Without an influx of fresh air, it is impossible to organize normal air exchange in the apartment. In summer, the issue is resolved traditionally - the window sash is fully opened or set to micro-ventilation mode. In winter, it will not be possible to constantly ventilate the premises, a maximum of 30 minutes during the day. One option to ensure proper ventilation is to install a supply valve on plastic windows. We propose to consider the feasibility of installing such ventilation valves, types and methods of installing window ventilators.

Which supply and ventilation valve should I choose for installation on windows and is it needed?

A ventilation valve for PVC windows is needed in order to create the correct microclimate in the room, since the design of profile systems does not provide for natural air circulation. Unlike old wooden windows, which belong to the category of “breathable - blown” materials and are capable of letting air through, plastic windows, aluminum and wooden windows are completely sealed, perfectly protect the house from dirt, dust and noise from the street, but are not always equipped with special devices for fresh air supply.

Compact ventilation devices (breathers, ventilators)

Breathers (ventilators) are compact systems for supplying fresh, clean air to rooms.

Breezer Tion 3s

Supply is carried out either naturally or using a fan. In the first case, quiet, electricity-saving operation of the device is guaranteed, but problems with ventilation are possible if there is no difference in external and internal pressure.

Review and review of Breezer Tion 3S:

A ventilator with a fan will provide proper ventilation regardless of external climatic conditions; you just need to select the required mode. In some models, performance depends on the fan speed, which also determines the noise level produced by the device and its energy consumption.

The devices are equipped with filters of varying degrees of purification. The number of elements and the level of filtration depends on the specific model, the most advanced of which are capable of purifying the air from the smallest dust particles. In addition, filtration at the molecular level (for example, neutralization of exhaust gases) is possible.

Ventilator Blauberg VENTO Expert A50-1 Pro

Breezers, unlike many ventilators, are more autonomous. It is enough to configure it once (specify the schedule, set the appropriate operating mode) and it will automatically maintain the desired microclimate in the room.

Breezer Tion o2

Supply valve - characteristics and features of the device

To dilute stale air in the room, the window design provides an air flow function. To do this, just put the sash in the correct tilted position and leave it that way. But, a problem arises with ventilation during rain, with heavy snowfall, or the most common problem of ventilation in winter is an increased supply of cold street air, and not all residents are comfortable with the discomfort from the cold. Supply ventilation valves will solve this problem. Not all of them are installed at the factory; in most cases they are mounted into the frame already when the window is in place; this is considered an additional element of the window and is installed upon request.

The valve consists of the following elements:

- Air intake - an outdoor unit with a visor that will prevent insects, fluff and dust from getting inside.

- The working channel is of a telescopic type - fixed inside the profile using a sleeve.

- Injectors.

- Filter.

- Adjustment element.

The last 3 elements can be attributed to the internal filling of the valve; their main task is to change the intensity of air flow.

Valve adjustment methods for PVC windows

Practical experience in using various models and types of ventilation valves has shown that for their effective operation it is necessary to have a control mechanism. Options with constant ventilation parameters turned out to be unsuccessful and simply unsuitable for use in domestic conditions.

As noted above, there are three types of regulation: manual, automatic and combined. The most convenient is considered to be an automatic device that uses the readings of a special sensor that monitors the level of humidity in the room. Depending on this, the required operating mode of the ventilation valve is set - from completely closing it to the maximum possible level of air exchange.

Rice. 12. Automatically adjustable valve.

The advantage of an automatic control system is that it reduces heat loss. This effect is achieved by the fact that the valve starts to work only if the humidity rises and there are people in the room. If there is no one in the room for a long time, then the valve operates at a minimum throughput mode or is completely closed.

The manual method of regulating the operation of the ventilation valve is more reliable, but requires constant attention and monitoring.

How does it work and why is it needed?

The valve is designed to create so-called passive ventilation, if you can call it that. If the temperature outside is less than +5 degrees, a pressure difference will be created, due to which street air will be sucked into the room naturally, due to the fact that the main exhaust ventilation is working in the room. If the temperature outside is higher and an air flow is needed, then the room must be equipped with a forced flow of outdoor air, or turned on permanently.

For this to work correctly it is important:

- So that ventilation works inside the room.

- The entrance door to the apartment was sealed.

- The doors in the rooms, on the contrary, were not airtight for air passage.

- Or there were passages in the walls to allow air to escape from the room towards the exhaust ducts

- It is necessary that there is a free exchange of air masses - there are gaps from the room

Window valves in appearance resemble a gap created in the frame of a window with shutters.

Clients often come to me asking how necessary it is to install this type of device. I never tire of saying that installing a supply valve on a plastic window allows you to create a comfortable, healthy microclimate in the room and remove stale air unnoticed by household members. Since there is no ventilation effect in any translucent window structures, they should be equipped with valves. Without them, it will simply be impossible to remove carbon dioxide from the room, which has accumulated in rooms where someone is constantly present, and with the help of valves it is possible to reduce the level of humidity, and, consequently, the growth of mold and mildew on slopes. The worst consequences of constant oxygen starvation for a person are deterioration in well-being and decreased performance.

After all, you don’t have to use air supply devices; it’s enough to ventilate regularly?

Yes, of course it’s possible, and many people do it, I’ll tell you about the disadvantages:

- A constantly open “window” is noisy and cold, especially in the cold season.

- You are guaranteed drafts, since the air masses are not controlled in any way.

- This option is ideal if you like to ventilate the room as quickly as possible, open the window slightly and maximum street air enters the room.

The conclusion suggests itself.

Most popular designs

Installation of ventilation valves on plastic windows has been used for a relatively long time. During this time, a fairly large number of reviews have accumulated, some of which have a negative connotation. It should be noted that this is not mainly due to the fact that the very idea of supplementing the design of a plastic window with an additional ventilation mechanism is ineffective.

Much more often, negative feedback from users who installed ventilation valves is explained by poor quality implementation of the plan. This can be either the use of low-quality products or installation errors.

Rice. 7. Installed ventilation valve.

Aereco window ventilation valves

Based on the above, it is quite logical and advisable to use tested and proven in practice fresh air ventilation systems installed on plastic windows. The products of the French company Aereco are rightfully considered one of the most popular and widely known brands.

In its products, the company uses modern development in the form of polyamide plates, which expand when the temperature rises. This activates the automatic ventilation valve. Sensors also monitor the lower temperature threshold of the room, reducing heat loss if necessary. Another important advantage of Aereco products is their relatively low cost.

Rice. 8. Installed Aereco valve.

Air-Box window ventilation system

Along with imported products from leading manufacturers of ventilation equipment, products from Russian companies are also present on the domestic market. The most famous and popular brand is the Mabitec Air-Box system for plastic windows. It is a structure of two components - external and internal.

For the Air-Box valve to operate effectively, the building in which it is installed must be equipped with a ventilation system. This is because the Air-Box product operates when pressure fluctuations occur.

Rice. 9. Installed Air-Box valve.

Disadvantages and advantages

The advantages of valves include:

- Continuous flow of outside air and constant indoor air circulation.

- No drafts, which is especially important in a children’s room where a child always lives.

- Creating the right microclimate in a room is important for a person.

- No condensation, reducing the likelihood of developing fungus and mold.

- Preservation of the noise and heat insulation properties of the structure.

- A simple option to use, the main thing is to control the humidity.

- Adjustable, you can let in more or less air.

Flaws:

- If you choose a mechanical valve, it will have to be adjusted manually at height.

- There is a possibility of freezing in winter if there is no traction and humidity indoors.

- If you do not install a filter, lint and dust may enter the room.

As for adjusting the amount of air entering the room, it depends on many factors: the number of people in the room, the weather outside, the temperature in the room, and the rate of air outflow through the ventilation.

Why is ventilation necessary?

- Too much or too little inflow. Even in good condition, natural circulation has a number of disadvantages. In winter, the draft in the mine is strong due to the large difference in the densities of the warm environment in the apartment and the cold environment outside. As a result, the room begins to blow from all the cracks, which leads to drafts. In summer the draft is too low, especially on the upper floors.

- High humidity. There are quite a few sources of vapors (cooking, cleaning, washing, waste products of the owners themselves, animals and plants). A family of four “evaporates” 5-7 liters of water per day, and humidity formation occurs at a rate of about 300 g/h. This is enough for the relative humidity (RH) in a modern apartment (area 120 m2) to be at least 70% (at t=20C). This indicator does not provide adequate comfort. And a person exhales up to 19 l/h of carbon dioxide, and its critical concentration (0.1%) can be reached quickly in a sealed room. Therefore, it is necessary that the humid atmosphere be replaced by a fresh, drier atmosphere in sufficient quantities: at least 30 m3/h per person.

- Condensate. If, at a constant pressure, the concentration of steam gradually increases, at a certain temperature (the so-called dew point) it will begin to condense. The higher the air temperature, the more moisture it can absorb. Dampness appears on the coldest surfaces of the room, for example, on a double-glazed window. Heating devices and additional sealing are unlikely to help cope with constant fogging.

Unsplash

The room requires an inflow of at least 30 m3/h. Meanwhile, building regulations require that no more than 7m3/h pass through the frame. How to resolve such a contradiction? It is suggested to ventilate the rooms by opening the doors slightly. The method seems simple, but there are many disadvantages. These are dust, drafts, noise (the sound insulation index is reduced by 2 times).

Companies offer a variety of supply ventilation valves for plastic windows. They can be divided into several types depending on the characteristics of the conducting channels.

Choosing the right valve

When deciding to buy a supply valve in Moscow, consider several parameters at once:

- The material of manufacture can be plastic or aluminum. It is worth choosing it based on the appearance of the window, for example, for PVC structures a plastic option will look organic, and for aluminum ones - aluminum painted in the color of the frames, although it is ideal for PVC and wooden windows.

- Type of installation - it can be mortise into the frame, or overhead on top of the window frame, while such an overhead reduces the height of the window frame. There is also a valve that is installed in a double-glazed window; a new one is needed; the old one will not be suitable.

- Type of adjustment - the manual version is much cheaper and more familiar, but the automatic one is simpler and more convenient to use. The cheapest ones come without adjustment at all, therefore, in strong winds they may not function and will blow heavily.

- Size – there are models that are simply invisible, while others stand out. Choose the one that suits you in your opinion.

- The presence of sound insulation will reduce the level of unwanted noise in the room.

It is believed that seam and slot models will be easy to install yourself.

know more

You have questions?

Write!

I'm in touch right now!

Average prices for the service

The final price for installation of a valve on a PVC window depends on the cost of the product, its functionality, air performance and design of the window unit, as well as the level of automation and installation method - with or without perforation.

Note. The price includes not only installation of the valve, but also checking the operation of the ventilation ducts and preventing the operation of the fittings.

Average prices for installation of ventilation valves depending on the brand, cost of the kit and productivity in m3/hour:

- Air-box Standard, 0.58 m3/hour of air, product price - 600 rubles, installation - 800 rubles;

- EMM, air flow 5-35 m3/h, automatic, kit price - 4,900 rubles, installation - 1800 rubles;

- Aquvent HY supply air, 8-42 m3/h, automatic, kit price – 3,800 RUR, installation – 2,000 RUR.

- MACO seam up to 5 m3/hour, product price - 480 rubles, installation - 900 rubles.

- Acoustic canopy A-EMM with protection against insects, product price - 850 rubles, installation 600 rubles.

- OKFIL window filter with replaceable filter, set price - 2000 rubles, installation 1000 rubles.

- Valve ENA 2 air capacity 5-35 m3/h, automatic, kit price - 5700 rubles, installation - 2200 rubles.

More about types

There are these types of valves:

- Seam - has a small capacity, is not good enough in terms of noise insulation of the room. To ensure optimal air flow, it is better to install 2 products per window. The undeniable advantages of this model include its affordable price, simple installation of such a valve, the installation of which does not require the dismantling of double-glazed windows and drilling of window frames.

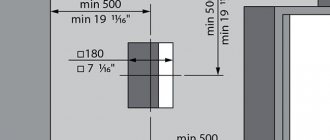

- Mortise - when holes are milled in a window product to the street and a cover is installed from the streets, and inside the mechanism itself with a filter to control the inflow, this is the best option, for sufficient air flow, you can put one on a window with a width of no more than 1500mm

- Slot cover - with dimensions from 60mm in height and width over the entire length of the frame. This is made in the form of a solid block, and is installed when installing the window, included in the design of the window opening and the window configuration. It has decent throughput. The excellent thermal and sound insulation properties of the window will be preserved, the throughput is 4 times greater than that of rebated windows, in this option I recommend the VILPE RENSON INVISIVENT valve; it will ideally solve the problem.

- Slotted mortise valve - this valve is installed in the area of the double-glazed window itself, while the old double-glazed window is removed and a shortened version is installed in its place so that the valve fits in the sash area. Ideally, such a valve should be stopped in production so that the double-glazed window can be manufactured in advance, and in this case there will be no additional costs. The ideal valve in this case I recommend VILPE RENSON AR 75

As for the type of control, it can be:

- Manual – often present in cheap models, it provides for mechanical adjustment of the valve to the desired operating mode using a part located on the body. The adjustment does not take into account the microclimate in the room.

- Automatic - in this case, the adjustment is performed by a mechanism built into the device, which connects to the smart home. Everything is controlled using a sensor inside the room - which will determine the level of humidity in the room and accordingly control the intensity of the incoming air flow.

On budget valve options, the regulators are equipped with handles to indicate whether the valve is open or closed, and the valve shutter indicates the position of which indicates the direction of the air:

Installation of a valve for a plastic window

As noted above, there are two ways to install ventilation valves for a plastic window:

- with dismantling and subsequent replacement of the double-glazed window with a new one with smaller dimensions. A ventilation valve is installed in the gap that appears between the opening and the window frame. This installation method has several disadvantages: o reducing the area of the window that allows light to enter the room; o additional costs of money and time required to order and manufacture a new double-glazed window;

- without dismantling window structures. In this case, the ventilation valve is installed in the window frame. The process itself takes an extremely short time - sometimes less than half an hour. This is very convenient, especially in cases where plastic windows were installed recently and do not require repair or replacement. In addition, installing the valve using the second method is ultimately much cheaper.

Rice. 10. Valve installation.

When choosing a ventilation valve model and method of installation, the vast majority of customers prefer to buy an option that does not require replacing window structures with new ones. This is understandable, since such installation will cost less and will be completed much faster.

Rice. 11. Possible installation option.

Installation of a ventilation valve for a plastic window is shown in the following video:

What to consider when choosing?

When deciding to purchase a ventilation valve, consider:

- Not all valves can be installed on an existing window, this needs to be diagnosed from a photograph or a paid visit by a technologist can be arranged; in Moscow it costs 2000 rubles, which are then taken into account in the cost of work and materials

- The capacity of the supply valve is a kind of device performance. It is affected by flow area and pressure. Numerical indicators do not always reflect real performance, since they may not take pressure into account at all. It is believed that a device with a throughput capacity of 20-35 cubic meters per hour at 10 Pa will become the norm.

- Sound insulation properties - it is believed that for comfortable use of windows, this figure should not be less than 30-35 dB. Some manufacturers offer windows with the highest noise-proof properties, then the valves must meet these parameters.

- The operating internal temperature and humidity conditions are an important parameter that will prevent the valve from icing up indoors in winter. To avoid this, a thermal break is created, that is, air must flow from the radiator to the valve area.

- Type and ease of adjustment - if it is important for you to control the level of incoming air, choose an option with an adjustment function.

To prevent unwanted dust and dirt, as well as insects, from entering the room, manufacturers equip some models with filters.

Advantages and disadvantages of ventilation valves for PVC windows

The disadvantages of using ventilation valves are usually associated either with the use of low-quality products or with installation errors:

- the likelihood of freezing at the valve installation site;

- the possibility of too much cold air entering;

- insufficient level of ventilation provided in hot weather;

- reduction in the level of heat and sound insulation of a window structure associated with the installation of a ventilation valve.

All of the above disadvantages can be eliminated if you comply with the requirements for installing the ventilation valve and use a quality product, for example, the Aereco and Air-Box models described above. In this case, the use of valves for supply ventilation will allow:

- ensure a constant sufficient supply of fresh air from outside;

- maintain the heat and sound insulation of the window structure at the required level;

- prevent the formation of drafts that are dangerous to the health of people in the room;

- reduce heat loss, which is achieved by regulating the level of incoming air.

If the installation rules are followed and high-quality ventilation valves are used, their use will allow you to maintain an optimal microclimate in the room with minimal heat loss.

Rice. 13. Valve design ensuring reliability and quality.

Let's compare ventilation options

- A mortise climate control valve for a window will be relatively inexpensive and extremely easy to use and install. Their operation is silent, but they are not able to maintain the original sound insulation parameters of the structure. For maintenance, regular cleaning is sufficient - once every 6 months. Do not wash them with chemicals.

- The valve on the window from above will work properly, but its peculiarity is that you need to install it on the window during installation and design it in advance so that the window is made to the appropriate size, and it has good sound insulation, and is high in cost.

- Wall inlet valve - this option requires installation using a special tool that makes a hole in the wall. In some options, filters are installed that clean the incoming air. Inexpensive and difficult to install.

- A breather is a powerful electrical device that includes a climate control, air supply and air purification system. The throughput is decent - up to 150 cubic meters per hour, and the noise level is very low - 19 dB. Some models may have an air heating function. This option cannot be installed by yourself; a specialist with experience must work here. The cost is high.

- A recuperator is an electric unit, which has in its design a fan for air inflow and outflow from the room, with heating and filtration. Decent productivity of more than 120 cubic meters/hour. and this option requires careful consideration of the possibility of installing equipment. The cost is high for the equipment itself and the work performed.

If you live far away from a highway or an industrial zone, and there are no more than 2 people in the room, you can opt for a classic valve, but if you are near a noisy road, then you need to think about more serious equipment.

Valve Installation Options

Installation of an overhead valve on a metal-plastic window block is carried out as follows:

- Remove the sash;

- Using a pencil and a ruler, mark the location of the future drilling (approximately in the middle, at the same level, in accordance with the dimensions of the valve);

- Using a drill of a suitable diameter, we drill according to the markings, after which we connect the holes by sawing with a nail file (it is much more convenient to use a hand-held milling machine, but unlike a drill, not everyone has one);

- Guided by the instructions supplied with the filter, we mount its elements;

- We put the sash in place.

More details can be seen in the video:

Installing a wall supply valve in a number of situations requires special equipment. This primarily applies to the installation of large-diameter valves in thick walls. To make a hole you will need a powerful hammer drill and a drill of the appropriate diameter and length.

Such a tool is rare in the household. In addition, difficulties may arise when working on upper floors. Otherwise, installing a wall valve does not require any professional skills and is carried out according to the attached manual.

For the process of installing such valves in an apartment, watch our video:

Subscribe

How to install a window valve yourself?

In order to install a valve, you first need to purchase it, and you can install the simplest one, the one that is installed without milling or disassembling the window structure, such a valve can be purchased at any store, and its price starts from 750 rubles

So, you will need a stepladder, a knife (preferably a stationery knife), a screwdriver or a screwdriver. You will need to remove part of the seal at the bottom of the opening sash, 100mm high, to allow air to flow through it into the sash area. And also cut out at the top under the valve itself and then follow the instructions. Devices are often equipped with valves, seals, fasteners - everything necessary for proper installation.

Let's get started:

- The elastic must be cut to the shape of the valve on both sides.

- Install the valve in place of the seal cutout

- Secure the valve using self-tapping screws.

- And the valve is ready for use

Using a thinner seal allows you to create natural air circulation, and regulate the flow intensity with a special handle. If there is a lot of blowing from the valve, then you can correct the situation in this way: in the area of the cutout of the seal, insert it back, but of a smaller size, and thus the inflow will be less.

Instructions for construction without perforation

This option is the simplest, can be performed by a home craftsman with any level of technical training , and does not require much time or the use of complex tools.

Such valves can be purchased in retail chains with and without adjustment of the volume of circulating air. In turn, adjustable valves can be either mechanical or electrical with automatic control.

Automatic systems have built-in temperature sensors with thermo- and hydroregulation, which ensure that the room does not become overcooled, and in addition, internal relative humidity is monitored.

Important. The volume of air circulation is regulated thanks to a damper that opens/closes depending on the size of the electrical signal coming from the primary sensors.

Necessary equipment

The main set of necessary consumables is included with the ventilation valve.

It includes:

- self-tapping screws;

- the valve itself measures approximately 35 cm;

- 1 piece of seal 35 cm and two 16 cm;

- 3 plugs for securing the device.

In order to secure this device, you will need a sharp knife, an electric screwdriver, a screwdriver, a ruler and sealant.

Step-by-step algorithm

Before you begin the process of installing the valve, determine the location on the valve for the valve. Experts recommend installing it in the center of the sash, and if it is narrow, then slightly offset so as not to interfere with the operation of the window fittings.

Algorithm for installing a ventilation valve without perforation:

At designated points, marked according to a pre-prepared template, cuts are made with a knife and the seal is removed from the groove.- To install the valve, fasteners are installed in the open groove - in the middle and 2 at the edges.

- To prevent the valve from moving, double-sided tape is glued to its body, on one side of which the protective film is removed.

- The valve side with tape is glued in the required place.

- Next, using self-tapping screws, attach the valve to the window sash.

- Screwing self-tapping screws into pre-assembled dowels through the valve mounting holes.

- Install a new seal between the fasteners of two short pieces that are supplied in the kit.

- Another seal, the longest of the set, is installed exactly opposite the supplied valve. It is narrower in size, therefore it provides a technological gap between the sash and the PVC frame, which facilitates the flow of outside air into the room.

At this point, the installation process is completed and they begin to adjust the required level of air flow using the damper. As a rule, its position on the far right corresponds to the maximum volume of air flow, and the position on the far left corresponds to the minimum. More precise recommendations for setting the ventilation valve are specified in the manufacturer's instructions.

Note! If the installation of one or two ventilation valves on PVC windows does not bring the desired result and does not provide the necessary indoor air characteristics, the apartment owner needs to take care of changing the existing ventilation system to a more efficient supply or recuperative one.

How to install if you need to do milling?

In some cases, installation requires milling. The valve should be located at the top of the frame, the sash must be dismantled, first removing it from its hinges. It is better to do this work in the warm season, cutting the hole carefully with a power tool, eliminating the possibility of damage to the seal. You will need 10 and 5 mm drills, silicone-based sealant, a jigsaw, and a template that will allow you to correctly mark the installation location.

- Mark the place.

- Drill a hole at the same level, connecting with a jigsaw in one plane. The resulting chambers should be filled with silicone sealant.

- Also seal the outer strip, attach it to the sash and connect it with self-tapping screws.

- Install the inner part.

- Check the strength of the fasteners.

- Install the canopy, securing it with self-tapping screws, and seal the joints with sealant.

- Place the sash in its original place and set the operating mode.

If problems arise after installation, it is likely that the ventilation system will need to be improved. The valve cannot solve the problem if there is a problem with ventilation, it will only help freshen the air and make the microclimate comfortable, provided that everything works perfectly.

It is better to entrust such work to professionals, the valve is not expensive, but a damaged window may cost rework and replacement with a new one, it is better not to risk it.

To get detailed advice on air flow, installation of valves, and working ventilation, you just need to leave your phone number in the callback request form on the website, or contact me in a way convenient for you: through social networks, WhatsApp, by phone number or by writing to [ email protected]

How to choose a window ventilator

Unfortunately, not all models have proven to work flawlessly. Some are covered with ice in severe frost. Others do not work without forced ventilation. Still others lack power. In order for the device to live up to expectations, you need to choose the right model.

Main selection criteria:

- design;

- principle of operation;

- ventilator equipment (recommended additional filters, sound membranes, etc. for metropolitan residents and residents of disadvantaged ecological areas);

- throughput - depends on the volume of the room, the number of people living;

- Material of manufacture - metal gratings freeze.

When purchasing, pay attention to the ventilator manufacturer, whose models have received the greatest approval from customers.

Popular brands of fresh air valves

The most popular brands for this type of product among buyers are:

- Air-Box;

- Aereco.

The difference lies only in the method of their installation. The first is fixed to the window sash without milling, and the second is with milling (with damage to the sash).

Today, equipping a plastic window with a valve for ventilation is quite a rare occurrence. Not everyone sees the benefit of this improvement in window design. However, it is not customary to save on health.

By paying just a little extra, you can provide the premises with an effective ventilation system in which human participation would be kept to a minimum.

Source: oknoudoma.ru/klapan-pritochnoj-ventilyatsii-dlya-plastikovyh-okon-vidy-i-preimushhestva/

Features of air duct installation

Before installing the valve, it is necessary to determine its location. The best place for this purpose is considered to be near the heating radiator on a load-bearing wall.

Supply device structure: 1 - external casing; 2 - fan; 3 - filter; 4 — insulated casing; 5 - adjustable body; 6 — decorative panel with a switch; 7 - ceramic element

- Step 1. Drilling a hole to install the air exchanger. The diameter of the hole should be slightly larger than the valve tube. This will allow you to correctly position the device and securely fix it in the wall.

- Step 2. Outside on the wall in the area where the device is placed, it is necessary to provide protection from rain. If it is not possible to do this (the valve outlet will be located in a place inaccessible for work), the hole must be made with a slight slope towards the street. This will prevent raindrops from entering the device.

- Step 3. Install the supply valve into the wall and fix it with construction foam.

To install the device you will need to drill into the wall.

Types of valves

This device provides control of the flow of the required amount of air into the room. It is noteworthy that the device does not require electricity or other energy sources to function.

It works thanks to the difference in pressure. The presence of a supply valve in the window design also has a positive effect on the degree of wear of the fitting mechanisms - there is no need to constantly open/close the sash to ventilate.

There are two types of ventilation valves - built-in and overhead. Due to their ease of operation, built-in valves are more popular among buyers than overhead valves.

In addition, after installing such a ventilation device on the profile, the appearance of the window structure practically does not change - only a barely noticeable insert appears on it.

To prevent the possibility of drafts in the apartment, you should opt for a valve equipped with independent regulation of the intensity of air flow.

According to the functionality, supply valves can be:

- standard;

- specialized (for fixed windows);

- soundproofing.

The design of a standard valve includes two components. The first is intended for the uninterrupted supply of street air into the room, the second - for its outflow to the outside.

Specialized valves are similar to standard ones, only they are designed for installation on windows with non-opening sashes (so-called “fixed windows”).

The noise damper is designed to stand guard and prevent excessive penetration of noise from the street.

Ventilation as a way to ventilate a room with PVC plastic windows

Installing fittings for modern sealed plastic PVC windows allows you to open the sashes, tilt them or make a “slit” opening for ventilation, but due to a number of technical and psychological reasons, residents do not always use this for the following reasons:

1. Intrusive advertising. Manufacturers of plastic windows have created among consumers the idea of a modern window as a window from which it DOESN'T BLOW. And my own everyday experience of many years of sealing cracks in old windows for the winter tells people that it is better not to open windows in winter.

It turns out to be a bit of a paradox: to keep the apartment warm and quiet, you need to keep the plastic windows closed, but to avoid stuffiness and condensation on the glass, you need to constantly open the plastic windows!

2. A person needs at least 25 m³ of fresh air per hour to ensure normal life activity and maintain sufficient working capacity.

Lack of oxygen affects the health and increases fatigue of people present in the room. In a two-room apartment of 50 m2 with a working gas stove, 140 m3 of fresh air is required every hour.

This means that every hour it is necessary to completely replace the internal air (impact or through ventilation). No one will ever open a PVC window 24 times a day for 5 minutes (especially at night!), so ventilation in the form in which it exists does not provide ventilation standards!

3. When opening a window, even in the “slit” ventilation mode, outside air enters from the window sill level, causing drafts in the area where people are located!

4. Sound insulation of a window unit is one of the main criteria when choosing a modern window, but the airborne noise insulation index is:

| Ventilation mode | Airborne noise insulation index, dB |

| PVC window CLOSED | 34 |

| PVC window sash installation in SLOT VENTILATION MODE | 18 |

| PVC window sash installation in VENTILATION MODE (TIRED) | 9 |

And here we see a paradox: by buying expensive multi-profile window systems with soundproof double-glazed windows, we deprive the window of all soundproofing characteristics by only opening it a little!

Ventilating a room by simply opening a window, even in the “slit ventilation” mode, also has other negative consequences:

- sudden temperature change;

- contamination of the room with dust and penetration of allergenic pollen into it;

- reduced security in terms of unauthorized access to the premises from outside (an open window, especially on the lower floors, attracts attention).

All of the above leads to the fact that residents, despite all the advantages of modern windows, experience discomfort due to impaired air exchange in the living room, but are reluctant to use the window fittings for ventilation.

How to make a supply valve for the wall with your own hands

To make a simple device you will need:

- grate from a bathtub or sink;

- filter (piece of foam rubber);

- insulation;

- plastic pipe;

- valve.

The plastic pipe will be the air duct; the piece must correspond to the thickness of the wall (a small margin can be provided). The optimal tube diameter is 10 - 12 centimeters.

Too large a diameter can lead to significant heat loss

- A grille is attached to one side of the tube; this will be the outer part of the device.

- A rolled-up insulation material (mineral wool, expanded polystyrene) is inserted into the tube. For this purpose, you can use pipe insulation. The layer thickness should be about two centimeters, this is enough to prevent freezing.

- Next, a foam filter is inserted into the tube.

- The last step will be installing the valve. You can make it yourself or purchase a finished product at any ventilation equipment store.

An alternative to a ventilator can be a grille with movable blinds. They can be closed and opened manually if necessary.

Related article:

Supply ventilation in the apartment with filtration. In our review you will learn how the device works, its varieties, step-by-step installation technology with photos and videos, useful tips and tricks.

Why is a window ventilation valve better than periodic ventilation?

When replacing old wooden windows with plastic ones, the existing microclimate in the house undergoes significant changes. Indeed, in the old days, fresh air mainly got inside through the cracks that abounded in wooden windows, still of the Soviet type. The disadvantage of modern plastic windows is the fact that they are sealed.

Tightly closed PVC structures do not allow noise constantly coming from the street - this is definitely a plus. However, the insufficient ability to saturate the room with fresh air is a serious disadvantage.

Just to correct this drawback, it is recommended to install a supply ventilation valve on the existing plastic window.

As is known, inhalation of oxygen-enriched air by a person has a positive effect on his health. According to medical literature, a person needs to receive about 30 m3 of fresh air every hour to ensure his full functioning.

If the room is insufficiently ventilated, dust, germs, and formaldehyde, released from various household items, accumulate in it.

If you constantly inhale all this, then in the end you can get inflammation of the mucous membrane of the eyes, “earn” shortness of breath, cough, constant reflex exhalations (in common parlance - sneezing), etc.

There is data on morbidity from insufficient cleanliness of homes - every day several thousand people begin to develop various diseases for this reason! And do you still doubt the need for a ventilation valve in your window?

Of course, a wide-open sash of a plastic window allows much more fresh air into the room than the same valve. However, how often does the owner want to ventilate the apartment in this way in winter?

More on the topic Ventilation device on the balcony - various techniques

And in the summer the situation is no better - you don’t want to deal with the endless noise, dust, fluff and blood-sucking insects threatening to break into your home. Therefore, the presence of a ventilation valve in the window is a justifiable necessity.

Need for installation

The main purpose of the supply valve is to ensure the flow of air from the street into the interior of the house. Why is this so important:

- If fresh air does not come from the street, the concentration of carbon dioxide in the house will begin to increase. And this will lead to a deterioration in the well-being of the people living in this house.

- Reduced air intake from outside creates conditions for increased humidity. And this is the reason for the appearance of colonies of harmful microorganisms in the form of mold and fungi. Accordingly, there is a high probability of developing asthma or allergies. Children, elderly people and family members with low immunity are at increased risk.

- High humidity also negatively affects building structures.

- If the house already has exhaust ventilation and the air flow is limited, then unpleasant odors and harmful substances in the air are poorly removed.

Of course, you can simply occasionally ventilate through the windows, but this is a temporary function that does not provide the proper concentration of fresh supply air.

Today, a window valve is increasingly being used as a means of bringing air in from outside. This is a good alternative. And we’ll also talk about it a little lower.

Supply window valve Source standart40.ru

Types of wall supply devices

To supply fresh air inside residential and any other premises, 3 types of valves are used:

- passive wall ventilators (natural inflow);

- transfer devices;

- Forced supply and exhaust units with air heating due to heat recovery.

Note. The cheapest and most primitive means of ventilating rooms are window ventilation valves (manufacturers: Aereco, Air Box, Vents). The disadvantage of ventilators is their low throughput. We wrote in detail about the principle of operation and installation methods in a separate article.

Ventilation diagram of a one-story country house with options for air supply devices

In addition to the listed products, so-called breathers are used in apartments - wall-mounted household appliances with forced pumping and automatic heating of air to a given temperature. Breezers are full-fledged air supply units, whose price is 3-5 times higher than any ventilation valve.

Natural inflow valves

Let's look at the design of a wall ventilator using the example of a fairly popular product KIV-125 from the KIV brand. Similar valves are produced by Domvent and Aereco. The design of a household appliance includes the following elements:

- air duct – PVC pipe with a diameter of 125 mm and a length of up to 1 m, inside – a heat-insulating, sound-absorbing insert;

- external supply grille with rain deflector canopy and insect net;

- silicone sealing ring for sealing inside the wall;

- double spring damper that regulates the amount of incoming air;

- coarse air filter class G3–G4;

- mechanical damper control drive;

- additional insulation, inner cap cover.

Reference. The Ukrainian brand "Vents" offers products with a telescopic air duct. The pipe is expanded to the required length, rather than cut to suit the thickness of the wall.

The supply unit is embedded in the outer wall, only the grille is visible from the outside, and the head with the adjustment knob is visible from the inside. The principle of operation is simple: air from the street enters the pipe, is cleaned by a filter and exits through the cracks in the head. Features of valve operation:

- the air flow is dispersed along the wall towards the ceiling;

- street noise is absorbed by the thermal insulation insert;

- damper petals can cover the air duct cross-section by 100%;

- adjustment is made using a handle or a special cord when the device is installed under the ceiling.

Inside the valve body of the KIV and KPV series there are 2 dampers, which can be opened by turning the control knob

Clarification. Airflow on other brands of valves may be controlled using a plastic gate or diaphragm.

The performance of the product depends entirely on the draft force in the exhaust shaft; at a vacuum of 10 Pa, approximately 55 m³ of air enters the room in 1 hour. But the ventilator is capable of passing a larger volume of air. For example, you turned on a kitchen hood, which will easily “pull” 150 m³/h through the valve.

Advantages of wall ventilators:

- energy independence;

- reliability, maintenance frequency – once a year (filter cleaning);

- affordable cost of the product;

- compatibility with any ventilation systems - natural, mechanical, combined.

In contrast to its many advantages, the passive supply ventilation valve has 2 significant drawbacks: it supplies cold air and sometimes freezes at low temperatures. True, frost appears from excess moisture (condensation) remaining in the room for various reasons. We will consider this nuance below in the instructions for installing the ventilator yourself.

Ventilation transfer elements

An interior door with tight shutters without a ventilation gap (or grilles) disrupts the air exchange inside the apartment. If you block the flows moving from living rooms to the exhaust shafts of the kitchen and bathroom, the ventilation in the house will stop functioning.

Diagram and location of installation of the ventilation flow element

It is not necessary to modify the sealed door between rooms - install bars or trim the panel. It is enough to build a supply and exhaust valve of the following design into the partition:

- 2 decorative lampshades for a hole Ø125–160 mm;

- hollow cylindrical insert made of noise-insulating material 15 cm long;

- 2 mounting rings + coupling bolt.

Comment. Transfer valves are made only for partitions up to 150 mm thick - half a brick plus finishing. For a thicker wall you will have to make a homemade mount.

Assembly of the supply and exhaust device is extremely simple: sound insulation is inserted into the finished hole, then rings are attached to the ends and tightened together with a bolt. Lampshades are installed on top to prevent light from penetrating from one room to another. For more information about the operating principle of the valve, watch the video:

Supply and exhaust valves with heat recovery

There are situations when a private house initially does not have exhaust ventilation ducts. Apartment ventilation can also be ineffective - the draft in the shafts of the upper floors is quite weak. The problem is solved by installing reversible supply and exhaust units.

Structurally, the installation is close to the ventilator, only inside the pipe there is an axial fan and a ceramic heat accumulator, shown in the photo. The wall reversing valve can operate in 3 modes:

- Only influx + filtration of outside air.

- Only exhaust from the room to the street.

- Heat recovery – combined mode, supply and exhaust operate alternately.

The main element of the unit is a ceramic heat accumulator installed inside the air channel.

The third mode is the main one. The algorithm is as follows: for 70 seconds, the fan drives air from the room to the outside through a ceramic heat exchanger. Then the reverse is triggered - the fan begins to blow in the opposite direction, drawing in outside air, which is heated by the battery along the way. After 70 seconds the cycle repeats.

Reference. Manufacturers implement a 180° change in flow direction in 2 ways: by switching the rotation of the impeller in the opposite direction or by turning the fan itself using an additional servo drive.

Advantages of using a recuperator valve:

- no need to build exhaust ducts from brick, plastic or galvanized pipes;

- heated air flows into the rooms;

- in summer, ventilation efficiency does not deteriorate;

- energy saving - the unit returns part of the heat expended by the heating system to heat the ventilation air;

Ceramic heat exchanger-recuperator accumulates heat and cold equally well - in the same way, the unit saves the cold produced by the air conditioner in summer;

- adjusting the amount and temperature of supplied air;

- choosing a model with the required productivity from 25 to 70 m³/h.

An unpleasant disadvantage of a supply valve with recovery is its high price. Judging by the reviews, it is this factor that prevents most users from buying this unit. Please note that for complete ventilation you will need several household appliances - one for each living space.

Other shortcomings do not play a special role, even the high noise level. You will learn more about the air handling unit with heat recovery from the video: