Almost every home craftsman has encountered this type of work such as installing a floor. And this is not necessarily a house or apartment. There is a garage and outbuildings. Therefore, craftsmen know firsthand that the greatest labor intensity and serious financial expenses occur in screeding.

The correct choice of the method of leveling it will help to minimize the cost of laying the floor, i.e. type of screed. And it can be wet, semi-dry and dry. Those who hire professional builders for repair work also need such knowledge. Otherwise, the workers will do what is most profitable for them financially.

Construction sites missed this point - at the time of preparation of the article, there are no comprehensive works on the comparative analysis of types of screeds on the Internet. You have to look for which screed is better, semi-dry or wet, or maybe dry, on various forums. And there the reviews and comments are the most contradictory, even going so far as to deny semi-dry screed as a type - well, the solution, according to some commentators, cannot gain strength with such an amount of water.

The editors of the StroyGuru website decided to fill the gap and post on their pages a complete analysis of the strengths and weaknesses of each type of screed, compare their performance characteristics, and provide recommendations for use in various situations.

Wet, semi-dry and dry floor screed - what is it?

The screed is used between the floor covering and the ground, in which there are differences in height. Of course, this entire base must be made even, smooth, without distortions.

In the arrangement of a leveling base, there are 3 types of screed:

- wet;

- dry;

- semi-dry.

Wet screed involves the use of a cement-sand mixture in combination with water and liquid filling of the floor.

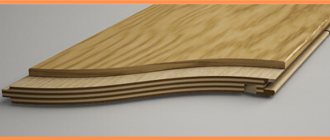

Dry floor screed, what is it:

- Light bulk material like expanded clay or permit.

- Metal profiles at the base.

- Sheets of chipboard or plasterboard laid on top and glued together.

Dry screed Source www.remontnik.ru

Let's take a closer look at the semi-dry version.

What is a semi-dry floor screed, pros and cons

Semi-dry floor screed is a technology according to which the leveling of the base is carried out using semi-dry sand-cement mortar and reinforcing elements.

This technology involves a semi-dry method of preparing the solution itself. It is made in the same weight proportions as the classic cement-sand composition. However, the presence of water in it is slightly lower than in the classic version.

The mixture itself is kneaded until it can be formed into balls. Considering the consistency, such component compositions are not poured onto the base, but covered.

The strength of the main building mixture here is ensured through the use of high-quality materials in the form of washed coarse sand and M500 cement, as well as polypropylene fiber and metal mesh. To fill semi-dry screed, special equipment is used - a pneumatic compressor (mortar pump).

Mortar pump for semi-dry screed Source prestigehouse.ru

pros

The main advantage of this technology is the minimum volume of water that is required during the mixing process, making it possible to walk on a freshly laid screed the next day.

The second advantage follows from the first. Since the solution is not fluid, the likelihood of flooding the lower floors during work is practically reduced to zero. Liquid solutions quite often, when poured, end up in the ceilings of floors, causing unpleasant situations for neighbors below.

In addition, semi-dry screed dries much faster, which has a positive effect on the timing of the work. The resulting surface is almost flawless in quality.

The following finishing materials can be laid on it, without preliminary preparation:

- carpets;

- laminate;

- linoleum coverings;

- parquet flooring;

- floor tiles.

Laying flooring on a screed Source stroimpilim.ru

Using a trowel during operation eliminates the appearance of voids and cracks on the laid surface.

The volume of water in a semi-dry screed is only one third of the total volume. This amount is already quite enough for the cement hydration process, and the surface dries very quickly. After just four days, the laid screed is ready for the finishing floor covering to be laid on it.

Also, do not forget that with a relatively small thickness of the semi-dry layer, it has high performance characteristics. This coating has good resistance to mechanical loads and impacts.

These properties of the coating are ensured by the presence of reinforcing fibers in it. In a comparative analysis of semi-dry and conventional cement-sand screed, the latter exerts significantly greater loads on structures. This is due to the lack of light components for reinforcement.

Semi-dry screed with underfloor heating system Source aplaster.ru

Minuses

The main disadvantage, being at the same time a plus, comes from the characteristics of the technology - the lack of fluidity of the building mixture. For this reason, preparing a solution without special equipment is a rather labor-intensive process.

Also, the technological process of laying the material is not yet sufficiently unified, since it is a fairly young construction technology. Experts in this field have not yet come to a consensus, so finding a quality performer is a difficult time. On the market of companies performing semi-dry screeds, one can, for example, note the company Eurostroy, which has been operating since 2012 and, judging by reviews, has proven itself on the positive side.

Semi-dry screed after sanding Source prestigehouse.ru

See also: Catalog of house projects made of reinforced concrete and expanded clay concrete blocks.

Which floor screed is better

Obtaining a high-quality, flat surface is possible by using all three technologies. In each specific case, the choice of method depends on the conditions and circumstances.

For example, if leveling needs to be done in an apartment on the top floor, it is better to use semi-dry and dry technologies so as not to spoil the ceiling covering of the neighbors below, and also to reduce the load on the floors.

Also, when using these methods, much less effort is required than in the situation with a liquid analogue.

For detailed characteristics of each type, see the table.

Different types of screeds Source www.kp.ru

If we compare which screed is better: semi-dry or wet, the first definitely wins in terms of speed of work, since it requires less time than when pouring wet.

Advantages of semi-dry floor screed:

- Speed of work - the base will be ready in 1 day, and up to 300 square meters of cement-sand mortar can be laid per shift

- No cracks due to the use of polypropylene fiber fiber

- No water leaks to the lower floors

- High grade strength

- The cost is lower than when pouring wet and dry screed

Minuses:

- Thanks to the use of special equipment, you will not be able to perform a semi-dry screed yourself.

- Due to the fact that the solution is prepared outdoors, work is carried out only down to -10 degrees.

In essence, what is a dry floor screed? It is a system in which bulk material, if installed incorrectly, for example by amateurs, is capable of shrinking. And, accordingly, the floor covering will crack. And then you will have to change the flooring again and make a screed.

Thus, semi-dry screed is a serious alternative to “wet” and “dry” work, having a whole range of useful characteristics.

An example of a finished screed with fiber Source prestigehouse.ru

Reasons for choosing semi-dry screed

As a rule, the main difficulties in leveling are caused by surfaces that have a certain angle of inclination, especially if there are noticeable irregularities on it. The use of semi-dry screed in such situations is most justified.

At the same time, it allows you to form a high-quality surface around pipes or holes. This technique not only allows you to significantly simplify and speed up the work, but also significantly reduce its cost.

To give the coating the required rigidity and prevent cracking, it is reinforced. The reinforcing layer is a fiber - fibers made from special polymer components.

The creation of such a screed involves several different technologies. The choice of a specific method depends on what result is needed upon completion of the work. When laying communication elements into the floor, the layer of screed increases, especially if the rough surface is quite uneven.

Scope of application

Semi-dry screed is universal and widely used in private and industrial areas, when constructing floors and roofs (flat version). It is also suitable for ground floors.

xRainManForumHouse Member

Question: is it possible to use semi-dry screed as floors on the ground? That is, when there is a compacted base, then insulation with all sorts of films. It seems that nothing should move, the water was diverted from under the house, we are not allowing it to freeze.

Pavel ShekhterProject Manager

Semi-dry screed can be used as floors on the ground, with a layer thickness of at least 8-10 cm and reinforced with metal mesh.

Using the semi-dry method, “floating” screeds are made on top of a layer of thermal insulation, used to reduce heat loss through the ceiling or to improve sound insulation parameters. If necessary, such a system can be combined with laying communications in the floor.

pakhomov_mvFORUMHOUSE Member

Please suggest someone who knows about semi-dry screed cake. In the apartment I plan to first lay the corrugated wiring and heating pipes, and then make the following cake:

- The first layer of PPS or EPS 30-40 mm is around (from the sides) the communications, as if flush. Previously, an option was considered instead of PPS/EPS - rough DSP 25 mm, but PPS is cheaper, simpler, faster.

- Next are two layers of ZI cotton wool (Shumostop or Rockwool Floor Bats).

- On top is a semi-dry screed 50-60 mm with reinforcing mesh.

Questions:

- What density of polystyrene foam is needed under the screed so that the screed does not spring or crack? 25 or 35?

- What is better/more effective and by how much, PPP or EPPS?

- Do the voids between pipes and between corrugations and gaps around communications need to be filled with something? Solution?

- Reinforcing mesh - can fiberglass mesh be used? Is it better or worse than steel?

Pavel ShekhterProject Manager

- The optimal density is 35 kg/m³.

- EPS is more efficient, it is stronger, and it has better heat transfer.

- The voids can be left and simply filled with screed, or filled with fine expanded clay.

- It makes no difference what mesh to use for reinforcement.

Basic technological steps during installation

As mentioned above, working with this building material requires some experience. The master must be able to knead the mixture exactly in those proportions that will reveal all the advantages of such technology.

Preliminary work before installation

The preparatory stage of work begins with preparing the foundation. The main operations are:

- cleaning the base from dust;

- removal of chips;

- removal of delaminations;

- jointing and sealing cracks.

This will prepare the base for the load that the screed will put on it.

After this, the surface is checked for the level of differences in area and the highest point is found. The required thickness of the screed is added to it and a zero level is obtained. Metal beacons are not used in semi-dry screeds, but are made directly from the solution.

The process of installing a semi-dry screed, namely installing a beacon Source prestigehouse.ru

Preparing the mixture

Despite certain difficulties in preparing semi-dry screed, this does not stop craftsmen from actively using it. When preparing the solution, the following materials are used:

- polypropylene fiber;

- coarse washed sand;

- plasticizer;

- Portland cement grade M500.

Mandatory equipment when installing a semi-dry screed is a pneumatic blower/mortar pump. All materials for the screed are mixed in it (cement, sand, fiberglass and water) and the finished solution is supplied through special hoses (up to the 30th floor).

The result should be a composition that, when compressed, slightly releases moisture and retains the shape of a ball. Reaching this consistency signals that the mixture is ready for use.

Preparation of the mixture Source prestigehouse.ru

Surface preparation

- Carefully inspect the floor: tap with a hammer to find loose areas of cement, remove them using a hammer drill, and fill the resulting voids with cement mixture. Expand and restore cracks, knock down noticeable bulges.

- The interface lines between the floor and walls must be treated with cement mortar, even if there are no cracks in these places.

- After this, remove stains of oil paint and grease from the base and vacuum it thoroughly.

Video description

Watch the video on how to make a dry floor screed with your own hands

Laying damper tape

A semi-dry screed does not require additional waterproofing, but it must be separated from walls and partitions. For this, a polypropylene tape is used, the height of which is made a couple of centimeters greater than the calculated thickness of the layer being laid.

Polypropylene tape is a compensator that allows you to level out expansion and contraction in the mixture that occurs during its setting. In addition, direct contact of the screed with the walls is excluded, which creates an additional barrier to the penetration of cold.

Polypropylene tape Source bitrix24.ru

Installing markers and guides

In the semi-dry screed technology, metal profiles are not used when installing beacons. Beacons are made directly from cement-sand mortar on the day of work in the form of small “islands” using a laser level. After installing the beacons, the screed is pulled from beacon to beacon using a rule, with regular checks by the straightener.

Displaying a beacon in a semi-dry screed Source instagram.com