, tables or online calculators are used. The indicator of average daily water consumption by one person is more significant in calculating the ability of a source to maintain a static water level with constant water consumption with a certain volume.

The main task of the electric pump is to sufficiently fill the main with water while simultaneously turning on the maximum number of plumbing fixtures that can be used by residents, taking into account working household appliances (washing machines and dishwashers).

Therefore, when tables are used to calculate and add up the water consumption of all plumbing fixtures, this is not entirely true - for convenience, an individual residential building may contain several sanitary units, an excessive number of showers and bathtubs, which the owners rarely use. If this plumbing is taken into account when calculating total water consumption, the result will be excessive capacity parameters of the purchased pump - this will lead to excessive energy consumption and unjustified financial costs.

To calculate the maximum volume of water consumption per unit of time for a family of three living in an individual residential building, you can use an online calculator or make simple calculations manually. If we take the three sources with the highest water consumption and add a small volume from household appliances (the tables indicate values that should not be taken into account - water consumption by appliances does not occur on a constant basis), then as a result of simple manual calculations we obtain the peak water consumption per family of 3 people - 2.5 cubic meters/hour. The indicator was obtained using the most water-intensive plumbing equipment - the bathroom; in the absence of such amenities, a water supply of 2 cubic meters per hour is quite sufficient.

Rice. 13 Table of water consumption for plumbing fixtures

If we use some online calculators, we will get slightly more water consumption by entering the data of the dishwasher, washing machine, toilet, bidet, which are expressed in units corresponding to other plumbing fixtures, and according to the compilers, consume water continuously.

Pressure

When calculating the pressure, the formula given above for organizing irrigation is used (H = Hv + Ng + Np + Nd), calculations are carried out using the same method, the main problem is calculating the hydraulic resistance, more precisely, that part of the pressure that will be needed to overcome areas of pipe resistance.

There are also tables taking into account the resistance of fittings, taps, bends, tees and other parts of plumbing fittings. Using online calculators, you can calculate the hydraulic resistance of a pipeline of a given length, depending on the material of its manufacture and diameter. If the line is made of hydraulically smooth HDPE pipes with a diameter of more than 1 inch and assembled in accordance with standard specifications, its hydraulic resistance can be taken equal to 20% of the entire length of the line.

For example, let’s calculate the pressure characteristics of a submersible pump installed at a depth of 10 m, the distance to the house is 50 meters, the length of the line in the house is 50 meters, the lift height from the basement to the second floor is 5 meters, the highest pressure in the system is 3 bar. Similar to the method discussed above, we get the result:

H = 10 + (5 + 5) + 5 + 115 x 20 / 100 + 30 = 78 (m.)

Based on the pressure characteristics graph, we determine a suitable electric pump; choosing a Gilex brand device to solve the tasks will not suit us (a supply volume of 2.5 m3/h corresponds to 41.6 l/m3), so we are not considering it. The corresponding model SQ-2-85 is in the Grundfos equipment line (Fig. 14, point 5), with which you can make a water supply system with the calculated parameters.

Rice. 14 Grundfos pressure characteristics

Rating of the TOP 15 best models

| Place | Name | Price |

| TOP 5 best pumps for wells up to 5 meters | ||

| 1 | UNIPUMP BAVLENETS 2 BV-024-40-U5. 20 M | 4 000 ₽ |

| 2 | KARCHER BP 1 Barrel | 5 000 ₽ |

| 3 | Grundfos SBA 3-45 A | 25 000 ₽ |

| 4 | DELTA Hydrounit-3 | 2 000 ₽ |

| 5 | PATRIOT VP-16B | 1 500 ₽ |

| TOP 5 best pumps for wells up to 10 meters | ||

| 1 | Grundfos SBA 3-35 A | 23 000 ₽ |

| 2 | Aquario ASP-25-100WA | 11 000 ₽ |

| 3 | DAB DIVERTRON 1200 M | 21 000 ₽ |

| 4 | GARDENA 5500-3 Classic | 12 000 ₽ |

| 5 | UNIPUMP ECO FLOAT-3 | 10 000 ₽ |

| TOP 5 best pumps for wells from 15 meters | ||

| 1 | GILEKS Water cannon PROF 55/75 A | 12 000 ₽ |

| 2 | UNIPUMP BAVLENETS-M BV 0.12-40U5. 15m | 2 000 ₽ |

| 3 | GILEKS Water cannon PROF 55/50 A df | 11 000 ₽ |

| 4 | GILEX Water cannon 55/75 A df | 12 000 ₽ |

| 5 | UNIPUMP BAVLENETS BV 0.12-40-U5. 25 m | 2 000 ₽ |

Recommendations from experts

When organizing the installation of a water supply system with your own hands, the most important task is the correct choice of pumping equipment, which should not only perform the assigned tasks, but also work for a long time without breakdowns. When selecting it, the following expert recommendations may be useful:

- The leaders in performance are centrifugal types, which are optimally used for wells - all others have lower efficiency, lead to silting of the source (vibration-type pumps), can only work with clean water (vortex pumps), and their analogues also do not have a float switch.

- To draw water from wells, you should use only well units with low pressure characteristics and high pumping volumes - in this case, their efficiency will be maximum, unlike well pumps not intended for use in wells.

- Choosing the right manufacturer is the main task when purchasing a pump. Almost all Chinese models are supplied with aluminum windings, which have high resistance and large energy losses, leading to increased heating - this factor reduces the efficiency of the electric pump. It is better not to use domestic and Chinese budget models from unknown manufacturers - some of them have an engine shaft oil seal, which was obsolete half a century ago and can allow sand and water to pass through at high pressure (all modern models have a mechanical seal with ceramic, graphite rings or similar materials) .

- If, after calculations, a model from a Chinese manufacturer is considered, then it should be taken into account that its compliance with the parameters specified in the technical data sheet differs by 20% downwards - therefore, you should choose a model with a similar margin in terms of technical characteristics.

- To obtain the optimal price-quality ratio, it is better to use pumps from an Italian manufacturer (Pedrollo, Speroni, Dab) - they are cheaper than Grundfos, made of high-quality materials, and have high technical parameters.

- Pumps with a float intake from the upper water layer will help improve the quality of drinking water sucked from a well - in this case, the liquid will be free of sand, which is found in large quantities in the bottom area, and the installation of additional filters will not be necessary.

Fig. 15 Well pumps for home water supply from leading manufacturers Grundfos, Pedrollo, Dab, Karcher

When choosing a device for water intake from a well, you should use centrifugal models with a float switch, specifically designed for these purposes - they are most suitable in terms of technical characteristics. The popular domestic unit Gilex Vodomet can be purchased for a price of about 100 USD; imported analogues will cost 3-5 times more.

Operating principle

All functionality is based on the movement of water due to the difference in internal and external pressure.

Operating principle step by step:

- After electricity is supplied, the coil (1) is magnetized and attracts the vibrator (2).

- The piston bends , a vacuum is created, the valves (8) open, water enters the suction chamber (4).

- The polarity of the current changes and the magnetization disappears , the shock absorber (5) tilts the vibrator back into place. The valves (8) close. Water flows into the discharge chamber (3).

- Re-magnetization occurs, the piston bends and water enters the outlet channel (11)

The pump operates on alternating current, the polarity changes 100 times in 1 second. As a result of the vibrations, the pump vibrates strongly, which is why it is called “vibrating”.

The vibration pump operates in 2 cycles Source moikolodets.ru