To some, a distribution box for electrical wiring will seem like a very insignificant element of a household electrical network. And really, what's the use of it? With the help of a switch we control lighting, we use sockets to power electrical appliances and equipment - these elements of the electrical network have a visible result. And the invisible, but very important result is that switches, sockets and lamps are connected to the general electrical network through distribution boxes. It is in them that the wires coming from the power source and going to the switching devices are connected.

How to install a junction box

Today, Enot Electric will tell you about several ways to install a junction box in concrete.

The electrical box is made of metal or plastic in the form of a small container. Inside this container, during installation work in the room, all groups of conductors are connected. The main purpose of the distribution box:

Possibility of maintenance and access to repair of the home electrical network. In the event of a failure of the room wiring along with the socket group, it is possible to troubleshoot all problems without any problems.

Availability of connecting new lines to room electrical wiring. This means the possibility of installing sockets if additional ones are needed. This eliminates the need to pull new cables from the main panel - it will only be enough to create an additional route from the distribution box.

It is possible to ensure uniform distribution of electrical energy throughout the room by creating additional directions of the electrical network and connecting them into one.

From the above, we can conclude that a properly installed junction box plays an important role when installing electrical wiring both in the house and in any other room.

What is a distribution (junction) box

This is an electrical product, which is a closed housing made of metal or dielectric material. The second option is preferable, provided that the material is sufficiently reliable from a fire safety point of view. That is, it must be non-flammable, or at least not support combustion.

Inside, power cables and supply wires are connected for consumers or switching devices. The junction box must provide protection for internal connections from dust, moisture, and foreign objects. In addition, the product prevents accidental contact with exposed areas of the electrical circuit (current-carrying busbars, contacts).

The shape of the box, as well as its dimensions, are not regulated - the format of the product is selected based on the installation conditions. However, manufacturers adhere to certain standards for compatibility with various fittings and components.

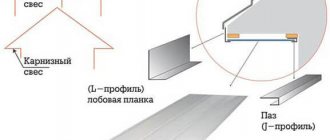

Insulators for external wiring

When laying open electrical wiring, insulators are used to secure the wires. These insulators perform a simple function - they are the base on which the electrical wire is attached. Both ceramic and plastic insulators are available for sale.

For the installation of open electrical wiring in retro-style rooms, ceramic insulators are used as a design element. In this case, special multi-colored ceramic insulators are used.

Ceramic insulators are made from high-quality material and have high performance characteristics:

- have high hardness and strength;

- resistant to changes in temperature and humidity;

- have high dielectric characteristics;

- have a long service life.

When installing open wiring on insulators, the following requirements must be met:

- the insulator should be located at a distance of about 4 cm from the edge of the socket, switch or junction box;

- with horizontal wires, there must be at least 5 insulators per meter of wiring. If the wires are arranged vertically, this distance may be slightly greater;

- When turning the wire, you must use 2 insulators located at an angle of 45 degrees.

How to install a fence made of corrugated sheets? You will find out the answer to this question by reading this article.

And here is an article about brick fences.

Design

The design of the distribution box is very simple and is a kind of container with a lid. The box for external installation has special holes with seals for wiring. In the photo below you can see the difference between the outer and hidden boxes.

Hidden and outdoor distribution boxes, respectively.

Although these products perform the same function, as you can see, they have their own significant differences.

You should also draw your attention to the fact that hidden-type boxes usually have special claws with springs installed on the sides. They are designed for fixation when installing wiring through a plasterboard wall.

Is it possible to do without junction boxes at all?

Theoretically, yes. But to do this, you will need to connect the distribution panel and each place of electricity consumption in the apartment with a separate wire. This will lead to high consumption of electrical wiring and the need to make wide and deep grooves. to be able to lay several rows of wire in them.

Ultimately, the disadvantages of this method will many times outweigh the disadvantages of using junction boxes. Savings due to abandoning the latter will be many times depreciated by increased costs for electrical wiring.

One can sometimes hear this as an argument against the use of junction boxes; Although laying a separate line to each point of consumption is economically inferior to the option with junction boxes, it is safer, since it eliminates the connection of wires at nodal points.

There is only one answer to this. Correct, professionally performed connection of wires in a junction box is absolutely safe. While everyone has the right to their own point of view, the option of using junction boxes is still more preferable than without them.

History of appearance

As soon as the first node was installed, in which several wires of an extensive electrical network were connected, the need to protect it immediately arose. First of all, from accidental human touches to a bare wire, which could result in electric shock. Protection from external influences - mechanical, dust, dirt, water - was also required.

Even during the first steps of electrification, it was invented to protect the place where wires were twisted with a box. At first, improvised means were used for this purpose, for example, cans from canned food. Holes were made in them into which wires were inserted and twisted together. The most important thing was to carefully cut out the holes, make their edges smooth and not jagged, so that the insulation of the wires would not be damaged.

However, very soon, electrical evolution led to the mass production of the necessary factory distribution boxes by manufacturers. Although even now, almost a century later, somewhere there will be a craftsman who will connect wires in a tin can in a garage or shed.

Well, if you are building a house or doing major renovations in an apartment, be sure to start with electrical installation work. First of all, start installing distribution boxes; do not use any cans or improvised means, even in utility rooms. Go to the electrical goods market, boxes are sold there in abundance - all sizes, configurations and degrees of protection.

Main function of distribution box

Using this electrical product, you can significantly reduce the cost of organizing electrical wiring. Without this element, each electrical appliance would have to be connected to a separate cable, which would increase the number of channels required for installation and spoil the appearance.

Proper distribution of the cable inside the box will increase the safety of residential and non-residential rooms. This is due to the insulation of connecting points with flammable materials contained in the wall. The design of the equipment is thought out to the smallest detail, therefore it guarantees ease of repair work.

But the main function of the box is related to the uniform distribution of electrical energy between all consumers installed in the room. In addition, the product structure takes into account potential expansion due to the addition of new branches of the electrical circuit.

Purpose of distribution boxes

Electrical wiring must be divided into groups depending on the energy consumer. For this purpose, similar structures are installed that perform important tasks:

- ensuring fire safety;

- aesthetics.

Under the body of the box there are conductors, which are thus protected from various damages. This allows you to increase the service life of electrical wiring.

Junction box with conductors

The main task of the distribution box

With this design, you can reduce the budget for organizing electrical wiring. After all, in the absence of a distribution box, a cable would have to be connected to each electrical appliance, which would create too many channels that would have to be hidden in the ceiling. In addition, all this does not look aesthetically pleasing.

At the same time, the correct distribution of conductors inside the box increases the level of fire safety in any type of room. This is due to the insulation of connections and flammable materials that are located in the wall. In addition, this design is convenient for repair work.

However, the main function of the distribution box is to distribute electricity between consumers that are installed in a specific room. In addition, the design of the product allows for expansion by adding additional branches (when it is necessary to install a new switch or socket).

You can add a branch to the distribution box for a new energy consumer

Methods for connecting wires in junction boxes

Putting the wires inside the box is half the battle. Now you need to choose a connection that is reliable and easy to maintain.

All cable line connections are divided into two main categories:

- Detachable, that is, the wiring can be disconnected and reconnected many times, without critical damage to the wire or connecting device. For example, a screw connection on terminal blocks.

- One-piece, that is, when the conductors are separated. the connection is destroyed. There is no big problem with this, it’s just that the cable gets shorter each time, and the connecting devices have to be purchased again.

The type of splicing when disconnecting boxes is selected based on the design of the overall network. If you plan to periodically disconnect one or two branches from a common box, it is better to choose a screw connection or reusable quick-release terminals.

For permanent connections that will not be dismantled for many years, the same terminals are used, only for one-time use. Despite the obvious drawback: the impossibility of reuse, such terminals provide more reliable contact compared to reusable ones.

If you use only copper conductor both in the backbone network and in subscriber branches, there are cheaper ways to permanently connect the wires:

- Twisting with welding. Creates reliable contact, without the danger of sparking and heating the wiring under heavy load. The connection is simple, but requires special equipment. As a last resort. You can melt the copper tips with a portable gas torch.

- Twisting with soldering. It is not as reliable as with tip reflow, but when using refractory solders, the connection practically does not lose strength, even when heated. The advantage is accessibility. A powerful soldering iron is easier to find than welding equipment. The basic rule: strength is ensured by twisting; we simply fill the voids with solder, improving contact.

- Twisting with mechanical fixation (crimping). A questionable method, since there is a possibility of damage to current-carrying wires.

- There is nothing to say about ordinary twisting: although it is not prohibited, this technique is practically not used.

Direct connection (disconnection)

Is it possible to organize electrical wiring without junction boxes? When branching no more than 2 lines, it’s easy. Several conditions must be met:

- If the connection is made by twisting, soldering with refractory solder is required. Crimping can be used.

- "T" shaped connections are undesirable; it is better to make a "Y" shaped branch.

- After connecting and checking the quality of contact, the splice area must be carefully insulated and protected from moisture. Especially if the connection is made in hidden wiring (plaster wall) or on the street.

Installation of a junction box

Installation of metal junction boxes involves only external installation of such products.

Therefore, the instructions in this case are simple:

- Bring tubular channels with wire to the entry points.

- Attach the pipes to the walls of the housing and bring the ends of the cable into its internal area.

The product body is secured to the wall with screws through the holes provided for this. Then connect the cables according to the diagram, close the box and secure the lid with screws.

Important! When working with wiring, you must remember that you need to completely de-energize the entire room, otherwise contact between screwdrivers and wires can result in an electric shock or cause a short circuit. To check the voltage in the network, use indicator screwdrivers or a multimeter. These two tools should be in every home

These two tools should be in every home

To check the voltage in the network, use indicator screwdrivers or a multimeter. These two tools should be in every home.

Experts advise using electrical metal junction boxes in any room. It's cheaper than plugging every wire into an outlet, and it's also much safer. It is not recommended to perform the installation yourself without special indicator screwdrivers and knowledge. Any interference with the wiring may result in a short circuit.

*Prices in the article are for April 2021.

Potential equalization boxes

Installing a potential equalization box is one way to protect the consumer from possible electric shock. Such devices have found their application in office buildings, apartments and private homes.

Potential equalization box

What is potential difference?

In the case when the potential value of current-carrying objects located in the same room is different, then a voltage arises between them, called a potential difference.

This situation is very dangerous from the point of view of the possibility of electric shock to a person in the room. Most often, this danger occurs in rooms with high humidity (kitchen, bathroom, toilet, shower).

Potential differences in household electrical appliances occur in the following cases:

- current leakage due to damage to the insulation of electrical network elements;

- improper connection of electrical equipment;

- malfunction of energy receiving devices;

- the occurrence of static electricity on device housings;

- the appearance of stray currents in the grounding system.

To avoid the occurrence of such unpleasant situations in the premises, a potential equalization system is organized, which essentially represents the combination of all metal structures into a single circuit.

Street products

If the first two types were suitable only for indoor installation, then the third option is suitable for those who decide to install the box outdoors. Installing a box outdoors involves exposure to natural factors such as rain, fog, frost, etc. Since all these factors have in common the fact that they create moisture, which can conduct electricity, outdoor types of boxes must be sealed. To do this, a special rubber seal is placed between the lid and the body, which prevents water from getting inside. The wires are inserted inside using crimp (collet) clamps.

However, it is worth adding here that the estimate for installing junction boxes will be more expensive than for installing conventional ones if the installation is done by specialists.

Types of distribution boxes

Based on the body material, boxes are divided into:

- Metal - for installation in rooms built from flammable materials (wood, plastic), or on walls insulated with flammable material. They may have a dielectric layer inside to reduce the likelihood of unauthorized contact closure.

- Plastic are the most common due to their low manufacturing cost. They are made either from non-flammable material, for use in conditions of high fire danger, or from materials that do not support combustion. That is, the junction box in any design should not become a source of fire, even if the wiring ignites inside.

According to installation conditions:

- For indoor installation. Designed for installation in walls and cladding. They consist of a body, which must be firmly held in the supporting structure, and a flat cover. In turn, the cover must be removable for access to the contact group or twists. In such boxes, the thickness of the case can be thinner, because it does not bear the structural load.

- As a rule, built-in boxes are made in a round shape. When installing into a monolithic wall, drilling an installation hole using a crown is much easier. For installation in drywall, you can use rectangular (square) housings. It is easy to cut such a hole in the gypsum board. From the point of view of connecting wires, it is more convenient to work with a square (rectangular) case.

- For outdoor installation (non-sealed) - conditions of use - indoors or closed cabinets. The housing is both protection from the external environment and a strength element of the structure. Therefore, it must be thicker and stronger. Distribution box6 To prevent foreign objects from getting inside, the outer boxes are equipped with sealing clamps for wires.

- For outdoor installation (sealed). Installation of the distribution box outdoors involves direct exposure to water, frost, and fog. Since water is a conductor, the inside of the housing must be dry. Therefore, sealed boxes have a rubber seal along the sealing contour of the lid, and crimp (collet) clamps for inserting wires.

- Of course, additional equipment of products (moisture protection, etc.) increases the cost. Therefore, when choosing a package, we usually proceed from the principle of reasonable sufficiency.

Junction boxes can be equipped with a ready-made set of connectors for wires. Or you buy an empty case, and the fittings are selected separately.

Features of electrical wiring installation

All electrical installation work is carried out only after installing the electrical panel and meter. After which the locations of the switching equipment are determined. In order to correctly lay wires and install socket boxes, an inspection of the cable route, conditions for laying wiring and electrical products is carried out.

The precision of electrification guarantees not only an aesthetic appearance, but also the safety of the entire home. So, when installing a socket box as a distribution box, you must follow the installation rules, these are:

- Fix the socket box in a wall made of brick, concrete, plasterboard using a building mixture.

- Install the socket box flush with the wall surface with the wiring closed.

- To fasten the glass, use special clamping screws with plates.

When laying the cable, you should use special fasteners that will protect it from mechanical damage and act as grounding. When designing an electrical network through sockets and switches, it is necessary to use only high-quality equipment.

Recently, installation socket boxes with a more in-depth shape have become in great demand, so that the stock of wires formed by loops or folds can fit compactly without sharp creases.

Conclusions and useful video on the topic

Visual instructions for installing a junction box:

It is not possible to cover all existing design variations of distribution boxes in one review. But the design principle and installation features for all existing products are almost the same.

Therefore, the instructions given can be considered universal for installing many models of junction boxes.

Those interested in the selection and installation of junction boxes are encouraged to leave comments, ask questions and participate in discussions. The feedback form is located in the lower block.

Electrical wiring without junction box

The wiring architecture is drawn up taking into account the interests and wishes of the home owner. Electrical installation is a series connection of a circuit without junction boxes. The conductors are connected to the electrical system one after another and are supplied from each lighting point, socket, and switch directly to the distribution board.

Before starting work, a preliminary calculation of the expected amount of current consumption when using the planned electrical appliances and devices is carried out. The connection diagram includes the necessary set of wires and cables, installation of sockets, switches, and electrical appliances.

New electrical wiring requirements consider using only copper conductors. Contact connections of wires during electrical installation play an important role in any electrical system. They must be resistant to mechanical damage and safe.

General description of products

Engineering communications are a network of a central channel, branches, and end points. For the system to function properly, it is necessary to form reliable nodal connections of individual elements. In the case of electrical wiring, the event is carried out using electrical junction boxes.

In fact, the device is represented by a box with a lid. Install it at each node branch. The main goal here is to isolate contact connections from possible environmental influences and unauthorized mechanical influence. It also protects the premises from fires during a short circuit and protects people from electric shock. Additionally, two problems are solved: access to contact nodes for various purposes, and a decorative component.

Types of distribution boxes

Distribution boxes are divided according to the following characteristics:

- by composition and raw materials used. Most boxes are made of metal using PVC;

- by type: oval, square, round;

- IP cover level of protection (without protection, with protection, sealed);

- by the method of inserting wires into the box. Also, the walls can be smooth with or without holes;

- by closing method: with adjustable lid, regular lid;

- The installation method can be hidden or open.

Types of products by size

Please note! There is some confusion in the naming of wiring boxes. A junction box is sometimes understood as a socket box, so people don't see the difference, but they are different things

Invoices

This type of box is installed on the wall. The product for hiding cables is practical because, if necessary, you can quickly find the point where the wires are connected.

Surface mounted type IP42

This installation method is used in industrial plants and offices, that is, in places where there are a large number of electrical energy consumers. In private homes, the distribution overhead box can be mounted in the utility room.

Domestic

Hidden wiring is installed in residential premises; the wires are laid in special cable channels and hidden behind the plaster. Such a distribution box is mounted in a pre-prepared trench in the wall, and cable grooves come from it. In this case, it can be installed either in a solid brick or concrete wall or in plasterboard.

When wiring is hidden, the cables are hidden in the wall

Solder box parameters

Below are three different types of shields and their characteristics.

Junction box for external wiring IP54-IP56

It is mainly used in conjunction with corrugated metal hoses. The product is made of ABS plastic. Protection level IP54-IP56.

Note! All subtypes of this box do not have seals according to the European standard, which provide a high level of protection.

Such shields are mainly installed on walls. Can be located in places of high humidity (bathroom). They are quite safe and have a nice minimalistic design.

Drywall box

Soldering shield for drywall

Used for internal wiring in conjunction with corrugated sleeves. The product is made of ABS plastic or polystyrene. Protection level IP 30. The box has holes where the wires will be inserted. They are mainly installed on ceilings using self-tapping screws with claws (included).

You may be interested in Description of terminals for wires

Important! Sometimes these tabs can damage the ceiling, so there is no need to screw them in with force.

Economy shield for external wiring IP55

Products of the JBR and JBS type for external wiring are used in conjunction with corrugated hoses. The product is made of ABS plastic.

Main types

Protection level - IP55. The cheapest option of the three above. These boxes are designed with gaskets for connecting corrugated pipes and providing a high level of protection. Attaches to walls and ceilings.

These three types are most often used for repair work, but there are also more expensive models.

Review of models on the market

Junction box Tuso

Characteristics:

- diameter 60 mm, depth 40 mm;

- installation, or branching;

- round in shape, consisting of a body and a lid;

- body and cover material - non-flammable plastic;

- fixing the cover with latches in the cover and body;

- used for installation in concrete and brick walls;

- it is possible to mount it openly with screws or self-tapping screws;

- number of inputs – 4 with rubber seals;

- moisture protection class -;

Price – from 20.00 to 35.00 rubles per piece.

Distribution box Legrand Atlantic IK10

Characteristics:

- dimensions 150*150*80 mm;

- rectangular shape for indoor installation,

- metal;

- fixing the cover with screws into the body;

- used for installation in concrete and brick walls;

- Possible mounting through the body or on brackets;

- supplied with perforated mounting rails;

- moisture protection class - IP66;

- internal and external paintwork - textured coating in RAL 7035 color;

Price – from 3173.00 to 3300.00 rubles per piece.

Where can I buy

You can resolve the issue as quickly as possible by visiting the nearest specialized store. The optimal option, in terms of price-quality ratio, remains purchasing from the AliExpress online store. Mandatory long waits for parcels from China are a thing of the past, because now many goods are in intermediate warehouses in destination countries: for example, when ordering, you can select the “Delivery from the Russian Federation” option:

| 3-pin waterproof distribution IP68 box | Distribution box, IP67 housing | Junction box, IP65 |

| 3-way distributor box, IP68 | Distribution box 2/3/4/5/6 way, IP68, 45A/450V | Mini junction box IP66, size 47*28*18mm |

Classification of electrical wiring boxes

Junction boxes for outdoor installation are divided according to several criteria.

Material:

- Polymer – polyethylene, polypropylene, polystyrene bodies.

- Metal - made of tin or aluminum and its alloys.

Purpose:

- Household - for wiring electrical wiring where single-phase networks are used.

- Industrial - high-strength mini-boxes where three-phase voltage wires are routed.

- Special – junction boxes for outdoor installation for routing signal cables of pulse, radio frequency and microwave equipment.

Installation method:

- Open type - wiring runs outside the surface.

- Hidden type - the cables are hidden inside the grooves.

Security level:

- IP44 – boxes that can be used outdoors under cover from direct exposure to rain, dust, and in rooms with a damp environment.

- IP55 – boxes that can withstand short-term direct exposure to water and do not allow dust to pass through. The most popular type of distribution equipment.

- IP65 – designed for installation in places highly exposed to the atmosphere, do not allow rain and dust to pass through.

- IP67 – can remain in a damp environment for a long time, for example, underground or on its surface.

- IP68 – able to protect wiring under water. They are designed for shallow depths.

Kinds

Boxes for connecting electrical wires come in different types and are classified according to many parameters.

By installation method

First of all, they are divided depending on the installation method:

- A distribution box for open electrical wiring (otherwise known as “outdoor installation”) is mounted on wall surfaces. To install it, no preliminary preparation of the base is required. It is attached directly to the wall surface using various fasteners.

- The distribution box for hidden wiring (it is called “internal installation”) is mounted in a special recess in the wall, which is drilled during installation work. These junction boxes, in turn, differ depending on the material of the wall in which they will be mounted. If it is in a concrete or brick wall, then you need to use a special crown to make a recess to fit the dimensions of the box. Simply cut a corresponding hole in drywall or other sheet materials.

By material

Boxes vary depending on the material from which they are made. First of all, these must be materials that would provide the connected wires with maximum protection for the entire service life. In this regard, electrical wiring boxes are made of high quality plastic and metals, which are also coated with a protective layer of anti-corrosion paint or primer.

For the manufacture of metal boxes, tinned steel sheets or aluminum alloys, which are not subject to corrosion, are used. If a fire occurs, the metal case will serve as protection for the contents of the box for some time, during which time it will at least be possible to de-energize the electrical network. Metal boxes are most often used in general purpose buildings (garages, utility rooms, sheds).

A plastic junction box will protect electrical connections no less effectively. For their manufacture, polyamide, polypropylene or cast fluoroplastic are used; these materials are not subject to decomposition by active substances. These plastic boxes provide excellent insulation against electric shock. In addition to good insulating properties, they also have sufficient mechanical strength. A plastic junction box is resistant to aggressive chemical liquids and can be kept in a humid environment much longer than a metal one. If there is a danger of open fire, then plastic does not burn, but melts; in this, of course, it is inferior to metal.

By other parameters

Distribution boxes vary in size and the following criteria play a major role here:

- their purpose;

- number of inputs;

- protection class.

At a minimum, the box can have two inputs, that is, two wires will be connected in it. The maximum number of inputs in one distribution box is 16. Accordingly, the more inputs, the larger the box in size and depth.

Boxes vary in shape and can be round, square or rectangular. For outdoor installation, it makes no difference at all what shape you use the box. But for indoor installation it is better to take a round one, because if you have a concrete wall, then making a hole in it is much easier than drilling a square niche.

All of the above criteria add up to the price of the junction box. The price is also affected by the degree of protection of this element:

- IP 20, IP 30 – for use only in dry rooms, there is no protection from humidity;

- IP 44 - for use outdoors and in rooms with high levels of humidity; when installing outdoors, you must choose a place under a canopy or canopy, and also avoid direct exposure to dust and water jets;

- IP 55 - for use in places exposed to precipitation, that is, boxes with this degree of protection can be installed outdoors in any conditions, they are completely protected from dust and water jets;

- IP 67 – for use outdoors in any weather conditions, as well as on the ground and in the ground;

- IP 68 - boxes with this degree of protection can be used immersed in water; as a rule, the immersion depth is additionally indicated for each product on the packaging or case.

For household electrical networks, boxes with a degree of protection of IP 55 are most often used.

Installation technology

Installation of unboxing boxes is carried out according to the following scheme:

- Creation of a network of pipes intended for laying cables from electrical installation products.

- Lines to switches and sockets are laid strictly vertically, and horizontal ones can be placed in niches formed by floor slabs or a wall.

- Fastening the junction box in the prepared hole using dowels or self-tapping screws and fixing it with plaster or alabaster (similar to installing socket boxes in a hidden way).

- Performing switching and connecting wires using terminals or by soldering.

- Insulated cables are carefully laid and covered, ensuring unobstructed access.

Installation

To install the box in the wall, you first need to prepare a hole. You will need a special tool, preferably a hammer drill with a special attachment called a crown. What is she? A ring with a pobedite or diamond cutting edge. In the center there is a drill designed for concrete; it centers the crown, and it then cuts out a round segment from the wall. Drilling is done to the required depth, then the cut segment is removed from the wall using a chisel and hammer (you can use a special spatula that is installed on a hammer drill). In a similar way, a deep niche is made for each installed element of the electrical network (sockets, switches).

Then from the hole it is necessary to punch grooves in which the wires or cables are laid. Their ends must be inserted into the box (it has several special holes for this) and left protruding 10-15 cm for installation of the connection.

Then the boxes are smeared into the niche using a solution of alabaster or building plaster. All that remains is to make all the necessary wiring connections and close the installed element with a lid. The wires are connected by welding, twisting and subsequent soldering, crimping with sleeves or terminal blocks.

Now you know almost everything about junction boxes. Always start your electrical repairs with them. Purchasing these electrical network elements is not a problem now; the main thing is to decide exactly which ones you need?

Junction box installation technology

So, let's talk directly about the process of installing and connecting the distribution junction box. If we talk about installing the box itself, there is nothing complicated or problematic here. Built-in versions of boxes are built into the walls, and overhead boxes are attached to the walls with dowels or self-tapping screws. Installation of a built-in box is more complex and time-consuming; in this case, it involves the creation of a special landing niche. In one of the walls, closer to the ceiling, it is necessary to make a niche of the appropriate size, this is where the box will be installed and secured with alabaster or cement mortar.

However, these procedures refer to the final stage of work. First of all, you should create a “network” of grooves - channels through which cables will be connected to the distribution box. The required number of drops to switch boxes and sockets must be in a strictly vertical position. In order to lay cables horizontally, it is recommended to take advantage of the gaps between the floor slabs and the walls.

After completing the preparation of the grooves and installation of the socket boxes, we proceed directly to the electrical wiring arrangement - an important part of this process will be the installation and connection of the distribution box. Often the process of connecting wires inside the junction box causes certain difficulties

To avoid them, we recommend marking each end of the cable in one way or another. For example, we connect the wire that supplies power from the electrical panel - we mark it with the appropriate word, we connect the cable from the socket block - the same thing, etc. Each individual electrical circuit that we connect to the distribution box must be labeled accordingly, in this case we will not face confusion later

Often the process of connecting wires inside a distribution box causes certain difficulties. To avoid them, we recommend marking each end of the cable in one way or another. For example, we connect the wire that supplies power from the electrical panel - we mark it with the appropriate word, we connect the cable from the socket block - the same thing, etc. Each individual electrical circuit that we connect to the distribution box must be labeled accordingly, in this case we will not face confusion later.

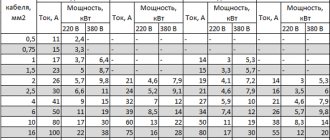

Cable cross-section

Now let’s take a break from the distribution box for a couple of minutes and say a few words about the cable cross-sections that are used when wiring a house or apartment. It is known that voltage is supplied to rooms from the electrical panel, as a rule, using a three or two-core cable with a cross-section of at least 4 square millimeters. This cross-section allows the cable to easily withstand any powerful power consumers. To connect sockets, cables with a cross-section of 2.5 square millimeters are used, and for a lighting system, a cross-section of one and a half square is sufficient.

Form

The shape of the boxes can be round, rectangular, or square. Structurally, they do not differ from each other and the choice of shape depends only on the number and thickness of the wires that must be connected to each other and placed inside the box.

Rectangular and especially square ones have a large capacity.

Connection principles

Connecting conductors in a junction box with caps

To avoid confusion, each wire is a different color for quick connections. The most popular combination of colors is considered to be: light green, green – grounding, blue – zero, white or yellow color symbolizes the phase

When connecting the device, it is important to strictly follow the sequence

To correctly connect the wires in the junction box, you must first draw up a project. It is necessary to determine the exact location of electricity collection points. Distribution devices in accordance with the diagram are installed in the most suitable and convenient places.

Wiring diagrams

It is necessary to become more familiar with the features of connecting the wiring from the junction box to consumers.

Prices for various types of voltage indicators

Voltage indicator

Connecting sockets

Often sockets are connected in groups on one line. So, 3 cables with several conductors are placed inside the box. Brown indicates the phase conductor, blue indicates neutral, and green or yellow indicates ground. Of course, some manufacturers use other colors.

Connecting sockets

The wires are laid out on a flat surface, and then cut to a certain length, but with a margin (so that it can be separated again). Next, it remains to fix them according to the diagram.

Connecting a switch with one button

This is where installation becomes more complicated. After all, there are three groups of electrical wiring with different connections. One conductor is responsible for supplying voltage from another box or panel, the second comes from the lighting fixture, and the third from the switch.

The phase conductor is fed to a switch, which is connected to the lamp. Here you should make sure that the voltage supply occurs precisely when the switch is closed. The neutral and grounding conductors from the lamp are connected to the shield.

The principle of connecting a switch with one button

Connecting a switch with two buttons

A three-core cable is connected to this type of switch (without a grounding conductor, because it is connected directly to the panel). The first conductor goes to the common contact of the switch, the second to the first button, and the third to the second button.

Note! The phase conductor is connected to the common contact, the zero is fixed directly from the board and lamps. The phase wires from the lighting fixtures are fixed with the cores on the buttons.

Connecting a switch with two buttons

Distribution box device

Terminal distribution box

According to its intended purpose, the device body must be light in weight and size, and also provide high-quality insulation of the wiring connections. Distribution boxes can have a rectangular, square or round body, in which there are holes for routing electrical circuits.

Devices intended for external installation have the following types of wall mounting:

- They can be installed on special tension lines, and also be equipped with special fasteners on the cable.

- The case is equipped with internal holes for secure fixation.

- External openings.

Switchgears are also divided by material of manufacture and dimensions. Experts recommend giving preference to plastic cases.

Briefly about the main thing

Distribution boxes are used to hide contact connections of conductors from contamination, moisture, and physical impact. Open access to nodes is also provided.

The boxes differ in design, installation method, application, material and permissible operating conditions.

Additionally, products can be equipped with rubber seals, covers, terminals and clamps, and fasteners.

According to the degree of protection, open boxes (socket boxes) are distinguished that protect contacts from dust, moisture or fire, and are permissible for immersion in the ground or in a body of water.

Ratings 0

Wire connection methods

As already mentioned, for various methods of connecting wires to a junction box, there is its own electrical installation technology, which consists of the length of stripped conductors, their bending and the use of appropriate tools.

Since each of the possible methods has many specific nuances and requires the use of special tools and skills, the types of wire connections are presented below in the form of a list with links:

- Terminal blocks;

- Wago terminal blocks;

- PPE caps;

- Connecting sleeves;

- Soldering wires;

- Welding of conductors.

Electrical installation of wires in a junction box using terminal blocks Each of the above methods has its own advantages and disadvantages, which you must become familiar with by studying the materials and following the links provided.

You should choose the type of connections for doing electrical installation yourself based on the availability of tools, skills, the ability to purchase materials and the expected quality of contacts. Wire welding is considered the most reliable, but it requires a special welding machine and specific skills. Soldering conductors, which also has good performance, requires soldering iron skills. Wago terminal blocks are quite easy to install, reliable if the products are correctly selected according to the load, and allow the connection of multi-core wires without the use of special lugs, but you should be wary of counterfeits.

Connections in the junction box are made using Wago terminal blocks

The use of sleeves is reliable; when using special products, it is possible to connect copper and aluminum, but the connection itself requires special pliers and is non-separable, which does not give a chance for easy correction of electrical installation errors. PPE caps are reliable if the technology is followed and the diameter is selected correctly. Terminal blocks require bolted connections to be securely tightened.

PPE caps in distribution box

Twisting in its pure form is not included in the list of compounds allowed by the PUE

Testing wire connections in junction boxes

After all connections have been made, the exposed areas of the conductors are insulated using heat-shrinkable tubing, and the wires are laid in junction boxes. The boxes themselves are left open until the installed electrical wiring is tested. First, voltage is supplied to the connected lines by turning on the corresponding circuit breakers.

Insulating connections in the junction box using heat shrink tubingIf, after switching on, nothing sparked anywhere and the machine was not knocked out due to a short circuit due to an erroneous connection of wires or poor-quality insulation of connections, the electrical wiring is tested with load current (loading), which is carried out by connecting various electrical appliances to the mounted lines. It is recommended to load each line with the maximum permissible current.

The download should continue for some time (preferably several hours). During this period, possible electrical installation defects will have time to manifest themselves. A visual inspection of the connections in the junction boxes should be carried out - signs of high temperature will be visible by melting of the insulation or terminal blocks

It is also important that there is no characteristic odor of overheated or burnt insulation.

Melted insulation of one of the connections in the junction box

After relieving the voltage, you should check all connections by touch - they should not be hot. If, when loading the electrical wiring with the maximum rated current for several hours, no comments are identified regarding the operation of the connections, then the electrical installation is considered normal, the junction boxes can be closed and the wiring can be put into operation.

Advantages of using junction boxes

A reliable connection of wires can be created inside the distribution box. A

distribution box correctly selected by type and correctly installed in the chosen location provides the user with a number of advantages.

- With this approach to organizing assembly units, there is no need to search for free cores to carry out the necessary switching.

- Knowing where the electrical external junction boxes are located, all that remains is to connect the new device to the existing electrical wiring, using their internal wiring.

- Finding the location for hidden installation is also easy - to do this you will need to examine the section of the wall above the outlet.

- Usually, at a distance of about 3-5 cm from the ceiling, you can find a whitened plastic lid of the box, which you simply need to open.

- Inside, you can create a reliable connection of conductors, guaranteeing high quality switching.

Due to the use of hidden installation of the distribution box, its presence does not disturb the overall interior of the room. If open installation is used, the bundle from the set of connecting conductors is laid in a decorative cable channel.

Classification

Boxes can be installed in open and hidden types. Which one to choose depends on the personal preferences of the owner of the premises. Each type is described in detail below.

Installation process

For hidden wiring

Concealed type junction boxes are characterized by the same technical properties as external type boxes. They are also made from plastic and polystyrene. Moreover, plastic is mainly used to produce the body, and covers are made from polystyrene.

For thick concrete walls, soldered shields are produced with a protection level of IP20-IP30. They can be round or square in appearance, the color ranges from white to blue, the lid is always in light colors.

For open wiring

For open wiring, round shields are usually installed. The material used is plastic of the same color.

For open wiring, the AP9 model is excellent, which is installed in places of high humidity (bathroom). The box body is made on the basis of two-component casting.

Size range

On the inside of the lid there is a special compartment around the entire perimeter. You can put a seal there if the box is installed in the bathroom.

For your information! The lid is mounted on a flexible spring, which is convenient during use.

The product protection level is IP 55.

Installation rules

Before installing the junction box, read the requirements specified in the main regulatory document for electricians, PUE, as well as useful tips for installing junction boxes:

- The box should be installed at a distance of 10-30 cm below the ceiling level.

- The distribution box must always be accessible. There are cases when it was installed at the required distance from the ceiling, but then during new repairs and installation of stretch or suspended ceilings, the box turned out to be out of reach (that is, the ceiling level dropped). There is an option to leave a small hatch in the new ceiling for easy access to the box. But, most likely, it will not have a very attractive and aesthetic appearance. It is best to move it to an accessible place in advance before making new ceilings.

- With a hidden version of the electrical wiring, a recess is made in the wall for each distribution box according to its size and shape (round or square). The depth of the niche is made such that the box does not stick out from the wall, and the lid, when closed, is flush with the wall surface.

- External models of boxes are mounted on prepared, decorated walls.

- If a high-quality repair has been made to the room, then you would not want to spoil its appearance with an unsightly lid covering the junction box. In this case, either decorate the lid to match your interior design (stick wallpaper or paint it to match), or choose a box with a decorative lid in advance.

- If you covered the box with wallpaper, be sure to remember its location so that, if necessary, cut off the wallpaper in that place and gain access to the wire connections. It is best to keep an electrician's home journal, in which all the points of the boxes and the routes of the wires in the grooves will be drawn. This is also very convenient if you need to drill into a wall for a painting or photo frame. Knowing the schematic layout of the wiring, you will definitely not stumble upon it with an electric drill.

- You need to look into the distribution box not only when smoke is already pouring out of it. It is necessary to periodically inspect the connections for heating, as well as tighten the contacts.

Methods for connecting wires in a junction box

There are several basic ways to connect the wiring in a junction box. In order to choose one of them, you need to consider the options in more detail.

Stranding and insulation

This is an old, but proven method of connecting wiring over the years. The bottom line is that the ends of the conductors are first stripped of the insulation layer and then twisted together with pliers. After which this place is wrapped with electrical tape.

This method has advantages:

- ease of installation;

- no need for additional expenses.

However, there are some disadvantages:

- poor-quality connection of cores;

- inability to connect copper and aluminum wires.

It is worth noting that conductors are often connected in this way during temporary installation of electrical wiring. According to safety regulations, the connection method is not suitable for rooms with high humidity levels.

Soldering or welding

It is in these ways that you can make a durable connection of wiring cores. First, their ends are carefully stripped of the insulating layer, then twisted, but without effort. Next, you will need to solder the wires using solder and a soldering iron so that they turn out monolithic. Then you need to wait until they cool naturally, and only then wrap them with electrical tape.

In cases of soldering thick wires, you will need to use a soldering iron with a dense copper tip.

The advantage of soldering is the reliability of the connections, but this method also has some disadvantages:

- the need to purchase a soldering iron;

- this is a labor-intensive process that not every beginner can handle;

- the connection is permanent;

- Over time, the level of resistance in the soldering increases, which leads to voltage leakage.

Often, instead of soldering, the cores are connected by welding. The process has a similar principle, only here a welding machine is already used, so the master must have the appropriate skills.

Crimping with sleeves

This is also one of the most reliable methods of fixing conductor cores. Here they are placed in a special sleeve and clamped with a crimping tool on both sides. After which this sleeve is wrapped with electrical tape or a cambric is attached to it.

It is worth noting that the cores are placed in the sleeve either from different sides or from one. In the case of the first option, they will be connected in the central part of the tube. When choosing the second option, it is necessary to take into account that the diameter of the cores should not exceed the volume of the sleeve.

The advantages of such a connection should be noted:

- reliability;

- affordable cost of sleeves.

Disadvantages of the method:

- The sleeve is used only once. This means that in case of repair, it is torn down and a new one is fixed.

- You will need to use a special tool for high-quality crimping on all sides.

- Wires made of aluminum and copper are crimped only with special tubes, which are difficult to find in stores.

- Electrical installation will take time.

Terminal connection

If the wiring is made of different materials, it is recommended to use special clamps with springs or screws. Connecting the conductors using this method is not difficult; all you need is a screwdriver. The main thing is not to overtighten the bolts.

Why are they called differently?

The electrical connection box has received several names at once - distribution, junction, branch, switch.

It is like an electrical distribution point, which receives voltage from a power source, and then disperses along several electrical branches - to sockets, switches, and lighting fixtures. Because the voltage in the box is distributed in different directions, it is called distribution. Since several electrical branches extend from the box, a synonym has appeared - branch.

Another name comes from the way the wires are connected inside the box. For a long time, soldering was considered the most reliable method. At the junctions, the wires were twisted and then soldered, due to which electricians began to call the boxes unsoldered.

In an interesting way, another synonym arose - exclusion box. The word “disconnection” can only be heard among professional electricians, and they came up with it, as if combining two concepts - distribution and connection. That is, they distributed in the box which wire should go where, and then connected them according to the diagram.

Now there are so many modern connection options - all kinds of terminal blocks, welding, insulating connecting clamps, sleeve crimping, terminal blocks, self-clamping terminals. However, boxes are still often referred to as breakout boxes.

We explained all this to you so that when you go to choose materials in electrical goods stores and see different names in different places, know that they all mean the same junction box.

Electrical Wiring Safety

Upon completion of the installation of electrical wiring, it is necessary to carry out a set of measurements to ensure that the system is ready to use modern household equipment and appliances. Checking the functionality of the electrical panel, wires, cables, sockets, switches makes it possible to correct mistakes in a timely manner. Testing shows that:

- electrical wiring contacts have reliable grounding;

- connections are correctly connected;

- there is no extraneous voltage or damage to the insulation;

- automatic protection device matches the wiring.

Accurate measurements of electrical wiring can only be carried out with the help of electrical laboratory specialists. For testing, control and measuring equipment is used, which shows losses and electricity consumption. Sockets, switches, and lamps especially require preventive inspection to avoid short circuits.