Hello, dear reader! The efficiency of modern ventilation devices largely depends on the quality of assembly of its elements. If the installation technology is violated, even with competently performed aerodynamic calculations, it will not be possible to produce a reliable system.

The connection of the air ducts to each other plays an important role. Let's consider their methods, features of application in various situations.

What is corrugation and why is it needed for exhaust devices?

Corrugation is a corrugated pipe used in the installation of air ducts, installed between equipment that provides circulation and exhaust of air in the room where they are installed, into the building ventilation system or directly into the external environment.

The corrugated exhaust pipe is a flexible element, which is determined by its design and production technology. Due to its mobility, corrugation is used when installing air ducts in hard-to-reach places and in areas located in curved and perpendicular planes of space. In addition, due to their attractive appearance, certain brands of corrugated pipes made of stainless steel and aluminum are used throughout the entire length of the air duct without additional decoration or covering.

Connecting a kitchen hood to the building ventilation system using a corrugated air duct

Corrugated air ducts are used to connect kitchen hoods and axial fans installed in a bathroom or toilet, when installing geysers and heating boilers of various types.

Conclusions and useful video on the topic

In the presented video you can hear a specialist’s opinion about plastic air ducts and tips for their installation:

When choosing ventilation elements, you need to carefully consider the layout of the system. Based on the plan, it is necessary to determine the design features of the air ducts, their diameter, throughput, fastening methods and other factors.

It is necessary to take into account what types of communications are already laid in the house, as well as the material of the walls, ceilings or other parts of the building along which it is supposed to lay a network that ensures air circulation.

Do you have anything to add, or do you have questions about the selection and installation of ventilation air ducts? You can leave comments on the publication, participate in discussions and share your own experience of completing the work. The contact form is located in the lower block.

Technical characteristics of corrugated pipes for exhaust

The main technical characteristics of the corrugation used for hood are its dimensions - diameter and length. The length is determined by the manufacturer and can be of a standard size or sold in coils, which allows you to purchase an air duct of the required length.

Rectangular corrugation is used in ventilation systems at enterprises and technical facilities

The cross-sectional shape of the corrugation can be rectangular or round. Rectangular models are generally used only in production facilities. The diameter of the produced air ducts is standard: 10/12/12.5/15/20 cm, as well as 30 cm and more, but these are dimensions that do not relate to the standard of such products. For the manufacture of corrugated air ducts, plastic and aluminum, stainless and galvanized steel, as well as textiles and polyethylene are used. According to their design, such products are of frame and spiral-wound type.

Price of corrugated hood: what you should consider so as not to overpay

Before purchasing, it is advisable to study the various offers on the construction market. Otherwise, you can simply pay extra money for a product of dubious quality. It’s better not to be lazy, go shopping and check out the price options on the Internet. Accurate measurements of the air duct will help you avoid unnecessary costs, then you won’t have to pay for extra centimeters of material.

It is important to consider the place where the corrugation is used. On the street, where the air duct is used as supply ventilation, providing heating or cooling, preference should be given to a model with a heat-insulating layer. The price of corrugation with insulation will be slightly higher, while guaranteeing not only high heat resistance, but also a low level of noise produced in the system. The insulator in such models is mineral wool. Thus, the pipe is a sandwich of an inner and outer aluminum layer and a layer of mineral wool. Therefore, the use of insulated corrugation is relevant in places where high noise levels are unacceptable.

Most often, flexible aluminum pipes are used for exhaust hood; their average cost is 140-180 rubles. per linear m

In everyday life, flexible pipes are most often used to connect a kitchen exhaust hood to a ventilation duct through which exhaust air exits. Usually this is an aluminum corrugation for a 120 mm hood; the price of such a product ranges from 140 to 180 rubles per linear meter. m.

It is advisable to buy a 120 mm corrugation for the hood with a small margin of length, taking into account turns and bends. At the same time, you should not buy an excessively long product, since during installation it needs to be stretched as much as possible, which will reduce the ribbing of the corrugation. And the fewer ribs, the weaker the vibration and the less noise emanating from the operating system.

Types of corrugated pipes for ventilation and their characteristics

The durability and efficiency of the corrugation depends on the material of manufacture. They come in three types: plastic, aluminum and steel.

Plastic corrugation for ventilation - the cheapest and most stylish pipe

Plastic models are made of polyvinyl chloride or polyethylene. These corrugations are the cheapest of all three types. Among the advantages are the presence of convenient connecting elements, a huge selection of size options, ease of installation, and light weight.

There are also disadvantages. Plastic corrugations for hoods are not recommended for use in high heat. In rare cases, they may melt.

Some models of plastic corrugations have stiffening ribs

Aluminum corrugated air duct - an option for aesthetes

Unlike plastic structures, aluminum corrugation is not afraid of high temperatures and does not corrode.

Aluminum corrugation easily changes its shape, is easy to install, and does not require additional protection from overheating

Among the obvious disadvantages are some vibration and noise during operation.

Steel corrugated pipe for exhaust: ideal, but not a budget option

There are options for corrugated hoods with a galvanized coating. These models are more durable, however, they are somewhat more expensive than aluminum structures.

With such a corrugated hood you will forget about problems with the ventilation system for a long time

Size range of air ducts

According to the regulatory documents mentioned above, round air ducts made of galvanized steel are manufactured with diameters of 100, 125, 140, 160,180, 200, 225, 250-2000 mm. The parameters of rectangular elements vary from 100 to 3200 mm.

One ventilation system can use parts with different configurations and parameters. To connect them, all kinds of shaped elements are used: tees, bends, adapters, diffusers

To select products of the right size, you need to know the design value of the air speed. In residential buildings with natural ventilation this figure should not exceed 1 m/sec, and with forced ventilation it should be 3-5 m/sec.

For each living space, you need to calculate the amount of air supplied. When making calculations, you need to rely on regulatory documentation - SNiP 41-01-2003 and MGSN 3.01.01 .

There are also special diagrams compiled by specialists that make it easy to find the duct of the required diameter for various options for standard systems.

Detailed information on calculating the area of the air duct and fittings is presented in this article.

Classification and scope of application

Corrugated pipe is present on the construction market in various modifications. These can be small-diameter models of various colors, made of plastic. You can also find a stainless steel water-permeable corrugation, which is considered to be the most reliable in use. Each buyer can select products based on the following parameters:

- material;

- price;

- size;

- color.

It is difficult for an inexperienced home handyman to immediately select an option that will solve emerging problems. A corrugated pipe is a very useful element for forming an exhaust ventilation duct. It makes installation work faster and easier.

It is necessary to understand the purpose of this product and the main types that exist on the market in order to choose the appropriate option. If you rush, you may purchase the wrong version of the pipe that will fit harmoniously into the interior.

Reasons for demand

Corrugation is very popular and in demand, as it has many functional characteristics . It is actively used by builders because it:

- has good strength;

- involves a large selection of materials and sizes;

- serves for a long time, maintaining all its characteristics.

The main ones are round and rectangular shapes. The first option is advisable to use for a kitchen hood. As for materials, you can most often find products made from the following materials:

- of stainless steel;

- aluminum;

- galvanized steel;

- on a textile basis;

- made of polyvinyl chloride;

- from low and high pressure polyethylene.

The scope of use of the object is directly determined by the diameter and type of material.

Types of materials

To install household ventilation, it is advisable to use products made of stainless steel or aluminum. It should also be noted that corrugated pipes are divided into spiral-wound and frame, in accordance with the method of their manufacture. The second type - aluminum corrugation for hood - in its appearance resembles a metal frame with foil or a polymer-based film on the surface. Such objects are classified as flexible air ducts. They have the ability to return to their original shape without being deformed, even when the corrugation has been extended to its full length.

Frame products are made from iron strips. They are only 50% flexible and can stretch 2 times. However, after this it is impossible to return them to their original appearance. To ensure the required shape, you need to make every effort, and it will not be possible to do without defects.

Many companies today offer to buy flexible corrugated pipes with and without thermal insulation. In the first case, it is possible to increase the scope of application of products. Four-layer flexible pipes are used for laying ventilation ducts indoors and outdoors. Besides, distance doesn’t really matter here.

Basic criteria for choosing a corrugated pipe for an air duct

When choosing corrugated pipes for connecting the hood to the ventilation system, the following parameters must be taken into account:

- pipe material;

- preparation method;

- shape and dimensions of the section;

- additional options.

Pipe materials

Corrugated pipes for air ducts can be made from the following materials:

stainless or galvanized steel. The advantages of the materials under consideration are absolute non-flammability, long service life and resistance to mechanical stress. However, the high cost and complexity of installation lead to a decrease in demand for this type of product;

Corrugated air duct pipe made of galvanized steel

aluminum. Aluminum corrugated pipe is lightweight and has an average level of rigidity, which facilitates installation of the air duct, durability of use and the possibility of use in different temperature conditions. Disadvantages include high noise levels and vibration;

Corrugated aluminum pipe

plastic (low or high density polyethylene, as well as polyvinyl chloride). Plastic corrugated pipe has the lowest cost, light weight and ease of installation. But such disadvantages as flammability, susceptibility to mechanical stress and the release of odor at high temperatures significantly reduce the possibilities of its use.

Corrugated pipe made of plastic

For domestic purposes, air ducts are most often installed from aluminum and stainless steel.

Manufacturing methods and their features

Corrugated pipes can be manufactured in two ways:

frame (a metal pipe frame, usually made of wire, covered with aluminum or plastic foil). Pipes made using this method are elastic and capable of returning to the shape specified by the manufacturer after repeated stretching;

Corrugated pipe made on a frame base

spiral wound (metal tape is wound onto a template). Such pipes can stretch greatly, but after stretching they do not return to their original position on their own.

Corrugated pipe made by spiral-wound method

Both spiral-wound and frame pipes can be installed in domestic premises.

Selection of shape and section

According to the cross-sectional shape, the air duct can be:

rectangular. This form is mainly used for the construction of ventilation systems for industrial purposes;

Corrugated pipe with rectangular cross-section

round, which is optimal for domestic ventilation.

Manufacturers produce pipes of different diameters and standard sizes. The selection of a suitable corrugated pipe diameter is made based on the diameter of the exhaust pipe of the exhaust device.

Extra options

To purchase a corrugation that is optimally suited to the given conditions, you must also pay attention to such parameters as:

- duct length. In accordance with the rules for the manufacture of a ventilation system for a domestic premises, bending the air duct at an angle of more than 90° is not allowed;

- the presence of a thermal insulation layer, which allows installation of the air duct outdoors, and in cold climates.

Corrugated pipe for laying outdoor air duct in cold climates

Guidelines for choosing the right pipe

A large selection of plastic air ducts offered by sellers can create certain difficulties when choosing the appropriate pipe option when arranging ventilation.

Therefore, to buy the right product, you should be guided by the following parameters:

- diameter and length;

- product material;

- quality;

- price.

The diameter must correspond to the recommendations given in the instructions for the purchased hood model.

If you choose a larger or smaller option, then expensive equipment may, at best, not cope with its functions of removing odors from the kitchen, and at worst, it may burn out from overvoltage.

When you go to the store to buy corrugation, you need to carefully study the technical characteristics of the hood, and before purchasing, do not hesitate to measure the product

There is no need to ignore the recommendations given by the manufacturer. Sometimes an air duct is supplied with the hood. It’s great if it fits in a particular case - the length will be sufficient and the material will suit you.

Otherwise, you will have to visit the building materials market yourself and purchase a more suitable option.

Another situation is when, along with the hood, they offer to immediately buy corrugation. Here you need to be extremely careful, because the seller does not always care about the client’s comfort.

He may offer a product that is stale or too expensive. In this case, the length must be measured in advance so as not to buy extra meters, trusting the experience of the seller.

The flexible pipe for ventilation in its original form has a length of 60-70 cm. But it stretches by 3 meters. This is worth considering when purchasing

The length of the corrugation required to connect the hood to the ventilation duct is measured with a tape measure. The measurement must be taken from the entrance to the hood pipe to the entrance to the wall. The path you should choose is the one that is to be repeated by the pipe.

It should be taken into account that the corrugation may bend, depending on the technical parameters specified by the manufacturer. For example, 180 degrees.

The ability to bend at the desired angle allows you to create the most optimal path. The pipe will be installed in a stretched state. This point should be taken into account.

The second parameter that influences the choice is the material of the product. Sometimes the color matches the plastic version. In this case, you need to be aware of the greater noise generated by the duct. If this issue is not fundamental, then the range of models can be expanded.

Polyethylene corrugation is not used for ventilation. These products, depending on the diameter, are suitable for transporting and pumping bulk and liquid substances

To ensure that your purchase does not disappoint, do not forget about documents confirming the quality of the purchased product. Don’t be embarrassed to ask the seller for a certificate of quality and manufacturer’s warranty.

In addition to the document, you should carefully inspect the corrugation - there should be no dents or suspicious scratches.

Don’t be afraid to stretch the flexible pipe to its full length and check it for gaps or holes - there shouldn’t be any. If the corrugation is of dubious quality, then it is better to refuse to purchase it.

The flexible pipe will be installed in the ventilation system in a stretched form. Therefore, you need to carefully examine it in this condition before purchasing it.

Price also matters. It’s good to study similar offers from other manufacturers before purchasing so as not to overpay. Also, knowing the required length of the air duct will significantly help save money.

When choosing, you should consider where exactly the corrugation will be used. If you plan to install it outdoors or in fresh air ventilation systems where there will be heating/cooling, then you should pay attention to models with thermal insulation.

It is more convenient to buy a finished product than to insulate a flexible pipe yourself.

In domestic conditions, corrugation is most often used in the construction of ventilation ducts that remove exhaust air from the kitchen, and in connecting exhaust devices.

The following selection introduces the steps of installing a hood with an air duct in the kitchen using a corrugated pipe:

You may also be interested in material about the types of plastic pipes for kitchen hoods.

What are air ducts for?

The term “air ducts” refers to specially made channels for ventilation, thanks to which air masses are supplied in a certain direction. Through such devices, oxygen is supplied to the interior of a residential or industrial premises, CO2 and other contaminants are removed.

In such systems, it is usually possible to regulate the intensity of the supply of air masses and their pressure using valves.

Various types of devices designed for air circulation are successfully used in residential buildings, in industrial spaces, as well as in public buildings

There are two ways to solve the air circulation problem:

- Option number 1 . In this case, natural or forced ventilation is limited, providing one exhaust duct to remove used air. New items enter through technological openings and/or doors and windows.

- Option number 2 . A more complex and efficient design is considered to be a supply and exhaust system, which involves laying two channels located separately from each other. Fresh air flows through one of them, and used air is removed through the other.

Often, several types of air ducts are used in one ventilation communication, which form a complex network with various branches, shafts, and sleeves.

Subtleties of installation and assembly

The process of connecting the corrugation to the hood and ventilation system will be within the capabilities of a home craftsman.

To complete this job, you will need to take:

- flexible pipe;

- clamps;

- aluminum tape;

- grille with check valve;

- silicone sealant;

- adapters from round to square.

The last point is useful when the hood has a square or rectangular pipe, and the corrugation is round.

Adapters for smaller and larger diameters are available for sale. They should be used only when necessary, so as not to reduce the performance of the exhaust equipment.

It is good to buy all the necessary parts together with the corrugated pipe.

This will prevent you from making a mistake with the number of spare parts needed.

All components for future installation of the air duct should be selected by first taking measurements at the site of the upcoming installation

If you need to connect 2 or more flexible pipes together, you can use aluminum tape.

It connects the material of metal air ducts well, provided that it is carefully glued to the surface.

Aluminum tape can not only connect 2 corrugations together, but also seal an accidentally torn hole

The corrugated pipe will have to be stretched to its full length. In this state, one end must be attached to the outlet pipe of the hood.

For fastening you will need to use a metal pipe and sealant.

The sealant should only be applied to a dry and clean surface. Otherwise, he will not be able to reliably close the joints

Then, every 1.0 meter vertically or 1.5 meters horizontally when laying the corrugation, you need to install additional clamps. These devices will ensure proper fastening of the air duct.

If the ventilation hole is only 0.5-0.8 meters away, then there is no need to install any additional clamps.

If the ventilation duct is long, you should not make sharp corners - each of them will reduce the performance of the hood by 10%.

If the ventilation entrance is more than 3 meters away, then you need to choose a more powerful hood model or run a corrugated pipe in a straight line under the ceiling to shorten the path. After all, the longer the channel, the more powerful the equipment should be.

Having installed additional clamps, all that remains is to connect the corrugation to the ventilation hole by inserting its second end into the corresponding hole in the wall grille.

Wall-mounted ventilation grilles are available with or without a built-in check valve

The joints between the grate and the pipe should also be thoroughly treated using sealant. Now we need to check the quality of the installation. To do this, you need to turn on the hood and attach a sheet of paper - if it is attracted, then everything is mounted perfectly. So you can start decorating.

The decorative casing of the hood itself can be used as decoration.

Sometimes this is clearly not enough. Then the owners use their imagination, choosing the most optimal option, for example, hiding the pipe in wall cabinets. This is especially true for built-in type hoods.

Sometimes the ventilation duct is hidden in a plastic box. If you also install lighting in it, then no one will guess about the metal corrugation inside.

Depending on the style of the kitchen interior, the corrugated pipe can be hidden under the suspended ceiling. If the furniture in the room is in high-tech style, then the metal corrugation will organically fit into the overall picture.

It happens that the air duct fits perfectly into the interior of the kitchen, being a logical continuation and not getting out of the overall composition.

What to pay attention to during installation

The corrugation for the hood is considered ideal if it is completely hidden in the wall cabinet.

The work is carried out without the use of special adapters and complex fastening elements, which makes it possible not to spend extra money on the work. The elastic ribbed design easily bends around obstacles, eliminating the need for additional connections and fittings. Before starting work, the corrugation is fully stretched and installed in such a way that it reduces noise when the fan operates. Otherwise, the resulting folds will certainly create vibration, and the operation of the hood will be accompanied by increased rattling. The corrugation is attached to the ventilation system pipe using special metal or plastic clamps. To carry out installation work correctly, you should follow simple rules:

- If the ventilation hole is located at a large distance from the hood, the pipe should be routed under the ceiling. This will help avoid sharp corners and make the system more efficient and reliable. For these purposes, it is better to use suspended ceilings, which will ideally hide the corrugation from prying eyes;

- you should carefully select the diameter, since a narrow air duct will create a large load for the fan, which will certainly affect its operation. If the hood has a round opening, do not use a rectangular pipe. This will make the work ineffective, since you will have to install special adapters that will reduce the flow of air through the air duct.

How is installation carried out?

- Before starting work, a grille with a built-in check valve is installed. It will help ensure the flow of fresh air to ventilate the room when the fan is turned off.

- By installing an anemometer at the base of the pipe, you can determine the volume of performance of the ventilation system, which should be at least three volumes of the kitchen.

- Before installation, check for the presence of reverse draft; to do this, attach a sheet of paper to the hood grille; it should adhere tightly to the hole. The presence of reverse draft can reduce the effectiveness of the forced ventilation system.

- When installing, you should try to ensure that the structure has as few bends and turns as possible, since this reduces the effectiveness of the work many times over.

The choice of air duct is made after purchasing a ventilation system, since the quality of the system as a whole depends on the correctly selected diameter. The diameter of the outlet hole must exactly match the parameters of the pipe; this is the only way to achieve maximum efficiency.

Often, trading organizations offer a corrugated pipe along with the hood. You can refuse the imposed service if you read the instructions in a timely manner and calculate the required amount of corrugation. Then you will buy the exact quantity without overpaying for extra meters.

An ideal way to make a chimney, you don’t have to worry about overheating the pipe. It is quickly and easily installed in any type of ceiling. When installing gas heating or water heating equipment, it can ensure maximum outflow of combustion products, making it possible to guarantee the reliable operation of boilers and boilers. A system of such pipes has proven itself well when installing fireplaces, stoves or other heating systems.

The steel internal frame and heavy-duty film allow you not to worry about the durability and reliability of the structure. Remember that the more responsible you are in choosing corrugation, the better and longer your ventilation system will work. You should not skimp on the outlet pipe, since carbon monoxide entering the apartment can lead to dire consequences.

Good reasons to replace the pipe

Corrugation is an inexpensive and very worthy solution to the problem of arranging ventilation at home. If it is installed correctly, there will be no problems with use. The main thing is to follow the recommendations specified by the product manufacturer.

You don’t have to take special care of the corrugated air duct. One unpleasant thing is that it is very inconvenient to get dust out of the walls. Over time, after 8-10 years, a rather thick coating of particles of fat, soot, and dust forms inside the pipe. It will not be possible to clean it. The only way out is to install a new corrugation.

If you compare the service life of 10 years with the cost of a new ventilation duct, then replacement does not seem like a problem at all.

When replacing, you must first dismantle the old pipe and then install a new one

When dismantling, you must perform all the steps as during installation, only in reverse order.

After removing the pipe, you need to thoroughly clean the joints, clean the ventilation grille, or replace it altogether. Then perform all the steps to install the new corrugation.

Getting rid of noise

There may be a couple of possible circumstances for the noise:

- unsuccessful modification of the box,

- use of fans,

- If a corrugated pipeline is used, then it was not possible to stretch it very much at the installation stage; as a result, its surface resembles a washboard and the air space makes a lot of noise when in contact with it.

In any of the above cases, sound insulation of the ventilation duct will be useful.

In addition to this, there are a couple of ways to combat noise:

cover the box with a layer of sound insulation. This material may be self-adhesive; under such conditions, it is enough to cover the entire surface of the box,

Note! There is an option to attach sound insulation to the inner surface of the box, but in this case there is a strong possibility of the material becoming damp and fungus developing on it

- If the main source of noise is the fan, then it is possible to reinstall it using anti-vibration flexible inserts. Or a less noisy one, in addition, a special installation can be installed behind the fan itself to counteract noise,

- a plate muffler can be used,

It is possible to replace solid air ducts with flexible ones, the friction of air against their walls will be significantly reduced, and accordingly, the noise nuisance will fall through the ground.

How to install corrugation on a kitchen hood

Anyone can install a corrugated pipe for a kitchen hood. This requires a minimal set of tools and very little time. In some cases, installation takes more than 1 hour. Below we will look at what is needed to install the corrugation and describe in detail the process of its installation.

Anyone can install a corrugated air duct

To create an air duct between the kitchen hood and the general house ventilation system you will need:

- corrugated pipe with a diameter corresponding to the size of the pipes on the hood and ventilation grille;

- two clamps (metal or plastic);

- ventilation grill with pipe;

- adapter;

- new residents with self-tapping screws;

- sealant and aluminum tape (if necessary);

- crosshead screwdriver;

- pliers;

- scissors or wallpaper knife.

Corrugation, adapter and clamps, that’s probably all you need to install the air duct

Step-by-step instructions for installing corrugations on a hood

As you will see from the step-by-step instructions, anyone can install the corrugation on the hood and connect it to the ventilation system. To do this you need to have minimal skills in working with a screwdriver.

| Illustration | Description of action |

| We buy and unpack corrugation of a suitable diameter and length | |

| In the wall cabinet to which the hood is attached, you need to mark and cut out a hole for the corrugated pipe with a jigsaw | |

| In our case, we will need an adapter from the exhaust pipe to the corrugation. It can be bought at almost any HVAC store, household appliances store or construction market. | |

| We install the adapter on the hood. For reliability, the connection can be treated with sealant | |

| We put a worm clamp on the end of the pipe and place it on a plastic adapter | |

| Using a screwdriver, tighten the clamp. The main thing is not to overdo it | |

| Our ventilation duct is routed into a plasterboard box. We took a pipe with a check valve, although most hoods are already equipped with one | |

| Carefully remove the pipe through the hole in the fume hood | |

| We also carefully straighten the corrugation, trying not to wrinkle it. | |

| We put a clamp on the pipe and connect it to the ventilation pipe with a check valve. Tighten the clamp using a screwdriver. At this point you can consider the installation complete |

Design features of corrugation

The corrugated pipe is based on a metal frame made of steel wire, which is twisted into a spiral. Using a spiral, the cylindrical shape of the product is formed. Material is placed around the wire spiral on both sides to create a pipe shape. When the rings are pressed, the covering material is folded into an accordion. In the stretched position, the material straightens, and the corrugation itself lengthens. The ability of the product to decrease and increase in length is very useful if pipe material needs to be transported or stored.

The spiral frame is not rigid, which means the corrugation bends easily, which is undoubtedly one of its positive qualities. There are positions in building projects when communications are laid in hard-to-reach and inconvenient places. It is in such areas that it is recommended to lay a corrugated sleeve. In this regard, it is simpler with a kitchen hood duct, because its length is short, and more often than not there are two or three outlets from straightness. Therefore, for the kitchen this is the best option for a hood.

Advantages of corrugations for connecting a hood

The advantages of a corrugated pipe for kitchen hoods are:

- The corrugated pipe duct is easy to install. It does not require the use of corner elements, since the corrugation can be bent at the desired angle.

- If necessary, you can connect several pipes using clamps, which is done quickly and easily. The entire structure is easy to assemble and disassemble, which simplifies installation, maintenance and disassembly in the future.

- The pipe stretches and contracts, without additional tools. It can be given the optimal length and laid along the desired path.

- Allows you to avoid creating 90 degree angles, making smoother bends. This reduces noise and simplifies the operation of the device (the fewer right angles in the air duct, the easier it will be for air to pass through it).

- Convenient to use for arranging an air duct in limited space and in a kitchen with a non-standard layout.

- Aluminum corrugation is easily cut using ordinary scissors.

- Acceptable price. Corrugated pipes are several times cheaper than metal or plastic pipes for exhaust hoods.

- On the construction market there are corrugations with different sections, which allows you to select the desired diameter for a specific hood.

- The corrugation cannot catch fire or melt during operation of the device, since it is designed for temperatures up to 300 degrees.

Main disadvantages

Corrugation also has obvious disadvantages:

- Due to the unsmooth surface of the pipe, grease and other dirt accumulate faster on its walls (both inside and outside). Washing all the folds until they are completely clean is much more difficult than cleaning a smooth plastic pipe.

- Due to the unsmooth surface, much more noise is created than in smooth-walled air ducts.

- The corrugation looks less aesthetically pleasing than a regular plastic pipe and fits worse into the kitchen interior. You have to either come to terms with this “decoration” or figure out how to close the corrugation of the hood.

Comparison with rigid plastic duct

Of all the exhaust pipes, the most common and popular options are aluminum corrugated and smooth plastic pipe. To make the right choice, you need to understand the fundamental difference between them:

- A plastic exhaust duct will cost more than aluminum corrugation.

- Plastic pipes cannot be stretched, compressed or bent. Therefore, you need to know in advance all the dimensions of the air duct, the length from the hood to the ventilation hole, angles, etc. In addition, the installation of such an air duct itself is more difficult than installing corrugations.

- A plastic duct is much more difficult to install in a confined space without compromising the performance of the device.

- A plastic hood does not get as dirty as a corrugated hood and is much easier to clean.

- A smooth-walled plastic air duct, unlike corrugated one, creates much less noise (since the air does not “cling” to the smooth surface).

- Plastic can be matched to the color of the kitchen and the style of renovation, since it is available in different colors. If necessary, it can be easily painted or covered with something.

Corrugated pipe in the kitchen does not look very nice

What is better to choose : corrugated or plastic? Decide what is more important to you: aesthetics and cleanliness (for plastic products), or low price and ease of installation (for corrugated pipes).

Types and differences of air ducts for hoods

The exhaust duct can be divided according to the following characteristics:

- According to the material from which the channel is made: plastic or metal.

- Shape: round or rectangular.

- By rigidity: flexible or rigid.

Features and advantages of metal (corrugated) air ducts

Corrugated metal (or rather, aluminum) pipe is the most popular option for creating an air duct. You can read more about the selection and installation of corrugations for the hood separately. Let's look at this option briefly below.

Corrugated air duct in the kitchen interior

- Diameter 100 mm: about 90 rubles per meter.

- Diameter 120 mm: about 120-130 rubles per meter.

- Diameter 150 mm: about 135 rubles per meter.

The advantages of such an air duct include:

- flexibility (the corrugation can be easily bent to give the air duct the desired shape);

- the ability to stretch and fold (and therefore the ability to adjust the length of the channel);

- ease of connection (for corrugation there is no need to separately purchase and install adapters and connecting elements).

Of the minuses:

- relatively high noise level (however, the noise of the motor of a running hood will still cover the noise from the air passing through the duct);

- faster contamination (than with PVC products);

- unsightly appearance (corrugation spoils any interior, so the metal air duct is almost always covered, which means you need to spend additional time and money on creating a “cover”).

Features and advantages of plastic air ducts

A plastic pipe is a rigid product that does not bend. The cross-sectional shape can be either round, rectangular or square.

Rectangular plastic duct for exhaust hood

The main advantages of plastic (compared to metal):

- noiselessness (a smooth, flat surface does not contribute to noise);

- ease of maintenance (smooth surfaces become dirty much more slowly and are easier to clean);

- aesthetic appearance: in the interior, a plastic pipe looks much neater than corrugated pipe.

The most successful solution is to use a rectangular duct. It is easy to run such a pipe along the wall, saving space. On the other hand, such a channel requires an adapter with which the rectangular pipe will be connected to the round openings of the hood and shaft. You will also need connecting elements to hold together a system of several sections.

Of the minuses:

- more complex installation;

- higher cost than corrugated pipes (both the pipes themselves are more expensive, and in addition you will need to buy additional adapters and elbows);

- inability to bend, stretch or compress the pipe.

More complex installation is the most serious disadvantage of plastic. The corrugated metal sleeve is flexible, it bends, stretches and folds easily. Even if you made a mistake in the calculation, it can be adjusted to the required conditions without any problems. But this will not work with a plastic air duct: it needs to be measured and planned as accurately as possible.

Plastic Air Duct Parts

- Plastic adapter from a rectangular channel 60x120 mm to a round hole with a diameter of 120 mm: about 150 rubles.

- Flat air duct, cross-section 110x55 mm: about 260 rubles per 1 meter.

- Round air duct, diameter 100 mm: about 250-270 rubles per 1 meter.

Which option is better?

The question of which air duct to choose (corrugated or plastic) is not critical. If it is correctly calculated and laid, the hood will work normally.

Minor differences include several points:

- Exterior to interior. Here plastic clearly wins. However, air ducts are often decorated, so the corrugation will still not be noticeable.

- Ease of installation. In this regard, it is clearly easier to take corrugation.

- Air duct price. Corrugation will cost a little less.

The nuances of installing corrugated air ducts

Sometimes, when performing installation work, non-standard situations arise that require separate consideration: the need to connect the corrugation or hide it from the visual space of the kitchen area.

How to connect

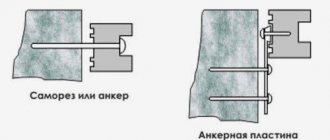

The need to connect several corrugated elements to each other arises in the case of an extended section of the air duct, which cannot be completed in its entirety. For the connection, special inserts are used (indicated by an arrow in the following figure), installed in the internal space of the corrugated pipe in both joined elements, after which the joints are tightened using clamps.

Connecting metal corrugation using a special plastic insert

If inserts are not available due to non-standard dimensions of the air ducts or for other reasons, the connection can be made using construction tape corresponding to the material from which the air duct is made.

How to hide corrugation in the kitchen

There can be a large number of options for how to hide a corrugated air duct in the kitchen, as evidenced by the following photos, which document the solution to a similar problem by designers and tenants:

The air duct is covered with the doors of wall cabinets The air duct is mounted behind a plasterboard structure The air duct is covered with a decorative box The air duct is closed with a decorative box in the style of kitchen design Laying corrugation behind a suspended ceiling Covering the air duct using a decorative element

Scope and nuances of using corrugation

Different types of corrugated products, which stand out for their size and type of material, clearly indicate the areas of application of this material. In addition to electrical and sewer systems, corrugations are widely used in everyday life. Here, pipes with a diameter of 100-150 mm are mainly used. But sometimes models with a cross-section of 200 and 300 mm are required.

Textile ventilation ducts are used mainly in production workshops. It is precisely because of the textile material that such corrugations are used in meat processing premises, in public canteens and other similar enterprises.

Sometimes during installation non-standard cases arise: connecting two corrugations or hiding it for external viewing in the kitchen.

Connecting two parts of a pipe

If the area for laying a corrugated channel is slightly more than three meters, it becomes necessary to attach an additional element. In this situation, special plastic inserts are used, on which the pipe is tightened with clamps. If such pipes are not available at the moment due to the non-standard dimensions of the channel, then the connection can be made using adhesive tape.

Invisible corrugation gasket

There can be many options for making the air duct invisible, here are just a few of them:

- in a hanging cabinet;

- facing slab;

- due to appropriate painting;

- behind the suspended ceiling.

In any case, in order not to disturb the interior of the kitchen, an extraordinary approach and ingenuity of the homeowner are required.

How to hide the corrugation from the hood?

Corrugation attached to the wall or laid on kitchen furniture can spoil the appearance of the interior. Therefore, it is disguised in different ways.

Drywall box

One reliable way to disguise corrugation is to sew the pipe into a plasterboard box.

First, a frame is made according to the dimensions of the pipe, and then it is sewn up with finishing material and finishing work is carried out.

Work on masking the corrugation in a plasterboard box is carried out in the following sequence:

- Markings are made according to which metal profiles will be installed on the ceiling and wall. Perpendicular lines are drawn from the ends of each profile. They are connected at the points where the third profile will be placed.

- Drill holes for self-tapping screws. They are performed through the profile.

- Dowels are fixed into the holes.

- Attach profiles.

- The corners located near the hood are equipped with a metal corner.

- All profiles are fastened to each other with transverse elements.

- Plasterboard sheets are fixed to the metal frame.

Then the box is decorated. The external joint of the panels is decorated with a plastic corner.

Plastic finish

Corrugation is often disguised behind plastic panels. They are practical and, in combination with a plastic ceiling, look aesthetically pleasing. The work is similar to the previous ones, only plastic panels are used instead of plasterboard sheets. You can choose their color to match your kitchen design.

Disguise behind the overlay

If the corrugation is hidden in the ceiling, a decorative overlay is used to mask its area before the hood.

This element is usually sold complete with exhaust equipment.

The product is a channel with a square cross-section and three walls.

Laying a channel through furniture

To lay corrugation through furniture, preparation is needed. For work you will need:

- jigsaw;

- Bulgarian;

- hacksaw for metal;

- pliers;

- polyurethane foam;

- sandpaper;

- roulette;

- hammer;

- drill;

- level.

First, they make a check flapper valve that prevents air from entering the room from the ventilation pipe. It is made of thin-walled aluminum or galvanized. It is placed on the cabinet. Subsequently, it is attached to the furniture using mounting glue.

After trying on the firecracker, a hole is marked on the cabinet. Then you need to outline the sides of the check valve box.

Sequence of work with the cabinet:

- The piece of furniture is removed from the wall.

- A hole for the hood is cut out in the bottom board. To do this, mark a rectangle along the frame of the hood and make a hole for the jigsaw. Carefully cut out the desired hole.

- Remove the shelves and make holes in them for the air duct. A hole is created in the top board for the cracker, leaving an allowance of 3 mm on each side.

Then the corrugation is inserted into the cabinet laid on the back wall. The upper edge of the pipe must be formed into a square under the hole in the top board. Then they push the corrugation into the hole and cut the corners by 2 cm to bend the edges to the sides.

The corrugated cabinet can be reinstalled. The bent strips of corrugation and cabinet wood at the corners are greased with silicone in an unbroken line. A box with a firecracker is inserted into the ventilation window.

Remove excess silicone with a rag soaked in vinegar.

All that remains is to install the hood:

- Equipment is inserted into the cutout of the bottom board of the cabinet.

- The corrugation is pressed out with the pipe facing up without putting it on.

- Fix the hood to the cabinet with screws.

- Place the corrugation on the pipe and secure it with a clamp. The main thing is not to seal this connection, since it will have to be cleaned.

It is important to think in advance about the location of the outlet and the electrical wiring for the hood. Particular attention is paid to grounding. Do not ground through gas pipes or water pipes.

Where is it used?

Installation of plastic ventilation pipes is possible in any domestic space, but places with high humidity levels and unpleasant odors especially need to be updated. For example, in a bathhouse, ventilation will prevent rapid wear of materials that lose their resistance under the influence of moisture and high temperatures, and will prevent an increase in the level of carbon monoxide and carbon dioxide. In the garage, the installation task is to remove car exhaust and fumes, dry the body, and blow out the inspection hole. In a chicken coop or other livestock area, the system ensures the elimination of harmful ammonia fumes.

Ventilation solves the same problems in a private house. There are many bacteria and viruses in the air, the number of which increases after illnesses suffered by the inhabitants of the house. Ventilating windows will not control invisible pests. This issue will be resolved only by arranging a system of air outflow and inflow channels.

Requirements for materials for sealing pipes

The materials that cover the pipes must meet certain criteria:

- Be resistant to temperature and steam.

- Have good sound insulation properties.

- Do not lose color over time from exposure to sunlight.

- Easy to clean, withstands washing with chemicals.

- Fire safety.

Typically they use drywall, metal, plastic or wood. The characteristics of the materials should be taken into account.

Plastic pipes can fade when exposed to direct sunlight, are easily damaged by impacts, and are scratched. Pipes with a round cross-section create less resistance to air movement, so the efficiency of the hood will be higher. Rectangular pipes are less noticeable in the interior, but to create good traction they should not be more than 3 meters long, and the turns should not be at an acute angle. In addition, before purchasing, you should take accurate measurements, select all the parts (straight sections, sleeves for bends, fastenings) so that the assembled structure corresponds to the distance from the hood to the ventilation shaft.

The corrugation must be well stretched before installation, then there will be less noise during operation of the device and better conditions for air movement. Unlike plastic and steel products with a smooth surface, aluminum corrugations are more contaminated from the inside: particles of fat, dust, and fumes settle on the folds.

Wood is used to seal pipes if the kitchen has wooden furniture. To increase resistance to aggressive factors, it is coated with protective materials.

Each of the proposed options has its pros and cons. It’s better to plan what the kitchen will look like in advance, thinking through and taking into account all the details. Then it will be possible to realize most of your desires, optimally combine functionality and beauty of execution.

Recommendations for choosing an air duct

Experienced specialists give a number of tips to make it easier for owners to choose products for arranging a ventilation system. Some of them:

It is best to buy products in branded stores or specialized retail outlets. In addition to the product, the kit should include instructions for use, as well as a warranty card.

If such documentation is missing, it is better to refuse the purchase. It is necessary to take into account the design of the products so that they fit organically into the interior of the room. The manufacturer is of no small importance. It is advisable to choose high-quality branded models. No need to focus on low prices

Of course, a high-quality and reliable ventilation system will be quite expensive, especially if good materials are used. However, you need to understand that high-quality models will serve for many years without complaints. Products must have sufficient performance. If the ventilation system is weak, the hood will not be able to cope well with its main task, so the exhaust air masses will remain in the room.

In addition, when choosing the components of the ventilation system, you need to take into account the main functions of the kitchen hood. The latter must meet the following characteristics:

- An attractive appearance is important so that the device fits organically into the interior, complementing it.

- Low noise level during operation.

- The ability to quickly and to the required extent remove foreign odors.

We invite you to familiarize yourself with a kitchen hood without a ventilation outlet (25 photos): models without an air duct

Price remains a significant selection criterion for homeowners; aesthetics and performance characteristics of ventilation ducts fade into the background. Flexible corrugation definitely wins here; it is much cheaper than other options, and fittings are not needed.

We will offer our recommendations on how to choose a ventilation duct for your hood:

- There are two types of channels suitable for external installation: plastic and metal.

The former are cheaper, but look worse; they are better hidden above cabinets or behind decorative cladding. On the left in the photo is the installation of a ventilation duct behind plasterboard sheathing, on the right is the gasket inside the furniture - For hidden installation, you can use any air duct: corrugated, PVC, galvanized. If you don't care about the noise level, use a cheap aluminum hose.

- In a country house, summer kitchen or veranda with a stove, connect the hood with a corrugated pipe. Plastic in such rooms quickly becomes dirty, and it is quite difficult to remove the yellowness.

- If an apartment has undergone expensive renovations, you cannot save money and spoil the interior. Match the steel frame, fittings and grille to the color of the hood. Stainless steel is perfect for a nickel-plated surface, and copper for a golden surface.

Exhaust air is removed through a pipe, which may differ in the following characteristics:

- by material;

- diameter or dimensions of the sides of the box;

- section shape;

- flexibility.

Caring for a corrugated air duct and the need to replace it

Corrugated pipe is a fairly inexpensive option for air duct from the kitchen hood to the ventilation duct. If everything is done correctly, its operation will be long and problem-free. However, dust and grease accumulate on the corrugation over time. It is necessary to periodically wipe the pipe with a soft cloth and soapy water. Particular attention should be paid to the places between the folds.

Although the service life of a corrugated pipe is up to 10 years, fat, fumes and soot accumulate inside it, interfering with the normal flow of air. These contaminants are practically impossible to remove. The best option would be to buy and install a new corrugation, especially since it will not cost much. After dismantling the old pipe, the new one is installed exactly as described in the step-by-step instructions.

Other connection methods

The flange connection of air ducts is quite reliable, but not particularly relevant due to its high cost. It has a high level of rigidity. On the one hand, this is a plus, but on the other, a minus, since with the slightest configuration changes, unsuitable parts can simply be sent for remelting.

There are many options for fastening such a connection. But the most common is spot welding. This method is the fastest and easiest. The disadvantage of this connection is that it is not reliable enough, especially when working with galvanized parts. Since zinc can burn out during welding, there is a high probability of corrosion of the welding seam, as a result of which the fixation of the structure will weaken. To avoid such consequences, it is recommended to use corrosion-resistant rivets for fastening instead of welding.

Comparison of flexible corrugation for ventilation with a rigid air duct

Many people prefer to use a plastic round pipe or a rectangular box as an air duct between the hood and the ventilation duct. This solution has its advantages and disadvantages. The advantages of plastic air ducts over flexible corrugated pipes include:

- quieter operation;

- low air resistance due to the smooth, flat inner surface;

- ease and simplicity of care;

- more aesthetically pleasing appearance compared to corrugated;

- no need for additional decoration;

- good tightness;

- good strength, eliminating the possibility of accidentally damaging the box or pipe;

- various section sizes and configurations.

We have figured out the advantages of plastic air ducts, and now we will look at how they are inferior to a corrugated pipe for exhaust. Among the disadvantages:

- more problematic installation, as more tools, increased attention and marking accuracy are required;

- the cost of a plastic box or pipe is higher than aluminum or plastic corrugation;

- more complex fastening system;

- low heat resistance;

- many different adapters and bends are required;

- the weight of plastic products is higher than that of aluminum or PVC pipes.

How to choose the diameter?

The main nuance when laying an exhaust duct is the correct size (diameter) of the pipe.

The main nuance: the diameter of the air duct should not be less than the diameter of the ventilation shaft opening. If you use a pipe with a smaller diameter than the hole, additional resistance will be created for the air flow. As a result, the performance of the hood will significantly decrease.

The selection rule is as follows: the diameter of the exhaust pipe must match the diameter of the hole leading into the ventilation shaft.

Common mistakes

The most common mistakes are made when installing corrugated or plastic air ducts. Thus, to install a plastic or corrugated pipe, it is important that its cross-section matches or exceeds in size the area of the air purifier outlet pipe. When purchasing hoses and exhaust equipment, you should pay attention to this.

The corrugated pipe must be installed as stretched as possible, which is not always observed. Its bends should not be less than the diameter of the corrugation itself.

When laying a plastic pipeline, the bend angles must be obtuse.

Basement ventilation

To prevent dampness, each basement must have ventilation.

Usually, for this purpose, vents or windows are installed around the perimeter of the base, which are periodically opened for ventilation. But the best solution is ventilation through special ducts installed in smoke ventilation units and extending beyond the attic floor or roof. The exhaust pipe starts at the basement ceiling and exits with the rest of the pipes above the roof of the house. To improve draft, it is advisable to lay it next to the smoke duct of a stove or heating boiler. The larger the cross-section of the exhaust duct, the better; in any case it should not be less than 140 x 140 mm. In summer, natural draft may not be enough, and you will have to install a fan in the exhaust pipe. Air flow is usually ensured due to non-density in the enclosing structures. You can also arrange special channels with air intake either from the street or from enclosed spaces (vestibule, veranda). It is best for the supply pipe to start in the attic. The supply and exhaust ducts are located on opposite sides of the basement, the first of them near the floor, and the second near the ceiling.