Author: Website editors

Publication date: 29.04.2019

Issues discussed in the material:

- Why are there different types of room ventilation?

- What are the types of ventilation systems?

- What features does natural ventilation have?

- What is mechanical ventilation

- What features does supply and exhaust ventilation have?

- Duct and ductless ventilation systems

- Ventilation with recovery

- What is the difference between stacked and monoblock ventilation systems?

- What are the most common types of industrial ventilation?

- How to install ventilation in production

- What kind of air ducts are used for ventilation?

- What types of ventilation filters are there?

- What types of smoke ventilation are there and what you need to know about them

Normal operation of any facility or even a separate room is impossible without a well-thought-out ventilation system. For this purpose, various types are used to supply fresh air and remove exhaust air. They can provide air exchange processes in different ways, which affects the quality of the microclimate and the cost of ventilation. In order to choose the right project, you need to know what types of ventilation exist and what their differences are. The answers to these questions can be found in our review.

Why are there different types of room ventilation?

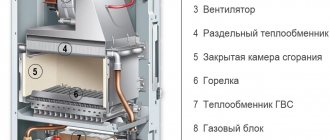

Ventilation is a process of exchange of air flows in which exhaust air is replaced by fresh air. The ventilation system is organized in those places where it is necessary to maintain sanitary and hygienic standards regarding indoor air parameters. The category of such premises includes places for permanent residence or temporary stay of people. Sources of air pollution include household and lighting appliances, gas or electric stoves, heating equipment and drying cabinets, as well as other devices. The types of ventilation in a private home differ significantly from the equipment used in industrial facilities.

During operation, any equipment, devices or devices emit products of incomplete combustion, heat and dust that settle on the surface of objects and furniture or are suspended in the air. To clean air masses, different types of ventilation and cleaning equipment are used.

For example, natural ventilation (ventilation systems that provide exchange of flows operate due to the difference in atmospheric pressure inside and outside the room) is widely used in various facilities. Under the influence of the wind, which creates a certain pressure, the air flow is forced into the building, while at the same time, on the reverse side, due to lower pressure, the internal “exhaust” air masses are removed outside.

Regular ventilation of rooms will help improve the functioning of natural ventilation.

To organize natural air replacement in buildings, special channels for removing air masses are provided. In residential buildings, they are usually located in the kitchen or bathrooms. A deflector is installed at the outlet of the channel - forced air suction. If the ventilation ducts work poorly, the draft overturns. This phenomenon means that exhaust air flows are returned back. Along with polluted air, dust, unpleasant odors from the upper floors and cold enter the apartment. Mechanical types of ventilation can eliminate such shortcomings.

When constructing any facility, an exhaust hood must be provided, without which it is impossible to provide comfortable conditions for living or working. For different situations, manufacturers offer the following types of exhaust ventilation:

- an exhaust ventilation system that provides air exchange for the entire facility;

- local equipment that is installed in a specific location for the local removal of contaminated air masses.

Exhaust ventilation equipment is used to work in heavily polluted facilities, and supply ventilation equipment solves the problem of organizing the supply of clean air. The most effective supply and exhaust system.

Selecting the most optimal scheme

One or another ventilation arrangement is chosen depending on many factors:

- type and dimensions of the building;

- materials used;

- the presence of various elements - plastic or wooden windows and so on;

- homeowner preferences;

- financial opportunities.

For their part, experts in practice have long decided on their preferences and consider the most optimal supply and exhaust circuit, which can be with natural or forced draft.

Options with natural air exchange

Above, we have already talked about the features of organizing a model with natural air exchange, using special ventilation ducts. Exhaust systems are usually installed in bathrooms and other auxiliary rooms, and supply systems are installed in residential areas.

This option is quite common since fresh air goes where it is needed. Although today the scheme seems somewhat outdated and is not always effective, and therefore is used less and less.

Forced supply and exhaust systems

They provide the highest comfort for residents due to their high efficiency. Fans for supply and exhaust are used here. You can use an air handling unit. Both fans are located in the PVU housing.

The equipment is installed either in one of the office premises or directly in the attic (this option is better). Air intake is carried out through an air duct led outside through the gable of the roof or through the roof.

Air ducts are distributed throughout all rooms. The larger the cottage, the more powerful the installation is chosen. It should be recognized that with such an organization, fresh air is distributed throughout the cottage very evenly.

The main disadvantage of such systems lies in their dependence on energy - they consume electricity and do not work during possible emergency and planned outages. In addition, electricity costs increase. However, these shortcomings are fully compensated by the high level of comfort.

PES with heat recovery

This system is a conventional supply and exhaust model, which has a built-in recuperator, which allows heat not to be released from the room along with the air emitted to the street. This heat is transferred to the flow coming from outside. For operation in winter, a recuperator with a built-in heater is used.

What features does natural ventilation have?

Every facility has its own ventilation system. Its work can be carried out by the method of ventilation, the installation of ventilation ducts. The inflow/outflow of air masses is also ensured by the presence of cracks and holes in the structural elements of the building.

Considering the apartment ventilation system that is used in our time, it can be noted that preference is given to natural type systems. The exchange of air masses in this case is carried out due to the following factors:

- difference in temperature indicators outside and inside the room;

- pressure drop;

- wind and the pressure it creates.

The advantage of using this type of system indoors is that its organization does not require significant financial investments, its design is easy to install and there are no energy costs for operation.

Also, various objects may contain natural systems that are influenced by factors such as temperature, direction and speed of wind flows. Operating efficiency is limited by atmospheric pressure, speed and volume of air flow. In the natural version, air parameters are determined by weather conditions and time of year: warm air is supplied in summer, cold air is supplied in winter.

Air movement

In order for natural ventilation in the room to work correctly, we will understand the reasons for possible obstacles in order to take them into account when designing. So, ventilation must displace a certain volume of air, replacing it with fresh air from the street. It is clear that the air outside and indoors has its own temperature and humidity, and the movement of air masses has its own intensity and direction.

It is very important to monitor the ventilation

For the classic pattern of air mass movement, you need conventional radiator heating, which is used in more than 90% of private houses and apartments, located under the window. Air in contact with the window surface cools more than air in contact with other surfaces. Cold air currents have a higher density, therefore, they are heavier than warm ones, and therefore rush down. Here they are picked up by heat from the battery, they mix and the already heated flow circulates around the room, giving off some of the heat to structural elements, walls, and furniture.

Having cooled, it falls down and replaces part of the discharged air formed under the battery. In such circulation there are no pressure differences, but gravitational forces create a constant cyclic flow within a given room. It prevents cold air from reaching the floor. The most uncomfortable zone will be the place where different temperature flows mix, and the rest of the room is in the so-called comfort zone.

If the heating battery is located not under the window, but against the wall opposite, the movement of air flows will be different. Thus, air flows in contact with the window fall down, where there is no heating, spread along the floor and, passing through the room, move towards the radiator. Heated by it, the air rises and continues its movement at the top. As in the classical scheme, a cyclic circle is formed. But, in this case, the temperature regime is completely disrupted, the discomfort zone is significantly increased. Cold currents cool the floor, making walking on it unpleasant. A clear difference between air flows increases the speed of their movement.

Sometimes this situation occurs even with the correct placement of windows and radiators. Here it is important to remember about the power and size, for example, if there is a battery under the window that covers only a third of it, then in places where there is no mixing of warm and cold air, zones of predominance of cold currents creeping along the floor will appear. To correct this phenomenon, you need to install either two batteries or one long one.

Important! In rooms where there are children, it is recommended to install radiators only under the window! A different arrangement of heating devices leads to colds due to a constantly cold floor. If it is not technically possible to install the radiator correctly, such a room cannot be used for a children's room or bedroom.

A similar situation occurs in rooms with panoramic windows. Basically, batteries are installed on both sides of the windows. Cold air rushes down to the floor, moving towards another heating device or through a door, creating a draft into another room. In addition, the windows fog up a lot, which indicates that there is high humidity in the room. A thermal curtain can correct this, but this is already an element of forced ventilation.

What is mechanical ventilation

According to the principle of operation, mechanical ventilation systems are no different from natural ones, with the exception of equipment that provides forced air supply. They consist of devices that create draft and provide air exchange. These installations differ in power, size and control method.

Existing types of mechanical ventilation systems have the advantage of being able to organize autonomous air exchange, regardless of weather and climatic conditions. In this case, air supply/removal can be carried out in the required calculated quantity. The use of filter elements, cooling and heating devices in mechanical ventilation devices greatly expands the functionality of the equipment and increases its efficiency.

There are practically no disadvantages to such systems, with the exception of their cost.

How to calculate the optimal air exchange rate?

When making calculations, you need to take into account the number of people living in the apartment. On average, 3 cubic meters of air should flow per square meter of living space per hour. However, the recommended rate of air replacement differs in different rooms. For a bathroom this is 25 cubic meters per hour, for a bathroom - 50 m3, for a kitchen with an electric stove - 60 m3 per hour, for a kitchen with a gas stove - at least 90 m3.

There is also another calculation recommendation: an adult consumes about 30 cubic meters of air per hour, a child about 20 cubic meters.

What features does supply and exhaust ventilation have?

Modern types of ventilation systems are also represented by supply and exhaust ventilation (or separately supply or exhaust). Their feature is balanced air exchange. Such a ventilation system requires the installation of a large number of air ducts, the installation of which requires considerable financial investments and the involvement of qualified specialists for installation and maintenance of the equipment. Therefore, local supply ventilation is used in the form of complex systems to serve large facilities and expensive cottages.

Conclusions and useful video on the topic

This video is a kind of educational program about ventilation. Here the very concept of ventilation is discussed in detail and all issues related to its competent design are covered:

Master class on installing a ventilation system:

Both business managers and private developers must understand that the normal functioning of those for whom they are responsible depends on the effectiveness of ventilation. Sometimes people's lives are also in question. You cannot miss this moment and save on it.

Have questions about the topic of the article, found any shortcomings, or have valuable information that you could share with our readers? Please leave comments, share your experience, and participate in discussions.

Duct and ductless ventilation systems

Duct ventilation has a distinctive feature in the form of an extensive network of ducts.

A ductless system has no ductwork. It is installed directly above the space that needs to be provided with ventilation, as well as in the openings of doors and window structures. The absence of an extensive network of air ducts completely eliminates energy costs. The advantage of the ductless design is ease of installation and maintenance.

Channel and conduit-free systems are represented by mechanical and natural types of systems.

The disadvantage of a natural duct system, as well as a ductless system, is the lack of control devices. Usually it is installed to solve a simple problem - to provide air access to the facility.

How to understand that ventilation is not doing its job?

There are several signs that may indicate poor performance of the ventilation system:

- “kitchen” and “toilet” odors persist for a long time after cooking;

- there is a high level of humidity in the room;

- stuffiness, stuffiness of air;

- Wallpaper may peel off on the walls and mold may appear;

- fogging of windows.

The lack of normal air exchange has the most negative impact on human health. Poor thermoregulation, combined with excess moisture and respiratory products, contributes to a decrease in immunity, leading to headaches, poor health, and exacerbation of chronic diseases.

What is the difference between stacked and monoblock ventilation systems?

A kit ventilation system consists of individual components - a muffler, a fan, automation, filters and other elements. To accommodate the system, a separate place is provided - a ventilation chamber or a space behind a suspended ceiling, for devices with low productivity. The ability to serve rooms of different sizes and for any purpose is one of the advantages of modular ventilation systems. They can be installed in small office spaces and supermarkets, and can also serve entire buildings. The disadvantage of the equipment is the need for special calculations when choosing a device based on power and large dimensions.

a monoblock ventilation system in a sealed, sound-insulated housing in several versions - exhaust, supply and supply and exhaust. The supply and exhaust units usually include a recuperator for economical energy consumption, which is spent on heating the supply air. Systems with a monoblock design have a number of advantages over typesetting devices:

- Placing the device in an integral sealed housing significantly reduces the noise level of monoblock systems. Thanks to this property, low-power monoblock ventilation systems can be installed in residential premises. To accommodate stacked ventilation systems with the same power, an isolated room or a ventilation chamber specially designed for this is required.

- All components of a monoblock design are selected, debugged and tested at the production stage, so it has greater operating efficiency and balanced operation of the entire system.

- The compactness of the case facilitates the installation of equipment; typesetting systems take longer and are more difficult to install.

What do you need to know when choosing air ducts?

First of all, you need to decide which air ducts will be used. There are two main options:

- Rectangular. They take up minimal space, but are less effective.

- Round. They provide the most intense air exchange, but require a larger volume of inter-wall space.

As a rule, round ducts are used. They can be:

- Tough. Less noisy and more efficient option.

- Corrugated. They are cheaper and easier to install.

In any case, try to use air ducts of the same diameter for the entire system - this is very important. If you still have to install channels of different sections, ensure a smooth transition between them.

What are the most common types of industrial ventilation?

An industrial ventilation system is a set of equipment used to ensure stable air exchange in large areas and to clean it from harmful substances. For this purpose, different types of industrial ventilation can be installed.

Industrial ventilation can be:

- General exchange hood

The simplest general ventilation is an exhaust hood in the form of a fan with air exhaust to a window or ventilation duct. The axial fan is replaced with a central one when the length of the ventilation duct is 30-48 meters and the pressure is below 30-40 kg/m2. As a rule, industrial facilities use general exchange systems in combination with other ventilation devices for maximum efficient air exchange. The use of several types of ventilation with filtering equipment helps to remove various harmful impurities released under different environmental conditions. Therefore, the use of one system is ineffective for high-quality air purification.

- Supply exchange of air masses

Assimilation of excess moisture, condensate, thermal energy and reducing the concentration of harmful substances - all these are the goals of general exchange ventilation. With its help, sanitary and hygienic standards and regulations provided for the workplace are maintained.

The supply general exchange ventilation system is capable of purifying and heating incoming air masses and maintaining a comfortable temperature in the room.

The principle of calculating natural air exchange by frequency

Exchange rate is a coefficient expressing the amount of exhaust air removed from a room within an hour.

The calculation is made using the formula: L=N×V

Where: L is the required volume of air; N - air exchange standards (regulated by SNiP, taken from the table); V is the volume of a specific room in m³.

Table. Air exchange rate for residential premises

How to install ventilation in production

To install even the simplest ventilation systems, special knowledge and professional equipment are required. To carry out work on arranging ventilation systems for industrial facilities, it is better to contact specialized organizations that not only have the necessary equipment and extensive experience in installation work, but can also design the main types of ventilation systems. When drawing up a project, specialists conduct a site inspection and select the most suitable types of ventilation for production premises. After this, the location of the main units of the system is determined: air intake fan, filter elements, distribution network, heating element, etc. There are different types of ventilation installations, but most often, the air duct distribution system is laid under the ceiling and covered with suspended ceiling structures. It includes 2 types of channels, which have their own design features:

- Flexible air ducts that connect the vent. equipment with main channels. They are also used for arranging turns in the main channels, for laying them in places with difficult access or for connecting to sprayers.

- Rigid boxes for laying air channels can be made of fiberglass materials, galvanized steel or aluminum. They are used for laying permanent lines in places with high pressure of the moving air flow.

The main stages of laying various types of ventilation air ducts:

Stage 1. First, you need to perform calculations to determine the required wall thickness of the air ducts, as well as determine the total weight of the air ducts. If the size of the suspended ceiling structure does not allow laying an air duct with the required cross-section in it, then flat ventilation ducts can be used.

Stage 2. Before performing installation work, it is necessary to mark the installation locations of the main fasteners. The distance between these points should be such as to ensure rigidity of the structure and protect it from vibrations.

Stage 3. Carrying out installation work.

Properly selected ventilation devices and professionally performed installation work provide comfortable conditions for productive work of employees and production equipment.

Specifics of duct hood

Exhaust air leaves the house through vents, ventilation shafts or air ducts. Ventilation ducts are usually led into the attic or connected to a ventilation shaft located in the center of the house.

Ventilation ducts in the installation and organization of natural ventilation in a private house are used mainly when installing the exhaust part of the system. Natural flow through air ducts is most often impossible or ineffective. In order for it to work at least somehow, a duct fan would have to be installed.

In natural ventilation schemes, ducts provide the exhaust part of the system. Exhaust air ducts in private homes are often combined into shafts

Air masses are pushed towards the exhaust of gravity ventilation by fresh portions of air drawn in through a window, a PVC window inlet or an open entrance door. The cross-section of air ducts is selected taking into account air exchange standards for certain types of premises, which are given in the collection of SNiP 41-01-2003.

In addition to residential and utility rooms in a private house, it is necessary to provide ventilation systems for a basement and storage built in it, a foundation without a basement, a cold attic or a furnished attic. In natural schemes they are provided with vents, gable and dormer windows.

Types of ventilation ducts

By location they are distinguished:

- Built-in . Constructed from hollow concrete or ceramic blocks and bricks. Such exhaust ducts are usually erected during the construction stage.

- Hanging . Made from galvanized steel or reinforced plastic. It is quite easy to install hanging channels, even after the house has already been built.

Air ducts are divided into round and rectangular cross-sections. Each type has its own advantages:

- Round duct . Easy installation, better air exchange, less weight;

- Rectangular duct . It takes up less space, is easier to disguise with boxes, false ceilings and walls.

In turn, pipes for a round air duct are rigid and flexible, i.e. corrugated.

Corrugated ventilation pipes are easier to install, but their installation is only possible on horizontal surfaces and on small areas of vertical walls

Rigid pipes allow air to move without any obstruction, so they provide the least resistance and minimal noise. However, with the help of corrugated pipes, installation is faster and easier.

What is a deflector?

A deflector is a special cap that is installed at the mouth of the exhaust pipe of the ventilation system. It cuts the wind flow, due to which a low pressure zone is formed, while the traction force can increase up to 20%.

The ventilation deflector also prevents atmospheric water from entering the ventilation system and prevents wind from blowing into the ventilation duct.

The deflector is installed at the mouth of the exhaust pipe. This device performs two important functions: enhances traction + protects against precipitation

The following types of deflectors exist:

- Cylindrical or Wolper's umbrella . It is a curved cylinder covered with a plate. It has average efficiency, protects ventilation ducts well from wind blowing;

- H-shaped deflector . The body is made of pipes in the shape of the letter H. It features increased protection against wind blowing, moisture entering the channel and reverse draft, but due to the design features it has low performance;

- TsAGI type deflector . The design includes a glass with an extension at the end, an umbrella lid and a cylindrical shell. Recognized as one of the most effective. It protects well from wind, snowfall, rain, and has the lowest resistance coefficient;

- Turbo deflector . It is a rotating ball with blades, it is characterized by increased efficiency, but usually costs a little more;

- Weather vane . Reminds me of a wing. The operating principle is similar to a turbo deflector.

The choice of deflector model depends on local conditions. In regions with high wind loads, ordinary fungi are preferred. In areas with low wind activity, it is better to install a deflector with a turbine; it will provide traction even with a light breeze.

What kind of air ducts are used for ventilation?

The channels through which air flows move are the most important element of all types of ventilation. Their main function is to remove exhaust air and ensure the supply of fresh air. For efficient air exchange, it is necessary to correctly calculate the diameter of the ventilation holes and determine the location for the channels. Competent installation technology plays an important role in the flawless operation of the ventilation system.

Modern natural and forced ventilation systems mainly use a channel for removing exhaust air masses. This is explained by the fact that there is practically no need to ensure inflow. Fresh air enters through the cracks of window and door openings, as well as through the technological openings provided for this purpose. To organize supply and exhaust ventilation, it is necessary to make a calculation and install two separate channels - for the supply of fresh air and the removal of polluted air.

Manufacturers of different types of ventilation systems today offer a large selection of components. In their catalogs you can select all the necessary parts and elements that, in terms of parameters and price, will be best suited for each specific case. When choosing an air duct, it is necessary to take into account the design features of the facility and the area of the room. Types of air ducts are divided according to several criteria.

Types of air ducts for ventilation according to design features are divided into:

- built-in air ducts in the form of ventilation shafts;

- external air ducts.

The efficiency of embedded systems is determined by a smooth and even surface, without unevenness or sagging of the solution. Anything that helps reduce the diameter of the air duct interferes with the normal passage of air. Built-in ducts are installed in brickwork and between concrete walls. In such systems, it is necessary to periodically carry out measures to clean the channels, which are carried out through the technological openings provided for this purpose, located at the bottom of the shaft.

External air ducts are made in the form of attached or suspended ducts, consisting of individual elements and pipes. The preference for one design or another depends on the architectural features of the object and the design of the room.

In addition to these criteria, air ducts differ in the material of manufacture:

- metal, for the manufacture of which stainless steel, aluminum alloys or galvanized steel are used;

- plastic, made of durable polypropylene, as well as other types of plastic ventilation;

- flexible, made of a special polymer or polymer-aluminum corrugated sheet with steel reinforcement.

Metal air ducts for ventilation. Metal pipes for organizing air ducts are characterized by high strength and durability. An important advantage of the metal is its resistance to high temperatures, corrosive formations and mechanical damage. They are characterized by ease and ease of installation, as well as a long service life.

The cheapest types of metal air ducts include products made of galvanized steel; products made of aluminum and stainless steel are considered more expensive. Preference is given to products made of galvanized steel, due to the good price-quality ratio.

Plastic air ducts for ventilation. The types and sizes of plastic ventilation systems are varied. They are characterized by maximum tightness, reliability and corrosion resistance. Installation of plastic air ducts takes place very quickly and without any complications, ensuring long-term operation of the devices. Due to these qualities, many consumers prefer polypropylene pipes when choosing air ducts. The only drawback of plastic products is their sensitivity to mechanical stress and high temperature.

Together with flexible air ducts, rigid pipes with accompanying fittings are used. Flexible elements are installed in places with complex configurations. During operation, they are characterized by an increased noise level (more than other types of pipes).

All air ducts can be presented in two versions:

- round;

- rectangular.

Round pipes are in greater demand than products with a rectangular cross-section. First of all, this is due to ease of installation, minimal air flow resistance and simple maintenance. Nipple connections and external couplings are used as connecting elements. This ensures the structure is completely sealed and eliminates air leakage.

To connect rectangular air ducts, shaped elements such as flanges, rails, latches and mounting angles are used.

Rectangular duct pipes are not as easy to install as pipes with a round diameter. Their shape reduces aerodynamic properties, but the undoubted advantage of rectangular pipes is their harmonious combination with different types of interior solutions. This is the best option for rooms with low ceilings.

When choosing air ducts, the layout of the ventilation network and the cross-section of the ventilation ducts are taken into account. The area and purpose of the premises are also determining factors when choosing pipes for arranging air ducts. To do this, calculate the required amount of air exchange in cubic meters per hour. Then the speed of air movement through the ventilation ducts is calculated. For a natural ventilation system, this figure should be 1 meter per second, for a mechanical one - about 5 meters per second.

Using diagrams compiled by experts, the size of the internal cross-section of the pipe is calculated based on the results obtained. Thus, for a forced or mechanical ventilation system with an air exchange volume of 300 cubic meters per hour and an air flow speed of 3 meters per second, the ideal option would be a pipe with a round diameter of 150 millimeters or a rectangular pipe with a cross-section of 100 - 200 millimeters.

When installing air duct pipes, it is important to make the right decision - to provide the pipes with thermal insulation or install them as usual. Air ducts with thermal insulation material are not covered by condensation, are more resistant to high temperatures, and have higher performance properties, which contributes to the uninterrupted operation of ventilation. Typically, thermal insulation is necessary for pipes located outside the facility or in unheated rooms.

In some rooms, it is necessary to provide sound insulation for air ducts. To ensure sound insulation, use the following recommendations:

- choose pipes with thick walls and large diameter;

- sheathe the surface of the pipes with special noise-insulating materials;

- use vibration isolation of ventilation devices - dampers and other types of fans for ventilation

Timely cleaning of air ducts helps maintain the operating efficiency of the ventilation system. In many situations, it is not necessary to dismantle individual structural elements to carry out cleaning activities.

Air duct cleaning procedures are carried out using chemical or mechanical methods. The mechanical cleaning method uses a vacuum pump or hydromechanical devices. The chemical cleaning method involves using special sprays or aerosols.

When calculating, selecting and installing air ducts, you need to be extremely careful, since the reliability of the ventilation system and the duration of its operation depend on this. It can be problem-free for the owner or it can cause him a lot of trouble and trouble in the future.

You should take a responsible and careful approach to the calculation, selection, and installation of air ducts, because their future operation depends on this. Will it be “cloudless” and problem-free, or will it cause the owner a lot of trouble and trouble.

What do experts recommend?

When installing ventilation in a house, there are many subtleties that it is advisable to take into account during design. Often, when work is carried out independently, the system does not work efficiently.

To avoid getting into this situation, experts recommend:

- entrust all calculations to professionals;

- select ready-made installations based on the calculations received - in many cases you can install them yourself;

- ventilation shafts in kitchens and bathrooms are always installed;

- in those rooms where there are heating stoves or fireplaces, ventilation shafts may not be installed;

- equipment that is placed in an unheated room, in the attic or outdoors, needs good insulation;

- It is recommended to use systems with a recuperator - this will reduce electricity costs and make the cottage warmer in the cold season.

Ventilation is an important condition for comfort in a country house. To obtain the most acceptable result, it is better to contact specialists who will carry out the necessary calculations and help you choose the right scheme. And don’t let it bother you that installing ventilation is an additional cost. Practice shows that houses with such systems become even more comfortable to live in.

Did you find this article helpful? Please share it on social networks: Don't forget to bookmark the Nedvio website. We talk about construction, renovation, and country real estate in an interesting, useful and understandable way.

What types of ventilation filters are there?

Filter elements of various types are an essential component of ventilation systems. Otherwise, people who stay indoors for a long time may develop health problems. They are caused by dust particles and various substances found in unpurified air. Asthma and other diseases may occur as a result of inhaling such air. To filter ventilation, various types of filters can be used, which can be classified according to the level of air purification:

- Rough cleaning. They ensure the removal of animal hair, sand and dust particles ranging in size from 0.5 to one millimeter from the air.

- Fine cleaning . Captures spores, sprayed paint and other particles as small as 0.1 millimeters.

- Superfine cleaning. They catch specks of dust invisible to our eyes.

Options for filter elements depending on the type of material used:

- coal;

- fiber;

- metal.

The type of material used to make the air filter determines the quality of cleaning.

- Carbon filter elements are capable of capturing not only mechanical particles, but many gaseous substances. These types of filters are very important for ensuring human health, as there are harmful gaseous substances that are odorless and invisible to humans. They are used in both domestic and industrial ventilation. One of the most striking examples of the use of a filter of this type is a gas mask.

- High temperature filters. The name itself speaks about the scope of application of ventilation elements of this type. Their main purpose is in rooms or places with high temperatures - drying chambers, saunas, baths or hot shops. Exposure to high temperatures negatively affects the appearance and quality of filter elements; as a rule, this causes deformation of the housing, which reduces the efficiency of the devices. High-temperature ventilation elements can operate even at 300°C.

- Pocket filters. At the first mention of these filters, associations immediately arise about the small size of the device, which can fit in a regular pocket. And this is partly true, since these filters are placed in a kind of pocket - in a special niche of the ventilation device. The material that serves as the filter element can be glass fiber or a material made from synthetic fibers. Modern types of pocket filters are represented by a new product with a filter element impregnated with an antiseptic. The main place where pocket filters are used are places and rooms with a high dust content and a high probability of fungus formation.

- Cassette and panel filters. The purpose of these ventilation elements is not limited to domestic conditions; they are successfully used in industrial kitchens and production workshops. Some models of cassette filter elements are made of materials that can be washed. Such cassettes consist of several layers of fine mesh made of galvanized steel. Disposable types of filter elements are coated with an adhesive and consist of a flammable substance, which simplifies their disposal - once contaminated, they are simply burned.

- Ceiling modules. Used for supply and exhaust ventilation systems. The body of the ceiling modules is characterized by tight seams and the use of filters with seals. During long-term operation and severe contamination, in some models not only the filter material is replaced, but also the entire module. This factor must be taken into account when choosing and installing a ventilation system for air purification.

In almost all models, only the filter is replaced when it gets dirty, so you need to choose high-quality material for the filter element. To do this, you need to take into account the type of ventilation system, which can be supply or exhaust, the purpose of the room and the air exchange rate in the system.

Air filters for the ventilation system are made of fibrous materials based on polyester or fiberglass. Each material has its own indicators, represented by density, degree of purification, breathability, level of efficiency and resistance.

These indicators are very important when choosing a ventilation system and when replacing filter elements. Factors such as the color of the material from which the filter element is made have no effect on the efficiency of the device; only the chemical and technical characteristics are important.

Replacement of the filter element is carried out independently or by professional craftsmen. When performing work to replace the filter, it is necessary to pay attention to the tightness of the housing at the joints and the quality of the filter material.

Instead of a resume

Let's try to summarize the above. Of course, it is impossible to cover all the nuances of choosing a ventilation system for a specific facility in a review article. We can only give a basic idea of why a ventilation system is needed, what it can and cannot do, and what the consumer should pay attention to when choosing such a system.

Now about the main thing. Remember, you always have the opportunity to deepen your knowledge, clarify what is left “behind the scenes” in the article, by asking a question to the experts, simply by filling out the feedback form, which you will find below. It's free, convenient, fast and informative. You can also receive a commercial offer free of charge and quickly by sending your request through the feedback form. Good luck!

Supply air circulation systems

This type is an improved mechanical ventilation. It includes many elements that allow you to purify the air, heat it, fill it with ozone, disinfect it and much more. Such a system can be either monoblock or assembled from different elements.

Based on the design of the installation, the following types of supply ventilation are distinguished:

- Monoblock system;

- Modular system.

But first, let’s look at the principle on which such a system works.

Calculation and calculation of ventilation ducts

The calculation of a natural duct-type ventilation system comes close to establishing the active section of the air ducts, which, in order to access the required amount of air, express a reaction corresponding to the calculated voltage.

For the longest network path, the voltage costs in the air duct channels are set as the sum of the voltage costs in absolutely all its places. In each of them, pressure costs are formed from friction losses (RI) and costs at points of resistance (Z):

p = Rl + Z

- where R is the specific stress loss along the length of the section due to friction, Pa/m;

- l is the length of the section, m.

Clear cross-sectional area of air ducts, m2:

F = L / (3600V)

- where L is air flow, m3/h;

- v is the speed of air movement in the air duct, m/s (equal to 0.5... 1.0 m/s).

By setting the speed of air movement through the ventilation, the area of its active cross-section and scale are read. Using specialized nomograms or tabular calculations for rounded air ducts, friction stress costs are determined.

What mistakes can be made

Natural ventilation is created quite simply with your own hands, but in the process of this work you need to take into account many nuances that many people simply do not know about. That is why they can make serious and significant mistakes, which lead to the fact that this engineering communication is not effective, so it will not be very easy and pleasant to use it. These errors include:

- Incorrect placement of ventilation holes, which can be made either too low or too high;

- Lack of ventilation elements on the second floor of the house, since many people think that for an effective system it is enough to provide its components only on the first floor;

- An incorrectly created roof slope, as a result of which cold air from the street enters through the outlet pipe, but the exhaust air cannot escape;

- Lack of natural ventilation in the bathroom, which is an enclosed space, leads to the formation of mold or mildew.

All of the above errors are quite common, and can lead to a system that simply cannot cope with its tasks. Therefore, it is important to approach the creation of natural ventilation thoughtfully and seriously.

Tips for arranging natural ventilation

Each room in country buildings or a country house has features that must be taken into account when installing ventilation devices.

In the bathroom

For a toilet and bathroom in a country building, it is necessary to provide the possibility of micro-ventilation through windows or doors.

In the bath

When installing ventilation in the bathhouse, it is necessary to place a supply duct at the location where the stove is installed. Street air penetrates from below, gradually displacing warm air to the ceiling, heating itself. The exhaust valve in the steam room is installed under the ceiling.

I open the valves when necessary to quickly dry the steam room or washing room.

In the boiler room

If a country house is heated with gas, it must have a separate room for placing equipment. A gas boiler is an object of increased danger, therefore the requirements for boiler hood equipment are quite serious.

The boiler room ventilation is mounted separately and does not cut into the common exhaust pipe; most often, an external pipe is used to get rid of smoke and gas.

Supply units are used to deliver outside air to boiler rooms. The weak point of the natural supply and exhaust system in boiler rooms is its dependence on wind power. In calm, windless weather, it is impossible to provide good traction.

Rotating ventilation ducts reduces efficiency by 10%.

In living rooms

To ensure effective air circulation between individual rooms in the house, it is necessary to install small holes or gaps between the door leaf and the floor at the bottom of the door leaves.

In the kitchen

When installing an exhaust ventilation grille above the stove, you need to place this device at a distance of 2 meters from the floor. This position of the hood allows you to effectively remove excess heat, soot and odors, preventing them from spreading throughout the room.