Having realized the dream of purchasing a country house, many buyers are faced with difficulties in choosing a suitable boiler for heating the building. How much power is enough to maintain a comfortable temperature level? What type of boiler will satisfy the buyer's needs? The purchase is important, so when choosing a gas boiler, you should carefully study all its characteristics.

Types and design of a gas boiler

Before we talk directly about all the components of a gas boiler, we need to consider what options there are for these heating devices.

Of course, they all have a similar structure, but, nevertheless, some models are equipped with individual features that are characteristic only of them. The classification of boilers operating with gas is as follows:

- samples of floor and wall type. If we talk about convenience, then wall-mounted equipment, which is more typical for private buildings, would be more acceptable. The main advantage of a floor-standing unit is its much greater power, as a result of which it can be used to heat a room with a very significant area. Such models are very often used in production;

- gas boilers of atmospheric and turbocharged type. To understand how gas heating with an atmospheric boiler works, you can recall the principle of operation of a standard stove, where air from the room enters a specially designed chimney due to natural draft. Turbocharged devices are equipped with a fan, which is included in the design, and the fuel combustion chamber is completely closed, so all the required amount of air comes from the street (more: “How does a turbocharged gas boiler work - principle of operation, advantages and disadvantages”);

- mechanisms with one and two circuits. The design of a gas boiler with one circuit is designed so that this equipment is used exclusively for heating rooms, while devices with two circuits can also play an important role in the water supply system, providing the room with hot water;

- boilers equipped with a conventional burner or a modulating burner (for more details: “What are the types of gas burners for heating boilers - types, differences, rules of use”). In the second case, the power of the operating equipment is automatically regulated, due to which fuel costs can be significantly reduced;

- devices with electronic or piezoceramic ignition. The first option is more convenient, since it is possible to ignite the fuel in the combustion chamber without the direct participation of the owners, and in the second case, it is necessary to turn on the device every time you start it by pressing a certain button.

Operating rules

During operation of an open-type gas boiler, it is necessary to ensure a sufficient air supply in order to ensure complete combustion of gas.

Otherwise, the efficiency of the unit will be low, and the volume of unburned gas will be large, with possible release into the room. In closed fireboxes, it is also important to monitor the sufficiency of air and the functionality of the blower fan. Basic rules for the safe operation of a heating boiler operating on gas fuel if there is a gas smell:

- immediately turn off the gas valve to the burner device;

- open windows for ventilation;

- in closed-type boilers, forced ventilation is turned on in the chimney system of the gas boiler;

- do not use electrical switches and matches;

- immediately turn off the open flame;

- report an emergency to the gas service.

Autonomous heating is gaining popularity; for many homeowners it has become as necessary in the cold season as an air conditioning system in the summer - an affordable level of comfort in residential premises that ensures normal life activities.

The main function in this is performed by modern boiler installations - technologically advanced, innovative units capable of solving multi-level thermal problems.

Design and principle of operation of a gas heating boiler

As mentioned above, most heating boilers are similar in design.

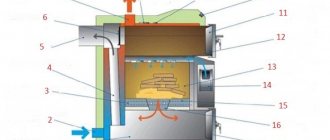

But in order to understand how to use a gas boiler correctly, you need, of course, to know what structural parts this equipment consists of. The basis of a standard gas boiler is the following elements:

- rectangular gas burner

. This design includes nozzles, which serve as a point for conducting gas into the combustion chamber. Thanks to these elements, the flame is distributed evenly, which makes the combustion of the coolant inside the system more efficient; - heat

exchanger This device is a metal box equipped with a built-in battery. Inside this box there are pipes through which the coolant circulates. Heating of water occurs due to the fact that the heat exchanger, heating up from the gas burning inside the chamber, transfers heat to it. If in a single-circuit type boiler there can be only one heat exchanger, then in double-circuit devices there can be two (primary and secondary); - circulation pump

. Using this device, the pressure that occurs in a circulation system operating on a forced principle is regulated. Not all boilers are equipped with such a part; - expansion tank

. The main purpose of this element is to temporarily remove coolant, which is necessary in the case of heating and expansion of water. This tank is equipped with a special container that can be suitable for any gas boiler. If you plan to use heating equipment over large areas, you can install another expansion tank; - a device responsible for removing fuel combustion products

. In atmospheric boilers, this element is connected to a separate chimney that has natural circulation, and in turbocharged mechanisms there is already a double coaxial type exhaust pipe, in which combustion products are removed by means of a built-in fan; - an automatic system that serves as the boiler control center

. Its main element is an electronic circuit that allows you to set the desired operating mode of the boiler based on the data displayed on the installed sensors.

In order for the service life of a gas boiler to be as long as possible, it is important that each of its elements functions reliably and properly (about

Briefly about the main thing

The design of a natural gas boiler is based on the following working units included in its design:

- Flame former.

- Heat exchange circuit.

- Pump.

- Expansion tank.

- Chimney.

- Control module.

- Automation.

A gas boiler operates on the principle of burning natural gas in a burner and transferring the released energy to the coolant through a heat exchanger. The units differ in the method of installation, smoke exhaust and combustion chamber, number of heat exchange circuits, type of ignition and heat removal scheme. Installation of equipment is carried out by specialists strictly according to technology. Regular inspection is required during operation.

Ratings 0

Circulation pump operation

What the performance indicators of the circulation pump will be depends, first of all, on the power at which the boiler operates, and this device does not have much influence on the operation of the entire system. It is very important that the pipes through which the coolant circulates are made of high-quality material, for example, steel or good plastic.

How to choose?

To choose the best gas heating unit, you need not only to study the characteristics of the model, but also to study reviews of consumers who are already using the equipment. Traditionally, the popularity rating of household heating units is headed by German-made models. Boilers of the Buderus, Bosch, and Valiant brands have the most enthusiastic reviews from consumers.

In addition to German-made models, the rating of popular models includes Italian boiler models. The best reviews about the brands “Ariston”, “Beretta”, “Baksi”. However, recently, due to changes in the exchange rate of the national currency, the ranking of the most popular brands included models of domestic and Asian production.

The best reviews are left for models made in South Korea. The ranking of the most purchased models included the KITURAMI and NAVIEN models. Both options have excellent performance characteristics, and the NAVIEN boiler is also relatively inexpensive.

Modern gas boilers are compact installations in which the main processes occur automatically. When choosing models, you should not only get acquainted with the description and characteristics, but also read reviews from consumers who are already using the equipment and know about its weak and strong points.

Operating principle of the expansion tank

This device has a significantly more serious impact on the operation of the gas boiler.

This device is designed so that in the event of an excess of coolant in the system, which usually occurs due to overheating of the coolant, the excess water is stored and subsequently used again. Approximate calculations show that the total volume of such a tank should be about 10% of the total water in the heating system, therefore, for the installation of such equipment, it is important to have data regarding the length of the pipes and the capacity of the heating system. To understand in more detail the features of installing a gas boiler, you can always study additional photos of all its structural parts and watch videos on their installation, which can always be found from specialists involved in connecting such equipment.

Video about the construction of a gas heating boiler:

Installation stages

Installation of a wall-mounted gas boiler is carried out by specialists using the following technology:

- Preparing the room for placing the unit in accordance with regulatory requirements.

- Creation of a ventilation system.

- Installation of fasteners and brackets.

- Installation of the unit.

- Supply and connection of heating system pipes.

- Connecting cold water supply.

- Connecting gas boiler equipment to a gas source.

- Installation of wiring, connection of electrical appliances and automation.

- Installation of a chimney.

- Checking, preparing and test running the boiler.

Important! In the room where the gas boiler is installed, safety regulations must be strictly observed. Wall decoration is allowed only from non-combustible materials. In addition, the presence of an air gas sensor is a mandatory condition for operating the unit.

Popular manufacturing brands

The efficiency and economy of gas heating is confirmed by the high demand for gas boilers.

A large number of companies produce this type of equipment. European companies are leading in this direction, but manufacturers from Southeast Asia and Russia are practically not lagging behind them. The number of firms is large, which creates serious competition between them.

The most famous companies are::

- Vaillant . A well-known German brand that produces reliable and high-quality gas boilers;

- Buderus . A company from Germany produces high-quality heating equipment of a high level;

- Viessmann . Another German company whose products are highly valued by users all over the world;

- Ariston . The Italian company is currently a subsidiary of Indesit.

- Baxi . Another well-known company from Italy;

- Protherm . Slovak company. Known for naming a series of gas boilers after animals;

- Navien . Korean manufacturer of inexpensive and high-quality gas boilers;

- ZhMZ . The abbreviation “Zhukovsky Machine-Building Plant” is well known in Russia. Non-volatile boilers from this manufacturer are characterized by stable operation and low prices;

- Lemax . The company from Taganrog (Russia) produces gas boilers of high quality and affordable cost.

The list of companies producing gas heating equipment is far from complete.

New companies are constantly emerging, and companies are merging into single holdings . Changing the situation contributes to the development and improvement of equipment, allows us to achieve better performance and reduce prices.