Gas heating equipment belongs to the category of high-risk devices, therefore its installation is clearly regulated and controlled by relevant standards and authorities. To install a gas boiler in a private house, it is necessary to comply with the requirements for the room, the location of the boiler in it, the requirements for ventilation and the chimney.

The installation of the boiler itself can be carried out independently, however, only the local gas service has the right to carry out acceptance and commissioning (connections to the gas main and commissioning). Before this, it is necessary to obtain permission, draw up a project, and conclude a contract for servicing the boiler unit.

Is it possible to install the equipment yourself?

In short, the installation of a gas boiler in a private house can be carried out by anyone, but commissioning of the equipment - acceptance and testing must be carried out by specialists from the gas service; connecting a gas boiler in a private house and operating it without their permission is impossible.

It is safest to entrust the installation of gas equipment to qualified representatives of a specialized organization. Only they will be able to carry out the necessary work competently, in accordance with the requirements of SNiP, and ensure the safe operation of the equipment. In addition, a competent specialist always works under a contract, which specifies who carried out what work, when and what.

Main types of gas boilers

Manufacturers of gas equipment offer customers different types of heating boilers running on blue fuel. They are designed for heating any area and, according to the type of installation, are divided into floor and wall.

The first of them are powerful, reliable and durable “flagship models”, designed for installation in houses with above-average square footage. There is only one general drawback of such models - they will have to be equipped with a separate room.

Modern floor-standing gas boilers Source vsemixfight.ru

Wall-mounted gas boilers are an excellent alternative for a small private home: they do not require a separate room - such devices are compact and versatile. In addition, their installation does not impose increased conditions on the load-bearing capacity of the wall - it only requires a layer of non-combustible material between the boiler and the base.

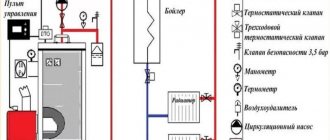

Some tips for connecting gas units to the electrical network

Many modern gas units require connection to an electrical outlet (a cable with a plug for connecting to a socket or a three-core insulated wire). In any option, the rule applies: connect the gas unit only through an individual circuit breaker directly to the panel. In addition, grounding must be done. It is unacceptable to use gas or water pipes for grounding. In the event of a power outage, backup sources are provided.

Requirements for the boiler room in the house

If the boiler output is more than 30 kW, then it must be installed in a separate room. All information on how to install a gas boiler in a private house is given in the SNiP standards, where there are clear requirements for the arrangement of a boiler room for heating equipment powered by fuel combustion.

You can place the boiler room in the attic, in the basement (basement) or simply in a separate room of the house. A mandatory requirement for this is free passage into the room, sufficient illumination and the arrangement of a rigid base.

In addition, installing a gas boiler in a private house requires the following boiler room:

- volume of at least 13.5 m³ for boilers with a power of 30-60 kW and over 15 m³ for models with higher productivity;

- convenient access to equipment.

Properly designed boiler room for a private home Source teploknam.ru

- within an hour, ventilation should provide three air exchanges;

- walls and ceilings are made of non-combustible material;

Important! Heating boilers are located at a distance of at least 0.5 m from flammable surfaces. And the partitions comply with the fire resistance standard RE1 45, that is, they must resist open fire for 45 minutes.

Types of wall devices

According to their functional purpose, gas heating units are divided into two groups:

- Single-circuit. Intended for heating only. They are connected to the heating circuit and heat the coolant. The organization of hot water supply in this case is carried out by installing an electric or gas water heater of any type.

- Dual-circuit. They heat the room and provide hot water. An additional circuit for heating water is built into the boiler. The technological feature of the device is that it is impossible to simultaneously heat water and heat the room.

The priority action of dual-circuit units is to heat the water; heating operation stops at this time. Considering that water can be heated quickly, the boiler heats the building quite effectively.

If the tasks of the gas unit are planned to include both heating the coolant and supplying hot water, then it is better to purchase a double-circuit boiler. They come with one or two heat exchangers. When equipped with two, two circuits can be served simultaneously

According to the method of fuel combustion, all devices are divided into the following two groups.

Group #1 - devices with an open combustion chamber

Such devices are also called natural draft heating devices. They take the oxygen necessary for combustion from the room in which the device is located.

To remove combustion products, they need a traditional type chimney. Thus, a mandatory requirement for installing such a boiler is the provision of good ventilation.

If the heating device is installed in a residential area, it must be equipped with high-performance supply ventilation.

The best option for installing a heating device with an open firebox is the presence of a separate room, the so-called firebox, where it is placed.

Systems with natural ventilation are quite popular due to their low cost and energy independence.

The figure schematically shows boilers with open and closed type burners

Group #2 - devices with a closed combustion chamber

Turbocharged devices are equipped with a closed combustion chamber. They take the air, without which the combustion process is impossible, from the street. For this purpose, the devices are equipped with coaxial type chimneys.

Such a chimney is made in the form of a structure of two pipes, one of which is nested inside the other. The combustion products are discharged outside through the inner pipe.

At the same time, street air flows in the opposite direction through the gap between the two pipes. It is clear that boilers with a closed firebox do not in any way affect the composition of the indoor air, which makes it possible to install them even in living rooms.

In this case, it is necessary to equip a coaxial chimney system, which is higher cost and more complex installation compared to a separate traditional chimney.

Requirements for a boiler room in a separate building

The advantages of a separate boiler room are increased safety, reduced noise levels and the ability to use the freed up space for other purposes. The disadvantage will be that the heating system will become more expensive, since it will be necessary to install an additional thermally insulated pipeline branch.

At the same time, the requirements for such boiler houses are as follows:

- separate foundation ;

- concrete base for the boiler;

- forced ventilation , which should provide three air exchanges within an hour;

- fulfillment of requirements regarding the size of the boiler room;

- no more than two heating devices can be installed in one room

- doors to the street should open outwards;

SNiP requirements for the external boiler room of a private house Source karelia-dom.ru

See also: Catalog of companies that specialize in insulating country houses.

- wall surfaces and ceilings are made of non-combustible material;

- the presence of a window with a transom for daylight and emergency ventilation - the area of the window opening must be suitable for the volume of the room (0.03 m2 per 1 m³);

- presence of a chimney , if it is needed for the device being installed (for wall-mounted devices with a capacity of less than 30 kW, a coaxial pipe is allowed to exit through the wall).

A sewer pipe is also connected to the boiler so that water can be drained from the system when it is replaced.

Flue gas removal

Channels and pipes designed to remove gas combustion products must ensure normal combustion in the boiler furnace. Due to this:

- the cross-section of the smoke exhaust duct should not be less than the dimensions of the boiler connecting pipe;

- it is allowed to reduce the cross-sectional area of the chimney if the design of the heating unit provides for the forced removal of combustion products and air supply;

- channels can be located inside capital walls and partitions of appropriate thickness or be attached to them;

- the material for the manufacture of chimneys must be fireproof and not subject to active corrosion;

- the design of the chimney must include a special hatch for cleaning the channel from soot and a device for draining the resulting condensate;

- the height of the chimney is higher than the ridge of the roof or a line at an angle of 15° when moving away from it.

All butt connections of elements are made airtight and exclude not only the release of combustion products into the premises, but also the possibility of air leaks and a decrease in draft.

Basic requirements for smoke exhaust and ventilation ducts

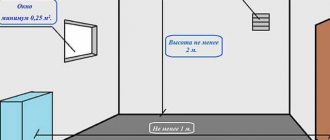

The room where the gas boiler is located must meet the necessary requirements, and not only the width and length of the room is regulated according to the power of the equipment, but also the size to the ceiling, which must be at least 2 m.

A ventilation duct must be installed in the boiler room; for this purpose, a hole with a cross-section of at least 0.02 m2 is provided.

The location of gas boilers corresponds to the installation conditions of the chimney. In this case, the parameters of the latter (height, channel area) in relation to the installed gas equipment must be strictly observed.

Chimneys for a gas boiler in a private house Source pinterest.ru

The size of the internal cross-section of the smoke outlet pipe is made the same or slightly larger than that of the device. According to NPB-98, inside the chimney opening the air flow speed should be 15-20 m/sec, and such draft can be ensured with a chimney pipe height of about 5 meters.

Important! Smoke must not be vented into a duct provided for ventilation. In boiler rooms that have a standard hood, air exchange should take place due to the incoming flow from outside the room and, partially, as a result of its penetration from adjacent rooms.

The best known manufacturers and models: characteristics and prices

Consumers whose budget for heating and hot water supply is not so limited should look for a super comfortable solution for China in products from German manufacturers. The middle price segment with a different set of options is occupied by products from other European or Asian countries. The Russian part of the market is also saturated with various options for outdoor gas boilers with almost any configuration at a significantly lower price.

Before deciding on a specific model of the future boiler, you need to decide: you only need a heating unit or a hot water unit, at what distance the boiler will be located and evaluate your own budget, then start looking at the following parameters:

- one or two circuits;

- power and efficiency;

- open or closed firebox;

- electric or piezoelectric ignition;

- appearance and design;

- cost of the product and reliability of the manufacturer.

After assessing these parameters for different models, you can decide on the purchase of equipment. Below we have given examples of the most successful and widespread models in Russia

BULAT series W and R

This is a joint development of the Russian Federation and Holland. Outdoor boilers of the W series are available with power from 24 kW to 105 kW, series R from 100 kW to 150 kW. The efficiency reaches 97%, which is considered a very high indicator for a convection gas boiler. Cascade power expansion, can include up to 3 heat exchangers, 3 pumps, 3 expansion tanks and 3 safety systems. Flexible automatic weather control and joint control of a cascade of boilers. Many additional options enhance user comfort; there is a GSM notification. The only drawback is the price.

Cost: 300,000-640,000 rubles.

Phoenix Series

A Russian-made set (Teplocenter LLC) of one or two boilers with an open firebox with atmospheric burners and circulation pumps, equipped with gas analyzers and emergency alarms (GSM). Single units are produced with heating capacity from 40 to 500 kW, double units - from 80 to 800 kW, with an efficiency of 92%. Individual equipment with cascade and weather power control systems is possible. In general, the series is distinguished by its individualization capabilities: choice of the boiler model used, automation options, notification not only via GSM, but also Ethernet. In terms of dimensions, the design is not compact.

Cost: 211,000-771,000 rub.

RS-H Series

RS-H units with an open firebox are equipped with an atmospheric burner and a circulation pump. Single boilers up to 100 kW have piezoelectric ignition and Italian safety automatics, the rest are equipped with electric ignition and American automatics. Flexible possibility of completing with additional options at the customer's request. The boilers of this series belong to the class of hydronic boilers (with a coolant velocity in the pipes of 1.5-2 m/sec), which makes it possible to maintain an extremely stable temperature even with strong heat losses.

Cost: from 240,000 rub. to calculated individually.

Gas appliance in a private home: requirements and main installation steps

To properly install the unit, you must first study the regulatory documentation and rules for performing this work. They talk about the features of installing gas appliances for the heating system.

Whatever type of boiler would have to be installed, it is imperative to comply with the requirements of certain norms and rules, such as:

- SNiP 41-01-2003 on heating, ventilation and air conditioning.

- SNiP 42-01-2002 on the gas distribution system.

- SNiP 21-01-97 on fire safety.

- SNiP 2.04.08-87 on the installation of boiler houses.

SNiP provisions contain all the necessary information for installing and starting a gas boiler Source optolov.ru

↑ Installation of a solid fuel unit with a heat accumulator

If the boiler does not have automatic loading of fuel, then it must be regularly added to the firebox yourself. This is inconvenient because the boiler needs to be fired according to a strict schedule.

This problem can be partially solved by a heat accumulator in the form of a tank of water, which is heated by the supply circuit.

Its installation allows:

- reduce the coolant temperature at maximum boiler operation;

- heat the cooled coolant when the temperature in the system decreases.

When choosing a buffer tank, it is necessary to take into account that for a house with parameters of 150 m² or more, a tank with a capacity of at least 1 m³ is required.

↑ Installation of an additional mixing unit

Another such unit is installed between the buffer tank and the heating registers.

Thanks to this element, it is possible to avoid large temperature differences when water boils in the circuit.

↑ Emergency circuit installation diagram

The main problem of heating a building with a solid fuel boiler is overheating of the coolant. It is necessary to prevent steam formation in the heating circuit, so it is necessary to cool the coolant in a timely manner.

There are 3 effective methods of cooling the coolant:

- Another heat exchanger is installed in the firebox. The first heats the coolant, and the second allows it to be cooled when it is very hot. The inlet pipe of the latter is connected to the cold water pipe, and the outlet to the sewerage system. To urgently cool the coolant, you need to open the tap on the pipe, after which cold water will flow through the additional heat exchanger.

- During the installation of the boiler, one heat exchanger is installed inside another, which allows you to quickly reduce the coolant temperature if necessary.

- 2 pipes are connected to the heat exchanger pipes, the first is connected to the cold water pipe, and the second to the sewer pipe. A valve is then installed to allow cold fluid to enter the system. As a result, some of the hot water will be discharged into the sewer.

All 3 methods allow you to achieve the desired result.

Operating rules

For safe use of gas, the connection diagram for a gas boiler in a private house must be followed. In addition, the following conditions :

- For starting the boiler only at normal humidity.

- Monitoring of technical condition by gas service specialists at least once a year.

- Installing a fine filter on the return pipe of the heating system.

- Natural or artificial ventilation in the boiler room.

- Compliance of draft in the chimney pipe with the requirements (10-20 m/sec).

In the event of a leak, promptly report to the emergency gas service.

Let's consider the method for finding the above fault.

When repairing a gas boiler, testing begins with the “weakest link” of the automation device - the draft sensor. The sensor is not protected by a casing, so after 6...12 months of operation it becomes “overgrown” with a thick layer of dust. The bimetallic plate (see Fig. 6) quickly oxidizes, which leads to deterioration of contact.

The dust coat is removed with a soft brush. Then the plate is pulled away from the contact and cleaned with fine sandpaper. We should not forget that it is necessary to clean the contact itself. Good results are obtained by cleaning these elements with a special “Contact” spray. It contains substances that actively destroy the oxide film. After cleaning, apply a thin layer of liquid lubricant to the plate and contact.

The next step is to check the serviceability of the thermocouple. It operates in severe thermal conditions, since it is constantly in the flame of the igniter; naturally, its service life is significantly shorter than other elements of the boiler.

The main defect of a thermocouple is burnout (destruction) of its body. In this case, the transition resistance at the welding site (junction) increases sharply. As a result, the current in the Thermocouple - Electromagnet circuit.

The bimetallic plate will be below the nominal value, which leads to the fact that the electromagnet will no longer be able to fix the rod (Fig. 5).

Date: September 25, 2021

Maintenance

Preventive measures for routine inspection of gas boilers include the following types of work :

- Checking the valves of the external and internal gas pipelines (disassembling, applying lubricant).

- Inspection of thermostats on floor-standing boilers.

- Washing or replacing filter elements.

- Inspection of nozzles , checking the tightness of the door, the operation of the igniter on floor-standing devices.

- draft control

- ice build-up in winter .

All components that have been subject to wear during operation must be replaced.

On a note! After completion of the repair and before starting the heating system, the gas service worker checks the tightness of all connections in the line. Usually a soap solution is used for this.

A competent preventive inspection will not only increase the service life of the equipment in use, but will also reduce gas consumption.

Repair and maintenance of gas equipment Source sanmaster62.ru

Floor type

Installing a floor-standing boiler is also not difficult, you need:

- Prepare a strong pedestal that can support the weight of the boiler. This is usually done by pouring a concrete solution, sometimes a sheet of galvanized iron is securely laid on the floor.

- Install the boiler, leveling its position using a building level.

- Connect the chimney to the unit, check the draft if there is no forced exhaust.

- Connect the device to the heating system by installing a filter at the end of the outlet line, i.e. just before the entrance.