Sectional doors are used today for insulation and sealing of various (including garage) premises. Such structures consist of a spring that absorbs vibration of the canvas, other fittings and guides. The canvas itself is equipped with special mechanisms designed for remote opening/closing using the remote control included in the kit.

Sectional doors

Sectional doors are found mainly in rooms where free space is limited. When opened, the canvas rises up, which significantly saves free space.

Sectional garage door design

Attention! Gate panels, which are made in any color, are coated with a special polymer coating during manufacturing, which protects the structure from corrosion and ensures a long service life.

If desired, a durable acrylic window can be built into the canvas to illuminate the garage, and thanks to insulating sandwich panels, the structure can operate in a fairly wide temperature range (from -50ᵒС to +70ᵒС).

Gate design

It is also worth highlighting the safety of such a design, because closing is ensured by a special locking system, which makes it possible to automatically lock the panel immediately after lifting. With proper operation and strict adherence to the manufacturer's instructions, the structure will last about ten years without repair or replacement of individual elements. Now let’s find out how to assemble sectional doors with your own hands.

Gate diagram

What structures are called sectional

Before you begin assembling the gate structure, it is important to become familiar with the features of the mechanism and the principle of its operation. Models of gates with a leaf in the form of sections are varied in design, control method, type of lift, but are similar in principle of operation. Sectional doors are a device equipped with a lifting mechanism with the following features:

- The classic canvas consists of two sections connected by hinges, but options with 4-6 sections are common.

- Guides (steel profiles with brackets) are fixed along the edges of the opening. They are attached not only to the opening, but also to the ceiling using a suspension.

- When the gate opens, the canvas, section by section, rises and is pulled along the guides into the space under the ceiling. During closing, the operation is reversed.

- Control can be manual or automatic. The lifting/lowering unit looks like a system of cables and drums; they are balanced by a spring mechanism.

Sectional curtain guide system Source mosoblzhilservis.rf

- The spring mechanism helps to balance the door leaf, making it easy to move sectional doors up and down manually, even for a lady of fragile build.

- The balancing mechanism works in two ways: using tension springs (implemented in small structures intended for private garages) or using torsion springs (more often used in industrial structures).

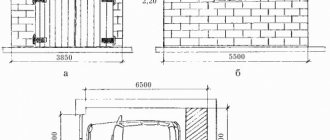

The size of the gate is selected according to the opening. Models for private garages are small in size and suitable for self-installation. The standard dimensions of private gate systems fit into the following dimensions:

- The section width ranges from 35-60 cm.

- Canvas height: 2-4 (less often 6) m.

- Length does not exceed 5 m (in a two-car garage).

conclusions

Every motorist can design an automatic garage door. To do this, you need to correctly draw up a drawing and properly equip the opening. It is important to choose the right materials based on the size of the garage door.

Recommended Posts

Design of a bathhouse with a terrace or veranda

Arrangement of a cellar in the garage for storing vegetables

How to make shelves for a garage with your own hands

DIY workbench

Bath interior inside

How to arrange a garage with your own hands

pros

When choosing the installation of sectional doors, owners are guided by the following design advantages:

- Products are characterized by an optimal price/quality ratio, especially from manufacturers who have organized production in Russia.

The sectional design is suitable for do-it-yourself installation Source planlook.ru

- Lifting the canvas inside the garage is a solution that saves space in front of the garage and does not require space inside it. This compactness is especially beneficial in small areas.

- Performance characteristics. For warm garages, choose a canvas made from sandwich panels. It is characterized by increased heat and sound insulation, and, subject to high-quality installation, it will make the opening airtight, and you will forget about dust and winter drafts. In a heated room, the temperature will always be comfortable.

- The gate system is made of non-flammable materials, which is important for safety.

- The warranty period for most models in the mid-price category, for example, from the manufacturer DoorHan, reaches 10 years; Car owners are offered not only warranty, but also post-warranty service.

- Installing overhead gates is beneficial due to their versatility: the sectional system will not be difficult to install in an opening of any size.

- Sectional structures are supported by their maintainability. If one of the sections is damaged, only that will have to be replaced.

Non-standard arrangement of the sectional structure Source prom.st

Many models of sectional doors are developed taking into account modern comfort requirements, which is expressed in the following capabilities:

- Manufacturers produce gate systems that comply with Russian construction standards and regulations. Such models are adapted for use in the Russian climate.

- Owners are increasingly choosing sectional doors with automation. The remote control allows you to control the movement of the web without leaving the machine. Garage automation is often equipped with a light bulb, so you can drive into a lit room.

- Modern overhead sectional doors are also an element of the design of the local area. You can choose a canvas of a suitable color and texture, or, if you don’t find a suitable one, paint it in any color according to the RAL card.

- Manufacturers offer a large selection of additional equipment (for example, decorative windows, mortise gates) and locking devices.

- The issue of safe operation is solved by installing protection units, these can be photocells or a device that blocks the break of a cable or spring.

Lifting sectional models fit into any environment Source avtosystems.ru

Why modern homemade garage doors are upright

Although time is a relative concept, not so long ago private garages were equipped exclusively with “as simple as five kopecks” swing gates. Two metal doors on hinges, with an upper and lower stop; if there is no second exit from the garage, then a door is cut into one of the doors. The doors were attached to a load-bearing frame made of metal profiles, either rectangular or U-shaped; in the first case, a threshold was created in the entry area. In fact, the whole process boiled down to welding the frame, welding the frames of the shutters, lining the shutters with metal sheets, installing and fixing the frame in the opening and fixing the shutters to the frame. The main advantage of swing structures was their simplicity and accessibility, especially at a time when metal cost a penny, and you could weld it yourself or ask your godfather, brother, or matchmaker. Disadvantages are abundant - unreliability and leaks, no matter how you observe the angles and planes, but through so many joints it still “siphons”. Plus, opening the valves requires additional space, and the main thing that people are paying attention to now is that they are inconvenient. Therefore, now the favorites are more ergonomic and practical options, for example, lifting ones.

FredikFORUMHOUSE Member

Lifting gates have a huge advantage - ease of use, even without an electric drive, to open them you need to 1 - open the bolts 2 - lift the gate up. Moreover, it will remain open under the influence of counterweights and the wind will not slam it shut at the most unexpected moment. Conventional gates: 1 – open the bolts, 2 – open one leaf, 3 – lock in the open position, 4 – open the other leaf, 5 – also lock. Laziness, however, is a great thing and an engine of progress.

But you have to “pay” for progress, in this case by complicating the design and high expenses on consumables even with a manual drive, not to mention automatic control. However, making overhead garage doors on your own is quite possible.

Minuses

Significant disadvantages include the relatively high cost of some models, which, however, is balanced by reliability and ease of use. Another disadvantage is the need for periodic maintenance, but any mechanical system requires it.

Experts do not recommend self-installation of garage doors, citing the following considerations:

- The car owner does not have the necessary knowledge and practical skills; he does not have special equipment. Installation “in your own way” will lead to unstable operation of the gate structure.

- Self-adjustment of the drive is most often done by eye. An incorrectly adjusted mechanism, in the event of unauthorized closing, can cause damage to people and equipment.

- The manufacturer will not be able to judge the reliability of installation made by an outside person. By performing assembly and debugging yourself, you will lose warranty service.

Sectional gates require periodic maintenance Source nashgazon.com

Therefore, you can install DorHan gates (or any other) on your own only if you have the appropriate experience and knowledge in such work. The desire to save money, not supported by the appropriate skills, cannot be a reason to install it yourself.

Possible additional options

Once the system installation is complete, there are many possible modifications, such as:

- glazing, ventilation;

- installing a gate in the door;

- installation of automation and security systems;

- ordering a manual gate lifting system.

Glazing, ventilation

These elements are located in the upper, middle part of the gate. If a person spends a lot of time in such a room, it is reasonable to order large glazing, which will reduce light bills. Glazing can be performed on small or large areas of the gate. A special profile is mounted into the section for holding glass-like materials such as acrylic and polycarbonate sheets. The latter is more expensive, but, unlike acrylic, it retains transparency longer. If there is a car indoors, then excessive sunlight can cause the paint on it to fade.

If there are ventilation air ducts in the room, additional equipment in the gate is not needed. Otherwise, it is better to install ventilation grilles in the door, which is easier than installing in the wall.

Gate built into the door

It is installed when there is no other way out of the room, and it is difficult to constantly raise and lower the gate. A built-in gate in a door is not cheap due to the complexity of the design. If desired, you can order a gate with a threshold. The absence of a threshold is more practical for bringing in bicycles and small equipment. However, not every manufacturer offers the option of installing a gate with a threshold.

Automation and security of premises with sectional doors

The automation system is supplied with a control panel. It has many pros and cons, the main one of which is dependence on the power grid. It can be neutralized using a battery and a manual unlocking system.

In order to increase the security of the premises, many owners order motion sensors. To avoid problems when using automated systems, photocells are installed that stop the operation of the mechanics when there is movement. You can also order a special warning lamp that will turn on and glow when the electric drive is running.

Manual gate lift system

If sectional gates do not have automation, then opening them is somewhat difficult. To simplify the process, manual gate lifting is installed in the form of a chain gear. This allows you to open and close them regardless of the presence of electricity. They are placed on structures with an area of up to 15 m2 and a height of up to 2 meters.

Tools and materials

Installation work is carried out using household tools; if something is missing, you can buy it or borrow it from friends. To complete the installation you will need the following tools:

- Hammer for driving dowel nails into concrete surfaces.

- Side cutters (nippers) for shortening the cable.

- Terminal screwdriver (flat) for connecting an electric drive.

- Universal screwdriver for screwing handle and lock.

- A set of wrenches for tightening bolted joints.

- Riveting gun for fastening profiles.

- Construction level (helps to control the correctness of horizontal and vertical planes).

- Measuring accessories: tape measure (to determine whether the opening is ready for installation), pencil for marking.

- Angle grinder for correcting the length of fasteners.

Installation of a garage lock Source samstroy.com

See also: Catalog of companies that specialize in the construction of fences and enclosures

- Drill with hammer drill, set of metal drills, concrete drills for drilling holes.

- Construction knife for unpacking components and removing excess sealant.

- Notches (bits) of 8 and 10 mm for fastening hinges, brackets, supports.

- Personal protective equipment: overalls, gloves, goggles, helmet.

The only specific tool is the crank, which allows you to bring the torsion mechanism into working position. But, in order to wind the coils of the spring, you can use a replacement, making it from any reinforcement with a diameter of 12-14 mm.

Before starting work, you need to check that the package contents match the installation card. The kit, designed for self-installation of garage doors, includes the following elements:

- Set of guide profiles.

- Sections (sandwich panels).

- Box with components (fasteners).

- Torsion mechanism.

- Additional components (for example, lock, automation).

Location of the main elements of sectional doors Source tvoygarazh.ru

Features of connecting sections

Special hinges serve as fastenings for individual panels. Gaskets are installed at the joints to prevent cold air from penetrating inside. I can also use other auxiliary materials to achieve maximum tightness.

There are cavities between the sections; rubber inserts are placed in them to protect against unfavorable climatic conditions. This creates an effective barrier that prevents wind and cold from entering the room. Sandwich panels can significantly reduce the percentage of heat leakage, which leads to savings on heating.

Assembly steps

The manufacturer develops instructions, and it is extremely useful to adhere to its recommendations, follow the technology and assembly procedure. From a safety point of view, it is important to use working power tools, as well as have experience in welding or plumbing.

If the assembly is carried out correctly, the gate will last for many years and will not require unscheduled repairs. The assembly of the gate structure sequentially goes through several stages

Measurements

It is necessary to check the dimensions of the garage opening for compliance with the requirements of the selected door system. In fact, this stage is performed before purchasing a sectional structure, since the features of the opening are critical for the correct installation of DorHan gates (or other models).

What needs to be measured and leveled before installation Source postroika.biz

There are models of sectional doors on the market with differences in design and type of lift. To avoid making a mistake, you can always get advice from a specialist. But, in any case, the choice is made based on measurements of the opening and taking into account the depth of the garage. At the measurement stage, the following parameters are checked:

- Width and height of the opening. They are measured at three points: bottom, middle and top. An important clarification: the maximum identified parameter is taken as a basis, and it is based on it during the installation process.

- The surface of the planes of the opening. It must be bloody and smooth. Before installing vertical guides, check the horizontal level of the floor. To do this, the C-profile is placed on the floor and its horizontalness is checked using a building level.

- The sides of the opening must be strictly vertical; you can verify this using a plumb line.

If the discrepancies in the data are significant, the opening will need to be prepared: level all surfaces, make sure they are correct, and only then go for the sectional doors.

Wide blade with automatic drive Source base64.eagleagent.com.au

Additionally, for the installation of overhead gates, it is important to know the following parameters:

- Ceiling. The upper horizontal lintel above the opening (up to the ceiling) must be large enough to accommodate the section lifting mechanism. There are restrictions on minimum sizes, but the optimal height is 400-600 mm. For some models the minimum value is increased, and this must be clarified in advance.

- If there are communications running along the lintel (or ceiling) that cannot be removed, then the lower point of the communications is taken as the ceiling level in the calculations.

- Shoulders (the distance on the left and right between the opening and the side walls). Since the guides are attached to the sides of the opening, these parameters determine which design you can choose and how to install.

- Depth (from the opening into the garage). It should be enough for sections of canvas that go to the ceiling.

Determining the space required to install a gate Source hotel-a.ru

- If you intend to install an automated modification, you should check that there is enough space not only for the guides, but also for the drive. In this case, the depth of the garage should be between 3290-4400 mm (depending on the system).

- If the garage is not deep enough for a ceiling drive, there is an alternative - an axial drive, which is mounted to the side of the opening. Such automation was developed for industrial structures; it is more powerful, but also more expensive.

The calculation of the minimum required depth (cannot be less) is based on the height of the opening according to a certain rule: the following value is added to the height value:

- Low lift: add 550mm.

- High lift: the number is increased by 850 mm.

- The area of the canvas does not exceed 8 squares: plus 400 mm.

- Area greater than 8 squares: plus 450 mm.

Ways to organize the ascent Source rial-ograda.ru

Do-it-yourself doorway preparation

The doors are attached to the garage doorway.

Determining the size of the opening is the task of the master. Take a building level and measure the walls, ceiling, and floor. The component placement lines must be parallel. Next, measure the height of the door plus 100 cm. This formula is useful if electrical appliances are installed. If the sections will open without a drive, it is enough to add 50 cm. Traditional lintel dimensions range from 25 to 50 cm. If you treat this point negligently, the design will turn out to be complex and will require a lot of money.

To ensure that the parts fit tightly to the doorway, it is recommended to improve thermal insulation, level and plaster the doorway.

Video description

About installing garage doors with tension springs in the following video:

Subtleties of assembly and installation of guides

Dorhan sectional doors can be installed in two ways. During standard assembly, the vertical guides are installed first. The distance from the end surface to the edges of the guides should be 25-30 mm.

The corner posts are secured to the wall of the opening with two self-tapping screws and washers, but without fully tightening them. The vertical guides are leveled, and only after that the screws are tightened. Bolts are used to fasten two types of guides. A C-profile is supplied complete with horizontal guides, which serves to increase the rigidity of the structure.

End support brackets are installed along the holes on the corner post; everything is fastened together using bolts and nuts. The bracket has a perforation along which it is attached to the wall of the opening with metal screws. The second method is used if the height of the door leaf exceeds 2 m. In this case, the guides are assembled on the ground.

Guide installation process Source mldokz62xmeo.i.optimole.com

Homemade overhead garage doors

GurzaForumHouse Member

Inspired by the works of my forum comrades, I also make overhead gates. I have already welded the gate frame (2.15x2.95 m) from a 20x40 mm profile pipe. The gate frame is made of channel No. 16. Channel No. 8 was used for the vertical and horizontal guides. Rollers from an old skateboard (diameter 65 mm, width after processing 35 mm). I think there will be no problems with attaching the vertical guides (by welding to the frame), but how to attach the horizontal ones?! This became a task for me. The distance on both sides from the gate to the wall is 1 m, the ceiling is made of 10x18 mm timber. So I want to ask advice from a construction guru, maybe you will have some ideas. I roughly drew a diagram. Thank you.

Gurza found a solution to this problem on his own.

GurzaForumHouse Member

Yesterday I hung one horizontal guide. I checked it with my weight (80 kg) and it held up perfectly! So, even if the gate weighs 160 kg, it will withstand it with a margin. I'm not a professional welder, so as it happens, it holds strong. I took the angle at 35.

But no one has canceled the saying “the first pancake is lumpy”; after Gurza put the gate leaf on rollers and grabbed it with welding, a jamb immediately came out. Namely, when raising the canvas, the lower corners rest against the frame, so we had to redo it. For anyone who wants to repeat it, the craftsman has posted the drawings.

And a photo of the gate, which I finally finished.

And this is just a rough draft, there are seals ahead.

As well as insulation and “aesthetics”.

Another homemade option, completely finished.

ochumelkinFORUMHOUSE Member

In two days I made myself this kind of gate, 3.20 x 2.20 m, with a gate - you can lift it, you can go in like that. I covered it with plastic to look like wood, it turned out great. No extra protruding parts when open or closed. In the upper position, a small visor remains above the threshold. The standard, cheapest automation is installed (although volatility is not my thing). Any type of locks can be installed, from latch bolts to electronic locks. The pregnant wife lifted it without strain; with careful adjustment of the springs, the sash hangs in any position. The material is standard: profile, corners, channel piece, etc.

Spring mechanism.

Members of our portal willingly share videos of their designs, for example – JOxaKER.

It is impossible to list, describe or show all possible variations within the framework of one article, and it is clear that it is quite possible to make homemade garage doors, even complicated ones, lifting ones yourself. Another thing is that this is not always advisable. And below we will look at why.

Video description

About installing sectional doors with your own hands in the following video:

Assembly of torsion mechanism and blade

The torsion mechanism is installed on models with electric drive. It allows you to use the gate system even if the automation fails or there is no power in the network. When assembling, it is important to strictly adhere to the order suggested in the instructions. When the guides take their place, assemble the canvas:

- Rollers with roller holders are mounted on the side supports.

- The remaining screws are secured to the corner post.

- The spring assembly and bearings are installed on the shaft (with the narrow side facing the bracket). The springs are installed in a mirror manner.

- Also, drums for the cable are mounted on the shaft (they are marked left-right).

The installation of sections starts from the top sheet. Roller holders with rollers are installed on the upper supports. The assembled shaft is lifted and installed in the bearings of the end support brackets. The flanges of the ends of both springs are secured with bolts. The cable is secured, passed through the technological hole and wound onto the drum in the amount indicated in the installation card. When the work is completed, check the tension of the cable; if necessary, it is adjusted.

Types of sectional door springs Source vorota-goroda.ru

Installation

Gate installation diagram

In this paragraph, we will dwell in more detail on the important points when installing gates, for those who have decided to install them themselves.

Sectional doors require free space across the entire width of the doorway:

- distance to ceiling 300 cm;

- distance on the sides is 450 cm.

The dimensions listed are maximum. Their deviation may be downward, but not exceeding the parameters established by the manufacturer.

Design requirements

Installation of sectional garage doors must begin with preparing the doorway. First of all, it must be cleaned of the fragile layer of cladding. If the garage structure is made of light blocks, then its walls should be reinforced with a metal frame. To complete the work you will need:

- perforator;

- drill, with built-in screwdriver functions;

- a set of installation tools;

- pobedit drills;

- measuring instruments (tape and level).

Note! The kit may not include fastening materials, so you need to stock up on them before starting work. Particular attention should be paid to the list of required screws, dowels and anchors, which is attached to the instructions. You should not purchase thinner and cheaper materials, as this can greatly reduce the performance of the gate being installed.

All sectional door schemes are transferred to the doorway. On the walls it is necessary to mark the places for fastening all the load-bearing elements of this structure:

- Vertical profile.

- Horizontal profile.

They perform the role of fixing the movement of the panels.

Video description

About the nuances of installing garage doors in the following video:

Subtleties of assembly and configuration

In order for sectional doors to function properly, it is worth remembering the following rules:

- During the assembly process, it is important to securely fasten all parts of the door system. This is a simple but effective prevention of misalignment, in which the blade seizes or jams.

- It is recommended to use hardware of the sizes specified in the instructions. Changing the parameters of dowels, bolts and screws leads to incorrect operation of the mechanism.

- If it is necessary to level the structure, metal plates are suitable. It is unacceptable to replace them with wooden elements or polyurethane foam.

Setting up automatic gates is carried out in three stages:

- Fix the blade in the lower position and adjust the sagging of the cable.

- Adjust the limits of movement of the electric drive using the remote control.

- Adjust the spring tension: loosen the fixation, and then scroll the spring to the desired tension level.

There may be several reasons for the misalignment Source local-garagedoors-gates.com

Appearance

Sections of this type of overhead gate can have a different appearance. There are several main types of outer surface - S, L and M profile, as well as fine wave and panel. This assortment includes sandwiches from any manufacturer. Some also have non-standard ones - with various decorative elements or transparent inserts (this is usually sheet polycarbonate). But their price differs significantly from the “basic” models.

The design of sectional garage doors can be different

Several types of surfaces add design variations - smooth, rough, with imitation wood surface. In addition, sectional garage doors are usually painted with protective paints, which give the door a more attractive appearance. But the main function of painting is protection against corrosion and climatic factors.

Briefly about the main thing

Self-installation of sectional doors is a labor-intensive, but doable task if you understand the principle of operation of the mechanism and have certain skills. To avoid problems, the manufacturer supplies its products with an installation card, which describes the assembly process step by step.

For a high-quality result, you need to stock up on the necessary tools and prepare the room. The design of sectional doors is sensitive to the slightest distortions, so it is important to make sure that all planes of the opening, floor and ceiling are truly horizontal and vertical. Installation begins with the assembly of the sectional canvas, then the guides are assembled and installed. At the end, the torsion mechanism is assembled, the blade is secured and final adjustments are made.

Ratings 0

Wicket insert

Sectional doors cannot be called simple in structure. However, some manufacturers took care and included in their designs the possibility of placing a gate for entry. But even here, different manufacturers of sectional doors have their own restrictions regarding the arrangement of such an entrance.

If you understand the details, the gate is more often used by pedestrians and cyclists. As a rule, the width of the entrance is 1.2 meters, and the height is over 2.5 meters.

There are no varieties of gates, that is, there are only swing gates. The exception is those cases when they are cut directly into the door leaf. At the same time, what kind of gate it is - swing or sliding - does not matter.