Today there are many different methods and devices for heating a room. Gas-powered equipment stands out among them. Its operation requires a cheaper type of fuel, and modern developments allow it to operate for a long time and without interruption. But here, as in any system, unforeseen circumstances can occur. Therefore, many people wonder what to do if the gas boiler is blown out by the wind.

Cause of failures

In order for the fight against the problem to be effective, it is necessary to study the possible causes. These include:

- trees close to the house;

- downdraft winds;

- a duct or chimney that is too low.

Another common reason for rapid decay is also common. This occurs in a room with a cold chimney. We are talking about cottages that suffered a long-term system shutdown. This difficulty most often occurs when trying to start heating in a country house or cottage. During the first tests, the gas boiler goes out in strong and weak winds. Even the slightest impulse becomes an obstacle to warming up.

To get out of this situation, you need to start heating the channel from the weakest operating mode, periodically increasing the power. The exhaust gas will escape into the atmosphere. When the optimal temperature is reached, a properly designed unit will function smoothly even with the strongest wind currents.

Troubleshooting

It is very important to detect malfunctions in the operation of a gas boiler in time and eliminate them in time to avoid accidents. The main sign of a gas boiler malfunction is very weak combustion of the burner or its complete absence

There can be many reasons for this manifestation.

Malfunction of the internal mechanism of the gas boiler

Another sign is that the burner is difficult or impossible to light. This manifestation can occur due to filter clogging, broken electronic contacts, or violation of the electrode gap. If the filter can be cleaned yourself, then if other problems arise, a professional approach is required.

Other signs of a gas boiler breakdown include noise and spontaneous shutdown of the device, nozzle whistling, and others.

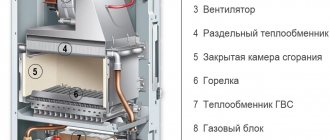

Influence of equipment parameters on the possibility of flame extinction

Among the most common causes of failures are:

- An incorrectly calculated ventilation system is a distance of less than 50 cm above a flat roof, 500 mm above a ridge (or parapet), etc. The errors are detailed in the image below.

- Violation of construction and technical requirements during installation - low-quality materials, non-compliance with SNiP.

To make adjustments, it is recommended to ask a professional if you have any questions.

There are often times when the reverse action valve comes into operation. This is caused by gusty winds that exert too much pressure from the street. Sensitive automation reacts quickly and the valve closes. Next, the fuel supply to the boiler is stopped and its operation stops completely. Regular repetitions force us to think through possible options for reconstruction. First, it is recommended to check whether the correct chimney height is selected. The difference between the highest point of the house and the canal should be at least 0.5 m. The diameter is calculated based on the parameters of the installed unit.

You can also improve draft by regularly cleaning the ventilation. This is explained by the need for a constant flow of air into the installation. If a small amount of oxygen enters it, then the intensity of gas combustion becomes weaker. As a result, the flame may go out completely.

How to deal with backdraft: main mistakes and misconceptions

Of course, extending the chimney is the simplest and most affordable option. It is important to take into account that the method cannot guarantee a positive outcome. In this case, you can mount a deflector on the top.

If this method is not effective, then the third option should be used. The pipe design needs to be reconsidered. The fewer angles and sharp turns there are, the higher the conductivity of heated air flows as they move through the pipes. This is a rather labor-intensive but effective technique.

Even significant extension and installation of the deflector does not fundamentally change the system. Strong and gusty air currents may cause the equipment to stop operating again.

Solutions if the boiler goes out in the wind

Changes in gas pressure do not occur very often. Moreover, the differences are so insignificant that they are unlikely to be the reason. Don't immediately look for a hardware problem. The design of the latest models of gas boilers is quite simple, but at the same time reliable.

The most commonly found deficiencies are:

- Formation of an ice clod that blocks the ventilation channel. It prevents the exchange of air particles that enables combustion. The appearance of ice is a natural phenomenon, because in addition to spent fuel, condensate penetrates into the pipes. It just freezes on the walls.

- Backdraft, which occurs due to strong and gusty winds, as well as during a sudden change in movement. It moves along the entire length of the structure and eventually reaches the boiler. The flame in it goes out.

Ice is an artificial obstacle, and its formation means that the structure was assembled incorrectly. To correct errors, you must immediately stop using the oven and contact a specialist. They will clean the pipe, install a condensate drain (umbrella, canopy) or a walk-through collector.

Backdraft is a great danger due to the extinguishing of the burner flame. The system in the latest generation boiler equipment is more modern. The automatic system quickly operates and stops supplying gas to the firebox. However, combustion products first enter the heating installation, thereby polluting the chamber. During subsequent switching on, they will penetrate inside. The reason for this phenomenon is most often the insufficient length of the chimney. To correct the situation you need:

- Structural changes.

- Installation of the stabilizer (thrust regulator).

- Installation of the deflector.

- Connection of (rotary) gate.

We make sure that the burner goes out due to the wind

In order not to waste efforts in vain, which sometimes happens in practice, it is worthwhile to accurately determine the reasons for the burner extinguishing, since this could be an automatic error, low gas pressure, or difficulties with the removal of combustion products. Characteristic signs of wind blowing are:

- visual changes in the shape and direction of the flame caused by the wind;

- characteristic sound of a vortex in the combustion chamber;

- the burner does not turn off without reason in calm weather, be sure to check this item!

A common cause of fading is low gas pressure in the line or incorrect flame height. At low gas pressure, the flame decreases and drops critically low to the burner. To prevent it from burning out, the automation turns off the burner and the boiler goes out. The normal flame height is considered to be 2-4 cm. If the burner flame height is less, it is necessary to adjust it, but we do not recommend doing this yourself; for this it is better to call the gas service.

It is also necessary to check the tightness of the connections and the entire chimney structure. First of all, if there is an inspection hole in the chimney, pay attention to it: it must be closed and hermetically sealed. If this is not possible, it is worth purchasing a modern sealed plug.

What to do if a strong wind blows out a gas boiler

If you determine that the problem is a consequence of air penetrating inside the chimney, then it is first recommended to check how well the entire structure is designed and constructed.

Next, you should make sure that the system as a whole is in good condition. Check the chimney design with the actual installation. Check if everything meets the stated requirements. If even minor inconsistencies are found, this is a reason to rebuild the chimney or modify it.

There are a number of criteria, compliance with which guarantees the uninterrupted and full operation of the heating installation:

- diameter, length, which are indicated in the project must comply with the approved documentation;

- the inside of the chimney is clean so that air can flow freely;

- the structural element of the chimney passing outside the room must be insulated.

If violations in the design were previously identified, then increasing the length is a simple and frequently used solution. The method is considered if there are some obstacles near the house (another building, trees) that interfere with the free movement of wind flows, forming turbulence.

When choosing this method, you should check if there are any other problems. Otherwise, the action performed will be inappropriate. Moreover, new difficulties may arise.

Installation of a draft regulator to “break” it

The most popular method is installation inside the chimney:

- 50 cm above the point of connection to the chimney;

- or in the same plane as it.

It should be noted that the practical application of this option must be discussed with specialists. If the structure is installed incorrectly, the rupture may in the future cause emergency situations or gas accumulation in the home.

Diameter change

There are a number of rules that will tell you what and how to do to prevent the gas boiler from blowing out:

- providing the recommended amount of oxygen;

- increasing the temperature for better fuel combustion.

Using a sandwich chimney (there is another pipe inside, but of a smaller diameter with insulation) significantly reduces heat loss, and the walls will warm up faster. The size of the sandwich directly depends on the size of the smoke exhaust channel. For help with calculations, you can contact specialists who will select the right product and assist in installation.

Before starting repair work, it is recommended to first check the condition of the ventilation system.

general information

If the gas installation stops functioning normally, constantly goes out and does not provide the required heat, it is possible that air currents have appeared in the combustion chamber, interfering with combustion.

In most cases, this phenomenon is accompanied by a corresponding alarm sign on the installation display, but this is not yet a reason to panic.

It is important for the boiler owner to carry out diagnostics in time, as well as determine the cause of the breakdown. Otherwise, the problem will begin to progress and the equipment will no longer produce the specified thermal potential. It is also possible that the temperature inside the building will decrease or the heating system will defrost, which will entail more serious consequences.

List of the main reasons for the boiler to blow out:

- Formation of an ice edge at important nodes.

- Loss of tightness of connections.

- Low gas pressure.

In this video we will look at how to eliminate the causes of boiler blowing:

In addition, there may be other reasons:

- Unstable operation of the electrical network.

- Malfunctions in the smoke shaft.

- Damage to automation.

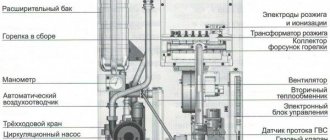

What type of gas boiler to choose so that the flame does not blow out

7-9 m/s is the minimum required speed that will ensure uninterrupted combustion. The hot air moves in a spiral. As a new turn passes, the speed increases, and the highest is recorded at the exit.

To date, units have been created in which natural advancement is replaced by forced one. Such models are called turbocharged, and their design assumes the presence of a closed compartment for the firebox, as well as two blower fans. One introduces air inside, and the other removes exhaust gases from the system. Even the wind itself does not affect combustion. If the fire goes out, this indicates a breakdown of one of the fans.

The wick burns weakly

Gas boiler wick

The wick burns weakly for two reasons: either it is clogged and needs to be cleaned, or you have weak inlet pressure. If you have a home controller, be sure to check its settings. You may need to increase the inlet pressure, as it constantly fluctuates due to the fact that gas consumption is different in different periods.

Accordingly, during the heating season, when gas boilers are operating, gas consumption is higher and the inlet pressure also drops. And the regulator, as far as you know, maintains a certain differential between the inlet pressure and the outlet pressure. Accordingly, this differential also drops, because of this your wick may burn weaker. Check the regulator setting and also clean the wick.

Rules for constructing a chimney to prevent blowing out

In order not to look for a solution in the future to the question of what to do if a gas boiler goes out due to the wind, study the building codes and rules:

- the location of the upper edge is determined relative to the distance from the roof ridge;

- it must be installed closer to the center, raising it above the maximum level by about 50 cm;

- the total length of the horizontal surfaces of the pipe should not be more than 3 m;

- a maximum of 2 angles/rotations can be introduced into the design;

- choose a rounded cross-section, since a square section reduces the traction force;

- Follow the rule of high-quality thermal insulation.

If the problem of blowing has not been neutralized, then many recommend installing specialized devices:

- deflector that prevents reverse draft;

- a regulator that helps increase the intensity of fuel movement;

- a cone installed on the edge of the chimney will prevent the fire from going out.

The final factor is competently and accurately calculated system add-ons. It is best to leave the adjustment to a professional.

What mistakes in chimney design could lead to this?

High-quality ventilation of the heating system and removal of combustion products depend on the chimney, so it is important to avoid mistakes during its design. The problem may lie either in an incorrectly calculated pipe cross-section that does not correspond to the power of the heater, or in a low-set pipe. The gases coming out of modern low-temperature boilers do not have enough energy to evaporate on their own, so when using such structures it is better to buy electric smoke exhausters. These fans are installed on the roof, prevent blowing, and also ensure the free exit of all fuel combustion products.

Also, an error may have been made when insulating the pipe. Because of this, the descendants of the wind, together with the low outside temperature, prevent the normal removal of smoke and the operation of the heater, respectively. Often, partial insulation of the pipe in the upper part helps solve the problem. But it is advisable to initially ask the engineers to take care of high-quality thermal insulation of the chimney in the boiler room, so that you do not have similar problems in the future. After all, some insulation options can only be applied at the creation stage.

Another source of problems can be a strong vertical deviation of the ventilation ducts. According to GOST, for wood and gas heaters the maximum deviation is 30 degrees and in an area of no more than 1 meter. If the boiler is equipped with a direct firebox, then you should take care of a direct-flow chimney; in this case, there are no other solutions. Otherwise, there may be a fire hazard, from which good traction will save you. There are no such clear rules with a gas boiler, but it is better not to exceed the restrictions described above. Take into account all these common design mistakes if you are just thinking about an autonomous heat source. After all, learning from the mistakes of others is much better than learning from your own.

Deflector installation

This is a special aerodynamic design that solves the problem of reverse thrust.

A standard type device is installed inside the chimney; the design must include a socket. The purpose of the umbrella is to prevent precipitation from entering the chimney. When it is improved with a wind protection ring, which reduces the “wind effect” and eliminates the possibility of the draft tipping over.

A standard deflector, as a rule, does not prevent blowing. Today, devices with a more complex structure are increasingly being installed. The most popular varieties are highlighted:

- smoke tooth;

- Grigorovich deflector;

- waller;

- spherical or rotating.

It should be noted that the first 2 types are the most popular in construction.

The simplest equipment increases the efficiency of the chimney by at least 15-25%; when installing a more complex design, the efficiency increases even higher.

Frequently asked questions and answers

The boiler is blown out by the wind, and the smell of gas is felt in the room. What is this connected with?

There may be a problem with the backdraft valve, but to be sure, it is necessary to inspect the injector burner. Attention should also be paid to control sensors. Over time, they fail and are not able to timely generate a signal about the need for an emergency shutdown of gas supply to the system, which is where the characteristic odor appears.

The flame in the burner is unstable, fluctuates with any gust of wind, often goes out, the temperature in the system drops, what could be the problem?

This is characterized by an increase in natural cravings, for which there are many reasons. It is necessary to inspect the hood, as well as the burner itself, adjusting the gas supply and flame height. If there are strong gusts of wind outside and the problem with attenuation occurs very often, a deflector is installed on the hood (chimney) to cut off vortex air flows.

In conclusion, it is worth noting that the problem with the boiler blowing out periodically occurs among residents of apartment buildings. As for private mansions, attenuation is caused by improper chimney design or insufficient draft.

In resolving the issue, it is important to make sure that the burner and control sensors are in good working order, since they can indirectly contribute to stopping the combustion process. All work must be performed by qualified specialists.

Causes of turbocharged equipment failures

The device, which is equipped with a turbine inside, is considered the most stable during operation. The following systems are built into these boilers:

- pressure regulation;

- forced removal of spent fuel to the outside.

Even despite their main advantage - uninterrupted operation, they can go astray from the standard mode. A built-in draft sensor will signal a failure in the heating system. Interruptions indicate that the installation was performed incorrectly. Once again, make sure that the correct equipment is selected for your home.

The instructions included with the sale describe in detail the criteria for installation. First, it is recommended to ensure regular ventilation of the room. If the assembly location is chosen incorrectly or the wind direction often changes in the area of the house, then the failure can be easily corrected with your own hands. Determining the root cause, as well as ways to solve the problem, are considered on the same principle as in the case of atmospheric devices.

In fact, there are many problems associated with heating in private homes. Even modern equipment can sometimes let owners down. However, this is not a reason to refuse such a convenient, modern and, at the same time, profitable heating system. Additionally, it is recommended to study the video why a gas floor-standing boiler blows out in the wind.

Ways to reduce

It involves using a special regulator. This device has a mechanism for regulating the pressure in the pipe and a special sensor that analyzes the current draft. It can create a pressure of 10-35 Pa. Works automatically. Such a regulator is the best solution, since it can both reduce and increase thrust. Thanks to it, there will be no backflow of smoke.

The blower is also very effective. It affects the supply of fresh air to the firebox. If you close it completely, then a minimum of air will enter the firebox and the draft will immediately decrease.