There are constant debates around laminate about how durable it is, what its quality is, and how long it lasts. And the big difference in opinions is easily explained by the fact that laminate comes in different varieties. It cannot be assumed that this coating, produced by various manufacturers, always has certain characteristics. And, based on the fact that one store can sell materials of completely different quality, the question arises - how to choose the right laminate? And the point here is not only in the color scheme, but in a large number of characteristics.

How to choose the right laminate

What is laminate?

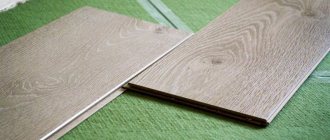

Laminate is a long laminated board (hence the name laminate), which consists of four layers firmly connected to each other, each of which has a specific function.

Laminate components

Lamels

- The lowest layer is called balancing or compensating . Due to it, the lamella receives a certain strength and rigidity, as well as a certain level of moisture resistance.

- Then comes the so-called load-bearing layer , which is most often made of fiberboard or HDF - a material that is a high-density fiberboard. It is this layer that is able to cope with the main mechanical loads experienced by the coating. The very locks that connect several lamellas into one sheet are located on this layer.

- The decorative layer is responsible for the attractive appearance of the laminate. It is plain paper with a pattern printed on it. Thanks to this method of decoration, the laminate can have any color or imitate stone, wood and other materials.

Laminate structure

On a note! Paper is typically impregnated with melamine to enhance its performance.

- The top layer of each lamella is a protective film made of melamine or acrylate resin. It protects the remaining layers of the laminate from moisture and the negative effects of other external factors. The layer is responsible for the wear resistance of the coating.

The process of laying laminate flooring is not particularly difficult.

Laminate is one of the best options among all types of flooring, guaranteeing optimal value for money. It is valued and used in buildings for various purposes and, of course, is most often installed in apartments and private houses.

Laminate is very popular today

Pros and cons of laminate flooring

It is not surprising that the material is very popular. It has many advantages over other types of coatings. Positive features of laminate:

- large selection of colors . Laminate flooring is easy to match to any type of interior;

- installation is simple and done quite quickly . The coating is easy to lay even alone;

- for its price (and depending on the class), the material copes quite well with external factors ;

- The coating is easy to clean and does not require additional treatment after installation . Depending on the type of installation, you can start using the floor almost immediately.

Installation of laminate (in this case, diagonally)

However, laminate is not an ideal coating; it has its drawbacks:

- the material does not like water . It is not recommended to install it in a room where the air humidity level is quite high;

On a note! There are certain classes of laminate, and lamellas belonging to them can also be used in damp rooms.

- laminate in general is not dangerous to health, but still it is not an environmentally friendly coating ;

- Compared to linoleum and carpet, laminate flooring has low noise insulation .

Moisture can lead to such consequences

Instability to humidity

This problem is often encountered by buyers who prefer cheap products from unknown companies. But it also happens that high-quality coating also deteriorates from exposure to water. The fault is with the joints between the dies.

It is the joints that are the most vulnerable place of the material. Any wet cleaning inevitably leads to the seepage of drops of moisture, which allows water to easily penetrate under the coating, as a result of which the laminate swells.

The undesirable effect can be eliminated by treating the locks with water-repellent wax or oil impregnations, as well as sealant or glue.

Types of laminate

Depending on the manufacturing technology and the type of top protective layer, two types of laminate can be distinguished.

- Laminate made using direct pressing technology is created immediately along with the top layer. Most often, this material is made for domestic use.

- High pressure laminate, or HPL , has a top layer consisting of kraft cardboard and a protective coating. During pressing, the top part of the coatings is exposed to high temperature (+140 degrees) and pressure of 2.5 million kg. The connection with the base occurs only at the second stage of production. This coating has high strength, is not prone to abrasion, and can withstand strong mechanical stress.

On a note! High pressure laminate is produced by only two companies - Alloc and Pergo.

Laminate in the design of a private house

In general, there are two types of laminate - commercial (or industrial) and household.

Household classes - main differences

Laminate, classified as household grade, has lower performance characteristics than industrial material. The average service life (warranty) is about 5 years. That is why such coating is not in demand in Russia, because its wear resistance is low, as a result of which the service life of the coating is reduced. Basically, these are classes 21, 22, 23.

Application of household laminate

Household laminate does not have a high degree of protection against moisture. Or rather, he almost never has it. This fact narrows the possibilities of its use in certain types of premises.

Industrial laminate grades

The service life of this material is much longer than that of household materials. It is 8 years or more. The category is represented by classes 31, 32, 33, 34. Despite the fact that this laminate is recommended for use in offices and conference rooms, it is also quite often purchased for laying flooring in houses and apartments. The explanation for this phenomenon is simple - a longer service life and the desire to reduce the cost of repairing the floor in the future.

Laminate installation process

Commercial laminate is much more reliable and durable than household laminate. Despite the higher price, its characteristics fully justify all investments.

Master Class. How to cut laminate

Basic information about the laminate use class

Above we talked about laminate classes. This flooring has a lot of them. The class is indicated on the packaging with lamellas and is represented by two numbers, where the first indicates the type of room in which the coating can be installed, and the second indicates wear resistance. Thus, the first number 2 indicates that the material can only be used in residential premises, and the number 3 states that the material is suitable for public premises. Depending on the degree of stability, there are three categories of material, designated by numbers 1, 2, 3.

Waterproof laminate is optimal for kitchens and bathrooms

On a note! The higher the number indicating the class, the stronger the laminate. Based on this, you can choose the most durable coating from those offered.

Table. Main classes of laminate.

| Class | Description |

| 21 | Material with the lowest wear resistance. The service life is only 2-4 years. Typically not used in residential areas, used only where the load on the floor is minimal. The maximum it is suitable for is decorating the floor in a pantry or home library. |

| 22 | The material is sometimes used to cover residential floors. But it is important to remember that the floors should not experience heavy loads. This is a good option for the bedroom. Service life – no more than 4 years. |

| 23 | Among household laminates, this is the most durable option. Suitable for creating flooring in the bedroom, living room, and less often in the hallway. The service life is also short - only 4-5 years. |

| 31 | Among the commercial types of laminate, this has the lowest strength, but is the most affordable in this category. The material is suitable for creating flooring in the bedroom, hallway, conference room, etc. The service life, depending on the intensity of use, ranges from 4 to 9 years. The thickness of the top protective layer of the coating is about 0.1-0.2 mm. The material can also be marked AC3. |

| 32 | The most commonly purchased type of laminate in Russia. The price-quality ratio is optimal for home use. The material is able to withstand intense household loads. Sometimes placed in shopping centers. The service life starts from 11 years. Also designated as AC4 material. |

| 33 | A very reliable and durable type of laminate, suitable for installation in rooms where floors experience significant loads. Suitable for floors in banks, cafes, dance floors. The thickness of the top layer is about 0.4-0.9 mm. Service life is about 15 years. Additional designation – AC5. |

| 34 | The class has no official confirmation, but nevertheless exists and periodically goes on sale. Very durable and strong material with high wear resistance. The thickness of the protective top layer is about 0.9-1.2 mm. The service life is record-breaking – up to 20 years. An additional type of marking is AC6. Can be used at home for decades. |

Table: laminate wear resistance classes according to GOST and EN

Correspondence between the laminate class and the type of room

Examples of using some laminate classes

Laminate is classified according to the European system EN13329. And in Europe, only laminates are now produced commercially, that is, those belonging to classes 31-34. But from manufacturers from Asia you can find more budget-friendly coating options. It is also worth remembering that laminate classes are a relative concept, since regardless of the marking, there may be lamellas that have too thin a protective coating. As a result, the coatings will serve differently. That is why you should make your choice only in favor of products from trusted manufacturers.

Consequences of short-term use of low-quality laminate

Reviews

To get a complete picture of the best choice of laminate, you can read the reviews from the owners of the material and if you want to add your review to the table, please write it in the comments:

| Author's name | Customer review |

| Maxim A | We chose German class 32 laminate. No changes in 3 years, although no one particularly cares about accuracy. |

| Leonid D. | The neighbors on the floor above have laminate flooring. They walk in soft slippers, this has been verified, but the noise is terrible, as if they were marching in soldiers’ boots. |

| Anna L. | Under no circumstances choose dark laminate! Any debris, stains, or dust are immediately visible. Small scratches are noticeable as if there were centimeter-long furrows. You have to wash it constantly. |

| Victor P. | We found a covering for the kitchen that was the same color as the cabinets. He has been in bed for 2.5 years, grade 32. There are no problems, but you should not drop metal or sharp objects. |

| Valeria K. | The material is light, strength class 32. It is very dusty, you have to wash it constantly, I tried all sorts of products, but it still attracts her. There are no scratches, I didn’t notice any squeaking either. |

| Igor D. | We bought laminate flooring for the kitchen at a sale. Dark and colorful, very beautiful. We constantly spill water, but so far no reaction is visible. |

| Nikita G. | German material, laid 4 years ago, 31 strength class. No scratches are visible, I can’t say anything bad. Our dog is large, but there are no claw marks, it runs on the floor without any problems. |

| Timur N. | We have had the coating for 2 years now. We took class 32 and laid it ourselves. One day our neighbors flooded us and it swelled up in one corner, but after about six months it went back into place. |

| Sergey Sh. | For coating it is necessary to use some kind of antistatic compounds. Dust is attracted strongly, you will be tortured to clean it. No problems, but washing is... |

| Fedor T. | I advise everyone to take textured rather than smooth material! There are no traces of bare feet on it, but on the smooth surface everything is always dirty. |

| Yaroslav L. | They laid the laminate directly on the linoleum (well, not directly, but on a cork backing). There are no squeaks or noises. No dust is attracted. Those who suffer from dust should have used a cork, it is the only substrate that creates an antistatic effect. |

| Valery E. | Laminate is paper glued to sawdust. We put it in the hallway, we wanted to put it in the bedroom, but we changed our minds and don’t recommend it to anyone. |

| Georgy N. | In different rooms there is different material, some Chinese, some German. The class is the same, 32 everywhere. There is practically no difference, there is a Chinese one in the bedroom, I like it the most. |

| Andrey U. | If the laminate is laid without following the rules, then you can hear a cat running on the floor from below. Don’t be lazy to do proper soundproofing, take care of your relationships with your neighbors! |

| Anton R. | For 4 years there have been 31 classes in the room. And they did repairs and carried everything that was needed. Nothing happened to it, it’s like new (almost). |

Judging by these reviews, problems arise due to non-compliance with installation technology. These issues should be resolved before installation; you need to familiarize yourself with the technology and not skimp on the substrate and sound insulation.

The presence of formaldehyde in the composition

Despite the fact that laminate is always and everywhere presented as an environmentally friendly material, it is not 100% environmentally friendly. This is especially true for cheap types of coating. They contain a fairly large amount of formaldehyde, a substance hazardous to human health. When the floor is installed and in use, the slats begin to release formaldehyde into the air. And a high concentration of this substance negatively affects the human condition.

Cheap laminate contains a considerable amount of formaldehyde

Laminate, which does not pose a health hazard, always has the appropriate marking - E1. This designation tells the buyer that the coating complies with European standards regarding the content of carcinogens.

In general, the components of the laminate are chemically quite harmless. Chipboard as the base of the coating consists of wood waste. It turns out that the “naturalness” of the laminate is more than 90%.

On a note! Laminate marked E2 and E3 has a higher formaldehyde content - 3 and 6 times more than E1, respectively. The most environmentally friendly type of laminate is labeled E0. But its cost is quite high.

E2, E3 – laminate, which contains melamine resin with the addition of formaldehyde

Laminate of categories E2 and E3 can be used in apartments and houses, but on the condition that there are no more products in the room that could emit formaldehyde. Unfortunately, both furniture and some types of wallpaper contain this substance.

The ability of a material to retain heat

The ability to retain heat is its heat capacity parameters. The higher the heat capacity, the longer the material will lose its initial temperature, despite external temperature fluctuations. Traditionally, heat-intensive building materials include almost all of their known representatives: brick, concrete, polystyrene, mineral wool, wood, gypsum and even glass. However, one must take into account the fact that the immediate value that will influence a person’s subjective sensations will be the thickness of the layer used: the thicker it is, the longer the process of heat loss occurs. When choosing a floor for a home, the consumer cannot always influence the thickness, since we often choose serial products.

Types of connection of laminate panels

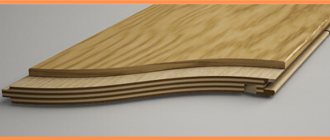

Each lamella has its own type of connection with another lamella, this allows you to create a durable and reliable coating on the floor that will not move apart and “walk.”

Click and Lock laminate locks

There are two types of connections.

- Click connection - the most modern type of lock connection. It has virtually no drawbacks. The tenon inserted into the groove resembles a kind of hook and, as it were, “hooks” the adjacent panel. Installation of such lamellas is quite simple and does not require effort. The hook-shaped tenons are inserted into the grooves at an angle of 45 degrees and the lamella is lowered to the floor. The lock snaps into place at the moment of a characteristic click. The fixation is reliable, and the floors, if necessary, can be disassembled 3-4 times during the entire period of operation.

Click laminate lock

- A lock type connection is the most economical option. The lock is characterized by the presence of a tongue and groove on different sides of the lamella. This option has been used for a very long time. To connect two lamellas, hammer the tenon into the groove using a hammer and a piece of timber. Constant monitoring of joints and monitoring for the absence of gaps is required. Unfortunately, the locks wear out quite quickly, which can cause gaps to appear on the floor. Also, such a coating cannot be quickly dismantled if necessary. It is recommended to additionally protect the joints with sealant from water penetration.

Laying laminate with Lock connection

Special glue can also be used to connect the lamellas. Unfortunately, it will not be possible to disassemble such a floor without problems.

Installation pitfalls

Each package of laminate flooring is equipped with instructions that allow even a person uninitiated in repair and construction secrets to carry out installation independently. Moreover, in case of an error, it is possible to disassemble the unsuccessful design and start over. However, this seemingly simple procedure is fraught with a requirement, the violation of which can lead to undesirable consequences - from loss of the right to warranty service to undesirable phenomena during operation (creaks, crackles, damage to locks). The surface of the base on which the laminate is laid must be dry and perfectly flat. Only a height difference of up to 3 mm per square meter is allowed. It is clear that in the case of laying laminate flooring on a wooden floor or on a sloppy concrete screed, it is quite difficult to fulfill this condition. Another consequence of violating the installation rules may be swelling (“bubbling”) of the assembled structure, which will also lead to failure over time.

Opinions from the forums:

“Apparently, the floor was not leveled well, and in some places the locks at the joints of the slabs simply broke.”

“I installed laminate flooring through a company. First they made the screed, and then laid it. Over time, I noticed that the floor was creaking in one place. I didn’t follow it right away. I don’t even know what to do - the money has already been paid.”

Leading brands in laminate production

Since demand creates supply, there are now a great many laminate manufacturers on the market for this material. The undisputed leaders are Quick-Step, Haro, Tarkett, Kaindl, Pergo. The products of these brands are not cheap, but they are of high quality and reliability. There is no need to be afraid of overpaying for a well-known name when choosing laminate flooring. This will save the buyer from the problems associated with the need for early repairs.

Prices for Quick-Step brand laminate

Quick-Step laminate

In general, by country of origin, the best laminate is made in Belgium and Sweden. But you can buy economy coating made in Russia or Germany.

Features of choosing a laminate

Prices for Tarkett laminate flooring

Tarquette laminate

Tips for choosing laminate flooring for your home

When choosing a laminate, you should always pay attention to a number of characteristics - mechanical and chemical resistance, resistance to temperature changes. Also, the material should be non-slip, not fade in the sun, and easy to install. And, of course, match the color and class to a specific interior design or style.

In fact, choosing a laminate is not so difficult. For many, this is generally a question of price and color; everything else interests them little.

In a bedroom or children's room, where the load on the floor is small, a low class coating can be used - 21 or 22. In the corridor, you should not lay a coating lower than class 23. To ensure the longest service life of the floor, it is worth choosing a material of at least 31 classes.

Only materials that are protected from moisture can be installed in the kitchen. The same applies to the bathroom. These rooms have high humidity, and cheap laminate flooring here will simply bulge and deteriorate. The ideal option is class 33.

How to choose a laminate

Thickness

Many properties of the floor covering depend on the thickness of the laminate.

The thicker the material, the more:

- soundproofing and thermal insulation qualities,

- resistance to loads,

- strength.

The optimal laminate thickness for an apartment would be 8 millimeters.

For rooms that are not used intensively, a flooring thickness of 7 mm is suitable.

It is also worth noting that a thick laminate is much more expensive than a thin coating, so it is not advisable to use it in rooms with little traffic.

How to choose laminate for your home?

Step 1. First of all, it is important to decide on the color of the material and select those options that are ideal for a particular interior style. This takes into account the geometric features of the rooms and the level of illumination.

Popular color options

Step 2. Among all the deferred color variations, you should choose the most suitable type of laminate that will have the required characteristics. First of all, you should decide on the brand. Slats from little-known and unreliable manufacturers are immediately swept aside. It is better to take more expensive material, but be confident in its quality, than to then change the coating ahead of schedule. Yes, and with the classification in this case it will be easier.

Samples of laminate flooring

Step 3. Next, pay attention to the dimensions of the laminate planks. If the floor in the room experiences significant load, then thicker slats are purchased. The reliability of the floor covering and its durability will depend on this. If the floors are under heavy load, lamellas are purchased within the range of 9-12 mm in thickness; for lower loads, it is permissible to use panels 6-9 mm thick. Considerable importance is attached to the width and length of the lamellas - the speed of installation will depend on this. The optimal width is 17-20 cm to imitate a plank floor and about 9 cm to create the appearance of parquet. The largest width of an individual laminate plank is 33 cm. In terms of length, the choice is usually made in favor of boards 128-136 cm. These are the optimal dimensions.

Laminate board dimensions

Step 4. Select the type of locking connection. For beginning craftsmen, it is recommended to opt for click locks. It is easier to assemble such a floor, and in case of an error or the need for rework, it is easy to disassemble.

Beginners are recommended to opt for click locks

Step 5. Moisture resistance is an important factor, especially if you plan to lay the coating in the bathroom or kitchen. Depending on the operating conditions, the appropriate class of material is selected. By the way, moisture resistance can be checked - to do this, a piece of laminate is soaked in water for 8 hours, and then its swelling is assessed. If the piece has increased in volume by a maximum of 18%, then the coating is of high quality and reliable.

Waterproof laminate

On a note! When installing even moisture-resistant material, the ends of the lamellas must be coated with a special protective mastic. The fact is that these parts of each plank are usually not protected from moisture.

Step 6. The material must be environmentally friendly. Here the availability of a certificate of conformity from the seller and the marking of the coating are assessed. A laminate marked E1 or E0 is selected.

Additional symbols that may be on laminate packaging

Step 7. The density of the laminate is also important. It should be within 850 kg/m3. Density is rarely indicated on packages, but you can find it out yourself from the data on the packages. To do this, the total area of all lamellas is multiplied by their thickness, after which the value is converted to cubic meters. Next, the total mass of the laminate is divided by the resulting value - the density is obtained.

Interior design with light laminate

Self-installation

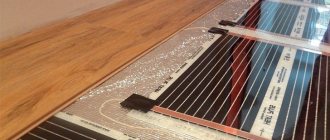

After the floors are leveled, there are no sagging boards and all irregularities have been eliminated, the surface should be thoroughly cleaned of dust, debris and shavings. Next, a thin-layer substrate (foamed polyethylene) is spread on this surface. It performs three functions at once:

- Leveling the surface with small flaws and differences;

- Additional waterproofing;

- Noise insulation.

Such material is usually sold in rolls of various sizes. Its installation should be done as follows: the roll is rolled out along the length of the room and cut into the required pieces. These pieces are glued together with construction tape or regular tape. This creates a continuous coating. Next, laminate boards are installed on this substrate.

They can be laid in many ways: diagonal laying, straight laying, etc. Diagonal laying is used mainly in small spaces. This allows you to visually expand the space. Direct installation is performed mainly perpendicular to the window. Thanks to this, the joints are less noticeable. But, if installation is carried out not on plywood sheets, but on floor boards, then the laminate panels should be laid perpendicular to the floor boards.

Diagonal laying method

Once the installation method has been chosen, it is necessary to measure the distance between the walls, parallel to the panels being laid. This will allow you to correctly calculate the required amount of material. If the last row of laminate boards has to be sawn off to a width of less than 1/3, then it is better to lay out the first row from panels sawn in half. The remainder of the sawn laminate boards will be used in the last row.

Before installation, all joints should be treated with a special paraffin-based compound. This will simplify the installation process (the lock will fit much easier) and will additionally protect the locks from moisture.

If a board with a latch lock on four sides is used, then the installation is done in rows, that is, they are joined together at the ends. Next, the next row is inserted from the side. For a quality connection of the boards to each other, it is necessary that the locking connection snaps completely into place. To do this, the inserted board is lightly hammered with a rubber hammer or with a regular hammer. Thus, row after row is laid.

Installation of panels with a latch lock

Installation of the entire floor covering should be carried out at a distance of 0.5-1 centimeters from each wall.

Laying with a gap from the walls

This gap is necessary to ensure that the coating does not swell when there is a change in humidity or temperature in the room. After all the laminate boards have been laid, the baseboards are installed.

Average score of ratings is more than 0

Share link

Comments There are no comments yet, but you could be the first...

Tips for working with laminate

Types of underlays for laying laminate

Cleaning and priming the subfloor

Base insulation and underlayment installation

Installation of the first row of panels

Applying adhesive and installing the panel