Automation for a gas boiler of the Arbat-1 model is a fairly simple device that provides basic functions of regulation and safety of heating systems. It is its technical specifications, possible examples of application and configuration procedures that will be discussed in detail in the future. Price offers for this component will also be indicated and recommendations regarding where to purchase it will be given. In addition to this, reviews from owners of heating and heating units based on such an automation system will be given.

Possible uses

Such automation for gas boilers is quite common. It is aimed at working in conjunction with an injection burner. Its advantages also include reliability and ease of operation. In addition to this, it has a very, very affordable price. A similar system is used both as part of heating systems and double-circuit units, which can not only heat the coolant, but also provide hot water.

Also, the automatic device for a gas boiler of this model allows its use in gas boilers. Another possible option for using Arbat-1 is gas hot water heaters.

Gas equipment for KChM 630 EUROSIT

In distant post-Soviet times, when natural gas for the population cost nothing, solid fuel boilers began to be produced with gas fittings of the APOK-1 type, which replaced solid fuel in the form of coal and wood. The gas supplied to the KChM had a complex and cumbersome device with burners that consumed gas within large limits. Nowadays, they have begun to produce more modern and economical gas boilers that consume less gas, but not all owners of private houses can afford them. Of course, old KChM boilers are not so aesthetically pleasing and modern, but if they are modernized, they can serve as heating devices for many years.

Technological features

It should also be noted that all previously discussed units must be household and not industrial. They should also be based on an injection burner. The operating principle of the latter is based on the fact that during the combustion of fuel, the required volume of air mass is “sucked in” naturally due to a special design. Again, the lack of a forced ventilation component means that the gas-air ratio is not always strictly met. Therefore, in one case there is an excess of fuel, and it does not burn completely. In the second case, more air is already produced, and the natural gas is not completely burned.

Let's consider the main advantages

- Efficient operation of the system on different types of gas supply.

- The system does not require connection to the electrical network.

- There is a starting gas filter and a special screw to regulate the fuel supply.

- Possibility of operation of the device at low gas pressure.

- Function to turn off the system when there is insufficient draft or when back smoke occurs.

- Stable temperature conditions.

- Possibility of smooth adjustment.

- Piezo ignition is modeled to make the device as simple and convenient as possible during operation.

- Constant outlet pressure.

- Simple design and compact dimensions of the device.

Basic contours. Characteristics

The automation of the Arbat-1 gas boiler includes the following main circuits.

Monitoring the presence of pilot and main burner flames. If it is absent, the gas supply is suspended.

Changing the gas supply depending on the degree of heating of the coolant. In this case, the desired temperature value is set manually. The regulation process itself is “two-position”. That is, when the maximum set temperature is reached, the gas supply stops. When the water cools to the lowest permissible value, the heating system automatically starts.

That is, this automation for a gas boiler essentially provides control of two main parameters: coolant temperature and the presence of flame. The technical characteristics of this system are as follows:

- The gas pressure should be between 1300 and 2000 Pa.

- Connecting size G1/2.

- The limits of water temperature regulation are 40... 90 0C.

- Accuracy - ±5 0С.

Malfunctions of gas boilers with gas valve 820 Nova. Date of entry: 06/08/2016. What you will find below is relevant for all models of floor-standing gas boilers with electrically independent gas valves 820 Nova (code 0820010 or 0820332) and Honeywell (type VS8620C). We have already repeated it many times and will repeat it again here: “Spit on the name of your boiler. The boiler is not being repaired. The boiler does not exist. The boiler is an iron jug. The gas valve or its equipment is being repaired.” Go! (Based on real events) Laws of practice for boiler repair: 1. The more we understand, the more complex the malfunctions that await us. 2. The complexity of the malfunction is due to its incorrect diagnosis, conceit and lack of “grip”. 3. Each person, according to their level of knowledge, has their own fault. 4. Failure always laughs at us. A difficult case. (A case is always considered difficult if at least a couple of people have already tried to start the boiler before us.) A client arrives for a temperature regulator for an ISHMA 50 gas boiler with an 820 Nova gas valve. The valve is non-volatile. Symptoms: The boiler operates only on the pilot burner. After igniting the igniter and further switching the control knob on the gas block from the “Ignition” mode to the “Main” mode, the boiler does not start. Turning the temperature control knob also does nothing. The main burner of the boiler does not start. Condition of the gas valve (photo): The craftsmen left two wires connected to the contacts to which the EMF from the Thermal Generator arrives through the wires, to which they connected a AA battery. From the battery, as the client said, the boiler started up immediately and, since the battery was not new, it only lasted for an hour. It is not clear who recommended the client (name Timur) to replace the temperature controller. In general, he took it and came for it, and this was our initial data. To make it easier for you to understand what we are going to talk about, let’s look at some elements using a photo of the gas valve (Timur is great! He quickly sent all the necessary photos). Here is a gas valve 820 Nova. Here is the version in which there is no burner power regulator on the body. Instead, a brass plug is installed in the middle of the valve. It doesn't matter.

What we should see with you: 1 - the wire that goes to the valve terminals from the Thermal Generator. The Thermal Generator itself is a “thick finger” with two wires that connect to the valve terminals. The thermogenerator, like a conventional gas control thermocouple, produces thermoEMF (electromotive force) measured in millivolts. More details to come. 2 and 3 are the wires that the technicians connected when trying to start the boiler from the battery. 4 - knob for switching boiler operating modes: Ignition, Main mode and Off. 5 — Piezo ignition button. When pressed, it produces a spark during the initial start of the pilot burner 6 - Gas control thermocouple. The photo shows that it is not screwed directly into the valve, but first goes into a brass breaker with contacts that go to the Overheating and Poor Draft sensors. Apparently all this was torn off and inserted directly. It’s not clear how, but nonetheless. One of the terminals hangs from above - most likely it came from the breaker. The second terminal is not visible. 7 - Wire from the Piezo button to the Electrode, which gives a spark to the pilot burner during initial startup. How it works? We switch the Handle (4) to the Ignition (Spark) mode. Click on it. The gas went to the pilot burner. Click the Piezo button (5) until the igniter lights up. As soon as the igniter lights up, hold the Handle (4) in the pressed position and do not release it. We are waiting for the control gas thermocouple (6) to heat up. We currently do not have sensors for overheating and poor traction. Then we don’t take them into account. The thermocouple has heated up, release the Handle (4), the boiler operates in pilot mode. The first solenoid valve is open. It will be open as long as the control gas thermocouple is in a heated state and generates EMF. If for any reason the igniter blows out or the gas turns off, the control gas thermocouple will cool down and the solenoid valve will close and turn off the boiler. It's clear. Also, any of the “poor draft” or “overheating” sensors can open the thermocouple power supply circuit to control the first valve of the block. By the way, this option is also used in Honeywell valves, where the gas control power circuit includes both of these sensors in series and only then enters the solenoid valve. After starting the igniter with the Thermal Generator (1), the following happens. It heats up, just like the Thermocouple (6) from the igniter flame. The igniter in boilers of this type is also called the pilot burner. Doesn't matter. When heated, the Thermal Generator (1) also generates thermoEMF, which is supplied to the terminals of the secondary valve located inside the block. If there is an EMF sufficient to open the second valve, this valve is always ready to open upon command from the temperature controller. Now attention! Let's reason in our case, when switching the Handle (4) to the Main mode position, i.e., when the gas supply is already open through both valves to the main burner, the latter does not turn on. The first valve is opened by the Gas Control Thermocouple (6), the second must be opened by the Thermal Generator (1). We know that the second valve was opened by connecting a battery. This is indicated by the two wires (2) and (3) in the photo, to which this battery was connected.

By the way, this technique has not been a secret for a long time. And if there is nowhere to wait for help (for example, it’s winter and night outside), you can use a similar technique and hold out at least until the morning. Continue like this. If the second valve of the block was opened only with the help of a battery, then the EMF generated from the Thermal Generator (1) is clearly not enough to open the secondary valve of the block and keep it open. That is, in our case, Thermal Generator (1) is definitely faulty. It must be said that Thermal Generator (1) does not “die” immediately and abruptly. The voltage drops gradually and on the most faulty Thermal Generator it is still very far from zero.

It is clear that Timur does not need a temperature controller at all, but a Thermal Generator (1). Timur said that he agreed with this and, having learned that he just needed to remove two contacts from the valve terminals and unscrew the nut securing the Thermal Generator in the pilot burner under the boiler (his hand could fit through), he went to change the whole thing himself.

Then the following happened. Timur waited until the boiler cooled down and replaced the Thermal Generator with a new one. I lit the boiler pilot, switched to the Main mode, but the main burner did not start and did not start. That is, no reaction at all! He connected the battery back and it started. I waited five minutes until the Thermal Generator was sure to heat up. And again nothing. We had one master who went there like this three times and gave up on it, saying that the new Thermal Generator was also faulty. And there was one company that repaired boilers, which returned the thermogenerator, they say, it was defective. Timur might have thought so too, but he didn’t say anything. And he wasn't a boilermaker, so he just listened to the phone and did it. This was his best quality, thanks to which he started the boiler. And there was one more thing that was impossible to even think about. Timur had a tester at hand!!! (A multimeter (tester) is a multifunctional device that allows you to measure current, voltage and circuit resistance.)

Then everything was simple. Apart from the thermogenerator, nothing opens the second valve. And nothing stands in the way of this chain not working. It's clear. We make sure that the new thermogenerator is in order. Timur unscrews the new Thermal Generator, places it on the candle flame and measures the EMF. 760 mV is excellent. In order to make sure that the old Thermal Generator is “dead,” he also checks it on a spark plug and sees an indicator of 240 mV, i.e. no longer working.

And it immediately becomes clear that the igniter flame does not heat the Thermal Generator properly. Moreover, what a coincidence! The thermogenerator is not working and at the same time the igniter is not burning properly!!! Of course, a perfectly working gas control thermocouple is confusing. Next, Timur turns the tube inside out. He looks at the igniter jet from there and immediately sees that it is in disgraceful condition. He thoroughly blows out the jet, installs it in its place and starts the boiler. The question is closed.

There is a second question. How many people with a boiler can the same thing happen to? We don't know. See Laws 2 and 3 above.

Setting procedure

Gas heating boilers in conjunction with this automation system are started as follows:

- The presence of traction is checked.

- Then set the thermostat knob to position “0”.

- We open the shut-off valves and supply natural gas.

- By pressing the start button for 30 seconds, we light the igniter.

- After this, the main burner will automatically light up.

- We set the required temperature value on the thermostat, and after that the system is in operation.

Flame and draft sensors

Flame and draft sensors work on this principle. The draft sensor reacts to deteriorating smoke draft and transmits an impulse to the control system. It is located in the smoke hood. Equipped with a plate made of an alloy of two metals: iron and nickel. When draft deteriorates, flue gases accumulate and heat the plate. It becomes deformed, the contacts open, and the flow of fuel into the combustion chamber stops. When the temperature decreases, the plate returns to its normal state.

The temperature sensor works on the same principle. When the water in the boiler heats above the set temperature, the lever mechanism is activated and the temperature regulator valve closes. The gas supply stops and the burners go out.

When the water cools, the sensor bellows contracts, the lever mechanism is activated, the temperature regulator valve opens, gas begins to flow, and the burners light up.

Price

Currently, this model of automation system for gas heating boilers, designed by Arbat-1, costs about 2500-2700 rubles. Possible places to purchase it are online stores, market kiosks, construction supermarkets and specialized retail outlets. Experience shows that it is most optimal to purchase such equipment in the last place. Still, this equipment is specialized in nature, and it is best to buy it from professionals. In other cases, problems may occur when starting up this equipment and its further operation.

Reviews

Automation for gas heating boilers "Arbat-1" has a number of significant advantages, which owners in their reviews include ease of operation and setup, low cost and reliability. But the main disadvantages of this unit include the fact that it is designed to work in conjunction with injection burner devices. The latter today can no longer provide the required quality of combustion of natural gaseous fuels and have a low efficiency factor. Therefore, use such devices only when repairing old boiler units.

Gas automation for an old-style boiler

The latest gas boilers are characterized by very high efficiency and power density. But their cost somewhat limits their scope of application, and it is irrational to throw away old boilers. Modern gas automation for an old boiler significantly increases its efficiency, safety level and profitability.

This is achieved through the use of micro-flare burners, precise thermostats, circulation pumps and other devices that increase the efficiency of heat transfer from burned fuel and reduce heat loss during coolant circulation. Modernizing an old boiler very often involves a significant amount of work to change the configuration of the entire heating system.

Old-style boilers, for example KChM, KST, KSTG, AOGV, were designed for gas parameters and the features of heating systems, the standards of which were changed decades ago. But the durability and quality of workmanship allow these boilers to be used for many more years. The technical characteristics of most old domestically produced boilers make it possible to select an automation that most advantageously uses the design features of the firebox and heat exchanger of a certain model.

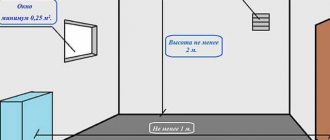

Gas automation for an old boiler must have an appropriate installation size in order to make the most efficient use of the internal space of the firebox and eliminate the occurrence of emergency situations. Some modern automation systems are developed taking into account the possibility of its use specifically on boilers of older modifications.

If you are planning to install such a boiler at your dacha, in a workshop, or even in your home, then you won’t have to look for a long time for gas automatics. Torch, ARBAT, APOK 1, Flame, PHOENIX, VAKULA and many other systems of domestic and foreign production will allow you to modernize the boiler and increase its operational level to the best modern models.

As a rule, gas automation for an old boiler does not require its structural modification. The changes concern only the burner device and the feedback system, which allows more precise control of the combustion process. All automation is adapted to domestic gas supply parameters and its installation and configuration does not take much time. When choosing an automation model, you should pay attention to the power of the boiler, the design features of the combustion part and the design of the heat exchanger.

It is very profitable to select and buy automation for old boilers in our online store. We serve Kyiv, Dnepropetrovsk, Lutsk, Vinnitsa, Chernivtsi. Deliveries of goods are made throughout Ukraine.