Spherical, domed dwellings have been known for a long time - yarangas, tents, wigwams, etc. - built on this principle. They are distinguished by their high stability and ease of construction, which is what earned them the popularity of our ancestors. But domed houses in their pure form, as a phenomenon of modern construction, appeared not so long ago - approximately in the second half of the last century. When the American scientist Fuller decomposed the dome structure into simple figures - triangles, from which the entire structure is often assembled. It is on this principle that many spherical houses are built today.

Projects of a domed house from a frame structure

Technologies for the construction of domed houses are constantly being improved.

The specific shape of a domed house requires special technologies and components. Its advantages - resistance to wind loads, excellent sound insulation, large volume - are so attractive that construction methods have been worked on tirelessly for almost 100 years.

The frame construction method made it possible to erect huge spherical buildings: exhibition shopping centers, museum complexes for large objects, stadiums, scientific facilities. Using the same technologies, you can build your own country house in the shape of a ball.

There are several projects of this type:

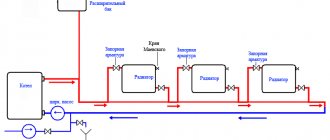

- Geodesic - the basis is a frame of triangular elements assembled according to the honeycomb principle. This system has a high load-bearing capacity. The higher the building, the more triangular and polygonal elements are used and the higher the structural strength. Beams and rods are connected to each other using connectors - this is the only acceptable method of fastening.

- Stratodesic - the dome has axial symmetry and is assembled from arched vertical elements. Horizontal lintels surround the dome. The segments of such a frame are trapezoidal in shape. The dimensions of the elements decrease towards the center of the dome. Fastening is carried out by cutting beams into each other, so that even wooden spheres are constructed in this way. The main feature compared to the geodetic model: here the torsional deformation is compensated by the skin, not the frame.

- Monolithic - a permanent structure erected from concrete or reinforced concrete. It is heavy, although durable. To construct a monolithic dome, two technologies are used: shotcrete and pouring into permanent formwork. In the first case, the “formwork” is an inflatable fabric pneumatic frame, the shape of which is bent and reinforced with reinforcement mesh, and then filled with concrete. The second method differs from the usual monolithic one only in the shape of the polystyrene foam formwork.

Dome houses built using frame technology are much lighter and usually stronger than conventional ones.

Frame

From hemispheres

Inflatable formwork for a monolithic structure

Two variants of one technology

The construction of frame houses is carried out in two ways:

- Using the Canadian Platform method. First, the ceiling and floor of the first floor are arranged, then large sections are assembled on it - entire walls or their segments. After installation in the design position, the structures are secured, insulated and sheathed.

Step by step assembly. All elements are cut out and fixed in place. First the lower harness, then the racks and the top harness. This method takes longer, but it allows you to get by with 1-2 helpers or even build a small house alone.

The “Canadian platform” is used in standard construction, when structures of a high degree of readiness are manufactured at the plant. They are brought to the construction site and installed using lifting mechanisms in a few days.

When building a frame house yourself, step-by-step installation is simpler and easier. With the efforts of two or three people, it is possible to install not only individual elements, but also enlarged blocks, combining the traditional method and the “Canadian platform”.

Construction materials and tools for work

Frame made of metal pipes for a domed house

Materials for constructing a spherical house depend on the type of project and the chosen material. The easiest way to build a wooden building with your own hands. For this you need:

- wooden beam for the frame with a cross-section of at least 50*50 mm;

- materials for exterior finishing - roofing, like flexible tiles, roofing felt;

- tape measure, corners, laser level or level;

- electric drill, jigsaw, grinder (it is best to use a woodworking machine);

- hammer, screwdrivers, metal scissors, brushes, etc.;

- fasteners - nails, self-tapping screws, screws (use fasteners made of galvanized steel);

- protective equipment - glasses, gloves, apron.

Only the static dome is constructed from wood.

Advantages and disadvantages of a domed house

Walls cool less in winter due to low wind load.

Spherical houses have several advantages:

- A sphere is a perfect aerodynamic shape. Thanks to it, such a building is resistant to wind loads.

- A dome, especially a geodesic one, is seismically resistant. A frame made of triangular elements evenly distributes the load. Even if 30% of all segments are damaged, the building remains intact.

- The structure, if it is not a monolith, has minimal weight. Even a large building does not need an expensive monolithic foundation.

- There are no partitions, lintels or columns in the interior spaces, which opens up wide possibilities for open planning.

- A domed house has a smaller heat transfer area than a conventional rectangular building. It's cheaper to heat it. In addition, natural ventilation and convection are effective here, so there is no need to build air conditioners or additional ventilation.

- The shape provides protection from external noise.

- Construction of a spherical building will cost less than a traditional one - 20–25% less materials are required.

- The aesthetic factor is also important: a house of such an unusual shape looks luxurious with minimal finishing work.

Shape of rooms in a domed house

Disadvantages of this solution:

- The rooms in the house have an incorrect configuration and expand from the entrance.

- There is no regulatory framework for the construction of such houses, so mistakes during construction are very common.

- Not all finishing materials can be used. For example, ceramic tiles, most roofing materials, and large panels cannot be installed.

- There are no basements or ground floors.

- In a one-story house, lighting is only possible through the roof.

The design of a domed house can be complemented by balconies, circular terraces, and external staircases.

Video description

Watch the video for the construction of a domed house:

- strength, increased seismic resistance, excellent aerodynamics;

- the dome can withstand high snow loads;

- good sound insulation and ventilation;

- originality and aesthetics at the highest level;

- excellent light characteristics.

House-sphere

Experts include the following disadvantages of domed houses:

- there are very few professional companies on the Russian market, the topic is quite new, enthusiastic dome builders are just trying to conquer our country;

- experience in calculations and absolute accuracy in the manufacture of parts is required;

- suppliers of high-quality raw materials are “worth their weight in gold”; good lumber is difficult to find;

- the period of useful use of the house is inferior to stone and block buildings;

- non-standard windows, made to special order, certain difficulties during installation.

But these disadvantages quickly disappear if you do not try to build a house yourself, but immediately turn to a construction company that has proven itself well in the construction market. This way you will save a lot of time and effort, and in the end you will get a high-quality domed house in which you will live cozy and comfortable. And the specialists will definitely take into account all your wishes regarding the layout.

House-sphere based on a geodesic dome

Features of construction

Strip foundation for a frame domed house

The construction of a spherical building has a number of features. The sizes of the segments limit the area of window or door openings. The curved surface does not allow equipment or furniture to be attached in the usual way. Constraints affect planning and operation.

- Removing the segment filler does not affect the strength of the structure. However, installing a polygonal door is not always possible. To install a regular one, they resort to tricks. The easiest way is to install a vestibule. If this fails, remove the frame segment with a reserve. A frame with shortened ribs is mounted inside the cavity and an entrance door is installed.

- The partitions inside the building are made of the lightest materials - plasterboard, wood boards and are placed randomly; they do not affect the structure in any way.

- The layout of the round building involves a common passage room in the center and segmented placement of the remaining rooms around it. Closer to the center there is a living room, bedroom, dining room, then a kitchen, bathroom, and corridors. If the house is two-story, a spiral staircase is located in the center.

- A beautiful addition is the glazed area in the center of the dome. This ensures sufficient lighting during the day and a view of the starry sky at night.

- Windows in a domed house are placed according to the same requirements as in a regular one. The shape can be traditional or repeat the shape of the segment.

Furnishing and decorating the interior is not that difficult. Only one wall can be left curved - the outer one. But if the interior is decorated in a futuristic style, they prefer to give the internal partitions an unusual look.

Building a domed house with your own hands

Insulation of a domed house

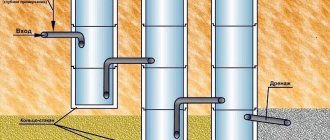

The construction of a round wooden house begins with design and marking. To do this, remove fertile soil from the selected area and mark the foundation. For a monolithic concrete structure, a more powerful and expensive foundation will be needed.

- A trench is dug under the foundation. A layer of sand and crushed stone is compacted at the bottom.

- They construct formwork from boards or plywood and pour the foundation. It is convenient to make permanent formwork. Made from polystyrene foam, for example, this option will also provide insulation for the house.

- All communications that must come from the underground - sewerage, water supply, heating - are laid at this stage.

- Wooden beams with dimensions from 50*50 mm are treated with antiseptics and fire retardants. Then the elements of each segment are cut to length, following the drawing. For convenience, it is recommended to number the arcs and crossbars. At the same time, door window frames and additional trim elements are made.

- Waterproof the foundation. It is better to use liquid bitumen mastics.

- The frame is assembled according to the chosen scheme. Wooden houses are rarely mounted on connectors. Here it is more rational to use cuts and inserts. It is allowed to duplicate fasteners with metal corners and self-tapping screws.

- The frame is sheathed on the inside with light material, like plywood. The outer frame is sealed with roofing felt or other rolled waterproofing material. The material is fixed with melted resin or glue.

- For waterproofing, sheathing is placed on the walls with a height slightly exceeding the thickness of the insulation. A heat insulator is attached to the resulting cells. It is better to cover a round wooden house with mineral or basalt wool. There is even an option for filling with sawdust, but it is a fire hazard.

- The insulation is covered with a vapor barrier. The film is overlapped and secured with staples.

- The external walls of the structure are decorated with clapboard, flexible plastic siding, and small metal panels - a scaly house. Often, one material is used for roofing and wall finishing - flexible tiles, for example.

Water supply and sewerage are connected after the house is fully assembled, flooring is laid and doors and windows are installed.

Manufacturability

Any developer will appreciate the time savings on house assembly due to the unique patented design of wooden locks. The frame of a small house is assembled by two people in a day, and the construction of a turnkey building, regardless of the season, takes from two weeks to a month and a half, depending on the model. You can bring a set of frame parts for a small house in a Lada Largus passenger van. All elements of the building can be easily carried by one person.

Thanks to the use of soft tiles to finish the entire surface of the “walls”, there is no need to paint the facade and worry about additional protection of the wooden structures of the house. During installation, it is easy to cover the first floor, and you can cover the rooms completely or partially, leaving a second light.

Tips for arrangement

A minimum amount of furniture is recommended in a domed house.

Domed frame houses are interesting for their unusual design. Most often, in interior design you only need to duplicate some elements of the external wall to achieve an impressive effect. However, this feature also imposes some conditions:

- windows must include swinging sashes, especially on the 1st and 2nd floors;

- you need to carefully consider the placement of sockets and electrical appliances, especially heavy ones - a refrigerator, a washing machine;

- For the most part, console furniture will have to be abandoned;

- design is carried out only in modern styles: high-tech, constructivism, futuristic; Baroque or Provence style design is not possible.

A domed house is a spectacular and practical solution. Such a building weighs less, is erected faster, retains heat better and protects from wind and noise.