A frame garage is one of the simplest options for building a utility room for storing a car. It is not only technically simple, but also cheaper than brick or concrete walls. Price and technical availability are the main advantages of frame buildings. How to build a frame garage yourself? What features are important to consider for reliable and correct construction?

Key aspects for drafting

Before drawing up a frame garage project, you need to understand all the features of its structure. One of the main advantages is the speed of construction. The time spent on work is reduced significantly in comparison with permanent buildings. In addition, there are the following advantages:

- Possibility of construction at any time of the year .

- Fastening using bolts , which reduces work time.

- There is no need to use expensive heavy equipment to carry out the work.

- Small amount of garbage and waste , which also saves time.

Metal profile for a garage frame Source ar.aviarydecor.com

The only problematic issue that needs to be taken more seriously is the foundation for a frame garage. There are several options :

- shallow slab foundation;

- area previously covered with asphalt ;

- monolithic non-buried slab ;

- shallow tape

When deciding on the foundation, you need to take into account the type of soil. Here you will need specialist advice.

An important point is the choice of material for the structure. It should be remembered that a wooden frame garage has one significant drawback - a high degree of flammability. At the design stage, measures to ensure fire safety are considered.

See also: Catalog of garage projects presented at the Low-Rise Country exhibition.

How to choose the right place to build

When choosing a place to install a collapsible structure, several circumstances should be taken into account:

- the place must be dry (not flooded by precipitation);

- the building should not block the windows of neighboring buildings;

- the garage is installed at a sufficient distance from neighboring buildings so that it is possible to install water drainage systems from the roof.

In addition, it is recommended to install the garage so that nothing blocks the passage for the car.

Types of frame garages

The type of frame garage depends on the material used in construction. There are several options. The most common are timber and metal profiles.

timber

The material has many advantages :

- it is environmentally friendly and vapor-tight:

- high energy saving ;

- possibility of finishing of any kind .

A garage made of wood has its advantages, but the material requires good protection Source rmnt.mirtesen.ru

A garage made of timber will look appropriate against the backdrop of any landscape and will successfully complement both a small house and a huge cottage.

Along with the advantages, there are also some disadvantages :

- the cost of materials is considerable compared to other options;

- the need to carry out a number of measures to protect the timber from rotting , parasites and ensure fire safety.

Metal profile

You can erect a frame structure from a metal profile very quickly. It also benefits in cost. Such a frame garage can be installed without a foundation, since its weight is insignificant.

There are also disadvantages:

- very easily susceptible to mechanical stress , dents appear quickly;

- the degree of thermal conductivity is very high , which creates inconvenience for staying in it in summer and winter.

Cost calculation

The cost estimate will be affected by the cost of materials - wood, fasteners, fittings. It's unavoidable. It is possible that transport services will be added for the delivery of wood or the ordering of a concrete mixture for pouring the foundation, or the supply of crushed stone.

In general, the construction will cost much less than a capital garage, and the labor will be free, thanks to the construction of the building with your own hands. In order to save money, construction can be extended over time (within reasonable limits), gradually accumulating materials and constructing such a necessary, inexpensive and extremely attractive external garage.

Project development

Having decided on the type of garage, they move on to the next stage - drawing up a project. At this stage, specialists need to express their wishes in as much detail as possible. Designers must have the following information:

- Determining the budget . After completing the calculations and receiving a certain amount, you need to throw in a small supply of money. Theoretical indicators almost always do not coincide with practical implementation.

A garage made of wood can be more expensive than a metal structure Source vizada.ru

- Clarification of the functionality of the structure . A garage is needed only for a car or additional storage of other things is planned. Perhaps there will be a mini workshop in it. The dimensions of the building and the arrangement of communications depend on this.

- Thinking through the prospects . Does the family plan to buy another car? If the decision is positive, you need to design a garage with two spaces for cars.

Frame covering

Next, the completed frame is sheathed with suitable materials. To do this, you can use corrugated sheets, sandwich panels or other similar panels. You need to select a specific material before creating the frame, so that the optimal distance is left between the individual wooden elements.

Suitable fasteners are selected for fastening the sheets. Usually, holes for fasteners are made in different panels at the factory, which greatly simplifies the procedure for covering the frame.

Finished projects

The construction of a frame garage is simpler based on its technology, but it cannot be done without drawing up a project. To understand what the future structure should be like, you can borrow ideas from ready-made diagrams. To clarify the task, we will present several projects that are in greatest demand among consumers.

Simple options

There are many options for frame garages designed for one car with a small reserve for storing things and tools. The most convenient projects with different functional contents will be presented for consideration:

- You can build a frame garage from boards measuring 6x4 m - the simplest design with a gable roof. The foundation is mounted from concrete slabs. The project provides for a small window to provide daylight. In addition to the garage door, a door is installed to exit to the street.

Wooden garage for 2 cars Source es.decorexpro.com

- Garage with additional storage room . The project takes into account space for one car and a utility room equipped as a storage room. A window is planned in one of the side walls and a door through which you can enter the utility room.

Project of a garage with a storage room Source sk-amigo.ru

Finishing work

The final stages of the work consist of arranging the roof, and for its cladding you can use corrugated sheets or metal tiles. Additionally, the garage is insulated, for which mineral wool or other suitable insulation is laid between the parts of the frame.

After this, various utilities are connected to the structure, which include heating and electricity. Next, gates, windows and doors are installed, for which appropriate openings must be provided in the frame.

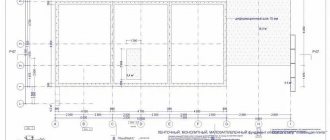

Displaying the project on paper

Having become familiar with the nuances of professional projects and choosing interesting points, they begin to sketch out ideas on paper. To begin with, the parameters of the garage are determined and plotted on the diagram. Standard sizes:

- 5x6 m;

- 4.5x6 m;

- 6x6 m;

- 6x8 m.

The last option is chosen for the construction of a double building. If large dimensions are required, then any parameter can be doubled.

After drawing the perimeter, mark the partitions, placement of windows, doors and other desired elements. In the case of a utility room, a space of about 2 m2 is allocated for it. For ease of installation of the gate, the ceiling level is planned to be no lower than 2 m.

Schematic representation of the garage Source b8.mxc.com.ru

Depending on the established dimensions, the amount of material is calculated.

Calculation

First you need to determine the desired size and shape of the garage. As an example, we will take the most standard and common option - a rectangular garage 7 m long, 4 m wide and 3 m high. In such a garage you can comfortably place any medium-sized sedan.

First we need to find the perimeter of the future garage. This is done according to the formula (A+B)*2.

(4 m + 8 m) x 2 = 24 m. This is the perimeter of the garage walls.

Now you need to find the area of the walls. To do this, use the formula: p*h. That is, the perimeter multiplied by the height: 24 m x 3 m = 72 m2. This is the area of all the walls of the building.

Next, it remains to calculate the volume of the walls, which means the volume of the timber we need. The section we took as an example is 100 mm or 0.1 m.

To find out the volume, you need to multiply the area by the cross-sectional size. In our case it is: 72 m x 0.1 m = 7.2 m3. This is exactly how much material will be needed to build a garage, taken as an example of size.

Do not forget that you need to subtract the size of the gates and windows from this size, but it is individual for each case. For example, there may be no windows at all, and the size of the gate may vary greatly. You can play it safe and not deduct the size of the gate, and the remaining timber will be a reserve for various unforeseen expenses or damage to the timber.

If you don’t want to spend extra money, then it’s enough to subtract the volume of timber needed for the gate from the original size. For example, the width of the gate is 2.5 m and the height is 2 m. Then we find the area: 2.5 m x 2 m = 5 m2. Next, we multiply the area by the cross-section and get 0.5 m3, which we need to subtract from the total volume of the required timber.

What is OSB board

OSB boards additionally insulate the room, as they consist of wood chips.

The raw material for OSB, as for chipboard, is wood chips. Both coniferous trees and some deciduous trees, such as maple, are used. Dried shavings are mixed with resinous compounds of natural and synthetic origin and laid in layers. The material is then compressed. The result is a slab body. It is trimmed to fit standard dimensions.

Boards are available for sale with different characteristics tailored to a specific application. They are usually divided into 4 classes.

- First class products are the cheapest, but are inferior in strength and moisture resistance to other options. It is suitable for making furniture and packaging, but it is not worth purchasing for interior decoration.

- Second class products are stronger, but still susceptible to moisture. It can be used in rooms with dry air.

- Third class boards (OSB-3) are quite moisture resistant. It is with them that it is preferable to sheathe the inside of the room.

- OSB-4 boards have the best performance qualities, but also a rather high price. If the homeowner wants to decorate the outside of the room with OSB, he should prefer this option.

Arrangement of layers of chips in an OSB board

In the production of OSB, resinous compounds containing formaldehyde are often used. In this regard, concerns are sometimes expressed about the possible harm of slab cladding to the health of residents.

There are two classes of content of this substance in products: E1 and E2. This division exists both in Russia and in Europe, while the requirements of Western companies are noticeably stricter. They classify material with a gas content of up to 8 mg per 100 g as category E1, and 8-15 mg as category E2. Russian standards regulate the presence of less than 10 mg of formaldehyde in the composition for class E1, and 10-30 mg for E2.

To be sure of the safety of the product, you should purchase European slabs of class E1 and pay attention to the substance content. If a homeowner wants to sheathe the inside of a garage with OSB or otherwise use the material for finishing non-residential buildings, he especially should not worry, since these premises are not a place for sleeping or permanent residence.

Some companies have already begun to produce boards that do not contain formaldehyde at all. They can be distinguished by their “Green” or “Eco” markings.

Pros and cons of the material

After installation on the walls, the OSB slabs will need to be coated with paint.

The slabs can be easily cut without crumbling and mounted on the sheathing. Other advantages of the material include:

- low price;

- attractive appearance;

- sufficient strength (but for a sheet of plywood of the same thickness it is greater than for slabs of any class except the fourth);

- thermal insulation qualities;

- resistance to mold and fungal colonies;

- good moisture tolerance, if it does not fall on the slabs regularly and in large quantities (if you use OSB-3 for exterior decoration, after 5 years the material will be damaged quite seriously).

The disadvantages include the formaldehyde content in the composition and swelling with delamination when regularly exposed to moisture. Due to the last factor, slabs (except for the fourth class) should not be used for external cladding. They can be used to decorate the inside of a garage and other non-residential buildings that are sufficiently protected from precipitation without any fear.

Separately, it should be said about the degree of flammability of the material. Newly purchased third class slabs almost do not have this property, although they are charred in a fire flame. As the slabs are used, this feature disappears. Scraps of material purchased 5 years ago are highly flammable.