To create comfortable conditions inside a building, it undoubtedly needs to be heated in winter and cooled in summer. The supply of heat to apartment buildings is ensured by the operation of the central city heating system.

In the absence of one, residents use an electric or gas boiler. The latter can only be installed if there is natural gas within walking distance of the premises. Typically, the choice of equipment brand and its installation occurs at the design stage and depends on many factors. And the dimensions of a gas boiler are determined based on the area of the room in which it will be installed.

How to choose?

Experts and installers call the area of the house the main initial parameter influencing the purchase of equipment. It is believed that the power of the unit should be selected at the rate of 1 kilowatt per 10 square meters of space. Here the size of the gas boiler is important, but is perhaps of secondary importance.

Professionals advise you to take note:

- number of residents in an apartment or private house;

- building materials from which the walls and roof are constructed;

- presence or absence of a basement;

- installation of heated floors or light floor coverings;

- weather conditions in the building area;

- number of window openings and quality of installation of double-glazed windows;

- type of window glazing;

- number of floors

We select a boiler according to different parameters

Now it’s time to talk about how to select a heating boiler according to its parameters. These parameters include the area of heated premises and the power of heating equipment.

Let's look at how to make the right selection of a heating boiler based on area. There are several points to consider:

- If your house is insulated according to the standards, its ceilings are 3 m, then the power will be determined at the rate of 1 kW per 10 sq.m.

- If the house is not insulated in the best way, or verandas and uninsulated attics are heated, then the power will be greater.

- If the boiler will be used not only to heat the house, but also to supply hot water, then the power will be increased by 20-50%.

Of course, if you do not have certain special knowledge, then you will only make an approximate choice of heating boiler power. After all, if you apply a more complex formula, then some more indicators are included.

Boiler power depending on the area of the house

Let's consider the formula for calculating the power of a heating boiler. Boiler power is the most important operating parameter. This does not depend on what type of fuel will be used in the future. If the power is not enough, you will freeze; if, on the contrary, you buy a device that is too powerful, then you will overpay.

To select the power of a heating boiler, consider the formula. So, this includes the following parameters:

- Room area S.

- Specific boiler power per 10 sq.m of premises Wud. – taking into account climatic conditions: Moscow and the region – 1.5 kW, North – 1.5 – 2 kW, South – 0.7 – 0.9 kW.

The formula will look like this: Boiler power = SWud./10.

When choosing a boiler, first of all it is necessary to calculate the energy demand of the heating object. The parameters of the heating system are calculated according to the heat loss of the room, which depends on the size of the room, the thermal conductivity of external walls, internal partitions and ceilings, the difference between external and internal air temperatures, therefore the final determination of the boiler power should be trusted only to professional heating engineers. But it is possible to pre-determine the power of the boiler, and accordingly, the cost of the equipment and its other parameters independently. Approximately, you can use the following ratio - 1.2 kW of boiler power is required to heat approximately 10 m2 of a well-insulated room with a ceiling height of up to 3 m.

The defining parameters that should be relied upon when calculating power are:

- area of the heated room (S);

- specific boiler power per 10m? premises, which is set taking into account amendments to the climatic conditions of the region (W spec.).

There are generally accepted specific power values for climatic zones:

- for the Moscow region - W beat. = 1.2 - 1.5 kW;

- for the Northern regions - W beat. = 1.5 - 2.0 kW;

- for the Southern regions - W beat. = 0.7 - 0.9 kW.

Calculation of boiler power (W cat) is carried out according to the formula:

W cat. = SW beat / 10

Often, for the convenience of calculations, the average value of W beat is used. equal to one. Based on this, it is customary to choose the boiler power at the rate of 10 kW per 100 m 2 of heated space.

Example:

1. Area of the heated room S = 100 m²;

2. Specific power (Wsp.) for the Moscow region = 1.2 kW;

W cat. = 100 1.2 / 10 = 12 kW;

The table shows the approximate power of boilers depending on the area of the house served (for the Moscow region).

Boiler room area

According to regulatory documents, the size of the room for a gas boiler is determined depending on the power of the equipment. This is the indicator that determines the degree of heating of the room. Therefore, it is better to entrust its calculation to professionals. For the smooth functioning of the heating system, a specialized company develops a design and technical specifications. You can independently select the room for installing the boiler and its brand, but you cannot connect the boiler without agreement with the necessary structures.

Depending on the power of the gas boiler, the overall dimensions of the room should provide the following area:

- 7.5 m2 - with the main characteristic of 30 kW;

- 13.5 m2 - with a power within 60 kW;

- 15 m2 - more serious boilers with an output of up to 200 kW.

Which is better: a factory or homemade model?

Some craftsmen, seeing the popularity and prevalence of universal models, decided to independently assemble the one they needed based on a solid fuel boiler. They purchase different types of burners and independently connect the boilers to the gas mains. Is this kind of work acceptable?

There is no need to do any re-equipment yourself. Why? There are two reasons for this:

- safety;

- uneconomical.

Usually, before the boiler reaches the store, it is tested in the factory. It is not possible to do this at home. Consequently, the home owner cannot be completely confident in the reliability of his equipment. Such boilers can pose a serious danger.

By purchasing a boiler from a specialized store, you can be sure that your home will be safe and the heating system will last for many years!

Product installation requirements

The main indicators that determine the possibility of installing a heating device in a particular room are:

- preventing combustion products from accumulating in the room;

- no smoke;

- prevention of emergency situations including fires.

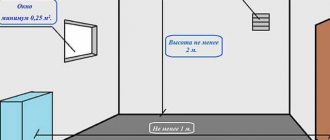

When a gas boiler is operating, the dimensions of the boiler room or other room with equipment are regulated by SNiP. The same standards establish fire safety, which is ensured during installation in compliance with the following rules:

- The distance from floor to ceiling should not be less than 2.5 meters.

- The installed hood carries out three air exchanges.

- It is necessary to have a window with an area allowed by the standards.

- The door must be equipped with a lower grille or replaced with another sample with a gap to the floor of 0.025 m2.

It is not permitted to dismantle a previously installed door and replace it with arches or curtain structures.

Alternative solution

Heat pump

Another heating source is a heat pump. The principle of its operation is similar to that of a conventional refrigerator. The compressor compresses the refrigerant, releasing excess heat into the condenser—it warms your home. In the condenser, gaseous freon turns into a liquid state. After the heat exchanger, it passes through an expansion valve and evaporates with a sharp drop in pressure. With sudden evaporation, the temperature of the heat exchanger drops to a very low level. Since the heat exchanger lies in the ground or on the street, it begins to take away heat from the environment. After the refrigerant turns into a gas in the evaporator, it returns to the compressor and a new cycle begins.

If we consider this solution in terms of efficiency, then it can rightfully be called the best, but with a bunch of reservations. To this day, heat pumps are quite expensive. Air heat pumps do not work in severe frosts, and not all residents have the opportunity to install geothermal ones. You can choose it as the main source of heat, but it is important to understand that its payback period is quite long.

How much gas is needed for heating?

Experts in the field of heating equipment calculate the gas consumption for a specific room and recommend a suitable gas boiler. The size of the unit, of course, affects the power, but does not always affect the amount of gas processed. According to the existing formula, the required parameter is determined as:

V = Q / (Hi x ƞ), where

Q—calculated thermal power, kW/h;

Hi—heat of combustion, kW;

Ƞ—efficiency factor.

Thus, if:

- the average boiler power, usually taken as power divided in half, is 5 kW per hour;

- the specific heat of combustion per 1 m2 is determined to be 0.1 kW (for example, for a house with an area of 100 square meters it will be equal to 10 kW);

- The efficiency, according to the equipment passport, is 95%,

then V = 5 / (10 x 0.95) = 0.53 m3/h.

If we calculate that the heating season is 200 days, and more specifically, 4800 hours, then the amount of gas will be calculated as follows:

0.53 x 4800 = 2544 m3.

Operating principle of automatic coal boilers

It is important to understand the structure and operating principle of modern automated boilers even without interest, because this knowledge will help you decide on the model. In order for a coal boiler and the heating and hot water system based on it to be able to operate autonomously, safely and cost-effectively for a long time, the following processes must be automated:

- loading portions of coal or other fuel;

- removal of ash from the combustion zone into the storage tank;

- the air supply from the boost fan to the burner must be regulated;

- the temperature in different rooms corresponded to the set temperature;

- the heated floor is heated as specified;

- hot water is available at all service points;

- Circulation pumps and mixing valves correctly direct the coolant and warm water.

The user's function is to select the operating mode (setting priority or schedule), or the coolant temperature, or the temperature in each room. Dynamic processes depending on weather changes, water consumption, quantity and quality of fuel, and air intake are monitored and interpreted by the processor. A full set of options for an automatic coal boiler is expensive, so often only the most labor-intensive processes are automated: loading fuel and air pressurization.

Organization of automatic feeding using a screw, the most typical device for modern models.

The principle of operation of the boiler itself has not changed: oxygen enters the burning coal through the blower, maintaining combustion, and exhaust gases go into the chimney. Thermal energy heats up the coolant located in the container around the burning coal, and the carrier goes through the pipes to the radiators. Having given off heat, the liquid returns to the boiler for heating.

There are two options for burning coal:

- Classic . Coal burns, and pyrolysis gases escape into the atmosphere.

- Pyrolysis . The exhaust gases are saturated with oxygen and burned, thereby increasing the efficiency of the boiler and increasing the burning time of one portion of coal at least twice, but the cost of pyrolysis models is also at least twice as high.

Structurally, the boiler is also traditional. With classic coal combustion, there is one firebox, the coal burns on grates, air is supplied from below naturally, its level is regulated by the ash door, and the exhaust gases are regulated by the chimney damper. The boiler body, also known as the coolant container, is surrounded by burning coal. In the pyrolysis version, a forced air supply system is placed above the classic firebox for afterburning gases and solid particles in them, so a well-functioning boiler does not smoke.

There are many implementations of coal-fired boilers with different levels of automation on the market.

Fuel supply system

The most labor-intensive and rather dirty task when operating coal-fired boilers with automatic feeding is loading fuel into it. By automating this process, you can ensure that the bunker is filled no more than once a week. If the budget allows you to automate the supply of coal to the boiler bunker from a seasonal warehouse, this will make life in the house comfortable throughout the heating period.

An example of organizing automatic feeding into a bunker from an external warehouse when the boiler room is located in the basement. However, such systems are not sold in ready-made or even modular form.

In coal-fired boilers, two types of automatic coal supply system designs were obtained: screw and drum type.

A hopper with coal for loading a pyrolysis (and often a classic) boiler is installed on the side of the boiler. At the bottom, the box is equipped with a screw, which is rotated by an electric motor at the command of the computer when operating in automatic mode or from a button in manual mode. The duration of engine operation is set by the computer, thereby determining the portions of coal loaded into the boiler. At the same time, the boost is turned on to control the combustion process.

A boiler with such automation maintains high efficiency when the rated power fluctuates from 30% to 100%, filling the hopper up to once a week, effectively responding to weather changes and user settings. Filling the bunker with high quality coal (fraction from 5 mm to 25 mm), depending on the model, is necessary once a week.

In classical combustion boilers, a bunker with coal is often placed above the boiler and automatic loading occurs using a drum (rotating grate). It, rotating around its own axis, supplies a portion of solid fuel to the firebox. After burning, the slag and ash fall into the storage tank. In this case, the fuel requirements are lower, and there are many specific design solutions for automating such boilers.

Ash removal

The second unpleasant procedure after loading coal into the bunker is removing slag, caked crust and cleaning the ash storage tank. If the boiler is not connected by a conveyor to a seasonal fuel storage, it is advisable that both procedures occur with the same cycle - once a week. Self-cleaning models still require attention, but every 4-6 weeks.

The system for automated ash removal into an external box is quite simple, but organizing it is neither easy nor cheap, so it is very rare in coal models.

The amount of ash in the storage tank is directly affected by the quality of coal, such as ash content. Direct combustion boilers are not too demanding on the quality of fuel and can even be heated with household waste. But ash removal will have to be done more often, and the declared characteristics can be obtained on coal with a moisture content below 30% and an ash content of less than 25%.

Pyrolysis boilers, in addition to low humidity up to 20% and ash content less than 15%, also require a certain size of coal fractions from 5 mm to 25 mm. Deviation from these requirements reduces the performance of the unit and increases the amount of ash. Part of the unburnt coal can be reused after sifting the ash from the storage tank

Automatic ignition of boilers using liquids, manual removal of ash from their storage tank and self-cleaning of burners can be offered as additional options for very expensive boiler designs and are quite rare. Unlike pellet models, you shouldn’t count on a self-cleaning system in coal models.

Classification of gas boilers

Heating equipment is divided into five types according to the raw materials used: gas, electric, solid fuel, liquid fuel and combined.

Whether it is a gas boiler of minimal size or a large, advanced model, it is classified according to many parameters:

- Installation location: floor, wall.

- Functional purpose: single- and double-circuit.

- Burner type - atmospheric, turbocharged, diffusion, complex.

- Ventilation - forced or natural.

Small-sized wall-mounted gas boilers, which are mounted within the kitchen, are suitable for apartments. When building private houses, it is better to separate a small room, use it as a boiler room and purchase floor-standing devices.

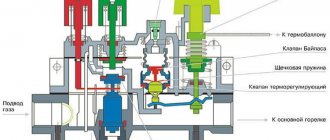

Basic operating principle

Everyone knows how boilers work. Their goal is to bring water that circulates through the system and heats the home to the desired temperature. The main difference between such devices is the type of energy carrier.

Most often boilers are:

- electric:

- solid fuel;

- gas;

- liquid fuel.

In this case, there may or may not be a water circuit.

Features of operation of universal boilers

If conventional heating systems can only operate on one type of fuel, then universal boilers operate on any fuel, and most often on two simultaneously. That is why you can hear that such units are also called multi-fuel.

Nowadays, installing such a device for a private home is the best solution. Due to interruptions in fuel supplies and jumps in their cost, you may find yourself in a hopeless situation. However, anyone who has installed a universal boiler model can easily use any fuel, just by changing some settings.

Baxi Nuvola-3 Comfort 240 Fi

The Italian-assembled model has a lot of positive aspects, including:

- wall mount;

- the area of a residential building or apartment allowed for heating is up to 220 m2;

- presence of a display;

- possibility of removing the control panel;

- operation on natural gas supplied through a main pipe or from a cylinder in a liquefied state;

- closed combustion chamber type.

In terms of overall dimensions, a gas boiler of this brand is considered quite large and heavy. After all, its weight is 70 kg, its height is close to a meter, its depth is half a meter, and its width reaches 60 cm.

A special feature of the model is 2 separated heat exchangers: the primary one is made of copper, and the secondary one is made of stainless steel. The temperature of the heating system is regulated by the Baxi boiler from 40 to 85 degrees. Net power starts from 10 kW and can increase by 2.4 times.

Since heating equipment from this manufacturer has a high price, buyers usually ask for clarification of the advantages of this product over others. In this case, experts note:

- Adaptation of the model to pressure surges in a gas pipe.

- Convenient ignition.

- Availability of storage boiler and expansion tank.

- Complete with an energy-saving circulation pump.

- Setting up operating parameters for a weekly period.

- The presence of automation that connects to an external temperature sensor and regulates parameters.

Solid fuel boilers

The most widespread are boilers that use solid fuel. They can be called traditional. Such units are used both in country houses and for heating various other objects. The advantage here is complete autonomy. If we are talking about a residential building, then such a boiler does not need electricity, since with a properly installed heating system, normal heating of the entire building is always ensured.

These devices generate heat during the combustion of coal, peat or wood. However, many models are “tailored” to the use of pellets or special granules (it is believed that the combustion of this type of fuel provides higher efficiency of an autonomous heating system). The disadvantages of solid fuel units include inconvenient operation and low efficiency. Added to this is the constant rise in wood prices due to ongoing deforestation. Another unpleasant moment is associated with the release of harmful combustion products during operation of the unit.

The production of granules and pellets is considered a more environmentally friendly option. This fuel is obtained by processing wood waste and the remains of other vegetation (husks, straw, etc.). The advantages of fuel pellets include ease of storage, excellent calorific value (higher than that of firewood and coal), resistance to moisture, and a minimum of ash after combustion. From an environmental point of view, of all the variety of types of solid fuel, pellets are clearly the leader.

Now about the disadvantages. The operation of units of this type requires constant monitoring. Moreover, both from a safety point of view and to maintain a constant temperature in heated rooms. Loading and removing remaining fuel is done manually. You also need to find a free, closed space to store fuel. For the safe operation of these devices, it is necessary to correctly design and construct the chimney. It is almost impossible to control the fuel combustion process, which is why only single-circuit models are produced in the world.

Compared to equipment running on electricity or gas, a solid fuel boiler is noticeably inferior in terms of efficiency. The advantages can be safely attributed to the relatively low cost.

Buderus Logamax UO72-18K

One of the budget options for German double-circuit gas boilers. The dimensions of this sample are much smaller than the previous Italian bestseller. Dimensions of 700x400x300 mm reduce the weight by 2 times, which allows you to look at the boiler from a different angle and find additional advantages in it in the form of:

- Safety systems that prevent emergencies due to a drop in pressure or an extinguished flame.

- Power 18 kW.

- Heating temperatures from 40 to 82 ˚С.

- Economical.

- Ease of use and settings.

- Switches off the device when the water overheats or freezes and in the absence of traction.

- Low noise level.

Some consumers complain about the poor quality of the plastic latches and the insufficiently detailed instructions for the unit regarding the recognition and repair of minor breakdowns.

The best known manufacturers and models: characteristics and prices

Now let's look at specific models so that you understand the difference between them. Still, the characteristics differ not only between specific models, but also between different companies. These are the most popular boilers in Russia.

Single-circuit

Let's start with boilers that are designed exclusively for heating.

BAXI ECO Four 1.24

Reliable fourth generation Italian boiler with a closed combustion chamber. The wide LCD display makes it easy to monitor and adjust the temperature. They do this using two modes. The first one is suitable for radiators. You can select a range from 30 to 80 degrees. The second mode involves the use of heated floors. The adjustable range is from 30 to 45 degrees. Safe operation is ensured by the most modern sensors. There is protection against freezing, pump pump blocking and a three-way valve.

Another feature is the modulating burner, which allows you to minimize noise when turned on. The boiler reaches the last 5 degrees of the set temperature at the minimum flame. Gas consumption at an efficiency of 91.2% is 2.78 m³. This model perfectly combines efficiency and European quality. But many owners say that the boiler is afraid of voltage surges, so it is better to install a stabilizer. Otherwise, this is a problem-free, most popular and widespread gas wall system in Russia.

Protherm Panther 25 KTO

The Protherm company produces its equipment in Slovakia and is part of the famous German corporation Vaillant Group. The model has gained quite significant popularity due to its efficiency and reliability: efficiency reaches 92.8%, closed combustion chamber, copper heat exchanger and pipes. Convenient control, high-quality spare parts, protection against freezing, overheating and pump blocking.

If you buy a boiler from the same company, you will get a single compact device. The boiler can be installed directly under the boiler, and all communications can be hidden in a special casing.

The boiler perfectly heats two-story buildings. You don't even have to install an additional pump. The owners themselves say this. Modulating burner and pneumatic gas valve ensure low noise levels. Excellent build quality. But the price is higher than similar models from other manufacturers.

Viessmann Vitopend 100-W A1HB 24 kW

A turbocharged model from a German manufacturer, which is considered the standard of quality. It is distinguished by one of the lowest practical gas consumption indicators in the price segment (although the maximum consumption is not a record low - 2.77 m3/hour). It is also known for its almost silent operation (double noise insulation), modulating burner, and a huge list of safety systems.

Modern automation allows you not only to regulate the temperature, but also to program the operation of the boiler for a week in advance - a rather rare function for this price category. The controls are simple, so don't worry about not understanding the functionality. And if you want to install a backup boiler, then the Viessmann Vitopend 100-W A1HB002 is best suited. After all, it has the ability to cascade connect two boilers. To obtain hot water, you can connect an indirect heating boiler.

Among the shortcomings, one can note only vulnerability to voltage surges (the protective mechanism is designed for 170-253 V, which is not always enough). Please note that today there are three generations of the model: A1HB001, A1HB002 and A1HB003.

<

The best German gas boilers The most efficient, reliable and functional models on the market

BAXI Duo-tec Compact 1.24

One of the best representatives of condensing boilers, repeatedly taking first place in authoritative ratings, is considered one of the “smartest” representatives of the budget segment. For example, Think technology allows it not only to adapt to different operating conditions (weather, gas composition, chimney parameters), but also to control different temperature zones.

The maximum gas consumption is only 2.61 m³ per hour, the efficiency is 105.7%. The heat exchanger is made of stainless steel, so it is not afraid of harsh operating conditions. A filter is installed at the cold water inlet. The model is single-circuit, but the three-way valve is already built-in. Despite the fact that the boiler is a condensing boiler, its dimensions are not particularly large. Yes and weight too. According to reviews from owners and installation experience, the boilers have been operating without problems for more than 7 years and are known for their high reliability.

When compared with the condensing boiler market, the model cannot be called the most efficient, but for its extremely budget price it is one of the best offers in terms of technical parameters.

Rinnai BR-UE30

Technological and smart Japanese boiler. A modulating burner with turbocharging, a copper heat exchanger and pipes, the boiler has very compact dimensions characteristic of Japanese models. The maximum gas consumption is only 2.87 m³ per hour, which is very significant for a power of 29 kW. For comparison, European boilers of 24 kW usually have approximately the same consumption. The set includes a remote control that can be hung separately in any convenient place.

It is possible to connect an indirect heating boiler, as well as disinfect it using the Anti-Legionella function. Switching to hot water will occur automatically using a built-in three-way valve. Rubber seals are installed at the joints, an anti-vibration insert is installed on the rear wall, and the front cover is additionally thickened. All this allows you to reduce the noise from the operation of the boiler to a minimum. There are many advantages, but the disadvantages include the high price of the boiler itself and spare parts (the need for which, of course, is rare in practice).

Review of Rinnai gas boilers The closest analogue of standard German quality

Dual-circuit

Most buyers still prefer double-circuit boilers, since they do not need to spend money on an additional water heater.

BAXI ECO-4s 24F

One of the most popular double-circuit boilers on the Russian market. Inexpensive, but very reliable. Closed combustion chamber, primary heat exchanger - copper, efficiency 92.9%. The maximum gas consumption is only 2.73 m³ per hour. The boiler is equipped with protection systems against freezing, overheating and condensation. At the same time, the boiler is well adapted to domestic conditions: unstable gas or water pressure, often not the cleanest coolant, automation and pump tolerate minor voltage drops.

Owners often note changes in temperature, but this is a problem with almost all instantaneous water heaters. To keep the temperature stable, you need good pressure in the water supply. As for unstable voltage in the electrical network, the boiler can withstand small surges. European assembly leaves no doubt about the quality. A filter is installed at the cold water inlet, which can significantly extend the service life of the heat exchanger and circulation pump. Considering the cost of the boiler, there are simply no disadvantages.

BAXI LUNA-3 240 Fi 25

Another, newer model from the Italian manufacturer BAXI. It differs from the previous one in its convenient control panel, which has a built-in programmer. This allows you to set a separate temperature for each day of the week. Capable of operating in underfloor heating mode. The maximum efficiency is 93%, and the gas consumption is quite acceptable - 2.84 m³ per hour. Long service life and efficient operation are ensured by a copper heat exchanger with anti-corrosion coating.

Many users do not understand the difference between the ECO and LUNA series. Everything is simple here. LUNA boilers have higher quality components, which is why they cost several thousand rubles more. It's like comparing a cheap smartphone and Apple. Both the quality and functions are better. For example, the boiler produces up to 14 liters of water per minute, since the secondary heat exchanger is quite voluminous. But LUNA is also a little larger in size. If finances and space allow, I would still recommend choosing this model.

Vaillant turboFIT VUW 242/5-2

German quality, reliability, ease of maintenance and operation - these are the associations that arise in my mind when I hear about the Vaillant company. It seems to me that this is one of the best gas wall-mounted boilers for heating a private home. Firstly, high efficiency, which reaches 93.5%. Secondly, low gas consumption compared to similar models. Only 2.66 m³ per hour. Thirdly, the company has already managed to prove that wall-mounted boilers can operate for 5, 7, 10 or more years without breakdowns. And numerous reviews confirm this.

Separate heat exchangers are installed, so there is no need to worry that the boiler will quickly clog. The main one is made of copper. The secondary heat exchanger, as is customary, is made of steel. A high-quality hydraulic unit, to which the company pays special attention. All pipes are copper, not rubber, connections are threaded, excellent build quality. All necessary protection systems are present. The turbine, servo drive and ignition operate almost silently.

I wouldn’t say that the boiler is budget, but it’s not too expensive either. Of course, when compared with European analogues. The company cares about its customers, so the turboFIT VUW 242/5-2 takes into account the comments of the owners of previous models. Even the price has become lower. Today they are excellent for Russian conditions. The boiler is equipped with a pump from the famous and reliable Grundfos company, as well as Sit automation. The disadvantages include expensive spare parts. Also, do not forget that it is advisable to connect the boiler through a voltage stabilizer.

Ariston

This is perhaps the most popular foreign brand, which has two possible options for installing a gas boiler. The manufacturer's floor-standing models are larger in size than wall-mounted ones. The same trend can be seen in the cost of equipment.

Thus, a copy from the expensive Unobloc GPV 24 RI Met series must be installed on the floor. Of the main technical characteristics you need to take into account:

- open combustion chamber;

- atmospheric burner;

- electronic ignition;

- heat exchanger made of cast iron;

- power 26.6 kW;

- presence of an expansion tank;

- possibility of connecting a boiler;

- dimensions 850x450x665 mm.

The cost-effective wall-mounted sample CLAS X SYSTEM 15 CF NG is tuned to Russian realities both in terms of fruitful work and in terms of cost.

If we simply characterize the product, we can note its reliable operation for the time declared by the manufacturer. After the end of the warranty period, it is quite difficult to achieve uninterrupted operation from an unsuccessful model. However, many buyers do not encounter problems for a long time, and therefore recommend a budget boiler to friends and acquaintances.

Selection of heating boiler by price, power, combustion chamber

Dear users of our resource, if this is your first time on our website looking for a heating boiler and you don’t know what kind of boiler you need, then we recommend using the heating boiler power calculation.

Here you can choose a heating boiler based on the fact that you already know what kind of boiler you need, the power of the boiler, where the boiler will be mounted: on the wall or whether it will be floor-mounted and, of course, taking into account the resources available for this. For selection, we suggest you indicate the criteria you need.

More detailed information can be obtained by clicking on the appropriate link as a result of selecting a heating boiler or by calling in Moscow +7(495)48-132-48

Criteria for selecting a heating boiler:

- boiler price

- number of circuits (single-circuit or double-circuit)

- boiler type (wall-mounted or floor-standing)

- combustion chamber (open or closed)

- type of coolant (gas, diesel, electricity)

- boiler power

- boiler voltage (220V, 380V, 220/380V)

In order to find out more detailed information about heating boilers, here is the classification of heating boilers:

by installation method (by installation location):

- floor (cast iron or steel)

- wall-mounted (mounted) (usually run on gas)

by type of energy carrier:

- liquid fuels (diesel, kerosene, fuel oil, etc.)

- solid fuel (solid fuel: firewood, coal, coke, sawdust, fuel briquettes, etc.)

- gas (liquefied gas, natural gas)

- electrical (the energy carrier can be electricity)

- universal (multi-fuel, combined) (energy carriers can be different, depending on the heating boiler)

by number of circuits:

- single-circuit, such boilers are intended only for heating; as a rule, such boilers have the ability to connect an external storage boiler.

- double-circuit (one circuit for heating, the second for hot water supply)

by combustion chamber:

- open, air, namely oxygen for combustion, is taken from the place where the boiler is installed. It must be well ventilated.

- closed, the air is taken, as a rule, from the outside, although such boilers can be converted so that the air is taken from the place where it is installed. Boilers with a closed combustion chamber, in turn, differ from each other in the method of air intake and smoke removal. Those. or with a separate smoke removal system, when two “pipes” approach the boiler - one of which supplies air, and the other removes combustion products. In boilers with a coaxial chimney, which are more compact, there is one pipe inside another. Air is supplied through one, smoke removal is carried out through the other.

according to the material of the main heat exchanger:

by type of burner (burner device):

- inflatable (fan) burner (gas or liquid)

- atmospheric burner (gas)

according to the method of coolant movement:

- natural circulation / gravity (without pump)

- forced circulation (with pump)

according to the amount of voltage required for operation:

by type of coolant:

- liquid (water or antifreeze)

- steam

- air

Viessmann Vitogas 100-F 29

This sample is considered the cheapest of the expensive models of the Viessmann brand. The price in this case is reflected in the quality and provides reliable heating in any conditions.

Non-volatile boiler type, floor installation, high efficiency, noiselessness, low fuel consumption - this is the minimum of the many advantages available. The manufacturer positions the boiler as a good option for providing heat with a long service life and full automation of most processes.

The average dimensions of a floor-standing gas boiler allow its installation not only in a separate boiler room, but also in the kitchen, of course, if there is free space. Professionals call weather-adjusting automation, an electronic control system and an additional electronic cascade control unit the advantages of the unit.

What is important to consider before installing such heating equipment?

Before installing such a heating system in your home, you should fulfill several important requirements. The boiler, as well as the entire system, must be installed:

- in a separate room;

- at a sufficient distance from the walls;

- only on a concrete foundation.

When the boiler and its elements are placed in an isolated room, this guarantees your safety. Under no circumstances should any objects, clothes, or shoes be stored in such a room. In short, there should be no flammable elements near the boiler other than fuel for equipment or boiler components.

Of course, if you are not a professional in this matter, then it is best to turn to the experts for help with installation. They will do their job efficiently and without any complaints. At the same time, if you have certain skills, you can take on this work yourself. All necessary materials and tools can be purchased at the store where the boiler was sold.

When connecting and setting up the unit, it is important to remember that good draft and high-quality ventilation are important for the full operation of the system.

Navien

When the brand is important to the consumer, and the price is high enough, Korean heating equipment will come to the rescue.

The advantages of the Navien product line, in addition to the affordable price, are:

- A specialized device in the form of a chip that monitors and regulates voltage drops.

- Possibility of working with low pressure.

- Remote control with display.

- Automatic power control.

- Compactness.

- A two-circuit system that allows, in addition to heating, hot water supply.

Interesting models include wall-mounted gas boilers for a private home, the size of which does not exceed 240 m2. Installers call Navien Deluxe 24K one of the most attractive examples in terms of cost. Unlike more expensive models, the boiler mostly performs the same functions as branded devices, but for less money. Technical characteristics that can evoke positive emotions are:

- dual-circuit operation of the device;

- closed combustion chamber;

- temperature inside the system up to 80 degrees;

- electronic control;

- the presence of a circulation pump;

- ability to accept natural liquefied gas.

Comfortable operating conditions are achieved due to automatic ignition, the presence of a thermometer, remote control and room temperature meter. Security is ensured by 6 additional options. The compact size of the gas boiler - 440 x 695 x 265 and low weight make installation and subsequent maintenance of the presented model easier.

What can be replaced

Today there are many options for heating your home and obtaining warm water supply, even without using a boiler. In particular, these are devices that allow you to efficiently and efficiently heat a home. Basically, they run on the energy generated when fuel burns, turning it into heat. Thanks to this, the room is filled with heat.

Most often the boiler is replaced:

- steam system powered by main heating;

- autonomous gas or electric system;

- stove heating, for which any fuel is used;

- fireplace;

- autonomous heating system powered by the sun or wind;

- air conditioning.

You can choose your own heating and combine it, from radiators and pipes to a fireplace and a portable heater.

Let's consider each presented type of heating system used to replace the boiler.

- Stove or fireplace. Both devices heat the room and water by burning wood or coal. To organize such a heating system, you will have to make a stove or buy a ready-made communication system and install it correctly. As a result, you can get economical and environmentally friendly equipment for heating, cooking and heating water. In this case, the stove can be made of brick or metal and immediately heat adjacent rooms.

- Air conditioner. Not many people realize that an air conditioner heats the air well during the cold season. Moreover, its installation will require a minimum amount of time, unlike a boiler. However, the disadvantage of such equipment is the high cost of maintenance, as well as the heating of a small number of square meters of space.

- Autonomous heating system with pipe and radiator systems connected to it. It can be obtained from the sun using devices called solar collectors. They are capable of converting solar energy into heat for the home. It can also be obtained from the force of the wind using a wind apparatus, consisting of a turntable with a generator and a battery device, or a wind station.

Important! These devices are suitable for efficiently heating a living space that is located away from the gas line. You can warm up even without using a central heating system, pipes with boilers and radiators

This can be achieved by maximizing the insulation of the home, changing the usual wardrobe for the home and psychological heating

You can warm up even without using a central heating system, pipes with boilers and radiators. This can be achieved by maximizing the insulation of the home, changing the usual wardrobe for the home and psychological heating.

Maximum home insulation includes insulating walls, adding heated floors to rooms, massive curtains on window openings, etc. Even when the boiler is operating, such nuances retain heat better and allow you to use the system economically.

Changing your home wardrobe routine includes starting to wear knitted sweaters, using blankets when relaxing, and using warming blankets with heating pads and warm drinks.

Psychological heating includes changing the design of the rooms, changing the overall color scheme of the rooms to warm shades, adding knitted decor and wooden accessories to the room, using aroma candles and taking photos of warm places. So, you can deceive yourself and force your body to psychologically receive heat.

In any case, you can find an option and a way to heat your home without a boiler. Such heating can warm you up even at sub-zero temperatures outside the window. Using the presented methods, you can heat your home even in the most difficult situation.

"Conord"

The manufacturer talks about the competitiveness of its product and at the same time warns buyers about special installation rules:

- On mandatory approval of the project with specialized organizations.

- During installation work, it is necessary to achieve uninterrupted water circulation by placing the lower pipe below the level of the radiators.

- When connecting to a heating system by welding, it is recommended to leave the threaded connections for subsequent dismantling for repair purposes.

- The equipment must be installed on a fireproof covering that exceeds the dimensions of the gas boiler by 50 cm in all directions.

- It is necessary to ensure the removal of combustion products through vertical risers or maintaining a slope when they are horizontal.

In addition, the general installation rules approved for all types of heating equipment cannot be neglected.

Experts call the floor-mounted single-circuit boiler KSts-G10 a popular model of domestic production. Among the advantages of the model, experts call the low cost and note a number of additional bonuses in the form of:

- Efficiency 90%;

- thermal power from 10 kW;

- maximum gas flow 1.2 m3/h;

- light weight;

- the presence of automation capable of modulating the flame;

- permissible pressure up to 5 atmospheres;

- ease of installation and maintenance.

A special feature of this specimen is also called the acceptable dimensions of a gas boiler for a private home. However, installation of equipment of this kind in an apartment is not permissible due to the impossibility of hanging the sample on the wall.

Useful features of universal boilers

Heating systems for private homes are now so advanced that we can only rejoice at some of the features.

Maintaining heat with electric heating elements

If the boiler heats your home only using solid or liquid fuel, it usually requires a lot of it. But if, at the moment of the most intense heating, electric heating elements are connected to operation, then fuel costs are significantly reduced.

It is noteworthy that during the operation of the boiler, in the event of a sudden stop in the fuel supply, the electric heating elements turn on automatically, preventing your house from cooling down. It turns out that if the boiler goes out or the fuel runs out, the boiler will not turn off, but simply switch to another mode.

This feature is very relevant where there are frequent interruptions in energy supply.

Selection of economical raw materials

Due to constant price jumps, sometimes you want to protect yourself. If today gas is one of the cheapest types of fuel, it cannot be said that this will be the case tomorrow.

Thanks to universal boiler models, the consumer can easily control their heating costs, and if the price of one type of fuel rises, they can easily replace it with a more acceptable one.

ZhMZ

The plant produces 5 series of gas boilers: “Beetle”, “Comfort”, “Universal”, “Economy” and “Economy Plus”. The last two series are represented by 3 options, and the popularity of the AOGV-17.4-3 model is very high due to the excellent combination of affordable equipment cost and long-term reliability. As the name suggests, the power of the unit corresponds to 17.4 kW, and the area to be heated should not exceed 150 m2. A floor-standing single-circuit boiler does an excellent job of heating a small private house. The boiler's weight of 47 kg and dimensions of 1200 x 456 x 458 mm do not cause any particular difficulties during transportation and installation of the product.

The brand has proven itself due to its use in boilers:

- technology for seamless welding of the heat exchanger tank;

- automation units that ensure safety and ease of use;

- a simple burner that can be replaced and is not difficult to clean;

- overheating sensor;

- room thermostat.

Prices: summary comparison table

| Model | power, kWt | Efficiency, % | Firebox dimensions, weight | Cost, rub. |

| Metal-Fach SMART EKO-20, Poland-Russia | 20 | 90 | 1250x1345x610 mm, 360 kg | 152 000-280 000 |

| Galmet Duo 17, Poland | 17 | 81-86 | 1130x1475x840 mm, 355 kg | 220 000-250 000 |

| ZOTA "Optima" 20, Russia | 20 | 82 | 1290x1590x890 mm, 376 kg | 151 000-211 000 |

| Pereko KSP Duo 18, Poland | 18 | 92 | 1160x1385x845 mm, 370 kg | 283 000-327 000 |

| Heiztechnik Q Eko Lux 15, Poland | 15 | 88 | 350x270x380 mm, 363 kg | 154 000-179 000 |

The main advantages and disadvantages of combined (multi-fuel) boilers

(+)

uninterrupted heating and hot water supply

(+)

choice of the most profitable or currently convenient type of fuel

(+)

no need for a backup boiler

(+)

no restrictions on installation

(+)

ease of use

(-)

higher price than a mono-fuel boiler

(-)

more complex setup than a conventional boiler

(-)

purchase and storage of several types of fuel

(-)

increased cost of repairs

It should also be mentioned that for a combination boiler all the advantages and risks present in traditional boilers operating on the same type of fuel as the combination boiler are valid (you can read in detail about the pros and cons of various heating boilers by type of fuel here).

Backup boiler paired with a diesel boiler

The best option for backing up liquid fuel heating would be either a second diesel boiler or a solid fuel boiler, as well as a gas boiler powered by a gas train - several cylinders connected to supply gas to the heat generator.

A second diesel boiler will work if your main unit fails. The backup will be powered from the same tank as the main heat generator.

If there are problems with the supply of diesel fuel or with the timely purchase and delivery of fuel, then a backup boiler using a different type of fuel will help out.

Why do you need a protection system?

Let's look at possible options for creating backup heating systems. The most reliable and progressive option is a modular protection system that can warn the user about a malfunction of the main heating equipment.

In the event of an emergency with the main boiler, sensors instantly signal a drop in temperature, and the backup boiler starts automatically. Thus, leaving your home for a long time in winter, you will be sure that you are insured against an accident and subsequent troubles associated with overcooling of the heating system.

Reserve boiler

Automation will immediately inform you about malfunctions. If the gas pressure drops below a preset level, the main boiler will not go into error due to the presence of a flame; after eliminating the cause of the failure, a restart will not be necessary and the presence of a service technician will not be required.

Rating of the TOP 15 best solid fuel boilers with a water circuit in 2021

| Place | Name | Price |

| TOP 4 best solid fuel boilers with a water circuit in price/quality ratio for 2021 | ||

| 1 | Teplodar Cooper Praktik 8 single-circuit | Find out the price |

| 2 | ZOTA Yenisei 14 14 kW single-circuit | Find out the price |

| 3 | Lemax Forward-16 17 kW single-circuit | Find out the price |

| 4 | Teplodar Uyut-10 10 kW single-circuit | Find out the price |

| TOP 4 best solid fuel boilers with a water circuit and electric heating element | ||

| 1 | Teplodar Kupper Praktik 14 14 kW single-circuit | Find out the price |

| 2 | Teplodar Kupper OK 15 15 kW single-circuit | Find out the price |

| 3 | Teplodar Kupper Expert-15 single-circuit | Find out the price |

| 4 | Teplodar Kupper OVK 18 18 kW single-circuit | Find out the price |

| TOP 4 best cast iron solid fuel boilers with a water circuit | ||

| 1 | Krontif Siberia 60 single-circuit | Find out the price |

| 2 | Kentatsu MAX-04 38 kW single-circuit | Find out the price |

| 3 | Sime SOLIDA EV 6 56 kW single-circuit | Find out the price |

| 4 | Krontif Siberia 30 single-circuit | Find out the price |

| TOP 3 best solid fuel boilers with a water circuit using wood | ||

| 1 | ZOTA Box 8 8 kW single circuit | Find out the price |

| 2 | Teplodar Kupper OK 9 9 kW single-circuit | Find out the price |

| 3 | Lemax Forward-12.5 13 kW single-circuit | Find out the price |