Strip foundations are often used in low-rise construction - they are easy to make, and they are universal, suitable for all types of buildings and almost all soils. Let's look at the strip foundation for a house from all sides: what it should be like according to construction science and standards, and how this theory is embodied by the hands of FORUMHOUSE users.

Design features Shallow strip foundation MZLF Fully buried strip foundation Tape: calculation algorithm How to build a strip foundation with your own hands Example: MZLF 11*14 m Example: foundation made of FBS 10x10 To help the strip builder

Information about the soil and nearby buildings

Starting to do something without prior preparation is simply unwise. The beginning of all beginnings in construction is the preparation of project documentation; and designing a house and foundation, in turn, can only be done based on the results of a geological examination of the site, which will reveal the individual characteristics of the soil and take into account the relief.

The lowest freezing point of the soil in winter will allow you to determine the type of foundation and its depth. It is better to entrust a detailed analysis of the soil and the choice of foundation type to qualified specialists.

Landscape design will help you choose the most convenient location of the house, auxiliary buildings, paths and gazebos. Modern technologies allow you to see your future home from all angles.

The linear dimensions of the base are only part of the foundation design Source moifundament.ru

Tape: calculation algorithm

This issue is given great importance at FORUMHOUSE.

al185MODERATOR FORUMHOUSE

I beg you not to prescribe a foundation design based on “people’s experience” and the advice of various advisors who “have always built this way.”

A member of our portal with the nickname MaximGvozdev created the LentaOnline v calculator. 1.0, which will help with the construction of this type of foundation. The tool can calculate the resistance of the foundation soil, the width and length of the designed tape, reinforcement and concrete, concrete composition, and the number of concrete batches in a concrete mixer.

For beginners, the FORUMHOUSE moderator with the nickname al185 recommends first deciding on the soil conditions (soil composition, groundwater level, topography) to design a strip foundation and resort to the following methods:

- Ideally, order a project from an adequate designer who can get good recommendations on FORUMHOUSE.

- You can borrow an already calculated analogue foundation design for similar soil conditions and a similar building.

- Master design for amateurs: an algorithm for designing a strip foundation for dummies.

Next, you need to compare the cost of the options received and choose the appropriate one.

Preparatory work

The preparatory work stage occupies an important place in the process of building a house. First of all, it is necessary to clear the area of construction debris, cut down excess trees and uproot stumps, and remove dry grass.

Preliminary zoning of the site will allow you to effectively use every corner during operation. It is best to level the surrounding area before starting construction work and laying the foundation. This will not only give the site an attractive appearance, but will greatly facilitate construction work at all stages. The terrain with large differences requires stepwise leveling of the territory.

Next, the exact location of the house is determined and the foundation is marked. To do this, pegs are installed in all corners of the future building. If the house is a standard rectangular shape, the result should be a figure with perfectly equal angles of 90°. If the angle is not maintained, it is necessary to achieve this result by moving the limit cord in one direction or another.

Along the future walls, at the same distance from each other, pegs are also installed and a rope or cord is pulled between them. The diagonals drawn between the corners of the building must be exactly equal to each other.

An example of checking angles in markings - if the diagonals are equal, then all angles are 90° Source homeframe.ru

When marking for a strip foundation, it is necessary to retreat from the walls of the house at a distance equal to the width of the foundation. Most often this figure is no more than 20 cm.

You can dig a trench either by hand or using specialized equipment. It is formed at least 20 cm below the freezing point of the ground, characteristic of the area in winter. It is necessary to dig a trench strictly following the markings and forming a flat bottom.

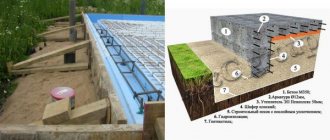

Ground floor, basement

- Setting out the axes of the structure;

- Excavation work using machinery;

- Construction of crushed stone and sand bedding with compaction;

- Concrete preparation device

- Installation of horizontal and vertical lining waterproofing

- Reinforcement of reinforced concrete structures

- Installation and dismantling of panel formwork using a truck crane

- Concreting the base slab, walls and floor slabs

- Sealing holes from studs, shells, sanding rust

- Drainage installation work

Methods for saving a house foundation

One of the exciting questions when building a house is how to lay the foundation for a house cheaply and with high quality. There are several ways to save at least a little:

- Digging the soil and pouring the foundation for a house with a concrete mixture is the most expensive stage in the construction of a country house. Whether to do all the work yourself or entrust it to professionals - everyone decides for themselves.

- Forming a shallow foundation will save a significant amount of money. However, it is only suitable for the construction of low-rise buildings made of lightweight materials. In all other cases, a deep foundation is used, erected below the freezing point of the ground.

- The formwork is assembled from boards, which can later be used as a subfloor or for other work in which the appearance of the material will be of secondary importance.

After the concrete has hardened, the formwork boards are removed and can be reused Source sovet-nso.ru

See also: Catalog of companies that specialize in foundation repair and design.

- When pouring a slab foundation, you can save money by using a thinner base with the formation of stiffeners.

- The possibility of using fiberglass reinforcement instead of steel materials will also allow for minor savings.

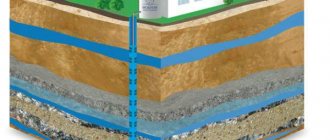

Waterproofing

It is imperative to pay attention to organizing proper waterproofing.

Waterproofing can be organized in the following ways, described below. Moreover, each option does not exclude, but complements the other:

- Special additives for concrete.

- Waterproofing at the stage of preparation for concrete pouring.

- Waterproofing foundation walls after pouring concrete.

- Organization of the blind area.

The foundation for a one-story house is ready for construction in just 14 days. Concrete will reach its full capacity a month after pouring. Accordingly, a month after pouring the concrete, the foundation is ready for a two-story house.

After 30 days, the poured concrete reaches 95% of the capacity required to construct the structure.

Features of pouring a slab foundation

Slab foundations are most often used in the construction of brick, frame and stone country houses. In this case, the slab is located not only under the load-bearing walls of the house, but also under the entire structure and requires the formation of a perfectly flat surface.

To fill a slab foundation, a sand cushion up to 30 cm high is poured, reinforced concrete slabs are laid, a reinforcing frame is formed and a concrete screed is made.

It is the most expensive, but it fully ensures the strength and reliability of the foundation during the operation of the facility.

The slab foundation has a rather complex structure Source profundamenti.ru

Making a sand pillow

In order to reduce the load on the foundation, the bottom of the dug trench is covered with a layer of sand, the so-called sand cushion. This, in turn, will allow you to save on building materials and significantly reduce construction costs.

As the name implies, coarse sand is usually used for such a cushion; in industrial construction, the use of medium-sized crushed stone or boiler slag is also acceptable.

The thickness of the sand layer should be about twenty centimeters. After this, the surface of the pillow should be tightly compacted, and the horizontalness should be verified with a level gauge. When all the necessary actions have been carried out, the sand cushion is filled with the required amount of water, which will allow it to shrink and be well compacted.

The top layer is covered with gravel or coarse crushed stone.

Features of pouring a columnar foundation

A column foundation is often confused with a pile foundation, but in fact these are two completely different technologies. If the piles are necessarily screwed in below the freezing depth of the soil, then the columnar pile is a hole, about 50-70 cm deep, the bottom of which is covered with sand, and concrete is poured on top, mixed with some stones.

On a note! A columnar foundation is not suitable for a residential building, since it is designed for ultra-light buildings - small bathhouses without a stone stove, gazebos, sheds and similar outbuildings.

A columnar foundation does not require additional waterproofing work, but, like a pile foundation, it excludes the possibility of arranging a cellar or basement. Since it is laid at a shallow depth, it is mainly used on sandy soils and sandy loams, which are indifferent to heaving and natural soil movement.

To pour a columnar foundation, concrete blocks are used, fastened together with reinforcement and filled with ready-made concrete mixture. Any material is suitable for forming concrete blocks:

- brick;

- stones;

- basalt;

- cobblestones;

- ready-made reinforced concrete blocks.

Columnar foundation - a shallow budgetary foundation for outbuildings Source stopdacha.ru

Columns are installed in all corners, as well as at intersections of walls and points with increased load at a distance of no more than 2 meters from each other. In this case, formwork is formed, pillars are installed and pulled together with reinforcing material. The entire structure is filled with a mixture of concrete.

By build type

And finally, according to the type of assembly, foundations can be:

- prefabricated (made of blocks, slabs or beams connected with cement mortar);

- monolithic (first the formwork is made, then concrete is poured into it) - and this is the most durable option;

- Combined (prefabricated-monolithic, monolithic-prefabricated, whatever).

As you can see, the choice is wide. Each option has its pros, cons and features. Therefore, each individual case requires careful consideration. Let us repeat, with this article we are not closing the topic of foundations, but, on the contrary, opening it up.

Lyudmila Gubaeva

Real Estate Tatarstan

Video description

To see all the work involved in preparing the site and pouring the foundation, watch the video:

Formwork

Before pouring the foundation for the house, it is necessary to form a strong, reliable formwork. To form removable formwork you can use:

- wood;

- metal;

- plywood;

- plastic.

Permanent formwork becomes part of the structure and avoids the dismantling stage. To form it use:

- expanded polystyrene;

- wood boards;

- fiberboard

Permanent formwork block for strip foundation Source ofacade.ru

To help the tape builder

Anyone can build a strip foundation for a house, provided all calculations are completed and all work is carried out responsibly. Our users, without much construction experience, made their monolithic strip foundations and structures from FBS, literally following the technology and strictly observing SNiPs. The materials on our portal will help you achieve a successful result.

On FORUMHOUSE you can get all the necessary theory, documents, constructs, reports, find step-by-step instructions for making a strip foundation with your own hands, study the strip design algorithm, read articles with arguments against carrying out geotechnical surveys and finally decide for yourself the main question: is it true? you need a sand cushion under the tape.

Our video talks about how to independently build a reliable foundation on problematic soils.

Subscribe to our Telegram channelExclusive posts every week

Pouring the foundation

Preparing a high-quality concrete mixture and pouring the foundation is an important stage in the construction work of a country house.

sand cushion

A sand cushion is a necessary element in the construction of any structure. To form it, the bottom of the trench is covered with river sand to a height of at least 20 cm. Each layer of sand is thoroughly spilled with water and compacted.

Formwork

To reinforce the foundation, reinforcement and reinforcing rods of various diameters are used. It is better to use thicker reinforcement along the trench. Reinforcing elements can be connected using soft wire.

Work progress

If you purchase concrete from a factory, you won’t have to think about how to pour the foundation for a country house. The automixer will evenly mix the concrete mixture to a uniform, plastic consistency and unload the finished concrete directly onto the site prepared for the foundation.

The automixer will not only bring concrete to the construction site, but will also pour it directly into the foundation formwork Source beton-house.com

Work begins from the corners of the foundation, trying to tightly fill all the voids. The concrete is evenly distributed around the entire perimeter using a shovel, excess air and bubbles are removed.

The finished foundation is wrapped in film and the surface is periodically moistened. This will help prevent the formation of numerous cracks during drying.

Example: MZLF 11*14 m

When building a foundation, future homeowners use different materials and offer their own solutions. Let's look at a few examples of tapes made by members of our portal. The work of our user with the nickname Alexey_$ received good reviews.

Alexey_$ FORUMHOUSE user

The height was 90 cm, they were buried 60 cm, of which in the end there was 30 cm of sand cushion and 30 cm of tape underground. The width varies and is indicated in the foundation design.

The trench was dug with a tractor according to markings made with white spray paint directly on the grass. While digging, Alexey “shot the level so as not to over-dig or under-dig.”

Small errors were eliminated with a shovel. High-density waterproofing material was laid in the trench.

The foundation design provided for a 30 cm sand cushion; pouring and compaction with a vibrating plate was done every 10 cm.

Alexey_$FORUMHOUSE Member

After all the manipulations, the error in level was within a centimeter over the entire area.

Ruberoid was laid out on the pillow in two layers

and set up the formwork: longitudinal boards 150x40 mm, every 60 cm - 100*50 mm. The inside of the formwork was lined with polyethylene and reinforced with 8-diameter studs.

12 mm reinforcement was knitted in 2-4 rows depending on the thickness of the tape (400 - 650 mm). The protective layer on the bottom was 5 cm, on the other sides 3-4 cm. Every 40 cm there were vertical jumpers with 8 mm reinforcement.

Alexey_$FORUMHOUSE Member

Spliced at least 50 cm, mating, where necessary, was carried out in a run.

Pouring concrete:

The foundation was covered with polyethylene. A little more than a week passed, the inside of the formwork was dismantled and waterproofing was done.

Backfilling: 10 cm of sand along the tape, the rest is sulinka - 5 cm below the level of the upper edge of the tape.

To reduce heat loss into the ground, the voids were insulated with EPS. This is part of the complex insulation of the sub-foundation space: voids + tape outside + blind area.

Alexey_$FORUMHOUSE Member

The house will have to spend the winter without heating for a couple of years and the influence of frost heaving forces will be reduced.

Conditions for accurately transferring the plan to the area

Marking the area

The main parts of the drawing are drawn on the same scale, but individual detail units are drawn in enlarged form for better reading. General scaling is performed within 1:100, 1:200, 1:300 and smaller.

To carry out the transfer, the axes of the structure are laid out on the ground. The surveyor maintains right angles and distance between lines. The directions of the axes are marked with a cord; the marking points are placed at a distance that will not be affected when digging trenches.

The laying depth is set by a level, while a ±0.00 mark is placed on adjacent walls, buildings or pillars, which serves as a guide for further height calculations.

The need for a plan

A drawing of the foundation of a building is made so that the structure erected on it is reliable and functions for a certain time. Owners should safely use entrances, elevators and stairwells as... the load from them is provided for when designing the support of the structure.

The foundation design for a house must meet the requirements:

- contain simple technical solutions that are convenient to implement on site;

- provide for advanced construction methods during construction with savings in labor costs and materials;

- include durable structures that do not tip over or slide in the ground;

- contain the required dimensions, tied to the axes of the walls of the house.

Material costs for the construction of the foundation are 10% of the total cost of the building in the absence of a basement and 15% in the case of using a basement floor. The labor intensity of the work is 12–15% of the figure for the entire building.

Ideal ratio

Before you start creating the foundation, you should decide which type should be preferred in a particular situation.

- Lightweight wooden structures, for example, a simple timber structure, can be placed on a columnar foundation. This will be especially appropriate for dry and dense soil.

- Columnar is also suitable for light frame structures (one floor).

- Wooden houses are placed on a shallow belt (up to 0.5 m). In case of high waters, a trench up to 1.2 m is dug so that the light structure “does not float in the spring.” This type of foundation for a house is especially appropriate for dry soil (a mixture of sand, gravel, stones), and for heaving soils, even if the water reaches 1 m.

- The ribbon look is also ideal for complex structures of frame houses (several floors).

- Large houses, including complex wooden structures, will “prefer” the most durable foundation - a tiled one. Especially if the soil is dense and dry or, conversely, the groundwater level is high.

A completely different story is the pile type. Durable screw bayonets are driven in at several points around the perimeter and do not require concrete mortar. They are used on all types of soil, with high groundwater levels and even on swampy soils. But they are not very suitable for rocky areas and complex house designs.

How is load-bearing capacity determined?

This is the name of the maximum load that the foundation can withstand without reducing its quality indicators. It includes the determined timing of the appearance of deflections, the level of rigidity, and the width of opening cracks.

Soil is made up of particles filled with moisture and air. Under heavy loads, pores shrink and change their shape. This has an impact on the soil, which may protrude from under the foundation. Due to such movements, cracks appear in the foundation, the building may warp and lose stability.

Taking into account these factors, it is recommended to clarify the maximum load, when exceeded, the soil may shift to unacceptable values. The settlement of the strip foundation is determined by the ratio of calculations of deformation and stress - there is an average indicator of the pressure acting on the soil.