Various lumber is used for exterior and interior decoration of the house. Dry and wet boards have different ranges of applications. There are a lot of important nuances to consider, which professionals will advise you on. This will help not only save on construction costs, but also avoid a number of problems in the future.

Edged materials are products processed using special equipment. They are made mainly from coniferous trees. The most popular budget options: spruce, pine. Larch is considered more durable and resistant to external influences, the properties of which can be found in detail on the Lesinter website. Houses in the construction of which this wood is used can stand for centuries without visible damage.

Edged products are also made from valuable species: red and ebony, cedar, beech, oak. The length depends on natural qualities: tree height, health, age. The average size of a molded product varies within six meters. Longer edged materials can be made to order. But you should take into account the fact of delivery to the construction site - problems may arise.

Massive or parquet - which is better?

Solid wood is a relatively new type of flooring and combines the advantages of floorboards and parquet.

If you look at its appearance, it resembles a large parquet. Solid boards are made from hardwood, expensive wood. Unlike parquet boards, it is made of solid wood without the use of glue. The parquet board is three-layer with a thin working layer that can withstand several sandings; if there is a deep scratch, the entire board will have to be replaced. The only advantage of parquet boards is that they are cheaper.

The solid board acts as a finishing coating. In its appearance, such a covering resembles a floorboard, and in its meaning it is close to parquet, sometimes it is called that way - massive parquet or solid parquet board. If the floor can be completely tinted, then in the case of solid wood, materials are used that allow you to see the pattern of natural wood, so wax or varnish is used for coating.

Types of wooden floors

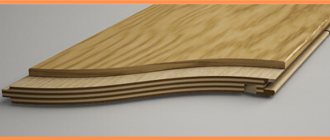

Example of a three-layer glued board for a tongue and groove floor

Wood flooring can be created from different types of building materials:

- Solid wood boards.

- Parquet (small planks with grooves and tongues).

- Solid wood parquet boards with grooves. Standard length: 0.5-2 m; acceptable thickness: 1.8-2.5 cm.

- Glued parquet boards. It looks almost like a solid parquet board, has the same dimensions and similar performance properties. It is somewhat cheaper, since only the top layer is created from a valuable type of wood (5 mm thick), while the rest are from inexpensive species.

Important! Glued board contains at least 3 layers.

Advantages and disadvantages

The advantages are as follows:

- natural coating that does not cause allergies and has a beneficial effect on human health;

- has high strength;

- long service life;

- it is possible to carry out repeated restoration of the surface by scraping it;

- easy and quick to install;

- has high thermal insulation characteristics;

- beautiful and expensive appearance.

There are no ideal floor coverings, so solid flooring has a number of disadvantages:

- the main disadvantage is the high cost;

- requires a high-quality subfloor;

- does not tolerate high humidity and temperature changes;

- to protect it from damage and moisture, it requires periodic treatment with oil and wax, and this is an additional cost;

- cannot be used to cover heated floors.

Half of these shortcomings are solved by using thermowood in the manufacture of the product.

Material

Oak

To make this flooring, different types of wood can be used, but most often it is oak. It has high performance characteristics, has a beautiful texture and a wide range of colors.

Merbau

Merbau wood is a serious competitor to oak; at first it has a reddish-brown tint, but after time it becomes silver-gray. The presence of yellow veins in the wood makes its structure beautiful and unusual. In addition, it has a long service life, does not rot, is not damaged by insects, has high strength and moisture resistance.

Teak

Solid parquet can be made of teak; its wood is resistant to moisture, so it can be used not only indoors, but also on terraces or other rooms with high moisture.

Larch

A solid larch board has high strength, and the presence of antiseptic elements in it prevents mold and rot from taking root. It is not afraid of moisture and has high strength, so it can be used in gyms, loggias, and open areas.

Ash

Solid ash board has high hardness, strength and elasticity. This is light wood, so its use allows you to visually expand the room.

Maple

Maple has a very light color, which can range from almost white to pink or yellow, it tolerates bending well, but is afraid of moisture.

Nut

A solid American walnut board can easily withstand changes in temperature and moisture, and cracks do not appear on it.

Wenge

Wenge wood is highly durable, but when dried quickly, it can become cracked, so if this process is carried out incorrectly, problems with this coating may appear over time.

Wood selection

The wooden covering is selected based on its ability to match: the type of room, temperature and humidity, the degree of expected loads and other operating conditions. Most often, residential buildings have flooring made of pine, spruce or larch. These species are strong, wear-resistant and much cheaper than deciduous species. However, aspen or oak will last much longer - not years, but several decades.

Important! Most often, edged boards or tongue and groove wood are used for laying a wooden floor. They do not need additional sanding.

Types depending on the method of cutting the wood and methods of its processing

- Radial , in this case a radial cut is made, which allows you to get an even color. The inclination of the fibers can be no more than 30%, and their radial bending no more than 30% of the length of the product, the size of the knots can be no more than 5 mm and any mechanical damage is not allowed.

- Select is obtained as a result of tangential cutting, which also makes it possible to obtain an even texture; knots can be no larger than 5 mm in size and no chips, sapwood or other damage are allowed.

- Natur can be made by any type of cut; in appearance, it is closest to untreated wood, so there may be slight differences in color, there may be dark knots with a diameter of up to 3 mm and light knots with a diameter of up to 5 mm. In addition, the presence of sapwood is allowed, the length of which is no more than 30% of the length and the width is up to 5 mm; mechanical damage, through knots and chips are not allowed.

- Rustic can also be made using any cutting method; such a board may have light knots up to 30 mm in diameter, and there may be end cracks up to 20 mm in size. The presence of damage and defects that cannot be eliminated by grinding and puttying is not allowed.

Types of lock connections

The presence of a locking connection allows for quick and easy installation of the specified floor covering. There are several types of connecting boards, and if previously it was only an ordinary tongue and groove, now new types of locking connections have appeared.

"Lock"

A more economical option is the Lock type, which provides a reliable and durable connection. In this case, the connection is made without the use of glue, but it provides high strength.

In order to install such a massive board, the base must be perfectly flat; with heavy loads on the floor, over time the locks can become loose and gaps may appear.

"Click"

The “Click” type lock is more durable and reliable; to connect, just bring the board at an angle of 45 degrees and press it a little, without the need to put much effort or use special tools.

In the presence of physical activity, such locks do not become loose and can be disassembled if necessary.

Unlike elements of the Lock system, in this case the locks do not break during installation, so the installation and disassembly of the floor covering can be carried out several times. As a disadvantage, it is worth noting the high cost of such a system, but due to the ease of installation and reliability, it is fully compensated for.

Laying boards on a concrete base

Options for attaching tongue-and-groove boards to joists using screws

To level the concrete base, you need to install beacons and pour a self-leveling mixture. Wood can only be laid on a perfectly flat floor, but the cement should not come into contact with the wood. To do this, the screed is covered with foamed polyethylene. It is laid with an overlap, creating excellent waterproofing. You can use mastic.

Final floor treatment

Upon completion of installation, the floor:

- Grinding;

- Leach;

- Primed;

- Paint or varnish.

Important! Impregnation and varnishes/paints are applied parallel to the wood fibers. Then marks from a roller or brush are not so noticeable.

Flooring Tips

In order to properly lay the flooring in your home, you need to adhere to the following recommendations:

- The boards are laid out so that the age-old rings face in different directions.

- The installation of floorboards is preceded by marking. They are numbered so as not to get confused in the order of installation.

- Nails are driven into wood at an angle.

- After laying the first floorboard, at a distance of 6 cm from the edge, staples are driven into the joists. The gap is closed with a thin strip. A wedge is driven between it and the bracket. When nailing it, the boards are pressed tightly together.

- Next, the floorboards are nailed and the staples are removed. The following elements are pressed with a lath and a wedge, and hammered in with a punch and nails.

- The last board is usually leveled with a plane, then glued and fixed with nails.

- Gaps between the floor and the wall are perfectly masked with skirting boards with grooves.

Dimensions

If we talk about the size of a solid board, then its width can be 70 to 200 mm, and its length from 60 cm to 6 meters. This floor covering does not perform a load-bearing function, but is decorative, so its thickness is comparable to parquet and is 15-22 mm. It is inconvenient to use long planks, so they are usually 70-120 cm long and 6-12 cm wide.

The dimensions of solid parquet use multiple ratios, which allows you to create different patterns and types of installation, unlike the installation of engineered boards where the pattern is specified by the manufacturer.

Flooring boards

The dimensions of the boards are selected with the expectation that each joint should be at a right angle to the edge of the board, in the center of the log. The first row of wood should be laid on beams along a stretched thread with a distance of 1.5 cm from the wall. The boards are fixed on all the joists. Holes for self-tapping screws are pre-drilled. Sometimes floorboards are fastened with staples and then with nails. The gaps between the wall and the covering are well masked with skirting boards. How to make a wooden floor on joists can be seen in the video:

DIY floors in a wooden house

Main manufacturers

There is a large selection of solid boards, but when purchasing it, it is recommended to give preference to well-known and reliable manufacturers who offer high quality products. The most popular manufacturers are:

- WertWood is a Russian manufacturer of solid and engineered wood with a full production cycle.

- COSWICK is a Canadian company, its facilities are located in Belarus, which allows it to obtain high-quality products at an affordable price;

- AMIGO offers products made from exotic wood species

- MAGESTIK FLOOR , the company's production facilities are located in different countries and produce both solid oak flooring and solid wood from exotic woods;

- SHERWOOD PARQUET offers products of impeccable English quality and exceptional appearance;

- besides this, there are many other manufacturers, for example MONTBLANC, PREMIER PARQUET, AMBER WOOD, LEWIS & MARK, DEKER and others.

Preparatory work

Before laying a wooden floor, it is necessary to treat the boards with antiseptic and fire-retardant impregnations. This will significantly extend their service life and also make them practically non-flammable.

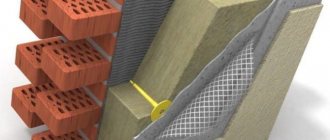

Also, before making a wooden floor, it is necessary to install waterproofing underneath it from any available materials: roll type or ready-made mastic on a bitumen or polymer basis. It should be secured in the form of a “trough” - that is, the edges of the waterproofing material should extend onto the wall.

Useful tips

- When choosing the type of wood, you need to consider the conditions in which it will be used and what loads it will withstand. In the hallway or living room it is better to use hard wood, and in the bedroom you can lay a solid board made of soft wood.

- After you have laid solid boards coated with oil or varnish, they can be additionally coated with a wax mixture or varnish, which will more reliably protect the surface. Depending on the intensity of use of the premises, this procedure should be carried out 1-2 times a year.

- When choosing a material, you must ensure that there is no mechanical damage on its surface. The thickness of the boards should be the same. If the material is in the form of a propeller, then it cannot be purchased.

Important! The maximum humidity of a solid board should not be more than 9%; to check it, you must use a moisture meter.

- Pay attention to the packaging - the boards should be packed in cardboard and then in polyethylene, this will ensure their maximum protection from humidity and temperature changes during transportation and storage.

Which ones and how to lay them

We have selected several videos that will help even beginners understand the flooring process. Not all of them are talking about bath floors; which boards are laid is also not always obvious, but the technology is the same if tongue-and-groove material is used, and if a poured floor is made, then two templates of equal thickness are inserted to leave standard gaps.

The first video describes in detail the theory of creating all the floor devices used in the bathhouse and the drain underneath it.

In the next video you can borrow some techniques, but you still shouldn’t use a channel:

The installation of flooring on a balcony is shown here, but the good thing is that everything is done according to the rules, and the author also showed how to deal with low-quality material that is supplied in sealed packages graded A-B, which makes it impossible to calibrate it on site.

The authors of the following video, which shows the installation of larch boards with tongue and groove in a house, give a lot of hacks and tips:

Well, one last piece of advice: since the board will still be deformed from moisture, lay it so that a hump is formed on top. To do this, at the end you need to look at where the arc of the annual rings is pointing - correctly, so that the arc bends downwards (the hump of the arc is downwards) - it will lead in the opposite direction. If installed correctly, the water will drain and the floor will be less likely to rot.

***

Good luck with your flooring so that you can live longer without repairs! In addition, readers will be interested in materials on the construction of the roof and ceiling of the bathhouse.