It is not for nothing that the failure of toilet fittings is recognized as one of the most unpleasant situations that occurs at home, in the office, at an enterprise, etc. Agree, neither a broken faucet nor a burnt-out lamp will create so much noticeable inconvenience.

This problem can be immediately eliminated if you know how to choose and correctly install a toilet valve. We will tell you in great detail which device is needed to close the flow of water into the tank, and which one is needed to drain it from there.

Here you will find complete information about the types of plumbing valves, the rules for their selection depending on the design of the tanks and installation methods. The article we offer contains reliable information, supplemented with useful diagrams, photos and videos.

Types of toilet valves

The most common type of toilet fittings is separate. It is used on all the most popular models of toilet cisterns and includes mechanisms for draining and collecting water, which are installed and operate autonomously.

Exhaust valves can be divided into types according to the method of actuation:

- Push . They are activated by pressing a button.

- Exhaust . The drain mechanism is activated by lifting up the rod that locks the drain hole.

- Lever . The lever itself can be placed on the tank or below, near the toilet. The device is activated by pressing a lever.

The lever system is used mainly in public restrooms due to its budget price, simple design and maintainability.

Inlet and flush valves for toilets are elements of the same system, but perform completely different functions

Push-type devices, in turn, can also be divided into types:

- single-level exhaust valve (with single-mode drain) - equipped with one button, when pressed, all contents are drained from the tank;

- single-level valve with a “stop” mode - in such a device, the first press leads to the supply of water to the toilet, the second stops draining;

- two-level (two-mode) outlet valve - the drain button consists of two keys, one of which drains part of the water, the second completely empties the tank.

Shut-off valve models can be divided according to the method of water supply: for side connection and for bottom water inlet.

And also according to design features:

- Piston device. The intake mechanism has a piston that is driven by a lever. A gasket installed at the end of the piston stops the flow of water into the tank.

- Diaphragm valve. This is the most modern device. Instead of a piston gasket, a silicone or rubber membrane is installed in it. It allows you to silently and quickly draw water, but is very sensitive to its purity - this is the main drawback that often leads to malfunctions.

In addition to separate ones, there are also fittings of a combined design, in which two valves - inlet and shut-off - are combined into one system. The performance of one depends on the performance of the other.

Installing and adjusting the fittings can be somewhat difficult for a non-professional. If one of the system elements fails, the entire mechanism must be replaced.

There are many types of intake valve models, but the differences between them are not too significant. The design of the float and diaphragm valve is the main thing that changes and improves in these devices

Method of filling the tank

The tank can be filled in two ways:

- through a side water supply;

- through the lower water supply.

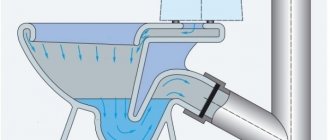

A tank with a side supply fills with water with noise, while with a bottom supply, water fills the tank almost silently.

But many manufacturers began to supplement the tank fittings with a side inlet with an outlet pipe. It is made of soft plastic and directs a stream of water to the lower zone of the container.

Thanks to this addition, flush tanks with side inlet stopped making noise.

General characteristics of shut-off valves

Drainage and water shut-off valves must withstand sudden pressure changes. On average, the operating rate ranges from 0.4 to 15 atm.

The water temperature at which the device will operate normally ranges from 2 to 45 °C. The working life is about 150-200 thousand cycles.

Almost every draining or filling device can be adjusted to suit the height of the cistern

The materials used to produce a toilet shut-off valve are:

- High pressure polyethylene. The denser this material is, the higher its strength. At the same time, an increase in density reduces its impact resistance at low temperatures.

- ABS plastic (a chemical compound of acrylonitrile-budadiene styrene). The material is resistant to mechanical stress, abrasion, aggressive chemicals, and insensitive to temperature changes.

For each valve model, the manufacturer indicates the permissible height of the tank; it can be from 295 to 500 mm.

It is also important to pay attention to the connecting size - if it does not match, use an adapter ring.

If you decide to replace a set of fittings in the drain tank. Price issue

The cost of a set of fittings for a Polish-made Cersanit tank with a bottom water supply is 650 rubles. The kit includes:

- exhaust valve;

- filling valve;

- ring sealing;

- plastic fitting BAS 24;

- metallized button and sleeve.

The fittings for the Vidima tank cost 1,250 rubles . But for products of this brand you can order a membrane separately . It will cost 300 rubles.

A drainage device for a Hybner tank with a stop function costs 1,800 rubles.

A tank drain valve made in Spain by Jika costs 2,800 rubles . The product is available in two versions:

- button height is short;

- The button height has been increased.

The Jika flush valve can be used in the ROCA and JIKA collection cisterns:

- dama senso;

- victoria;

- era;

- vega, etc.

Domestic-made fittings are much cheaper. For example, Uklad (manufactured in Pskov) will cost the buyer from 250 to 340 rubles.

Ryazan offers interesting options. They produce RBM with three types of valves:

- direct action;

- membrane;

- back pressure.

They can be used in tanks with both side and bottom water supply. They have models with rod and push-button start mechanisms.

Universal design:

- with a rod mechanism costs from 99 rubles ;

- with a backpressure membrane valve (push-button) costs from 205 rubles .

Installation and adjustment of the exhaust valve

The flush valve mechanism is designed to supply water to the toilet. Manufacturers produce many different device configurations.

For example, for the economical use of water, a two-level fitting has been developed in which the drainage can be complete or partial. Single-level devices are sometimes equipped with a “stop” system, which stops the draining process as soon as the button is released.

When purchasing a device, you need to pay attention to the material from which the locking gaskets are made.

If previously domestic manufacturers used only rubber, now they are increasingly made from silicone. This material has no mechanical memory and is not deformed.

Silicone and rubber gaskets and a conical lip on the valve seat provide multiple protection factors and prevent valve leakage

Installation of fittings step by step

If the flush mechanism is broken or outdated, there is no need to change the toilet tank - you just need to replace the faulty element.

Do you want to replace your toilet cistern with a new one? Detailed replacement instructions are provided in our other article.

Even if the toilet model is outdated, the manufacturer produces a new, but suitable device. It is better, of course, that the tank and shut-off valves belong to the same brand.

The water flush valve kit includes a flush valve, a sealing gasket, an adapter ring, fastening the tank to the toilet, as well as detailed installation instructions

Next, the installation of a drain valve will be shown using the example of a device for a dual-mode drain with a cable. Install the tank on the toilet. To do this, put gasket 14 on the base of valve 12.

You may also be interested in information about choosing and replacing the gasket between the toilet and the tank.

Schematic representation of the valve components. Knowing the structure of this device, it is easier to configure and adjust it

The valve is installed in the hole of the tank and the nut 15 is tightened from the outside, onto which the gasket 16 is then put on. It will ensure the tightness of the connection.

Bolts 13 are installed in the mounting holes in a certain sequence.

It is important to maintain the sequence of fastening bolts 13 and do not forget to attach them intermediately to the tank

Install the cable mechanism. Its end is secured in the rocker arm 8 so that the plastic casing is wound in all the way.

Then lower the body of the drain valve 9 into the base 12 and secure it by turning it to the right. Check that the device does not touch the walls of the tank and the intake valve mechanism.

Before installing the cable mechanism, check that the cable is securely fastened in the holder. If it comes loose during transportation or installation, it must be secured.

Next, adjust the height of the overflow tube 7. To do this, you must first turn it clockwise to remove it from the lock. After setting the required height, it is locked again by turning it counterclockwise.

When the tube height is correctly adjusted, the water filling level should not rise closer than 20 mm to the edge of the overflow tube.

The edge of the overflow tube, in turn, if there is a side hole in the tank (for connecting to the water supply), should be 10 or more millimeters below it.

Next, attach the push button to the tank lid. A special holder is designed for this. Connect the button to the cable so that it does not twist and does not cling to the filling valve. In tanks with a non-standard opening, an adapter ring is used.

If necessary, you can adjust the water filling level in the toilet cistern using the inlet valve settings.

In a correctly installed device, the valve ring, when the button is pressed and released, should fall freely and tightly close the hole for draining the water. If this does not happen, then you need to adjust the length of the cable by rotating the regulator

Adjusting the water drain

You can change the volume of remaining water after complete drainage using regulator 10 on the toilet valve body.

To increase the balance, it is raised; to decrease, it is lowered. You can adjust the valve so that the water completely drains from the tank by lowering the regulator all the way down.

To adjust full or partial drainage, manufacturers provide an adjustment mechanism that allows you to set the required volume of flushed water

The small drain is regulated by a similar principle. But still, there are some differences. In some models, the adjustment lever is freely accessible; in others, the lever must be unlocked by turning to the right.

And then, when you raise the lever, the drain volume will decrease, and when you lower it, vice versa.

If the drain tank overflows, you need to adjust the overflow tube. To do this, just like during installation, you need to turn it clockwise and set the required height. Then it is fixed back by turning it in the opposite direction.

After installation and adjustment, the functionality of the system is checked - the small and large drain buttons should perform their functions.

When you press the small button, the small flush should be triggered, the large one should empty the tank almost completely, depending on the settings.

Different valve models can be configured differently, but the general meaning of the settings remains the same - it is based on the principle of operation of the system

You may also find useful information on how to properly disassemble the drain tank.

Popular design models

OLI design

There are quite a few manufacturers of replacement plumbing equipment. Both domestic and foreign models are presented on the market. Imported systems are more expensive than domestic ones. But you can separately purchase replacement elements for them. The most popular equipment is from companies such as Alca plast (Poland), OLI (Portugal), Geberit (Switzerland), Grohe (Germany).

The Portuguese company OLI regularly presents innovative developments in the field of plumbing systems. It was she who created the double flush valve 20 years ago, reorienting the industry towards the economical use of water.

Among OLI's latest developments is the Azor Silent range of fittings, equipped with a silent filling valve. It allows you to reduce the noise level when filling the tank to 6 decibels (for comparison: the rustling of leaves produces a noise of 15-20 decibels).

Another interesting solution is the OLIpure system with a built-in detergent reservoir. Each time you drain, add a few drops of liquid detergent or cleaning agent to the water (they can be used at the same time). The cleaning agent is in an isolated container, so the internal mechanisms and rubber seals are not exposed to aggressive chemicals.

Trusted Russian manufacturers supply fittings of decent quality, and the cost of the sets is significantly lower than their foreign counterparts. You can choose from such manufacturers as Virken-Rus LLC (Moscow), Uklad JSC (Pskov), Arkon LLC (Tula), PKF Protex LLC (Tula). Domestic enterprises also produce replacement elements suitable for imported fittings.

The Virken company regularly introduces its new developments to the market. Among the latter is a flush column with patented QUICK FIT technology, which allows you to connect the flush mechanism directly to the existing fixture base without disconnecting the tank from the toilet. The mechanism is considered one of the most universal on the market also because instead of the central pillar there is a flexible cable installed, which does not require adjustment to the height of the tank.

The fittings sets of this company are also popular on the market due to their seals made of silicone. It does not react with impurities contained in water, retains its integrity and elasticity during temperature changes, and does not deform over time, unlike rubber.