The main enemy of a fisherman during winter fishing is the cold. A tent will help protect you from it. However, without additional heating sources, the temperature drops quickly. The situation is saved by a heat exchanger designed for installation in a tent.

For winter fishing in a tent it’s good, but until the temperature outside drops below -10 degrees, or the wind rises, or night falls

What is a heat exchanger and how does it work

A heat exchanger is a metal structure in which various types of fuel are burned. They are equipped with large heating elements, due to which thermal energy is released outside. All models are equipped with a combustion product exhaust system.

Standard set that comes with the heat exchanger

Heat exchangers consist of several parts that are interconnected:

- The main unit is the burner . It burns fuel of one type or another, which produces heat.

- Output system . It prevents combustion residues from entering the tent.

- Heating elements . Allows you to maintain a positive temperature in the room longer.

For winter fishing, a heat exchanger is an irreplaceable thing. Thanks to it, a person can stably maintain a certain air temperature in his tent. This will allow the fisherman to warm up after going out on the ice or even spend the night comfortably in nature.

The principle of operation of a heat exchanger installed in a tent

Below the heat exchanger are various heat sources that burn the fuel. Warm air rises through special tubes and is then evenly distributed throughout the entire inside of the tent. Hazardous combustion products are discharged outside through the chimney.

Some devices are additionally equipped with a fan that operates from a portable battery. It allows you to quickly disperse heat throughout the tent and improve the heating of its remote parts.

Types of heat exchange units for a private home

For industrial purposes, welded and semi-welded heat exchange units are used. They are able to withstand aggressive environments (for example, freons or sea water), high pressure and temperature. In private housing, plate devices of two other types are installed: collapsible or soldered. Each variety has its own set of characteristics.

Gasketed plate heat exchangers are suitable for domestic and professional use. They have the following properties:

- Collapsible models consist of plates installed alternately and are fully repairable; They can be disassembled for maintenance (de-scaling).

- You can adjust the power by adding or removing plates. As the load changes, system performance changes.

- High-quality materials are used in the production of the heat exchanger, which ensures a high heat transfer coefficient and minimizes heat loss.

- When moving, the coolant (water) forms vortex flows and starts the self-cleaning process.

- If you follow the operating rules, the collapsible model will last 15-20 years.

Collapsible model available for maintenance Source ecomash.ru

What types are on the market?

Devices are classified according to the type of fuel they burn to produce heat. It can be:

- Alcohol . Heat exchangers that operate on alcohol are distinguished by their compactness. However, they are not able to warm the fisherman in severe frost. Most often used as an additional means of heating.

- Solid fuel (firewood) . Heat exchangers operating on solid fuel (wood, briquettes) are the most common among fishermen, because... it can be found in any forest. The main disadvantage of contraction is its large weight and size.

- Gasoline . Liquid fuel devices are compact. However, they have not become widespread due to the explosive properties of gasoline.

- Gas . Fish use devices that operate on gas quite often. Their distinctive feature is their small size and safety of use. Gas enters the burner from the storage facility through a special hose. The fuel supply is regulated by a valve.

Electric heat exchanger

Note! There are devices on sale that operate on electricity.

Each person decides which option to choose based on personal preferences.

Indirect heating boilers

The most common water heaters are Leroy Merlin indirectly heated boilers. Heating is carried out from a tubular electric heater, a gas burner, and the heat of the heating system. The housing is protected by a special casing and thermal insulation to prevent heat loss through the Leroy Merlin water heater. The control panel is equipped with a temperature sensor and is connected to a heating device. When the sensor signals a decrease in temperature, the heating is turned on automatically.

Closed boilers

Closed Leroy Merlin boilers are used in centralized heating. Attention! Due to the expansion of the coolant when heated, increased pressure is created in such systems, which can cause system elements to fail. To avoid this, an expansion tank is provided for excess water; pressure gauges, thermal mixers, and pressure reducers can be installed.

Open type boilers

An open Leroy Merlin boiler can supply only one water point with hot water. They contain a special mixer, which allows you to shut off the connection of the heat exchanger to the main line. Increased water pressure is observed not at the outlet, but as it flows into the heater, due to which not the most expensive and durable materials can be used in the production of such devices. The special mixer also allows you to drain excess water when the pressure in the system increases. This element can also be used in closed boilers, but in open ones it is required.

What to look for when choosing a device

The first thing a person who is going to buy a heat exchanger must decide on is the type of fuel. Each type has its own advantages and disadvantages. It is impossible to give specific advice here; it should only be noted that recently devices operating on gas and kerosene, as well as safer electric options, have become increasingly popular among fishermen.

Next, it is recommended to check the quality of the case. It should be free of rust, cracks and other defects.

The main criterion for choosing a device for many fishermen is its size. Indeed, if you plan to get to the fishing spot by car, you can buy a larger, and therefore more powerful, heat exchanger. It’s another matter when a person goes on a hike. Here preference is given to lightweight and compact devices that can fit in a backpack.

Do not put a large heat exchanger in a backpack

Watch the video: Operating principle of a heat exchanger for heating systems

Heat exchangers for heating a private house circulate in the outer pipe, while the inner pipe is occupied by sanitary water. During heating, when gas is burned, heat is supplied directly to the coolant. When working for hot water supply, the heat after the coolant passes to the circuit. Attention! Using a bithermic heat exchanger for a heating system, a secondary heat exchanger and a three-way valve are not needed. Due to this, the price of the boiler is reduced, and its reliability increases.

There are also disadvantages to such designs. In hot water mode, the volume of heated water is less than in other types due to the limitation of heat transfer. It is not recommended to use bithermic heat exchangers for heating boilers in regions with a large amount of hard salts in the water: due to the large temperature difference in the equipment, salts are deposited at an accelerated rate.

You can separately distinguish the so-called mini-boilers. This name was given to heat exchangers with a large capacity. This equipment is of the highest class, expensive, but very effective. In appearance, mini-boilers are similar to a Leroy Merlin water heater with a coil. The coolant circuit passes through the coil itself, the hot water circuit through the walls.

Review of the best models

On the modern market you can find a wide selection of heat exchanger models. Before you go shopping, you should check out the best ones.

Gas heat exchanger SIBTERMO ST-4.5 from Omsk manufacturer

The body is made of aluminum alloys, which have good thermal conductivity. Covered with heat-resistant paint. It is capable of heating not only a tent, but also a small living space. The unloaded weight of the device is 7.4 kg. It operates on gas. Price 16,500 rub.

Review of the Sibtermo heat exchanger:

Sukhovey

The external casing of the Sukhovey heat exchanger is made of stainless steel. Inside there are aluminum tubes, which ensure good heat transfer. The basic package includes a fan, the power of which can be adjusted using a dimmer. The outlet pipe is located at the bottom of the housing. This greatly increases the efficiency of the device. The weight of the device is only 2.9 kg. Price 9,500 rub.

Electric battery heat exchanger Desna BM

The device can operate in automatic and turbo modes. Power is supplied from a battery or batteries.

It is noted that the efficiency of this device is slightly higher than that of similar devices. It heats the air quickly. Products made of flammable materials must not be placed near the device. The heat exchanger body quickly heats up to a high temperature. Price 11,000 rub.

Bullfinch

The device body is made of stainless steel with a thickness of 1.5 mm. Covered with heat-resistant paint. The device is designed for operation at extremely low temperatures. Equipped with folding legs. The basic package includes a carrying container, which can also be used as a table. Price 4,700 rub.

Ripus

Made from steel alloy coated with anti-corrosion protection. Compact dimensions make it possible to install it even in small tents, and low fuel consumption increases operating time. Hazardous combustion products are quickly removed through the chimney. Price 3,150 rub.

How to choose a heat exchanger for a tent - video review:

Advantages and disadvantages

The operating principle of a plate heat exchanger provides the following advantages of its use:

- Effective heat transfer without mixing liquids (thanks to high-quality seals).

- Ability to adjust temperature and increase power (by adding plates).

- Compact dimensions, easy installation and reliable operation.

- Performance characteristics: corrosion resistance, minimal pressure loss, self-cleaning ability (liquids move with turbulent turbulence).

- The device allows you to use one heating source simultaneously for DHW and the heating system. You can reduce your coolant costs and avoid purchasing additional equipment.

- The house becomes more autonomous as the dependence on external utility networks is reduced.

The disadvantages of the heat exchanger include its cost. For many models (especially from well-known manufacturers) it can hardly be called budget. Also, do not forget that the unit is not an independent heater. To operate, it uses an external coolant heated to the required temperature.

Welded model of a heat exchanger Source strojvodproekt.ru

Installing a heat exchanger in a tent - safety comes first

The heat exchanger is located on a flat surface on the floor of the tent. It is recommended to place a sheet of metal or plywood under the bottom for greater stability of the device. The chimney is connected at one end to the device, the other is inserted into a special hole in the tent. Combustion products will be removed through it. If this is not done, people in the interior may be poisoned by carbon monoxide.

Next, fuel and/or current sources are connected to the device. After this, the heat exchanger is ready for operation. All that remains is to light the fuel or turn on the power.

Safety

There should be no flammable objects near the unit. On models that operate on gasoline and gas, it is recommended to periodically check the condition of the cylinder for fuel leaks.

You should also pay attention to the tightness of the chimney. If a fisherman notices that the heat exchanger body is hot, you should immediately turn off the power to the device. Otherwise, an explosion may occur.

Do not leave the device unattended for a long time. Even if there are no visual signs of malfunction, the operation of the device should be carefully checked periodically. Don't neglect this. We are talking about human life.

Important! The burner must not be used as a cigarette lighter.

Design and principle of operation

Modern models of heat exchange devices have several parts. Each has its own important role:

- fixed plate - all incoming pipes are attached to it;

- pressure plate;

- plates equipped with inserted sealing type gaskets;

- top and bottom guides;

- rear pillar;

- threaded studs.

This unique design of the heat exchange device makes it possible to achieve the most efficient layout of the entire surface of the operating unit.

How to upgrade a purchased heat exchanger

On some models of heat exchangers, users sometimes have to modify the factory equipment. Behind the coolers, craftsmen place small grilles to direct the air flow, and also install fan regulators.

Also, some fishermen prefer to install additional valves on the burners to minimize the access of carbon monoxide to the tent. Often it is necessary to extend the chimney so that it can be inserted into the corresponding hole.

A common modification is the installation of an additional stand, which increases the stability of the device.

Criterias of choice

When determining the optimal model of the device, you should rely on the technical characteristics of the product:

- DHW connection diagram;

- level of thermal load;

- parameters of the heating and heated medium.

The last point takes into account information such as inlet and outlet temperatures in winter and summer, potential fluid flow and permissible pressure losses, and the percentage of power reserve. This information is used as a basis when calculating the performance of a plate heat exchanger.

How to make a heat exchanger for a tent with your own hands - drawings and video instructions

Most fishermen prefer to use a homemade heat exchanger rather than a store-bought one.

To create the simplest version, you will need several sheets of stainless steel. The body can be made composite or collapsible. After assembling the outer walls according to the drawing, which is freely available on the Internet, you should proceed to assembling the pipe.

Blueprints:

Drawing

Important! The cutout for the pipe must clearly correspond to the dimensions of the burner.

Next, you will need to assemble the components of the future heat exchanger into a single whole. Many fishermen use a car radiator from a stove as a heating element. It is inserted into the inside of the burner and covered with a metal sheet that prevents it from direct contact with the flame.

You can use a similar device from an old computer as a fan. It is located on the back wall of the unit, not far from the heating element. After connecting all the parts, all that remains is to attach the legs to the lower part.

The result is the simplest solid fuel heat exchanger in design.

How to make a heat exchanger for a winter tent with your own hands - video instructions:

Classification of heat exchangers

Heat exchangers for heating a private house largely determine the functions and design features of the boiler; with their help, cold water receives heat from already heated water. The heat exchanger also transfers heat to the coolant. Depending on the way this task is implemented, these units are divided into:

- Primary.

- Secondary.

- Bithermic (combined).

Primary heat exchanger for heating system

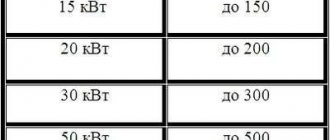

The primary heat exchanger is a large diameter curved pipe with copper plates. The surface of the device is coated with anti-corrosion paint. The differences between the models of primary heat exchangers are insignificant; they usually relate to the methods of connecting the pipe, the size of the device and the power. The last indicator depends on how many plates are installed and how long the pipe is.

The work is negatively affected by salt deposits, dirt, and soot. A heat exchanger for a heating system contaminated with these substances does not sufficiently circulate the coolant, and the thermal conductivity of the walls decreases. To avoid this, they resort to regular preventative maintenance, flushing, and cleaning. Special filters can also help.

Secondary heat exchanger for heating a private house

DHW or secondary type heat exchangers are equipped with steel plates. The plates are characterized by high thermal conductivity; in combination with a large heat exchange area, high efficiency of the device is achieved, despite the high fluid flow rate.

The rapid movement of the coolant protects the device from salt deposits on the walls. Unlike other types of heat exchangers, in this case the flow of cold and heated water coincides in direction.

Bithermal heat exchanger for heating system

Boilers Linea Isy, Immergas Star kW, Hermann Habitat 2 are equipped with bithermal heat exchangers. These are dual-circuit devices that provide heating and hot water supply. The design feature is the presence of a so-called “pipe in a pipe”; copper plates are installed on the surface of the unit.

Repair of equipment

During operation, various parts of the unit may fail. They should be repaired in a timely manner. A common problem is a clogged chimney. You can solve it with a regular brush.

During transportation and use, the housing may become slightly loose. This may result in the device malfunctioning. It is recommended to periodically stretch it.

You should monitor the condition of the connecting hoses on the cylinder. If there is any suspicion of a leak, it should be replaced immediately.

The heat exchanger will be useful to those fishermen who like to go fishing in winter. It allows you to maintain a comfortable air temperature in the tent for a long period of time. To purchase a unit, a person can use store-bought options or assemble it with his own hands.

Technical parameters of models

When studying the assortment, rely on the following technical characteristics:

- the material from which the panels are made - these can be refractory compounds, thin sheet steel, pure titanium;

- the maximum permissible medium pressure in the unit usually does not exceed 25 kgf/cm²;

- in each node the number of plates used starts from 7-10, their number is determined by the future area of application;

- devices can withstand coolant temperatures of no higher than 180°C.

One working unit is capable of providing a heat exchange area in the range of 0.1-2100 square meters. m.

Nuances of installation and connection

The heat exchanger is used only in conjunction and does not imply independent use. During installation, the unit is surrounded by auxiliary equipment, such as check valves, control and measuring devices in the form of thermometers and pressure gauges, shut-off valves (manual valves and gate valves), and circulation pumps.

The connection is made according to one of the following schemes:

- single-stage parallel (independent) method;

- two-stage mixed;

- two-stage sequential.

Installation of a plate heat exchanger

In the first case, there is a significant saving of usable space in the installation area. The key advantage of this method is its ease of execution (which is important in conditions of repair, maintenance, or replacement of a unit). The disadvantage of the technique is the inability to heat a cold working environment.

With a two-stage mixed method, the temperature of the incoming coolant increases due to the reverse flow, as a result, the efficiency of the bundle increases by 35-40%. But in this case, to ensure hot water supply, it will be necessary to provide two heat exchangers in the system, which increases the cost of purchasing and installing equipment.

The sequential two-stage method allows you to increase the efficiency of using the working environment and stabilize the load on the network. Compared to the parallel circuit, the coolant costs are reduced by 50%, and compared to the mixed method - by 25%. The only drawback of the solution is the impossibility of fully automating the heating unit.