Heating systems using gas as fuel are highly efficient and reliable. The thermal energy generators in them have impressive efficiency and are safe to use. There are several ways to organize gas heating for a private home.

There are solutions both budget-friendly and more expensive with maximum efficiency and operational stability. We are ready to share with you proven options for installing a gas heating system. Using our recommendations guarantees the construction of a trouble-free and secure network.

The information we provide is based on building regulations. The information offered for review is supplemented by visual photo illustrations, diagrams and video tutorials.

Features of water heating: system requirements

The dominance of water heating in the private sector is explained by its advantages:

- System reliability. The process is ideally simple and streamlined: water heated from the boiler circulates in the pipes in a closed circuit, gives off heat and returns back.

- Heat capacity (and heat transfer) of water. It is sufficient to heat a residential building efficiently and evenly. Other coolants (including antifreeze) have worse performance.

- Cheap. Water is a cheap and environmentally friendly coolant.

Disadvantages can be considered:

- Expensive pipeline installation.

- Constant consumption of funds for heating the system (and where is it not constant?).

- Thermal inertia. The effect after turning on water heating is not felt immediately (compared to air heating).

- Care. It is necessary to monitor the condition of the system: metal elements are susceptible to corrosion, heating radiators must be kept clean (dust reduces heat transfer).

- Features of functioning. Turning off the heating in the winter can lead to an accident (the water will freeze and burst the pipes). Owners of summer cottages should consider replacing water with antifreeze (or replacing the system).

If water flows from the tap, the system is not aired Source binbank-info.ru

Before the water runs through the pipes, giving off heat and lifting the mood, it must be heated. The heating method (type of heating) is selected based on several criteria:

- Availability of fuel (its price and possibility of uninterrupted receipt).

- System installation costs (cost of labor, equipment and materials).

- Maintenance and repair costs.

The dangers of natural gas

If the gas content in the air is exceeded , such an atmosphere can cause poisoning . A dangerous concentration in the presence of a spark causes an explosion, leading to fires and destruction of house structures.

Any energy is dangerous if you do not control the serviceability of the devices. The mixture of air and gas becomes explosive when the room atmosphere exceeds a certain percentage. Flavorings are introduced into the mixture so that in the event of a leak, a person can detect the presence of gas in a volume of no more than 1/5 of the lower concentration of the explosion .

Toxicity

Exceeding the norm of gas in the air leads to poor health and even death. The first signs of deterioration are headache and shortness of breath.

Symptoms of mild poisoning:

- pounding in temples;

- chest pain and dry cough appear;

- watery eyes, nausea;

- sometimes auditory and visual hallucinations occur;

- The heart beats faster and blood pressure rises.

In case of severe poisoning, loss of consciousness occurs convulsions begin a coma develops paralysis occurs . automatic sensors in the gas system of your home that can turn off the supply.

If you smell gas, a person should immediately turn off the gas in the apartment and call emergency services.

Explosion hazard

A gas leak in itself is not a disaster, but it leads to an emergency situation, an explosion. The cause of air ignition can be a burning cigarette or a lit match. When you turn on electrical appliances a random spark , which will also cause an explosion. If there is a sour smell of gas in the house, you should not turn on the electricity or lights.

All adults and children should know the rules of behavior when smelling gas :

- close the valve or supply valve;

- open windows, doors, create a draft;

- call specialists.

Compliance with safety rules, timely inspection of hoses, burners, and units will preserve the integrity of the premises and health.

System components

Before work begins, a project for the future heating system is drawn up. The heating scheme for a private house with a gas boiler takes into account the size and location of the building, on the basis of which the components are selected:

Heat generator

The type of heating system is determined by the selected fuel. Depending on the fuel used, there are:

- Gas boilers. Gas can be obtained centrally or you can create your own storage facility.

- Diesel.

An economical and reliable method of heating is a gas boiler Source sedmoycanal.com

- On solid fuel. The raw materials are coal, firewood, peat, fuel briquettes or pellets (wood fuel pellets).

- Electrical. Electrolysis (electrode), induction devices, as well as boilers with heating elements are used.

- Combined. Popular options are combinations of gas with solid or liquid fuel.

- Universal. The design has several fireboxes for different types of fuel.

Pipes

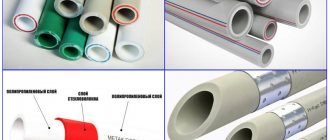

Installation of gas heating in a private house involves the use of several types of pipes:

- Steel. There are ordinary and galvanized products that are connected both by welding and mechanical (threaded) methods. They can cause an accident (rupture) if the water is allowed to freeze.

- Polymer (plastic). They are not subject to corrosion, are silent, and can withstand frost without problems. Pipes have a significant coefficient of thermal expansion and do not cope well with high temperatures (only metal pipes are suitable for installing a chimney and piping a boiler).

Copper pipes in the heating distribution of a private house with a gas boiler Source vizada.ru

- Metal-plastic. Composite (multilayer) products, reliable and durable. Installation is carried out using fittings.

- Copper. They are not afraid of freezing due to their plasticity, and have high thermal conductivity (higher than that of steel products). Copper pipes are subject to electrochemical corrosion and are also expensive.

Expansion tank

Water has significant thermal expansion (when heated to 90°C, its volume increases by 4%). If in an open (non-sealed) system this is not critical, then in a closed (with forced circulation) it can lead to equipment damage. In order not to spoil the system and compensate for the pressure in the pipes, an expansion tank (hydraulic accumulator) is built into it.

The expansion tank is a sealed steel (sometimes stainless) cylinder consisting of two compartments. A flexible membrane is built between the compartments, separating the hot coolant and the pressure-compressed gas.

Algorithm of operation of the expansion tank Source kvartirnyj-remont.com

Radiators

Manufacturers produce batteries for different heating systems; they differ in the material of manufacture (cast iron, steel, aluminum, bimetallic radiators) and in the number of sections. There are several types of heating radiators:

- Sectional. Old cast iron radiators and modern tubular steel varieties.

- Panel. All-stamped steel, with heating and convection plates, on which the thermal power of the radiator depends.

- Vertical (towel rail).

- Convectors.

- Warm floor systems.

Devices and accessories

The water heating system needs monitoring. For this purpose are intended:

- pressure gauges;

- control and safety valves (shut-off valves and thermostatic valves).

The pressure gauge on the expansion tank controls the pressure in the heating system Source dvamolotka.ru

See also: Catalog of companies that specialize in heating and water supply.

Briefly about the main thing

The design of a natural gas boiler is based on the following working units included in its design:

- Flame former.

- Heat exchange circuit.

- Pump.

- Expansion tank.

- Chimney.

- Control module.

- Automation.

A gas boiler operates on the principle of burning natural gas in a burner and transferring the released energy to the coolant through a heat exchanger. The units differ in the method of installation, smoke exhaust and combustion chamber, number of heat exchange circuits, type of ignition and heat removal scheme. Installation of equipment is carried out by specialists strictly according to technology. Regular inspection is required during operation.

Ratings 0

Gas heating: types of supply

There are two ways to supply gas to the house - centralized and autonomous; The choice depends entirely on the location of the property.

- Main gas. Continuous gas supply is more functional and environmentally friendly, but is not without its drawbacks. Gas pipes are usually laid underground, which prolongs operation, but is more expensive. The cost of work is also affected by the distance of the gas pipeline; To approve the connection, it is necessary to prepare and approve a package of documents. Unreasonably long connection times and the high cost of work force us to pay attention to an alternative method of gasification.

- Gas holder. The loud name hides a storage tank for liquefied natural gas. When there is no main gas pipeline nearby, the solution will be a gas holder, whose operating principle resembles a huge lighter and is suitable for any type of boiler. Autonomous gas heating of a country house is a common occurrence in Europe, where a thrifty owner would not even think of stretching a line several kilometers long. A properly selected gas tank (taking into account household fuel consumption) is replenished 2-3 times a year.

Gas holder - autonomous gasification Source distroy.ru

Fee for gas connection to a private house

After completing all legal formalities, the contractor sends an application to the executive body for tariff regulation to establish the cost of technological connection. In this case, the customer must be notified no later than 5 days from the date of sending the application. The application is accompanied by a connection agreement, a positive expert opinion of the estimate and design documents, estimate documentation indicating the cost of each type of work.

Having studied all the documentation, the executive authority, within 22 days, excluding weekends, approves the amount of payment for each type of work separately. If the applicant refuses to connect the household to the gas pipeline after concluding an agreement and conducting examinations, the owner of the household will compensate the contractor for all confirmed expenses.

Advantages and disadvantages of gas heating

Using gas for heating has many advantages:

- Price. Gas heating is beneficial due to its better price and efficiency ratio compared to other types of fuel.

- Safety. Thanks to automation, there is no need for constant attention to the process. The work is monitored by sensors; the owners’ task is to regulate the temperature in the house.

- Dimensions. The gas boiler has small dimensions, which allows it to be placed in a small room. A room for storing fuel is not needed (which cannot be said about firewood, coal or diesel fuel).

- Economical. Modern gas boilers are capable of heating large areas; some models (double-circuit) additionally supply hot water.

- Independence. A gas tank allows a household to be independent of utilities.

Economy of gas heating Source otoplenie-gid.ru

- Environmental friendliness. The fuel is stored in a gas holder, the combustion products escape through the chimney (no need to rake out the ash, there is no unpleasant odor).

Heating a house with gas has some negative aspects:

- The installation of boiler equipment operating on natural gas is coordinated with the Gaztekhnadzor service, which is accompanied by the preparation of a project, an agreement and the collection of permitting documents (licenses).

- For safe operation of the system, a separate room with good ventilation, a separate exit to the street and a chimney is required. Automation that monitors gas leaks is also needed. Systems with an open (atmospheric) burner are a potential fire hazard.

- A change in gas pressure in the pipeline can lead to boiler failure. Some models are adapted to such force majeure.

- Some systems require electricity.

A boiler room with an open burner needs a high chimney Source permhistory.ru

Choosing a heating gas boiler

Modern gas-fired heat generating equipment has a variety of automation and is able to operate in several modes. It can be floor or wall mounted.

The second option is more compact, but has power limitations. If the model is chosen for a large private house, then you will have to purchase a powerful floor-mounted unit.

Gas boilers are divided according to the method of execution, type of ignition, energy efficiency, number of circuits and method of removing combustion products

The principle of operation of a gas boiler is extremely simple - the fuel is ignited in the burner using piezoelectric elements or electronic ignition, then as a result of burning the fuel, thermal energy is generated, which is transferred to water through a heat exchanger.

The latter is already used as a coolant in the heating system or consumed in the hot water supply.

In terms of operating efficiency, traditional convection gas boilers are inferior to condensing boilers. The productivity of the former does not exceed 90% of energy consumption. Manufacturers of the latter guarantee 100% efficiency, some models promise 105 and even 110%

The heat exchanger in a gas boiler can be made:

- made of steel (stainless steel);

- copper;

- cast iron

The most common options are made of steel. This metal is cheap and ductile, so cracks from constant heating/cooling appear less frequently.

But steel elements, with constant interaction with water from a gas heating system installed in a country house, quickly begin to corrode.

A cast iron heat exchanger is the most durable, a steel one is cheaper, and a copper one is the most efficient in transferring heat to water

Cast iron is less susceptible to corrosion, but it is quite heavy. Most boiler models with cast iron heat exchangers are floor-standing. It is problematic to mount such heavy and large equipment on the wall.

If you need a compact and extremely lightweight heating unit, then the best option is with a copper coil. However, it is the most expensive among analogues made of other metals.

To supply the cottage with heat and hot water, you can choose a scheme with two single-circuit boilers or an option with one double-circuit installation

The piping scheme and the principle of its use depend on the number of circuits in a gas-fired water heating boiler. One heat exchanger was originally intended for organizing a gas heating system in a private house. For hot water supply, it is necessary to install another boiler or immediately select a double-circuit model.

It is best to heat hot water for domestic needs in a storage boiler. Streaming models are less economical. They will spend more gas on heating.

Wall-mounted gas boilers are a fully equipped miniature boiler room. Their design has its own circulation pump, expansion tank and safety group. Most wall-mounted equipment serves two circuits

Which combustion chamber is better?

In order for the gas in the boiler furnace to burn, it needs a constant supply of oxygen. It is taken directly from the boiler room or drawn in from the street. The first option involves natural air flow, and the second – forced air flow using a fan.

Gas boilers are equipped with two types of combustion chambers:

- Closed - oxygen is supplied through the gap between paired pipes of different diameters. Combustion products are discharged through an internal channel.

- Open - air enters the firebox from the room with the heating installation through the supply valve. Combustion products are discharged through a round smoke channel.

The first option is independent of the area of the room. Suitable for rooms of any size. The coaxial type of chimney can be removed from a unit with a closed firebox through a wall or an upper ceiling with a roof.

In the second case, you will have to install a high chimney pipe of 5–6 meters, otherwise the draft to suck the required volumes of oxygen into the combustion chamber will not be enough.

But gas boilers with an atmospheric burner do not require an electrical connection. There is no fan in them, everything happens naturally without forced circulation.

Boilers with closed chambers and forced air injection have a higher efficiency compared to open ones, but they require a constant power supply to operate

It is recommended to install gas water heaters with an open firebox in special rooms with good ventilation. If you install them in living rooms, they will greatly reduce the amount of oxygen in them.

It will no longer be possible to do without a forced ventilation system. And this means additional costs for the installation and subsequent operation of air ventilation equipment.

Characteristics of condensation models

In conventional gas boilers, water vapor generated during gas combustion flies out into the chimney. During the combustion process, little of it is formed, but it still carries a fairly significant amount of thermal energy. To avoid wasting this heat, condensing boilers were developed.

Flue gases in a condensing boiler, before exiting into the chimney, pass through a secondary heat exchanger, where they slightly heat the cold water entering the unit

The operating principle of these installations is based on the fact that when cooled, the exhaust gas vapor transfers heat to water from the return of the heating system. In this case, the temperature of the coolant increases slightly, but the recuperator is quite suitable as an additional source of thermal energy.

Condensed water from the condensing boiler is discharged through a special pipe into the sewer or into a separate container. Here it is worth clearly understanding one nuance - the condensate formed is actually a weakly concentrated acid. Moreover, up to 4–6 liters can leak per hour.

If this liquid is poured into a septic tank, then all the microbes living in it will be destroyed. If there is a treatment station in a country house, condensate from the boiler cannot be drained into the sewer system. With the design of the chimney everything is simpler; just take one that is designed for boilers with a closed chamber.

Design diagrams for heating wiring of a country house

Design features make it possible to divide heating wiring diagrams into types:

- Single- and double-circuit (one- and two-pipe). The scheme depends on the type of boiler; single-circuit is used only for heating, double-circuit is also capable of heating water.

- Passing and dead-end. Types of two-pipe wiring. In the first case, the movement of the hot and cooled flow occurs in the same direction, and the water turnover time for each radiator (and the rate of their heating) is the same. A dead-end scheme involves counter-movement of flows; At the same time, radiators located closer to the boiler heat up faster.

- Vertical and horizontal. Conventional division according to the position of the pipes (risers) supplying water to the radiators. For one-story private houses, a horizontal scheme is used. In dwellings with 2-3 floors, it is used if vertically located tubes do not fit into the design (horizontal ones are easier to hide).

Radiator heating diagram for a two-story house; horizontal two-pipe distribution Source poradnuk.com

Device, main components

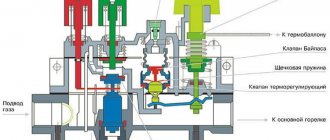

A standard gas fuel heating boiler includes the following main operating units:

- Burner.

Carries out gas combustion and uniform distribution of the generated heat to the heat exchange circuit. It can be conventionally atmospheric or turbocharged - equipped with forced exhaust of combustion products.

- Heat exchanger.

It is a box with a curved tube located inside through which water passes for heating. Divided into single- and double-circuit. Made from copper, steel and cast iron.

- Circulation pump.

Provides constant water pressure in the pipeline for its optimal distribution throughout the system.

- Expansion tank.

Prevents emergency expansion of water and its vapors inside the system.

- Smoke exhaust.

Carries out the removal of combustion products to the outside. It can be conventional - atmospheric, as well as turbocharged - with a fan for forced exhaust of gases to the street.

- Control block.

Provides configuration of system operating parameters. Connects wires, sensors, sensors, electrical circuits.

Gas boiler control module Source stroy-podskazka.ru

- Sensors for automatic control of safety parameters.

Gas automation for boilers monitors the stability of operating parameters and the safety of the system. Prevents the development of an emergency situation for various reasons - overheating, traction shutdown, loss of flame in the burner, etc.

Advice! A standard double-circuit boiler produces up to 8 liters of domestic hot water per minute. If higher consumption is required, it is better to install a single-circuit model combined with a storage water heater. The volume of household boilers varies widely - from 50 to 300 liters. This is quite enough for the everyday needs of a private home.

Boiler powered by a gas boiler Source domkotlov.by

Schematic diagrams of gas heating

Installing gas heating is a profitable solution for a country house. Gas heating systems are connected according to two principal (suitable not only for gas) schemes:

With natural circulation

They are often called gravity or gravity systems; The operating principle is based on the physical properties of the coolant. Heated water has a lower density than cold water. The return pressure of the cooled liquid (which has passed through the pipes and given off heat) displaces the hot liquid from the boiler. It rises up the heating riser, filling horizontal pipes and radiators.

Installation of heating boilers in a private house Source vashslesar.ru

To ensure that the system works efficiently and the water does not stagnate, the heating pipes are installed with a slope of 3-5°, and the boiler is installed as low as possible (for example, in the basement). The scheme has obvious advantages:

- Simplicity. During installation, it is necessary to fulfill only one condition - to organize the slope of the pipeline.

- Independence. A scheme with a gas heating boiler does not require electricity.

- Silence. The diagram does not include devices (circulation pumps) that create background noise.

- Practicality. The service life is 25-30 years without major repairs.

The heating scheme for a private house with a gas boiler is a single-pipe horizontal water heating system with natural circulation Source rusolymp.ru

There are also disadvantages:

- Contour length limitation. For the system to function effectively, the length of the closed loop should not exceed 30 m, which is only feasible in small houses.

- Service. Gravity-flow structures are prone to clogging; Periodic washing is required.

Regulations and design documentation

Absolutely all requirements for the installation of gas boilers are freely available in the following building codes and regulations:

- SNiP 31-02-2001;

- SNiP 2.04.08-87;

- SNiP 41-01-2003;

- SNiP 21-01-97;

- SNiP 2.04.01-85.

Further, data and figures taken from the relevant SNiPs are used.

1. You need to start by submitting an application for approval of technical conditions. The presence of this document gives the applicant the right to begin installation and connection of heating equipment to the central gas main. The application is submitted to the gas service, where it is reviewed by specialists within thirty calendar days.

To speed up the receipt of the above document and avoid possible delays, the application must indicate the estimated average daily volume of natural gas that will be required to meet heating needs. This figure is calculated individually according to the standards given in the first of the listed SNiPs.

- For a domestic gas boiler with a hot water supply circuit and used in central Russia, fuel consumption is 7-12 m3/day.

- A gas stove for cooking consumes 0.5 m³/day.

- The use of a flow-through gas heater (gas water heater) consumes 0.5 m³/day.

For a number of reasons, after the gas service has reviewed the application for permission to connect, it may be refused. At the same time, the responsible body is obliged to issue the owner of a private house a document that officially indicates all the reasons for the refusal. After they are eliminated, the application is resubmitted.

2. The next step after receiving technical specifications is an even longer but necessary process - creating a project. The main part of this document is a plan diagram, which indicates the location of the boiler, metering equipment, gas pipelines, as well as all connection points.

An appropriate specialist is always involved in drawing up the project. He must have permission to do this work. It will not be possible to develop a project on your own. In any case, the gas service will not accept for consideration a document prepared by a non-specialist.

After drawing up the project, it must be submitted for approval. This is done by the gas service department that controls gas supply in a specific locality or area. As a rule, it takes up to 90 days to approve the project, and only after receiving a positive response can work on arranging the boiler room and installing the heating unit begin.

The following documents must be attached along with the project and the application for its consideration:

- technical passport (available with the equipment);

- official operating instructions (a copy is possible);

- certificates;

- a document confirming the compliance of specific equipment with safety requirements.

It is also recommended to consult with a specialist drafting the project. He will provide the most up-to-date information on these issues, talk about possible innovations, changes in legislation and common pitfalls. This knowledge is guaranteed to save you a lot of time and nerves.

Approval of the project, just like receiving specifications, may result in refusal. At the same time, the owner is given an order indicating errors, shortcomings or inconsistencies that need to be eliminated. After corrections, the application is submitted and reviewed again.

Video description

About choosing a heating scheme in the following video:

With forced circulation

The circuit includes water pumps that force the water to circulate forcibly. The pump circuit does not limit the use of heating circuits; Top and bottom bottling of coolant, one- and two-pipe circuits are possible. The circulation pump is often installed in front of the boiler and allows you to do without organizing a pipeline slope.

The main condition for a forced circulation circuit is uninterrupted power supply for the entire heating period. The disadvantage of the system is that it becomes airy (usually at the beginning of the heating season).

Comparison of schemes with natural and forced circulation Source yandex.kz

Combined system

Combines the previous types, with its own characteristics:

- The distribution of metal pipes is installed with a slope.

- The pump is connected using a bypass pipe.

If the power grid is intermittent, the house is heated through natural circulation; the pump turns on if you need to quickly warm up the house.

Causes of gas explosions in houses

It is best to install a special alarm system for high concentrations of carbon monoxide or household monoxide in the atmosphere . The signal will be transmitted to gas service workers and rescuers.

Main reasons for the emergency :

- deterioration of communal and intra-apartment pipes;

- faulty devices;

- human negligence.

Valera

The voice of the construction guru

Ask a Question

It is human negligence that often becomes a risk factor. The owners heat the room by turning on the burners, which is not allowed. The fire goes out due to a draft, so an unattended stove becomes the cause of a tragedy.

Selection options

The principle of operation of gas boilers is simple: when gas is burned, energy is released, which is accumulated by water and then released in residential areas, heating them. There are several criteria that help evaluate the benefits of a particular gas device model. In addition to the manufacturer and the price of the device, most criteria are interrelated; this makes it possible to conduct a comprehensive assessment.

When designing gas equipment systems for heating a private home, medium-power boilers are often located in utility rooms Source diatec.com.ua

Installation stages

Installation of a wall-mounted gas boiler is carried out by specialists using the following technology:

- Preparing the room for placing the unit in accordance with regulatory requirements.

- Creation of a ventilation system.

- Installation of fasteners and brackets.

- Installation of the unit.

- Supply and connection of heating system pipes.

- Connecting cold water supply.

- Connecting gas boiler equipment to a gas source.

- Installation of wiring, connection of electrical appliances and automation.

- Installation of a chimney.

- Checking, preparing and test running the boiler.

Important! In the room where the gas boiler is installed, safety regulations must be strictly observed. Wall decoration is allowed only from non-combustible materials. In addition, the presence of an air gas sensor is a mandatory condition for operating the unit.

Video description

How to choose a gas boiler in the following video:

Purchasing a gas boiler

When purchasing, you should choose an organization that not only sells boilers and related equipment, but also installs them. This approach allows:

- Receive expert advice not only when purchasing, but also when installing, debugging and operating equipment.

- Be confident in the quality of the boiler and its service (timely delivery of spare parts).

- Be sure that there are no problems with warranty service (which may arise if the installation was carried out by a third-party technician).

Professional installation of gas heating - efficient operation of the system Source yandex.lv

Practical recommendations

Gas heating installation schemes must be thought out to the smallest detail, so projects must be carried out by professionals.

One example of drawing up a professional heating system plan

When choosing equipment for gas heating, remember that the main indicator is the area of the heated room. The volume of equipment, the number of radiators, the footage of pipes, fittings, valves and valves, and plugs depend on it.

When choosing a method for laying heating pipes and installing them, remember that the cold and hot distribution lines must be laid with a slight slope directly towards the hot water flow.

Experts recommend installing taps on each battery. Thanks to this, it will be possible to control the supply of hot water to a separate room of a private house. If you are using an expansion tank of 20 to 30 liters, then it should be installed at a height of 3 meters above the heating boiler.

Gas fireplace

Many country house owners use a gas fireplace as an alternative to gas water heating; they find this method practical - the fireplace decorates the interior and saves money. The fireplace copes with the task if the living area is small (up to 60 m2); It is mainly used as a source of additional or backup heating.

Gas fireplaces have a lot to offer - efficiency, convenient regulation and clean combustion Source yandex.lv

Types of domestic gas

The energy carrier for home use ignites quickly, contains a minimum volume of solid particles, and burns without soot or smoke. The composition contains a flammable mixture and a small amount of modifying additives.

There are two types of domestic gas in an apartment:

- natural;

- liquefied.

The quality of gas fuel, the standard of concentration of impurities for the natural type is regulated in GOST 55.42 - 1987, and for LPG - in GOST 20.448 - 1990.

Natural

It consists of hydrocarbon compounds, mainly includes methane (about 98%) , as well as additives of other gaseous substances (butane, ethane, propane, pentane). In the depths of the earth it is found in gaseous form or dissolved in liquid and oil.

Characteristics of natural fuel:

- density in dry gaseous form - 0.68 - 0.85 kg/m³, in liquid form - 400 kg/m³ ;

- ignites independently at +650°C ;

- begins to evaporate at +161.5°C ;

- with air it becomes explosive at a concentration of 4.4 - 17% of the volume.

Air is 1.8 times the natural gaseous mixture , so in the event of a leak, the gas rises and does not collect at the bottom.

Liquefied

It is brought into this state by artificial cooling to a temperature of -160°C in order to be conveniently transported and stored. The result is a colorless, odorless liquid.

Technical indicators:

- density 0.41 – 0.5 kg/l , the value changes with changes in temperature and pressure;

- boils at a temperature of -158° – -163° C;

- in liquefied form it is non-toxic, non-aggressive and non-explosive .

At ordinary temperature and pressure, liquid turns into gas and mixes with air . If there is contact with an open flame at this time, the substance will ignite. The liquid mass is transported in gas carriers with cryogenic tanks . After restoration, it can be transported in gas pipelines.

Documents for the boiler

Let's say you have equipped the furnace room in compliance with all requirements. Are we buying a boiler? It is too early. First of all, check if the previous gas papers have been lost, and bring them out into the light of day:

- Gas supply contract if the boiler is a heating boiler. Subconsumers can only install hot water boilers.

- All documents for the gas meter. Any boiler cannot be installed without a meter. If it doesn’t exist yet, there’s nothing you can do, you need to install it and arrange it, but that’s a different topic.

Now you can buy a boiler. But, having bought it, it’s too early to install:

- The BTI needs to make changes to the registration certificate of the house. For privatized apartments - through the organization operating the house. In the new plan, a closet under the boiler should be shown, and clearly marked: “Furnace room” or “Boiler room”.

- Submit an application to the gas service for the project and specifications. The required documents also include a technical passport for the boiler, so it must already be purchased.

- Install the boiler (see next section), except for the gas system. This can be done while the gas workers are preparing the project, if the premises are approved.

- Call a specialist to make a gas connection.

- Submit an application to gas workers for commissioning.

- Wait for the gas service engineer to arrive, he will check everything, draw up a conclusion on suitability and give permission to open the gas shut-off valve to the boiler.

Two-pipe system with top wiring

In a two-pipe heating system with overhead wiring, the expansion tank is placed at the highest point.

This two-pipe scheme is very similar to the previous one, only here it is provided for the installation of an expansion tank at the very top of the system, for example, in an insulated attic or under the ceiling . From there, the coolant goes down to the radiators, gives them part of its heat, and then is sent through the return pipe to the heating boiler.

Why is such a scheme needed? It is optimal in multi-storey buildings with a large number of radiators. Thanks to this, more uniform heating is achieved, and there is no need to install a large number of air vents - the air will be removed through the expansion tank or through a separate bleeder that is part of the safety group.

Advantages and disadvantages of a two-pipe system with top wiring

There are a lot of positive features:

- it is possible to heat multi-storey buildings;

- saving on air vents;

- you can create a system with natural coolant circulation.

There are also some disadvantages:

Using vertical wiring will lead to additional difficulties when installing hidden heating.

- pipes are visible everywhere - this scheme is not suitable for interiors with expensive finishing, where elements of heating systems are usually hidden ;

- in tall buildings it is necessary to resort to forced circulation of the coolant.

Despite the disadvantages, the scheme remains quite popular and widespread.

Features of installation of two-pipe systems with top wiring

This scheme eliminates the need to locate the heating boiler at the lowest point. Immediately after the boiler, the supply pipe is diverted upward, and an expansion tank is installed at the highest point. Coolant is supplied to the radiators from above, so a lateral or diagonal radiator connection scheme is used here. After this, the cooled coolant is sent to the return pipe.