Home » Classification of gas boilers » Operating principles » Setting the modes of the Immergaz gas boiler

Heating equipment made in Italy by Immergas has long been known on the Russian market. It includes modern technologies and has the ability to connect other auxiliary devices, for example, a room thermostat or an outdoor programmer. Setting up a gas boiler Immergaz allows you to control the operation of the unit in two modes: via the remote control or using a panel located on the body.

…

- 1 Turning on the gas boiler

- 2 Setting the unit power

- 3 Programming settings

- 4 Other gas boiler settings

Turning on the gas boiler

Before turning on the gas boiler, you should check that the pressure in it is at the level of 1-1.2 bar and the gas supply valve is open. Then the Main handle must be moved to the “Remote control” or “DHW and heating” position. When one of the modes is activated, the top green indicator lights up.

If the unit is in the “Remote Control” mode and the remote control is connected to the boiler, the manual switches stop functioning. Setting up a gas boiler and turning on various functions is done from the remote control. When the remote control is activated, indicators 2 and 3 on the unit body are constantly lit, above which there are images of a water tap and a radiator. Indications of modes or failures are displayed on the remote control display.

If the knob is turned to the “Remote Control” position and the remote control is not connected, the heating knob will turn off, but the hot water knob will work.

When the “DHW and heating” mode , the heating knob is used to adjust the heating power, and the DHW knob is used to change the temperature of the water circuit.

…

If any light in the group, which includes 7 indicators located on the right, blinks, this indicates a malfunction.

How to properly set up a gas boiler?

Find out here the features of a wall-mounted gas boiler

Gas boiler temperature regulator - purpose and types

Installation and operation

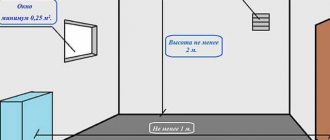

In order for Italian gas equipment to work properly and uninterruptedly, its installation must be carried out by specialists. They also carry out the setup and first launch. The device must be suitable for the heated area. Each device comes with instructions detailing the installation process. How to install a wall-mounted boiler:

- The device is attached to the wall.

- The device is grounded - it will protect it during thunderstorms, and connected to the electrical network.

- Install the expansion tank. If forced circulation of the coolant is provided, install a pump.

- Connected to the heating system.

- The system is tested for leaks; the instructions describe this process.

- Remove oxygen accumulated in the pipes.

- When the connection is complete, perform the first launch.

Setting the unit power

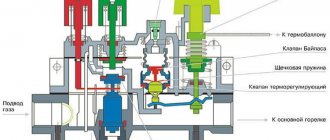

You can adjust the optimal power of the Imeergas gas boiler using the gas valve. Setting the operating power of a gas boiler is carried out as follows:

- set the DHW switch to the desired position;

- open the hot water tap;

- adjust the required power using the adjustable nut on the gas valve;

- adjust the heat output by turning it clockwise to increase it, or counterclockwise to decrease it.

The minimum heat output can be adjusted using a plastic screw located on the gas valve. The adjusting nut must remain motionless. It is recommended to turn off the power to the valve modulation coil and then turn the screw clockwise to increase the pressure or counterclockwise to decrease the pressure. After this, the power to the coil must be returned.

…

Note! The minimum power should not be less than that specified in the characteristics of the unit.

Connection

Diameter of coaxial chimney 60/100 mm Connection of a separate chimney (diameter 80 mm) yes Dimensions (WxHxD) 440x756x240 mm Weight 29 kg Before purchasing, check the technical specifications and equipment with the seller <header>

Manufacturers

- 102EVAN

- 99Lemax

- 75Protherm

- 72MORA-TOP

- 67Baxi

- 50Navien

- 44ZOTA

- 40Buderus

- 40Ariston

- 28Vaillant

- 28Viessmann

- 26Kentatsu

- 26Kiturami

- 25Teplodar

- 24Pechkin

- 24ZhMZ

- 23Ferroli

- 23Bosch

- 19Electrolux

- 17Oasis

- 14Borinskoe

- 14Haier

- 13Beretta

- 12RusNIT

- 12Wattek

- 11Siberia

- 10Conord

- 10Stropuva

- 10Teplotech

- 9Immergas

- 9Hearth

- 9Kospel

- 9Elektromash

- 8Wespe Heizung

- 8Leberg

- 8Rinnai

- 8Arderia

- 8Savitr

- 7Roda

- 7NMK

- 7Ural-Mikmah-Term

- 6Daewoo

- 6Rostovgazoapparat

- 6Dzenzelevsky Boiler Plant

- 6Zerten

- 6Master Gas

- 6Federica Bugatti

- 6Mr. Heat

- 6Karakan

- 5Elsotherm

- 5Alvin

- 5Wolf

- 5Rilano

- 5TRAYAN

- 5Sirius

- 5Mimax

- 5Koreastar

- 5FACI

- 5Reco

- 5Mizudo

- 4Sime

- 4Bourgeois-K

- 4ATON

- 4Viadrus

- 4BaltGaz

- 4Alphatherm

- 4Fondital

- 4Tiberis

- 4Stoker

- 4Bauertherm

- 4Geyser

- 4Dozatech

- 4Neva Lux

- 4Intois

- 3Saturn-heat

- 3Rugas

- 3Territory of heat

- 3Thermotrust

- 3Baltur

- 3Galan

- 3De Dietrich

- 3Olympia

- 3UralProm

- 3STOUT

- 3TMF

- 3Signal-Teplotechnika

- 3Electrovel

- 2Unilux

- 2Maxi-life

- 2MOST

- 2Atmos

- 2Northerner

- 2Kostrzewa

- 2Pelletron

- 2Keber

- 2Lavoro

- 2Termofor

- 2Thermona

- 2ROC

- 2Chaffoteaux

- 2Burnit

- 2Alpine Air

- 2Froling

- 2Zharstal

- 2Gazlux

- 2Siberian master

- 2GREIVARI

- 2ERDO

- 2KAZ

- 2VIRA

- 2Nova Florida

- 2Yaik

- 2MOZYRSELMASH

- 2Unical

- 2HydroSta

- 2Tenko

- 2SAKOVICH

- 2Lavoro Eco

- 2Resource

- 1Celtic-Rus

- 1Innovita

- 1Verpat

- 1Pereko

- 1Atem

- 1Metal-Fach

- 1Parpol

- 1Vesuvius

- 1ThermoStyle

- 1Flames

- 1CAMPFIRE

- 1Heiztechnik

- 1Alpenhoff

- 1TEPLOV

- 1Italtherm

- 1Royal Thermo

- 1BIASI

- 1Thermex

Programming settings

Immergaz boilers of the Zeus series allow the user to program their own settings, each of which has its own indication.

To activate the programming mode, set the main control to the Reset position and hold for 15-20 seconds until the top indicator flashes. Then you need to switch the main regulator to the “DHW and heating” mode.

First, the first programming level is activated, which will allow you to adjust the parameters. You can determine the programmable parameter using 10 indicators, indicated by the corresponding icons:

- 1 – minimum heating power;

- 2 – maximum heating power;

- 3 – heating switch-on timer;

- 4 – parameter of smooth power control;

- 5 – pause time before ignition when working with a thermostat or remote control;

- 6 – thermostat of the DHW circuit;

- 7 – circulation pump;

- 8 – heating of the DHW circuit;

- 9 – gas;

- 10 – operation of relays and safety sensors.

The activated parameter will flash. At the same time, the upper sensor will also blink. You can adjust the required value using the DHW heat exchanger temperature switch.

After selecting a parameter, move the main switch to the Reset position and hold it until the indicator of the corresponding parameter goes out. After this, the mode switch is released.

A second level of programming is now available. Activation of parameters is indicated by blinking of the corresponding indicators. The values are changed using the heating temperature controller. The selection is confirmed by moving the main switch to the Reset position. After this, the mode indicator should go out. Programming mode will turn off if there is no activity for 30 seconds or the main switch is turned to the OFF position.

The automatic gas boiler provides power modulation depending on the room temperature. By setting the maximum and minimum performance values, the unit will operate within the set power range.

Competitors

Table. Comparison with competitors and analogues Photo ModelRatingPrice

| sample in review Immergas Nike Mythos 24 3 R | 6,4 | RUB 37,938 |

| Ariston CLAS X SYSTEM 15 CF NG (RU) | 5,4 | RUB 38,530 |

| Ariston CLAS X SYSTEM 15 CF NG | 6,2 | RUB 39,472 |

| BAXI ECO-4s 18F | 7,3 | RUB 38,371 |

| Navien GA 23KN | 6,1 | RUB 38,005 |

| Fondital Minorca CTFS 24 | 6,5 | RUB 38,500 |

| Fondital Victoria Compact CTN 24 AF | 6,4 | 38,000 rub. |

| Immergas Eolo Star 24 3 | 6,5 | RUB 38,899 |

| Immergas Nike Star 24 3 | 6,3 | RUB 37,351 |

| MORA-TOP Meteor PK24SK | 5,8 | RUB 36,297 |

Other gas boiler settings

The gas boiler is equipped with an electronic timer that prevents frequent ignition of the burner. According to the factory settings, the timer is set to 180 seconds. It is possible to set the timer time from 30 seconds. up to 255 sec.

The gas boiler is equipped with a circulation pump, which has two operating modes:

- the first one turns the pump on and off based on a signal from the thermostat or remote control (the 1st light will be on);

- the second is designed to operate when the main switch is in heating mode (the last light will be on).

The user of the Immergaz gas boiler has the opportunity to activate “DHW heating”, which will constantly maintain the water temperature in the secondary circuit at 50°C. This allows you to quickly get hot water.

Neutral reviews

Advantages:

works well so far

Flaws:

broke down, then at least we were crying without heat for a week until the repairman arrived

A comment:

The boiler worked for 5 years and the control board burned out; the board costs 100 USD without warranty. and work 50 b.r. new, but the warranty on the new board is only half a year, which is very upsetting. Another big minus is that no one undertakes to repair this boiler except for one single monopolist company and the local gas networks (whose professionalism is doubtful).

repair is problematic

Advantages:

silent

Flaws:

consumes gas excessively, heats water unevenly

Thunderstorm, power surge (there is a stabilizer) and repairs for 11 thousand rubles. The master said the board is burning out... all over Vladikavkaz... Just a holiday for the “Giraffe”... it’s never possible to swim at a normal pace. the water is either boiling water or cold... (especially pleasing when you are in foam) The pressure drops constantly... I almost didn’t follow it... cold...

Why shouldn't you carry out repairs yourself?

The only reason why you should repair a boiler yourself is solid experience in repairing boilers and the corresponding specialty. Otherwise, it’s better not to take risks and turn to professionals.

- The technician will promptly identify the true problem and its causes.

- The specialist will offer various solutions and may recommend additional equipment.

- An experienced person has all the necessary tools needed to repair or replace parts.

In addition, the technician will do it as quickly as possible, and you can enjoy a safe and properly functioning boiler.

Expert advice

- Before you begin repairing the Ariston boiler, you need to press the “RESET” button (translated as reset, playback, zero) and restart the heating installation. Often this helps restore its functionality. As a rule, the occurrence of an error is caused by voltage instability - a typical case in the private sector.

- If an Ariston boiler does not have a display and its indicator lights are blinking, it is not a fact that a malfunction has occurred. This happens when the Comfort mode is turned on. The heat generator is forced to adapt to the microclimate in the room, hence its periodic switching off/on

Ariston CARES X 24 FF control panel diagram with explanations

Decoding

Parasitic flame - this is how the malfunction is described in the instructions for the boiler. Error E35 is not typical for Baksi, it is rare, and even experts find it difficult to accurately diagnose the equipment. On thematic forums, the emphasis is on the failure of the Baksi board, although failures are mainly caused by external factors: instability of power supply parameters, improper grounding, interference, and a number of others. The cost of the control unit reaches 30% of the price of the Baxi boiler, and if error E35 occurs, you do not need to immediately purchase a new board - the reason for the unit stopping is not necessarily its malfunction.

Baxi boiler control board

Causes

Loud operation of the equipment is caused by the following possible reasons:

- There is a shortage of water in the heating system, the presence of airiness - you should definitely check the pressure gauge readings, and also bleed the air from each battery.

- The formation of scale in the coolant, which breaks off with temperature changes and contributes to overheating of the antifreeze.

If the boiler becomes noisy, do not ignore it, but immediately call a specialist to find and fix the problem.